Effect of Crushing Method on the Properties of Produced Recycled Concrete Aggregates

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials Used for the Production of Concrete

2.2. Concrete Characteristics

2.3. RCA Production

2.4. Characterization of RCA

- The first method consists of a thermal treatment [38]. It is based on several cycles where the aggregates are soaked in water then heated to 300 °C progressively to detach adherent mortar from the surface of NA. This is due to the micro-cracking presented at the interface between aggregates and mortar because of their different thermal dilation coefficients. This method is only suitable for coarse RCA, since mortal removal needs “brushing” of the RCA which is difficult with fine RCA.

- The third method uses image analysis [61,73] to quantify the amount of residual mortar on a flat polished section, which is efficient with coarse RCA, but the distinction between fine aggregates and cement paste is difficult. Moreover, a statistical approach is needed and it is time-consuming to obtain the reliable results.

- The last method had been developed by Zhao [44] and is based on the dissolution of cement paste in a solution of salicylic acid. This method has been shown not to dissolve calcareous aggregates.

3. Results and Discussion

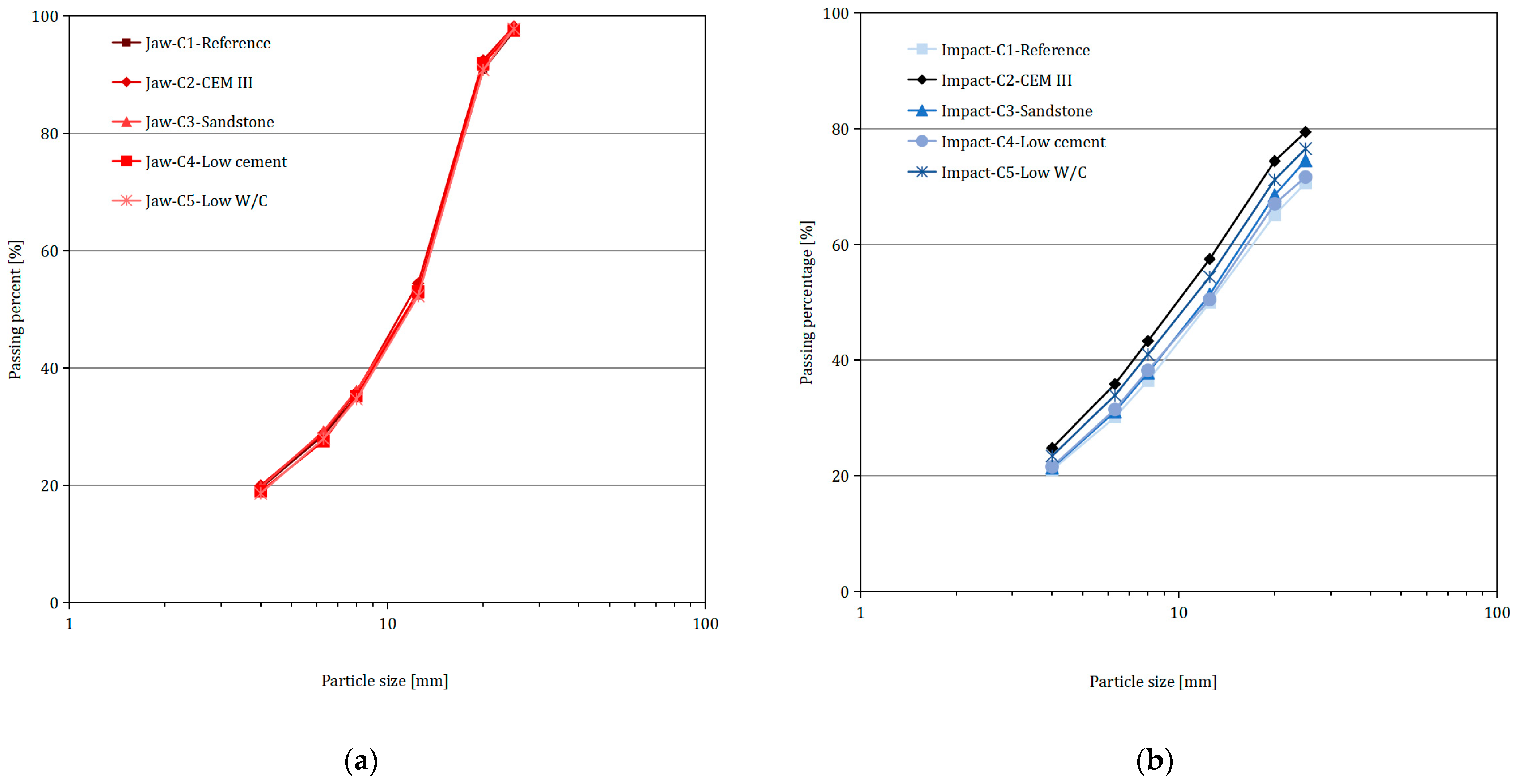

3.1. Particle Size Distribution

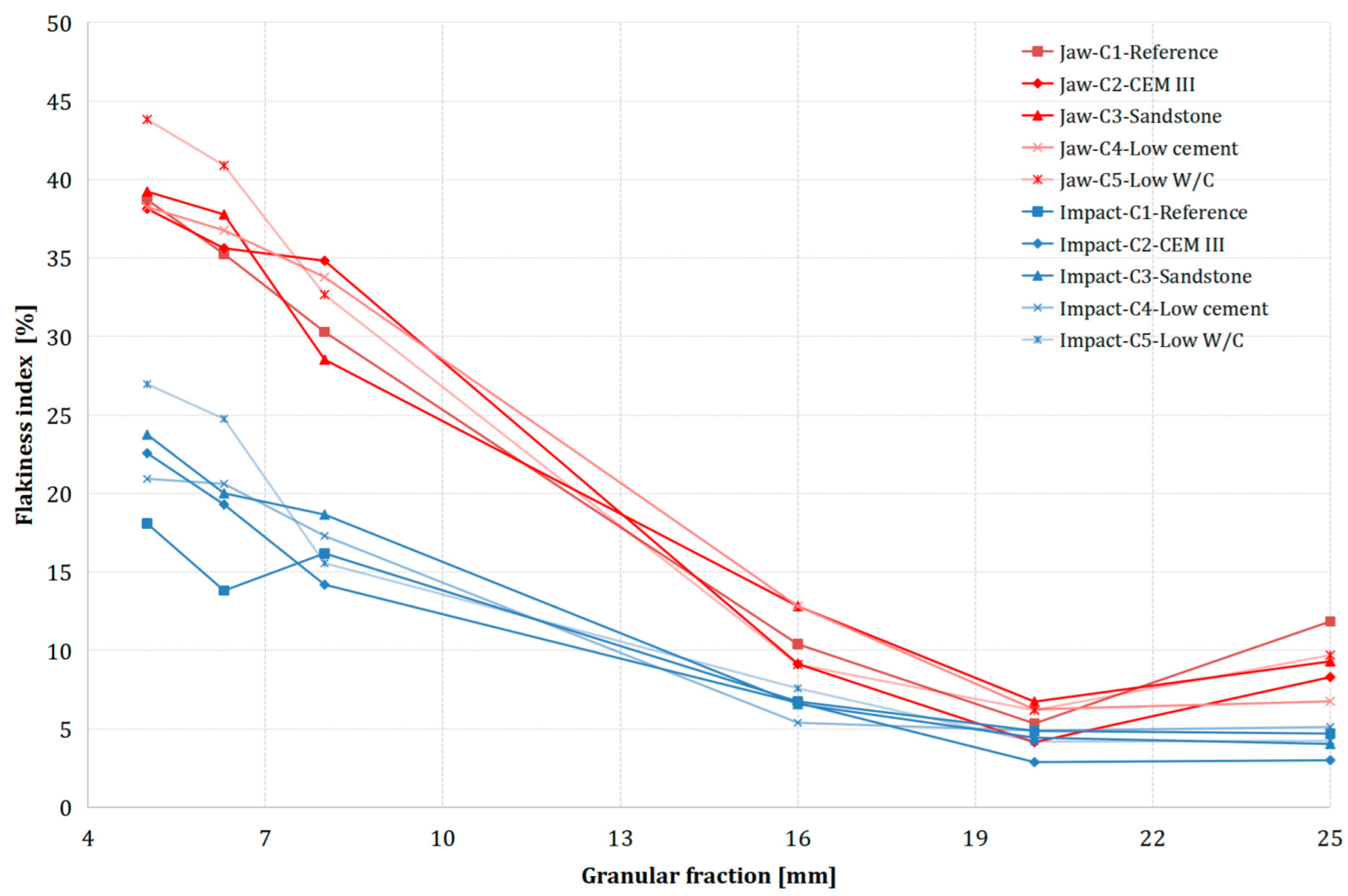

3.2. Morphology

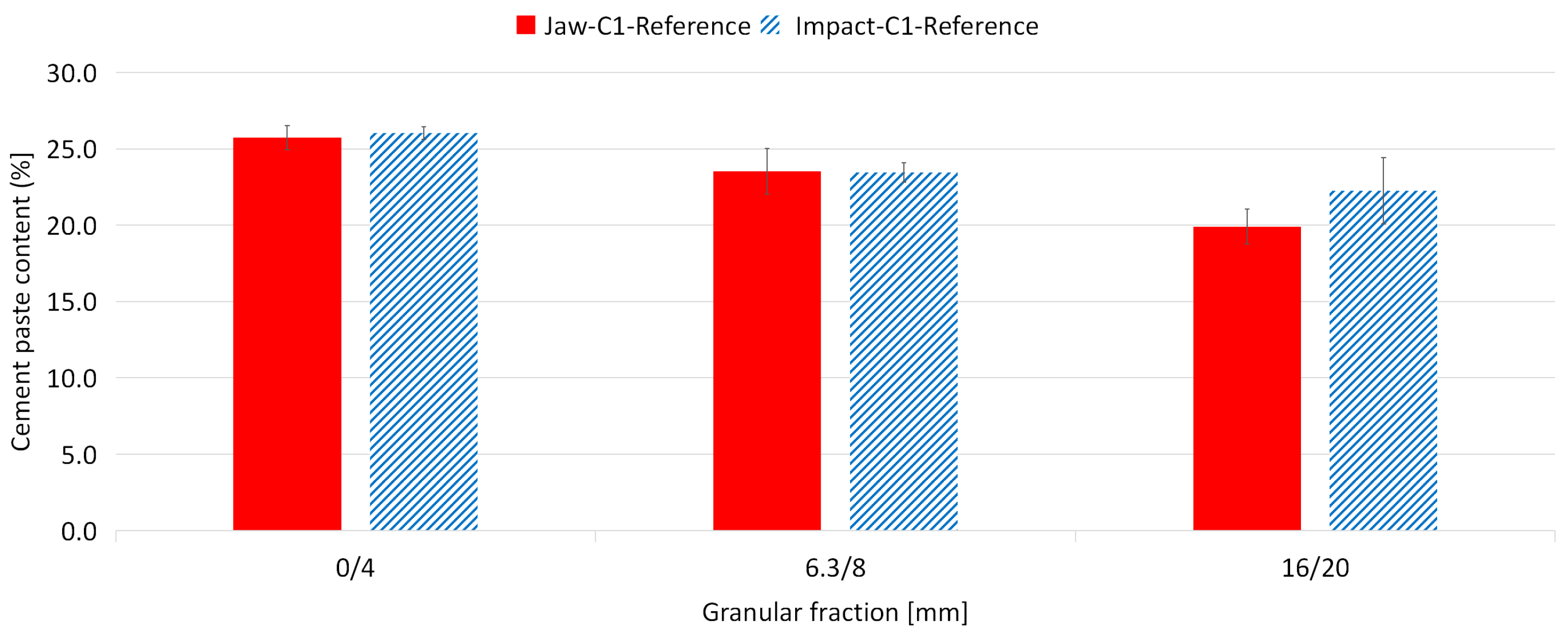

3.3. Hardened Cement Paste Content

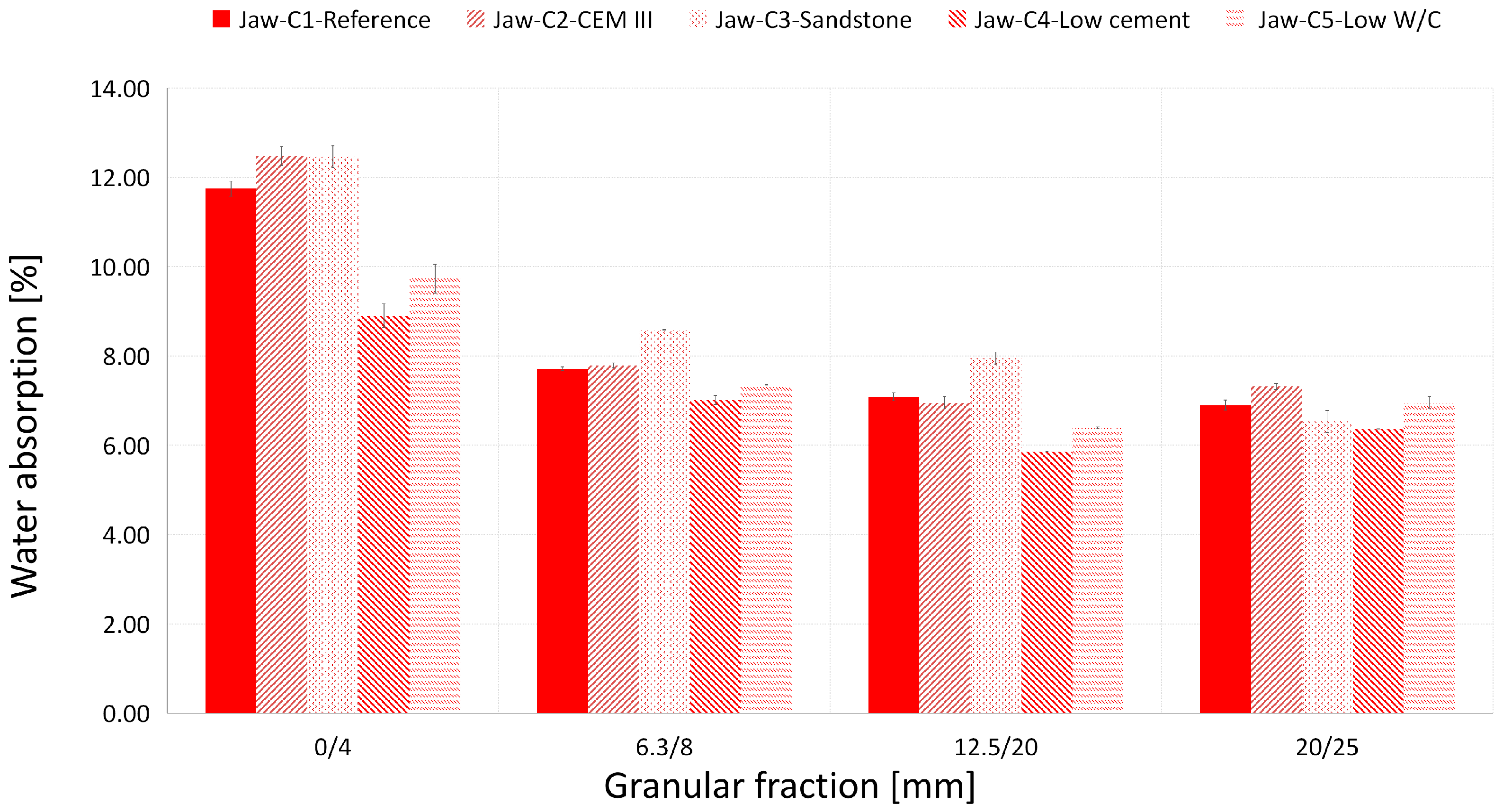

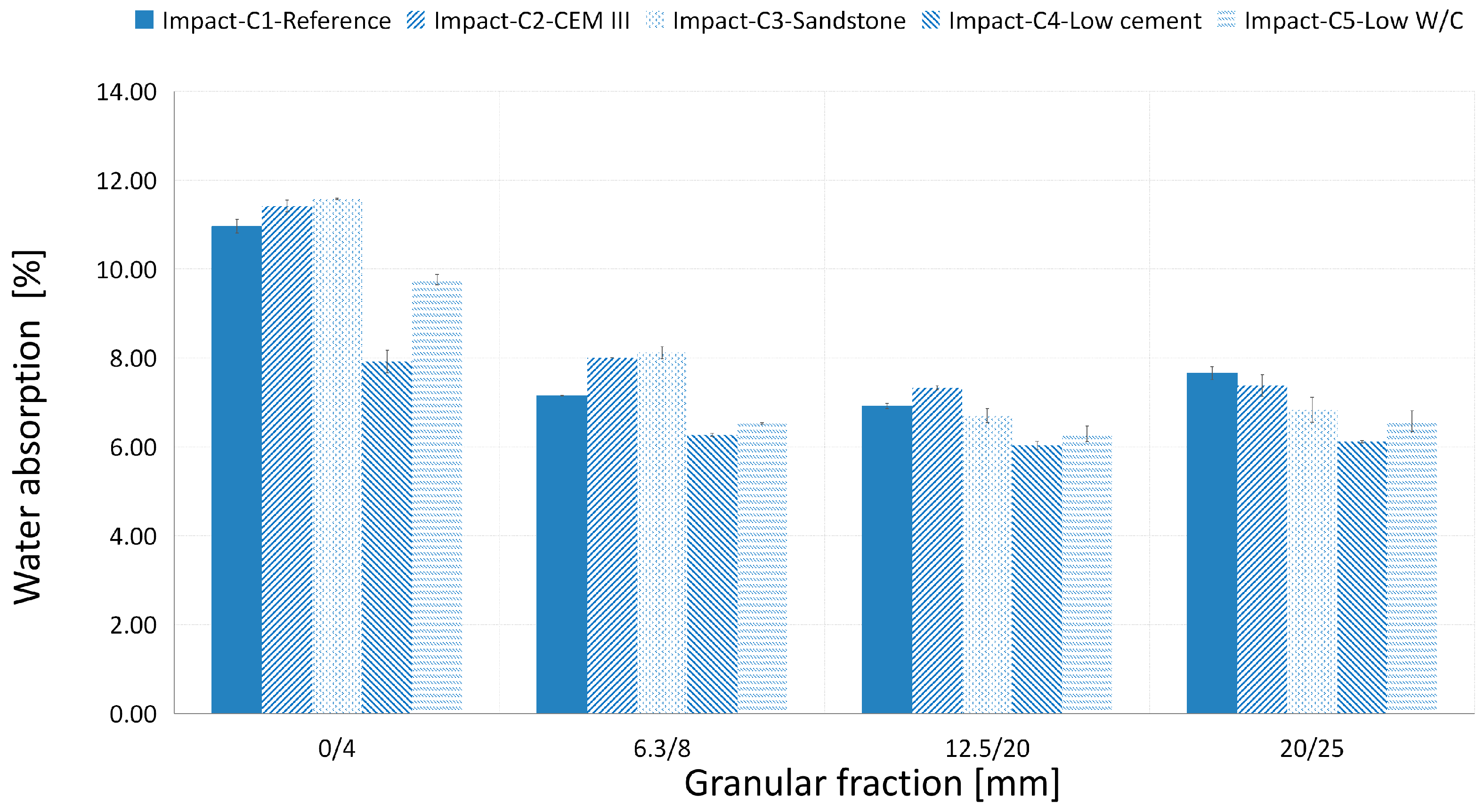

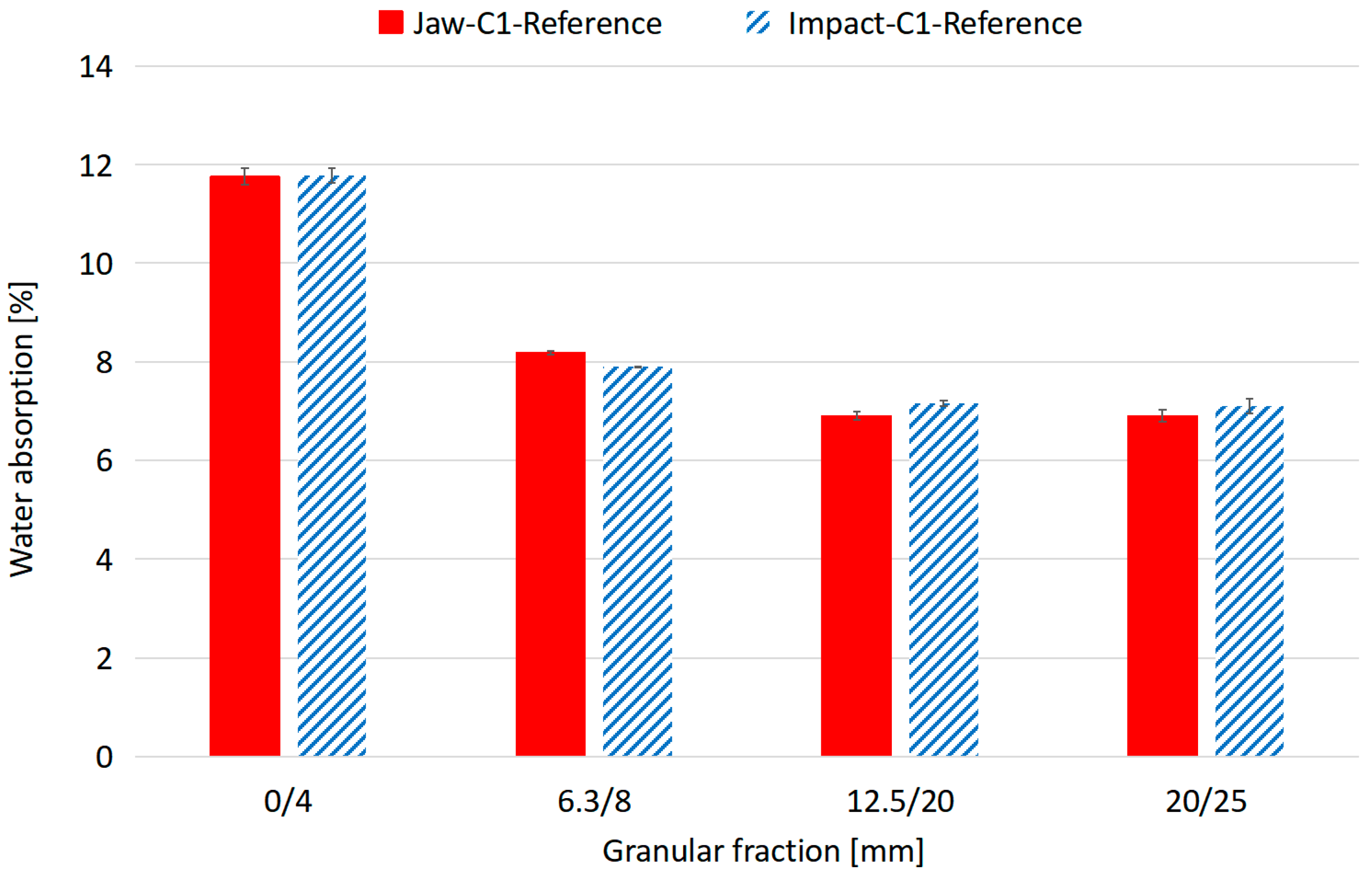

3.4. Water Absorption

4. Conclusions

- (a)

- The impact crusher results in the production of aggregates possessing more spherical geometric characteristics, a broader spectrum of grain sizes and a relatively higher content of fine particles as compared to those obtained from the jaw crusher. In addition, the crushing method exerts no discernible impact on the hardened cement paste content and the water absorption in the context of the studied concretes. The W/C ratio in the range from 0.46 to 0.56, as well as the type of NA in the parent concrete, do not seem to have any influence on the properties of the produced RCA.

- (b)

- The flakiness and shape indexes decrease with the increase in the granular fraction. The larger granular fractions have a lower residual hardened cement paste content and water absorption than the smaller fractions, which indicates that larger fractions of RCA are mostly composed of NA with a bit of adherent mortar.

- (c)

- In the case of using a jaw crusher to produce RCA, the water absorption and morphology indicators of RCA show their minimum values when the granular fraction is close to the maximum diameter of the NA in the parent concrete. This correlation indicates that the breakage mechanism of the jaw crusher does not affect the RCA in a similar manner to the impact crusher.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Delvoie, S.; Zhao, Z.; Michel, F.; Courard, L. Market analysis of recycled sands and aggregates in North West Europe: Drivers and barriers. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Banda Aceh, Indonesia, 19–20 June 2019; p. 012055. [Google Scholar]

- Gursel, A.P.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Georgiades, M.; Shah, I.H.; Steubing, B.; Cheeseman, C.; Myers, R. Prospective life cycle assessment of European cement production. Resour. Conserv. Recycl. 2023, 194, 106998. [Google Scholar] [CrossRef]

- Ravindrarajah, R.S.; Loo, Y.H.; Tam, C.T. Recycled concrete as fine and coarse aggregates in concrete. Mag. Concr. Res. 1987, 39, 214–220. [Google Scholar] [CrossRef]

- Ong, K.; Ravindrarajah, S.R. Mechanical Properties and Fracture Energy of Recycled-Aggregate Concretes. 1987. Available online: http://scholarbank.nus.edu.sg/handle/10635/74242 (accessed on 30 August 2023).

- Zhang, T.; Chen, M.; Wang, Y.T.; Zhang, M.Z. Roles of carbonated recycled fines and aggregates in hydration, microstructure and mechanical properties of concrete: A critical review. Cem. Concr. Compos. 2023, 138, 104994. [Google Scholar] [CrossRef]

- Coelho, A.; de Brito, J. Economic analysis of conventional versus selective demolition—A case study. Resour. Conserv. Recycl. 2011, 55, 382–392. [Google Scholar] [CrossRef]

- Pereira, P.M.; Vieira, C.S. A literature review on the use of recycled construction and demolition materials in unbound pavement applications. Sustainability 2022, 14, 13918. [Google Scholar] [CrossRef]

- Hansen, E. Recycling of Demolished Concrete and Masonry; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef]

- Delvoie, S.; Zhao, Z.; Michel, F.; Courard, L. WPT1-Technical REPORT of the Best-Practice in Producing Recycled Aggregates and Sands; Université de Liège: Liège, France, 2018. [Google Scholar]

- Everaert, M.; Stein, R.; Michaux, S.; Goovaerts, V.; Groffils, C.; Delvoie, S.; Zhao, Z.F.; Snellings, R.; Nielsen, P.; Broos, K. Microwave radiation as a pre-treatment for standard and innovative fragmentation techniques in concrete recycling. Materials 2019, 12, 488. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.L.; Lin, D.H.; Chang, N.B.; Lin, K.S. Recycling of construction and demolition waste via a mechanical sorting process. Resour. Conserv. Recycl. 2002, 37, 23–37. [Google Scholar] [CrossRef]

- Omer, M.M.; Rahman, R.A.; Almutairi, S. Strategies for enhancing construction waste recycling: A usability analysis. Sustainability 2022, 14, 5907. [Google Scholar] [CrossRef]

- Marinkovic, S.; Radonjanin, V.; Malesev, M.; Ignjatovic, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Nedeljkovic, M.; Visser, J.; Savija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. Quality improvement of recycled concrete aggregate by removal of residual mortar: A comprehensive review of approaches adopted. Constr. Build. Mater. 2021, 288, 123066. [Google Scholar] [CrossRef]

- Ruiz, L.A.L.; Ramon, X.R.; Mercedes, C.M.L.; Domingo, S.G. Multicriteria analysis of the environmental and economic performance of circularity strategies for concrete waste recycling in Spain. Waste Manag. 2022, 144, 387–400. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Setkit, M.; Leelatanon, S.; Imjai, T.; Garcia, R.; Limkatanyu, S. Prediction of Shear Strength of Reinforced Recycled Aggregate Concrete Beams without Stirrups. Buildings 2021, 11, 402. [Google Scholar] [CrossRef]

- Leelatanon, S.; Imjai, T.; Setkit, M.; Garcia, R.; Kim, B. Punching Shear Capacity of Recycled Aggregate Concrete Slabs. Buildings 2022, 12, 1584. [Google Scholar] [CrossRef]

- Krampitz, T.; Lieberwirth, H.; Hartl, S.; Nüsse, A. Zerkleinerung von Porenbeton in konventionellen Zerkleinerungsmaschinen der Bauschuttaufbereitung. Chem. Ing. Tech. 2022, 95, 1–12. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Fiol, F.; Perumal, P.; Ortega-López, V.; Manso, J.M. Using recycled aggregate concrete at a precast-concrete plant: A multi-criteria company-oriented feasibility study. J. Clean. Prod. 2022, 373, 133873. [Google Scholar] [CrossRef]

- Imjai, T.; Kefyalew, F.; Aosai, P.; Garcia, R.; Kim, B.; Abdalla, H.M.; Raman, S.N. A new equation to predict the shear strength of recycled aggregate concrete Z push-off specimens. Cem. Concr. Res. 2023, 169, 107181. [Google Scholar] [CrossRef]

- Imjai, T.; Garcia, R.; Kim, B.; Hansapinyo, C.; Sukontasukkul, P. Serviceability behaviour of FRP-reinforced slatted slabs made of high-content recycled aggregate concrete. Structures 2023, 51, 1071–1082. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Pham, T.L.; Wang, P.J.; Gao, G. Behaviors of semi-precast beam made of recycled aggregate concrete. Struct. Des. Tall Spec. Build. 2014, 23, 692–712. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Liang, J.; Meng, Y.; Rong, H.; Li, D.; Chen, Y.; Lv, J.; Jiang, Y.; Liu, Y. Straightening methods for RCA and RAC—A review. Cem. Concr. Compos. 2023, 141, 105145. [Google Scholar] [CrossRef]

- Hansen, T.C.; Boegh, E. Elasticity and drying shrinkage concrete of recycled aggregate. J. Am. Concr. Inst. 1985, 82, 648–652. [Google Scholar]

- He, H.; Stroeven, P.; Stroeven, M.; Sluys, L.J. Influence of particle packing on elastic properties of concrete. Mag. Concr. Res. 2012, 64, 163–175. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Assaad, J.J.; Mardani, A. Limestone replacements by fine crushed concrete and ceramic wastes during the production of Portland cement. J. Sustain. Cem. Based Mater. 2023. [Google Scholar] [CrossRef]

- Lippiatt, N.R.; Bourgeois, F.S. Recycling-oriented investigation of local porosity changes in microwave heated-concrete. Kona Powder Part. J. 2014, 31, 247–264. [Google Scholar] [CrossRef]

- Guo, Y.C.; Zhang, J.H.; Chen, G.M.; Xie, Z.H. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Zhang, H.H.; Xiao, J.Z.; Tang, Y.X.; Duan, Z.H.; Poon, C.S. Long-term shrinkage and mechanical properties of fully recycled aggregate concrete: Testing and modelling. Cem. Concr. Compos. 2022, 130, 104527. [Google Scholar] [CrossRef]

- Rashwan, M.S.; Abou Rizk, S. The properties of recycled concrete. Concr. Int. 1997, 19, 56–60. [Google Scholar]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Establishing a relationship between modulus of elasticity and compressive strength of recycled aggregate concrete. J. Clean. Prod. 2016, 112, 2171–2186. [Google Scholar] [CrossRef]

- Zhao, Z.F.; Courard, L.; Groslambert, S.; Jehin, T.; Leonard, A.; Xiao, J.Z. Use of recycled concrete aggregates from precast block for the production of new building blocks: An industrial scale study. Resour. Conserv. Recycl. 2020, 157, 104786. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutierrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Dhir, R.; Paine, K.; Dyer, T. Recycling construction and demolition wastes in concrete. Concrete 2004, 38, 25–28. [Google Scholar]

- Mazhoud, B.; Sedran, T.; Cazacliu, B.; Cothenet, A.; Torrenti, J.M. Influence of residual mortar volume on the properties of recycled concrete aggregates. J. Build. Eng. 2022, 57, 104945. [Google Scholar] [CrossRef]

- dos Santos, J.R.; Branco, F.; De Brito, J. Mechanical properties of concrete with coarse recycled aggregates. Struct. Eng. Int. 2004, 14, 213–215. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M. Re-Use of Construction and Demolition Waste in Housing Developments; Nova Science Publishers: New York, NY, USA, 2008. [Google Scholar]

- Bai, G.L.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Zhao, Z.; Remond, S.; Damidot, D.; Xu, W. Influence of hardened cement paste content on the water absorption of fine recycled concrete aggregates. J. Sustain. Cem.-Based Mater. 2013, 2, 186–203. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Tam, C.T.; Zhang, M.H. Effects of the parent concrete properties and crushing procedure on the properties of coarse recycled concrete aggregates. J. Mater. Civ. Eng. 2013, 25, 1795–1802. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vazquez, E.; Mari, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Sun, D.S.; Shen, S.S.; Huang, W.; Liu, K.W.; Wang, A.G.; Chen, J. A review of quality of recycled aggregate and its effect on durability of recycled aggregate concrete. Mater. Express 2022, 12, 1415–1426. [Google Scholar] [CrossRef]

- Touzé, S.; Bru, K.; Ménard, Y.; Weh, A.; Von der Weid, F. Electrical fragmentation applied to the recycling of concrete waste—Effect on aggregate liberation. Int. J. Miner. Process. 2017, 158, 68–75. [Google Scholar] [CrossRef]

- Ulsen, C.; Tseng, E.; Angulo, S.C.; Landmann, M.; Contessotto, R.; Balbo, J.T.; Kahn, H. Concrete aggregates properties crushed by jaw and impact secondary crushing. J. Mater. Res. Technol. JMRT 2019, 8, 494–502. [Google Scholar] [CrossRef]

- Haase, R.; Dahms, J. Material cycles on the example of concrete in the northern parts of Germany. Beton 1998, 48, 350–355. [Google Scholar]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Rombi, J.; Stochino, F.; Mistretta, F. The role of parent concrete in recycled aggregate concrete. In Proceedings of the 20th International Conference on Computational Science and Its Applications (ICCSA), Cagliari, Italy, 1–4 July 2020; pp. 368–378. [Google Scholar]

- Grubl, P.; Ruhl, M. German committee for reinforced concrete (DafStb)–Code: Concrete with recycled aggregates. In Proceedings of the International Symposium Organised by the Concrete Technology Unit, University of Dundee, London, UK, 11–12 November 1998. [Google Scholar]

- Ghorbani, S.; Sharifi, S.; Ghorbani, S.; Tam, V.W.Y.; de Brito, J.; Kurda, R. Effect of crushed concrete waste’s maximum size as partial replacement of natural coarse aggregate on the mechanical and durability properties of concrete. Resour. Conserv. Recycl. 2019, 149, 664–673. [Google Scholar] [CrossRef]

- Hansen, T.C. Recycled aggregates and recycled aggregate concrete second state-of-the-art report developments 1945–1985. Mater. Struct. 1986, 19, 201–246. [Google Scholar] [CrossRef]

- Zhao, Z.; Courard, L.; Michel, F.; Remond, S.; Damidot, D. Influence of granular fraction and origin of recycled concrete aggregates on their properties. Eur. J. Environ. Civ. Eng. 2018, 22, 1457–1467. [Google Scholar] [CrossRef]

- Yagishita, F. Behavior of reinforced concrete beams containing recycled coarse aggregate. Demolition Reuse Concr. Masn. 1994, 43, 331–342. [Google Scholar]

- Fleischer, W.; Ruby, M. Recycled Aggregates from Old Concrete Highway Pavements; Thomas Telford Publishing: London, UK, 1999. [Google Scholar]

- Florea, M.V.A.; Brouwers, H.J.H. Properties of various size fractions of crushed concrete related to process conditions and re-use. Cem. Concr. Res. 2013, 53, 278. [Google Scholar] [CrossRef]

- Nagataki, S. Recycling of demolished concrete. Spec. Publ. 2001, 200, 1–20. [Google Scholar]

- Nagataki, S.; Gokce, A.; Saeki, T.; Hisada, M. Assessment of recycling process induced damage sensitivity of recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 965–971. [Google Scholar] [CrossRef]

- Ibrahim, M.; Alimi, W.; Assaggaf, R.; Salami, B.A.; Oladapo, E.A. An overview of factors influencing the properties of concrete incorporating construction and demolition wastes. Constr. Build. Mater. 2023, 367. [Google Scholar] [CrossRef]

- NBN EN 206. Concrete—Specification, Performance, Production and Conformity. CEN: Brussels, Belgium, 2014.

- NBN EN 480-1. Admixtures for Concrete, Mortar and Grout—Test Methods—Part 1: Reference Concrete and Reference Mortar for Testing. CEN: Brussels, Belgium, 2014.

- NBN EN 12350-2. Testing Fresh Concrete—Part 2: Slump Test. CEN: Brussels, Belgium, 2019.

- NBN EN 12350-6. Testing Fresh Concrete—Part 6: Density. CEN: Brussels, Belgium, 2019.

- NBN EN 12390-3. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. CEN: Brussels, Belgium, 2019.

- Wilson, J. Recycling of construction and demolition waste: The Dutch experience. Quarry Manag. 1996, 23, 03059421. [Google Scholar]

- NBN EN 933-1. Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. CEN: Brussels, Belgium, 2012.

- NBN EN 933-3. Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness Index. CEN: Brussels, Belgium, 2012.

- NBN EN 933-4. Tests for Geometrical Properties of Aggregates—Part 4: Determination of Particle Shape—Shape Index. CEN: Brussels, Belgium, 2008.

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Fournier, B.; Isgor, O.B.; Zavadil, R.; Razaqpur, A.G.; Foo, S. Quantification of the residual mortar content in recycled concrete aggregates by image analysis. Mater. Charact. 2009, 60, 716–728. [Google Scholar] [CrossRef]

- NBN EN 1097-6. Tests for mechanical and physical properties of aggregates-Part 6: Determination of particle density and water absorption. CEN: Brussels, Belgium, 2000.

- Cazacliu, B.; Le Guen, L.; Hamard, E.; Roux, S.; Braymand, S. Chapter 2: Elaboration des granulats de béton recyclé. Ouvrages Sci. 2018, 31–55. [Google Scholar]

- O’Mahony, M. Recycling of Materials in Civil Engineering. Ph.D. Thesis, Oxford University, Oxford, UK, 1990. [Google Scholar]

| Name of Concrete | C1-Reference | C2-CEM III | C3-Sandstone | C4-Low Cement | C5-Low W/C |

|---|---|---|---|---|---|

| Type of aggregate | Limestone | Limestone | Sandstone | Limestone | Limestone |

| NA 2/7 mm (kg/m3) | 368.8 | 368.8 | 368.8 | 405.1 | 367.1 |

| NA 7/14 mm (kg/m3) | 345 | 345 | 345 | 379 | 343.4 |

| NA 14/20 mm (kg/m3) | 433.5 | 433.5 | 433.5 | 476.2 | 431.5 |

| Sand 0/4 mm (kg/m3) | 604.9 | 604.9 | 604.9 | 664.4 | 602.1 |

| Type of cement | CEM I 52.5 | CEM III 52.5 | CEM I 52.5 | CEM I 52.5 | CEM I 52.5 |

| Cement quantity (kg/m3) | 400 | 400 | 400 | 320 | 452 |

| Cement paste volume (dm3/m3) | 351 | 358 | 351 | 282 | 351 |

| Efficient water (kg) | 224.2 | 224.2 | 224.2 | 180.6 | 207.1 |

| W/C ratio | 0.56 | 0.56 | 0.56 | 0.56 | 0.46 |

| Superplasticizer (g/kg cement) | 0 | 0 | 0 | 6.8 | 3.3 |

| Properties | C1-Reference | C2-CEM III | C3-Sandstone | C4-Low Cement | C5-Low W/C |

|---|---|---|---|---|---|

| Slump (mm) | 155 | 176 | 182 | 135 | 146 |

| Slump class | S4 | S4 | S4 | S3 | S3 |

| Density (g/cm3) | 2.35 | 2.31 | 2.31 | 2.36 | 2.31 |

| Compressive strength (MPa) (mean and standard deviation) | 56.0 (±2.4) | 61.6 (±0.7) | 52.7 (±2.5) | 56.0 (±6.4) | 66.9 (±0.7) |

| C1-Reference | C2-CEM III | C3-Sandstone | C4-Low Cement | C5-Low W/C | |

|---|---|---|---|---|---|

| Jaw crusher | 14 | 11 | 13 | 11 | 12 |

| Impact crusher | 8 | 6 | 6 | 7 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hubert, J.; Zhao, Z.; Michel, F.; Courard, L. Effect of Crushing Method on the Properties of Produced Recycled Concrete Aggregates. Buildings 2023, 13, 2217. https://doi.org/10.3390/buildings13092217

Hubert J, Zhao Z, Michel F, Courard L. Effect of Crushing Method on the Properties of Produced Recycled Concrete Aggregates. Buildings. 2023; 13(9):2217. https://doi.org/10.3390/buildings13092217

Chicago/Turabian StyleHubert, Julien, Zengfeng Zhao, Frédéric Michel, and Luc Courard. 2023. "Effect of Crushing Method on the Properties of Produced Recycled Concrete Aggregates" Buildings 13, no. 9: 2217. https://doi.org/10.3390/buildings13092217