Multi-Criteria Assessment of Timber-Based Structural Systems for a Grocery Store

Abstract

:1. Introduction

2. Literature Review

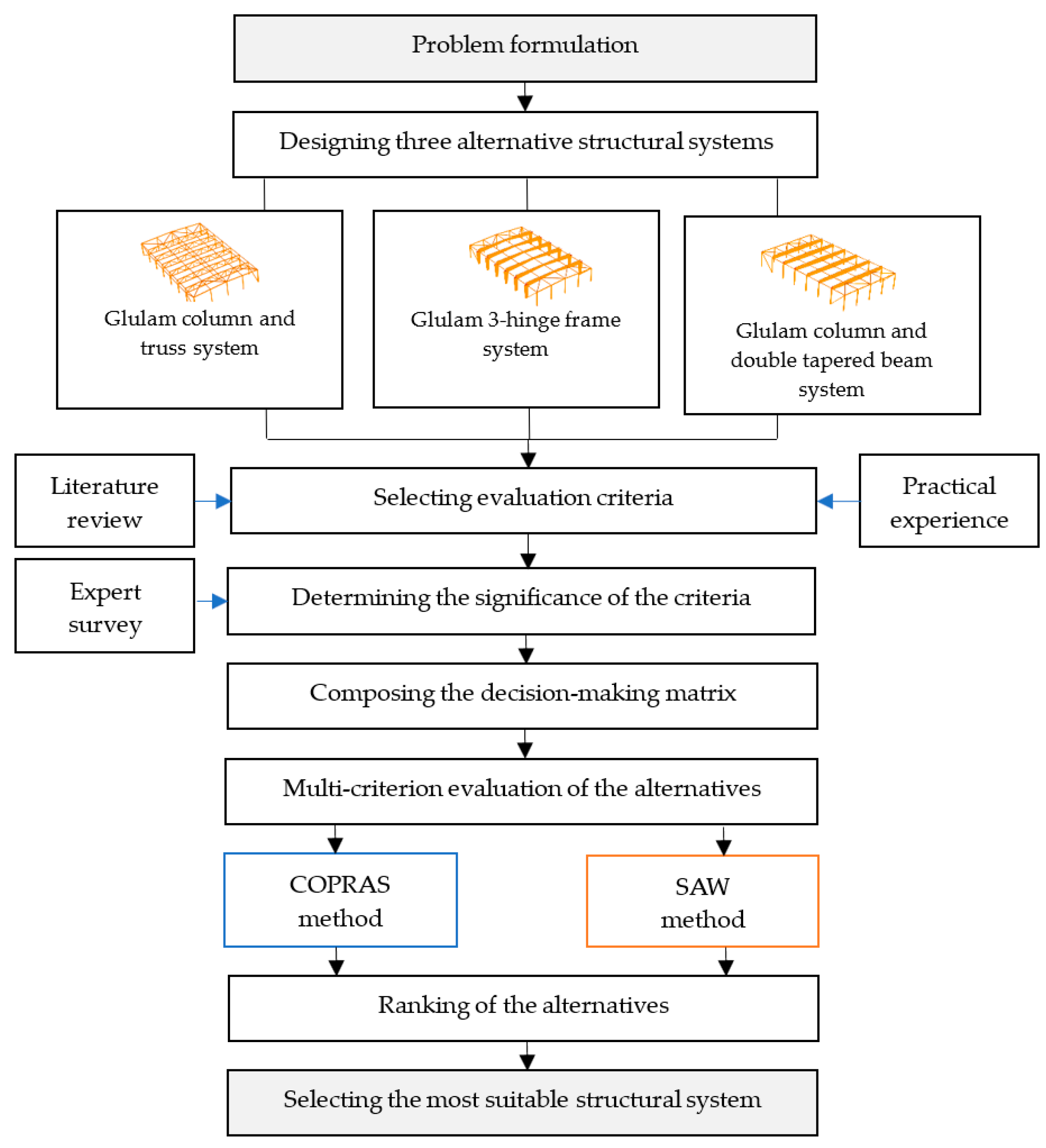

3. Materials and Methods

- Experts are representatives of design/construction or similar companies;

- Experts are acquainted with the commonly used timber-based structural systems;

- Experts have a technical background in civil engineering;

- Experts have experience of more than five years.

4. Case Study

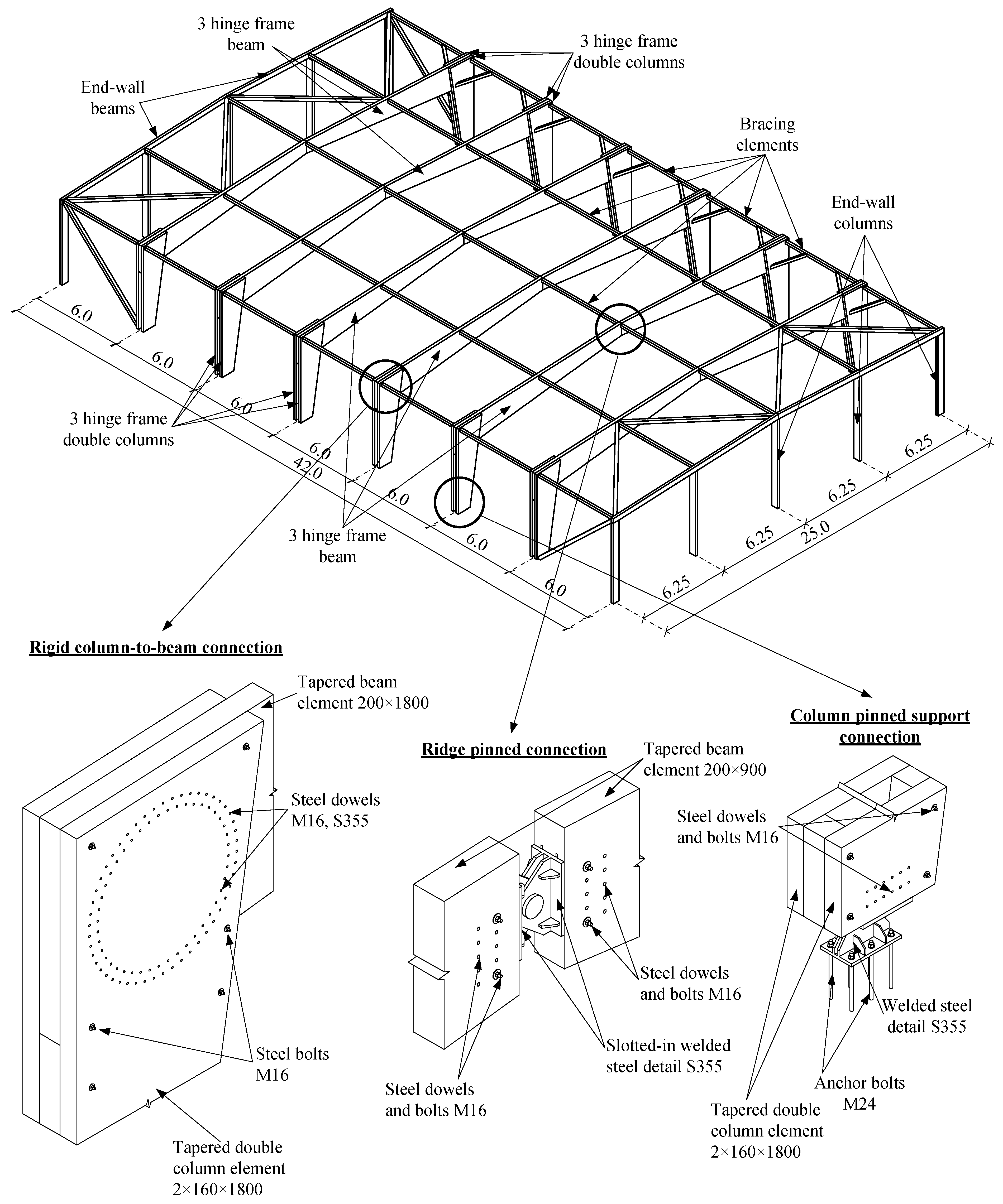

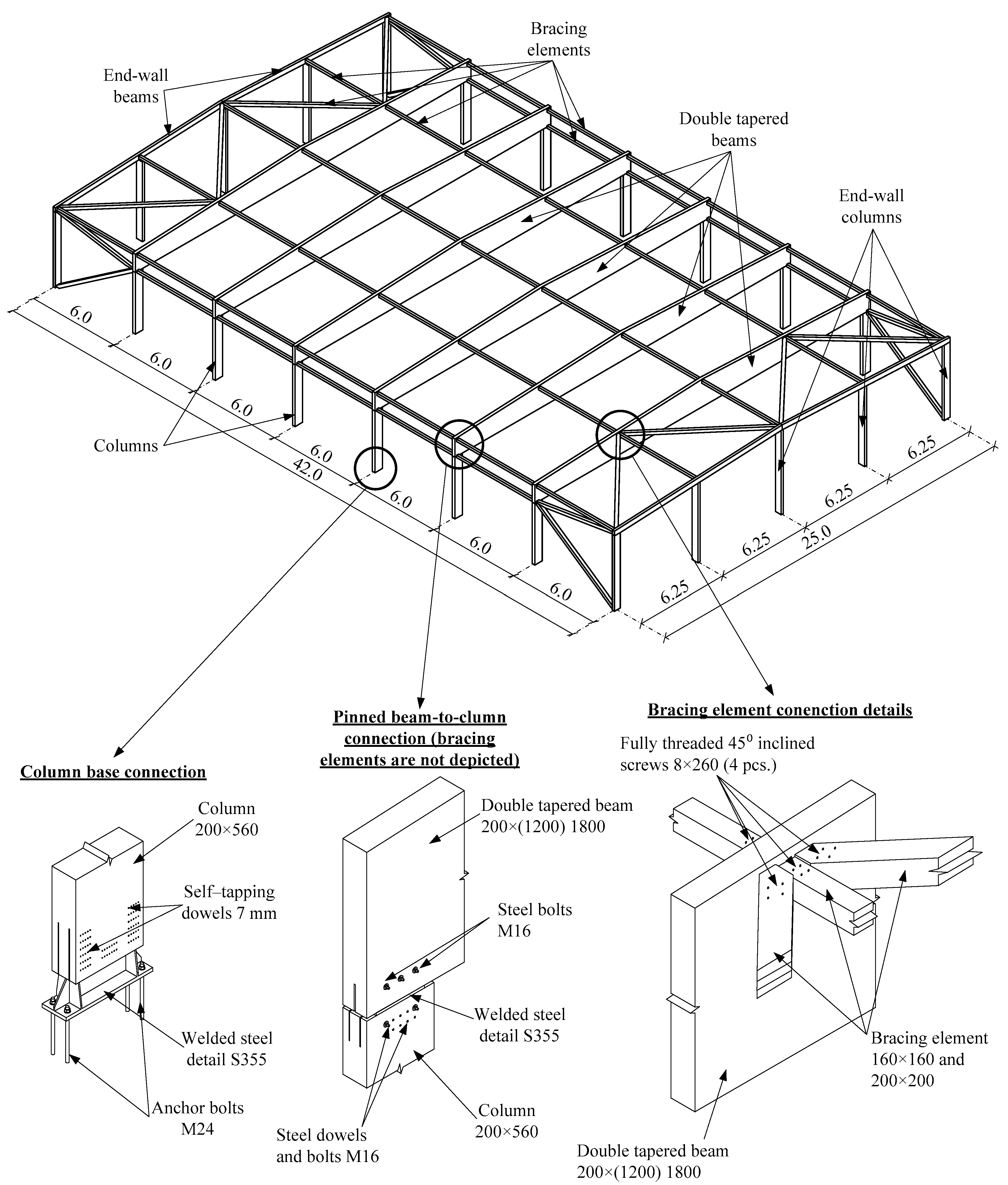

4.1. Description of the Alternative Structural Systems

- Bending strength fm,k = 28.0 MPa;

- Tensile strength ft,0,k = 22.3 MPa/ft,90,k = 0.5 MPa;

- Compression strength fc,0,k = 28.0 MPa/fc,90,k = 2.5 MPa;

- Shear strength fv,k = 3.5 MPa;

- Modulus of elasticity E0,mean = 12.6 GPa/E0.05 = 10.5 GPa;

- Density ρk = 425 kg/m3/ρmean = 460 kg/m3.

- Permanent load: 0.60 kPa for the roof and 0.25 kPa for the walls;

- Snow load: 1.60 kPa;

- Basic wind velocity: 24.0 m/s with a terrain category of II.

4.2. Evaluation Criteria and Their Significance

4.3. Multiple-Criteria Assessment

5. Discussion

- The efficiency of alternative timber-based structural systems was determined based on ten proposed criteria. Changes in criteria may change the ranking of alternatives.

- The significance of the criteria was determined by experts and reflects their opinion. The significance and priorities of the alternatives may change if other experts are involved in the survey.

- Some attribute values of alternative structural systems, i.e., the total cost of load-bearing structures and the total assembly cost, were determined based on the prices in Lithuania in 2022. If the same methodology is used in other countries, the values must be recalculated. In addition, the transportation distance from the factory to the building site has to be estimated.

6. Conclusions

- An expert survey revealed that the most significant criteria in the selection of timber-based structural systems are the total cost of load-bearing structures, with a significance of 0.1774, the total quantity of glulam (0.1491), and the maximum utility ratio according to ULSs (0.11414). Such results are in line with the findings of other studies.

- The ranking of the alternative structural systems by COPRAS methods revealed that the most preferred structural system alternative is the glulam column and double-tapered beam system, with an efficiency index of 0.3377, followed by the glulam three-hinge frame system (0.3323) and the glulam column and truss system (0.3300).

- The evaluation of the alternative structural systems by SAW methods revealed the same ranking results. The obtained efficiency index is 0.8405 for the glulam column and double-tapered beam system, 0.8279 for the glulam three-hinge frame system, and 0.8219 for the glulam column and truss system. Therefore, it can be stated that the glulam column and double-tapered beam system is the most preferable alternative. Its advantages are the lowest price of load-bearing structures, the lowest total quantity of steel details and fittings, and the highest maximum utility ratio according to SLSs.

- All designed structural systems have their advantages and disadvantages, and their efficiencies, determined by MCDM methods, depend on the significance of criteria. The significance of criteria can be re-evaluated based on a particular project and the client’s requirements. In this case, the ranking of the structural systems may change.

- Environmental criteria, e.g., CO2 emissions and embodied energy, could be included in the set of evaluation criteria.

- To achieve higher accuracy, the AHP method could be used in the future to evaluate the significance of criteria.

- The same research problem could be solved by other MCDM methods. In future research, it is envisaged to apply the ARAS method, which provides a comparison of the proposed solutions with the optimal solution to be set by the client.

- The proposed structure of the grocery store is relatively simple. The authors aim to continue their research on the selection of multi-layer timber-based structures using MCDM techniques. Additional specific evaluation criteria, such as floor weight, height of the flooring, and engineering integration of elements into the load-bearing system, will be used for this purpose.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Description |

| The level of significance | |

| The cumulative rank of the ith criterion | |

| Efficiency index | |

| n | The number of alternatives |

| M | Decision-making matrix |

| m | Number of criteria |

| The significance of the ith criterion | |

| r | The number of experts |

| S | The total square deviation of the rankings of each criterion |

| The sum of weighted normalized maximizing attributes | |

| The sum of weighted normalized minimizing attributes | |

| The lowest value of S−j | |

| The degree of freedom | |

| W | Kendall’s coefficient of concordance |

| The significance of the concordance coefficient | |

| The attribute value of the jth alternative | |

| The normalized attribute value of the jth alternative | |

| The weighted normalized attribute value of the jth alternative |

References

- Invidiata, A.; Lavagna, M.; Ghisi, E. Selecting design strategies using multi-criteria decision making to improve the sustainability of buildings. Build Environ. 2018, 139, 58–68. [Google Scholar] [CrossRef]

- Chen, Z.J.; Gu, H.M.; Bergman, R.D.; Liang, S.B. Comparative life-cycle assessment of a high-rise mass timber building with an equivalent reinforced concrete alternative using the Athena Impact Estimator for buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Amor, B.; Blanchet, P. Evaluating the link between low carbon reductions strategies and its performance in the context of climate change: A carbon footprint of a wood-frame residential building in Quebec, Canada. Sustainability 2018, 10, 2715. [Google Scholar] [CrossRef]

- Hart, J.; Pomponi, F. More timber in construction: Unanswered questions and future challenges. Sustainability 2020, 12, 3473. [Google Scholar] [CrossRef]

- Tam, V.W.-Y.; Lu, W. Construction waste management profiles, practices, and performance: A cross-jurisdictional analysis in four countries. Sustainability 2016, 8, 190. [Google Scholar] [CrossRef]

- Tupenaite, L.; Kanapeckiene, L.; Naimaviciene, J.; Kaklauskas, A.; Gecys, T. Timber construction as a solution to climate change: A systematic literature review. Buildings 2023, 13, 976. [Google Scholar] [CrossRef]

- Amiri, A.; Ottelin, J.; Sorvari, J.; Junnila, S. Cities as carbon sinks-classification of wooden buildings. Environ. Res. Lett. 2020, 15, 094076. [Google Scholar] [CrossRef]

- Hart, J.; D’Amico, B.; Pomponi, F. Whole-life embodied carbon in multistory buildings: Steel, concrete and timber structures. J. Ind. Ecol. 2021, 25, 403–418. [Google Scholar] [CrossRef]

- D’Amico, B.; Pomponi, F.; Hart, J. Global potential for material substitution in building construction: The case of cross laminated timber. J. Clean. Prod. 2021, 279, 123487. [Google Scholar] [CrossRef]

- Abed, J.; Rayburg, S.; Rodwell, J.; Neave, M. A review of the performance and benefits of mass timber as an alternative to concrete and steel for Improving the sustainability of Structures. Sustainability 2022, 14, 5570. [Google Scholar] [CrossRef]

- Zang, X.; Liu, W.; Wu, D.; Pan, X.; Zhang, W.; Bian, H.; Shen, R. Contemporary fire safety engineering in timber structures: Challenges and solutions. Fire 2024, 7, 2. [Google Scholar] [CrossRef]

- Gutiérrez, N.; Negrão, J.; Dias, A.; Guindos, P. Bibliometric review of prefabricated and modular timber construction from 1990 to 2023: Evolution, trends, and current challenges. Sustainability 2024, 16, 2134. [Google Scholar] [CrossRef]

- Kuys, B.; Mridha, M. Aesthetic preference of timber joints in architectural products. Sustainability 2024, 16, 154. [Google Scholar] [CrossRef]

- Santi, S.; Pierobon, F.; Corradini, G.; Cavalli, R.; Zanetti, M. Massive wood material for sustainable building design: The Massiv–Holz–Mauer wall system. J. Wood. Sci. 2016, 62, 416–428. [Google Scholar] [CrossRef]

- Strobel, K.; Nyrud, A.Q.; Bysheim, K. Interior wood use: Linking user perceptions to physical properties. Scand. J. For. Res. 2017, 32, 798–806. [Google Scholar] [CrossRef]

- Zhang, X.; Lian, Z.; Wu, Y. Human physiological responses to wooden indoor environment. Physiol. Behav. 2017, 174, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Tilleman, R. 3 Mass-Timber Shops That Put the “Super” Back in Supermarket. 2023. Available online: https://metropolismag.com/projects/3-mass-timber-shops-put-the-super-back-in-supermarket/ (accessed on 10 March 2024).

- Premrov, M.; Žegarac Leskovar, V. Innovative structural systems for timber buildings: A comprehensive review of contemporary solutions. Buildings 2023, 13, 1820. [Google Scholar] [CrossRef]

- Tenório, M.; Ferreira, R.; Belafonte, V.; Sousa, F.; Meireis, C.; Fontes, M.; Vale, I.; Gomes, A.; Alves, R.; Silva, S.M.; et al. Contemporary strategies for the structural design of multi-story modular timber buildings: A comprehensive review. Appl. Sci. 2024, 14, 3194. [Google Scholar] [CrossRef]

- Pastori, S.; Mazzucchelli, E.S.; Wallhagen, M. Hybrid timber-based structures: A state of the art review. Constr. Build. Mater. 2022, 359, 129505. [Google Scholar] [CrossRef]

- Ilgın, H.E.; Karjalainen, M. Contemporary tall residential timber buildings: What are the main architectural and structural design considerations? Int. J. Build. Pathol. Adapt. 2023, 41, 26–46. [Google Scholar] [CrossRef]

- Balali, V.; Zahraie, B.; Roozbahani, A. A comparison of AHP and PROMETHEE family decision making methods for selection of building structural system. Am. J. Civ. Eng. Archit. 2014, 2, 149–159. [Google Scholar] [CrossRef]

- Tamosaitiene, J.; Gaudutis, E. Complex assessment of structural systems used for high-rise buildings. J. Civ. Eng. Manag. 2013, 19, 305–317. [Google Scholar]

- Balali, V.; Zahraie, B.; Roozbahani, A. Integration of ELECTRE III and PROMETHEE II decision-making methods with an interval approach: Application in selection of appropriate structural systems. J. Comput. Civ. Eng. 2014, 28, 297–314. [Google Scholar] [CrossRef]

- Terracciano, G.; Di Lorenzo, G.; Formisano, A.; Landolfo, R. Cold-formed thin-walled steel structures as vertical addition and energetic retrofitting systems of existing masonry buildings. Eur. J. Environ. Civ. Eng. 2015, 19, 850–866. [Google Scholar] [CrossRef]

- Turskis, Z.; Urbonas, K.; Daniūnas, A. A hybrid fuzzy group multi-criteria assessment of structural solutions of the symmetric frame alternatives. Symmetry 2019, 11, 261. [Google Scholar] [CrossRef]

- Tupenaite, L.; Gecys, T.; Kanapeckiene, L.; Sajjadian, S.M.; Naimaviciene, J. Selection of structural system for wooden public building: Multiple criteria approach. In Proceedings of the 13th International Conference “Modern Building Materials, Structures and Techniques” (MBMST 2019), Vilnius, Lithuania, 16–17 May 2019; pp. 691–697. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.J.; Yepes, V. Multi-criteria assessment of alternative sustainable structures for a self-promoted, single-family home. J. Clean. Prod. 2020, 258, 120556. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.J.; Navarro, I.J.; Yepes, V. Neutrosophic multi-criteria evaluation of sustainable alternatives for the structure of single-family homes. Environ. Impact Assess. Rev. 2021, 89, 106572. [Google Scholar] [CrossRef]

- Zumrut, I.B.; Baran, H.B.; Ozbalta, T.G. Multi-criteria decision-making approach for selecting a structural system of an industrial facility. Organ. Technol. Manag. Constr. 2022, 14, 2656–2665. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Castillo-Lopez, E.; Rodriguez-Hernandez, J.; Canteras-Jordana, J. A review of application of multi-criteria decision making methods in construction. Autom. Construct. 2014, 45, 151–162. [Google Scholar] [CrossRef]

- Stojčić, M.; Zavadskas, E.K.; Pamučar, D.; Stević, Ž.; Mardani, A. Application of MCDM methods in sustainability engineering: A literature review 2008–2018. Symmetry 2019, 11, 350. [Google Scholar] [CrossRef]

- Emovon, I.; Oghenenyerovwho, O.S. Application of MCDM method in material selection for optimal design: A review. Results Mater. 2020, 7, 100115. [Google Scholar] [CrossRef]

- Zhu, X.; Meng, X.; Zhang, M. Application of multiple criteria decision making methods in construction: A systematic literature review. J. Civ. Eng. Manag. 2021, 27, 372–403. [Google Scholar] [CrossRef]

- Klumbytė, E.; Bliūdžius, R.; Medineckienė, M.; Fokaides, P.A. An MCDM model for sustainable decision-making in municipal residential buildings facilities management. Sustainability 2021, 13, 2820. [Google Scholar] [CrossRef]

- Tiwari, V.; Jain, P.K.; Tandon, P. A bijective soft set theoretic approach for concept selection in design process. J. Eng. Des. 2017, 28, 100–117. [Google Scholar] [CrossRef]

- Ong, C. Glue-laminated timber (Glulam). In Wood Composites; Ansell, M.P., Ed.; Woodhead Publishing Series in Composites Science and Engineering; O’Reilly Media, Inc.: Amsterdam, The Netherlands, 2015; pp. 123–140. [Google Scholar]

- EN 1995-1-1; Eurocode 5: Design of Timber Structures—Part 1-1 General—Common Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 1995.

- Kendall, M.G. Rank Correlation Methods, 4th ed.; Griffin: London, UK, 1970. [Google Scholar]

- Zavadskas, E.K.; Kaklauskas, A. Pastatų Sistemotechninis Įvertinimas; Technika: Vilnius, Lithuania, 1996. [Google Scholar]

- MacCrimmon, K.R. Decision Making among Multiple—Attribute Alternatives: A Survey and Consolidated Approach; RAND Memorandum, RM-4823-ARPA; Rand Corp.: Santa Monica, CA, USA, 1986. [Google Scholar]

- Podvezko, V. The comparative analysis of MCDA methods SAW and COPRAS. Inz. Ekon. Eng. Econ. 2011, 22, 134–146. [Google Scholar] [CrossRef]

- EN 14080; Timber Structures—Glued Laminated Timber and Glued Solid Timber—Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- Efinger, D.; Ostertag, A.; Dazer, M.; Borschewski, D.; Albrecht, S.; Bertsche, B. Reliability as a key driver for a sustainable design of adaptive load-bearing structures. Sustainability 2022, 14, 895. [Google Scholar] [CrossRef]

| Reference | Application | Alternatives | Methods * | Criteria |

|---|---|---|---|---|

| Invidiata et al. [1] | Selecting the design strategies for a multi-family social building | X-Lam; Reinforced concrete frame; Steel frame | AHP and COPRAS | Number of hours in which there is internal thermal comfort, primary energy demand over the life cycle, carbon dioxide emissions over the life cycle, and cost over the life cycle |

| Balali et al. [22] | Selecting the structural system for low-rise multi-housing project | 3D panel with light walls in building frames; LSF; ICF; Tunnel formwork system; Tronco | AHP and PROMETHEE | Cost, ease of construction, energy saving, dead load, number of stories, life cycle time |

| Tamosaitiene and Gaudutis [23] | Assessing structural systems for 24-storey administrative building | Semi-rigid frame (sectional monolithic concrete); Semi-rigid frame (monolithic concrete); Semi-rigid frame (steel beams and columns, concrete span); Rigid frame (monolithic concrete); Rigid frame without beams (monolithic concrete) | COPRAS-G | Effective height of the structural system (storeys), typical floor-to-floor height, lengthwise step of a column, transverse step of a column, length of a slab span, price for the design of the structural system, terms of performance, price for the construction of the building, embodied energy, embodied carbon, price for the demolition of the building |

| Balali et al. [24] | Selecting the structural system for multi-housing project | LSF (light steel frame); 3D panel; ICF (insulated concrete formwork); Tunnel formwork system; Tronco; Timber; D2; CFT (concrete-filled steel tube) | ELECTRE III and PROMETHEE II | Cost, ease of construction, energy saving, maximum dead load, number of stories, age, durability |

| Teracciano et al. [25] | Selecting vertical reinforcement and energy retrofitting systems for existing masonry constructions | Reinforced concrete; Masonry; Steel; Glued laminated timber; Cold-formed thin-walled steel | TOPSIS | Structural, economic, environmental, and energy criteria |

| Turskis et al. [26] | Assessing structural elements of frames | Three cases of steel frames; Precast reinforced concrete columns and beam; Precast reinforced concrete columns and steel beam | AHP, ARAS-F, and MULT-F | Costs, impact on the environment, instalment time, weight, consumption of steel, consumption of concrete |

| Tupenaite et al. [27] | Selecting structural system for wooden public building | Double-tapered glulam beams and columns; Laminated veneer lumber (LVL) trusses and columns; Single-tapered glulam beam and type I steel column | SAW | Achieved useful height of the building, partial factor for material, eco-friendliness of materials, massiveness of structure, structural aesthetics, assembling complexity, simplicity of foundation design solution, simplicity of structural system production |

| Sánchez-Garrido and Yepes [28] | Comparing alternative sustainable structures for single-family home | Reinforced concrete; Autoclave-cured and aerated concrete; Elesdopa double-wall structural elements | MIVES | Energy consumption, improving environmental impact, cost, certainty of the final cost, period of construction, responsiveness, added value, user comfort |

| Sánchez-Garrido et al. [29] | Comparing alternatives for the structure of single-family homes | Reinforced concrete structure and brick walls; Prefabricated option with semi-dry assembly (Ytong material); Elesdopa double-wall structural elements | NAHP-G and VIKOR | 43 indicators considering all stages of the life cycle |

| Zumrut et al. [30] | Selecting a structural system for industrial facility | Prefabricated reinforced concrete system; On-site reinforced concrete system; Steel structural system | AHP and TOPSIS | Project cost, project duration, project lifetime, labor and equipment requirement, recycling opportunities, resistance to environmental effects, suitability for installation and natural lighting needs |

| Option | Total Quantity of Glulam GL28h, m3 | Welded Steel Details, kg | Fittings, kg |

|---|---|---|---|

| Option I: Glulam column and truss system | 50.10 | 3260.00 | 1550.00 |

| Option II: Glulam 3-hinge frame system | 82.49 | 1440.00 | 1810.00 |

| Option III: Glulam column and double-tapered beam system | 68.41 | 2060.00 | 1030.00 |

| No | Criterion | Max/Min * | Measuring Unit | Description |

|---|---|---|---|---|

| C1 | Total cost of load-bearing structures | k€ | Min | The total cost of glued laminated timber elements, welded steel details, and fittings. The production and transportation from the factory to the building site are also included. Determined by a survey of glulam manufacturers located at >1500 km from the factory to the building site. |

| C2 | Total quantity of glulam | m3 | Min | The criterion takes into account all load-bearing glulam elements. The provided quantity of glulam is the actual sum of the volumes of separate elements (see Table 2). |

| C3 | Total quantity of steel details and fittings | kg | Min | The total quantity of welded steel details necessary for the assembling of separate glulam elements, connections, and support details. All glued laminated timber elements are assembled using custom-made welded steel details and bolts, dowels, and screws (see Table 2). |

| C4 | Maximum utility ratio according to ultimate limit states (ULSs) | % | Max | According to the Eurocodes, it is allowed to design structures up to a 100% utility ratio. The utility ratio is determined by both element design and connection design. In the structural design of timber elements, it is usually hard to reach high utility ratios when the determining factor is connection design. The parameter defines the structural efficiency of the analyzed system. Calculated using Dlubal Rfem 5 and Mathcad 14 software. |

| C5 | Maximum utility ratio according to serviceability limit states (SLSs) | % | Max | The utility ratio for serviceability defines the efficiency of the structural system in terms of vertical and horizontal deformations. High utility ratios for serviceability limit states could be easier to reach for structural systems with a relatively low number of connections, as systems with connections are more sensitive to deformations. Calculated using Dlubal Rfem 5 and Mathcad 14 software. |

| C6 | The total available height of the building | m | Max | The total height of the building is defined as the sum of the internal effective height of the building below the roof structure and the height of the roof structure. The height directly influences the total costs of the entire construction and maintenance of the building. Determined in design process. |

| C7 | Total assembly cost | k€ | Min | The total assembly cost includes the lifting equipment rent, manpower, and all other costs related to the assembling of load-bearing structures. Determined by a survey of timber construction companies. |

| C8 | Complexity of assembly | Points | Min | The complexity of assembly takes into account the speed of assembling separate structural elements. This criterion also evaluates the need for lifting equipment for the heaviest structural elements. It is a qualitative criterion evaluated on a 3-point scale: 1 = the simplest assembly, 2 = the moderately complex assembly, and 3 = the most complex assembly. Determined based on the knowledge and practical experience of the authors. |

| C9 | Architectural aesthetics | Points | Max | The architectural aesthetics are evaluated by the biophilic design concept of the building load-bearing structures. Glued laminated timber structures are exposed and, therefore, the natural appearance of the structures is significant. It is a qualitative criterion evaluated on a 3-point scale: 1 = the worst appeal, 2 = the moderate appeal, and 3 = the best appeal. Determined by the authors. |

| C10 | Simplicity of the foundation design solution | Points | Min | The simplicity of foundation-laying solution to bear the load of timber superstructure. It is a qualitative criterion evaluated on a 3-point scale: 1 = the simplest foundation design solution, 2 = the moderately simple foundation design solution, and 3 = the most complex foundation design solution. Determined based on the knowledge and practical experience of the authors. |

| Expert | Profile of a Company | Years of Experience |

|---|---|---|

| E1 | Structural design of timber structures | 11–15 |

| E2 | Construction of timber buildings | 11–15 |

| E3 | Structural design of timber structures | 5–10 |

| E4 | Construction (different structures) | 21–25 |

| E5 | Construction (different structures) | >26 |

| E6 | Construction (different structures) | >26 |

| E7 | Inspection of the buildings | 11–15 |

| Criterion | E1 | E2 | E3 | E4 | E5 | E6 | E7 | Sum | Significance |

|---|---|---|---|---|---|---|---|---|---|

| Total cost of load-bearing structures | 10 | 10 | 10 | 10 | 9 | 10 | 10 | 69 | 0.1774 |

| Total quantity of glulam | 9 | 9 | 9 | 8 | 9 | 7 | 7 | 58 | 0.1491 |

| Total quantity of steel details and fittings | 8 | 8 | 7 | 9 | 6 | 8 | 8 | 54 | 0.1388 |

| Maximum utility ratio according to ULSs | 7 | 7 | 8 | 7 | 8 | 9 | 9 | 55 | 0.1414 |

| Maximum utility ratio according to SLSs | 3 | 6 | 6 | 5 | 7 | 6 | 6 | 39 | 0.1003 |

| Total available height of the building | 4 | 3 | 3 | 3 | 3 | 3 | 1 | 20 | 0.0514 |

| Total assembly cost | 6 | 5 | 4 | 4 | 4 | 4 | 5 | 32 | 0.0823 |

| Complexity of assembly | 5 | 4 | 2 | 2 | 2 | 5 | 2 | 22 | 0.0566 |

| Architectural aesthetics | 2 | 2 | 5 | 6 | 10 | 2 | 3 | 30 | 0.0771 |

| Simplicity of the foundation design solution | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 10 | 0.0257 |

| Total | 386 | 1 | |||||||

| Criteria | Min/Max | Significance | Alternative Structural Systems | ||

|---|---|---|---|---|---|

| Option I | Option II | Option III | |||

| C1 | Min | 0.1774 | 87.059 | 83.664 | 66.875 |

| C2 | Min | 0.1491 | 50.1 | 82.49 | 68.41 |

| C3 | Min | 0.1388 | 4310 | 3250 | 3090 |

| C4 | Max | 0.1414 | 89 | 97 | 93 |

| C5 | Max | 0.1003 | 64 | 85 | 99 |

| C6 | Max | 0.0514 | 6.78 | 6.2 | 5.8 |

| C7 | Min | 0.0823 | 30.564 | 45.372 | 34.546 |

| C8 | Min | 0.0566 | 3 | 1 | 2 |

| C9 | Max | 0.0771 | 3 | 2 | 1 |

| C10 | Min | 0.0257 | 2 | 1 | 3 |

| Criteria | Weighted Normalized Criteria Values | ||

|---|---|---|---|

| Option I | Option II | Option III | |

| C1 | 0.0650 | 0.0625 | 0.0499 |

| C2 | 0.0372 | 0.0612 | 0.0507 |

| C3 | 0.0562 | 0.0424 | 0.0403 |

| C4 | 0.0451 | 0.0492 | 0.0471 |

| C5 | 0.0259 | 0.0344 | 0.0400 |

| C6 | 0.0186 | 0.0170 | 0.0159 |

| C7 | 0.0228 | 0.0338 | 0.0257 |

| C8 | 0.0283 | 0.0094 | 0.0189 |

| C9 | 0.0386 | 0.0257 | 0.0129 |

| C10 | 0.0086 | 0.0043 | 0.0129 |

| The sums of weighted normalized maximizing indices S+j | 0.1281 | 0.1262 | 0.1159 |

| The sums of weighted normalized minimizing indices S−j | 0.2179 | 0.2135 | 0.1984 |

| 0.3300 | 0.3323 | 0.3377 | |

| Rank | 3 | 2 | 1 |

| Criteria | Weighted Normalized Criteria Values | ||

|---|---|---|---|

| Option I | Option II | Option III | |

| C1 | 0.1363 | 0.1418 | 0.1774 |

| C2 | 0.1491 | 0.0906 | 0.1092 |

| C3 | 0.0995 | 0.1320 | 0.1388 |

| C4 | 0.1297 | 0.1414 | 0.1356 |

| C5 | 0.0648 | 0.0861 | 0.1003 |

| C6 | 0.0514 | 0.0470 | 0.0440 |

| C7 | 0.0823 | 0.0554 | 0.0728 |

| C8 | 0.0189 | 0.0566 | 0.0283 |

| C9 | 0.0771 | 0.0514 | 0.0257 |

| C10 | 0.0129 | 0.0257 | 0.0086 |

| 0.8219 | 0.8279 | 0.8405 | |

| Rank | 3 | 2 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gecys, T.; Tupenaite, L.; Kanapeckiene, L.; Naimaviciene, J. Multi-Criteria Assessment of Timber-Based Structural Systems for a Grocery Store. Buildings 2024, 14, 1335. https://doi.org/10.3390/buildings14051335

Gecys T, Tupenaite L, Kanapeckiene L, Naimaviciene J. Multi-Criteria Assessment of Timber-Based Structural Systems for a Grocery Store. Buildings. 2024; 14(5):1335. https://doi.org/10.3390/buildings14051335

Chicago/Turabian StyleGecys, Tomas, Laura Tupenaite, Loreta Kanapeckiene, and Jurga Naimaviciene. 2024. "Multi-Criteria Assessment of Timber-Based Structural Systems for a Grocery Store" Buildings 14, no. 5: 1335. https://doi.org/10.3390/buildings14051335