Long-Term Behavior Related to Water Ingress in Mortars Which Combine Expanded and Natural Cork Lightweight Aggregates and Eco-Friendly Cements

Abstract

:1. Introduction

2. Experimental Setup

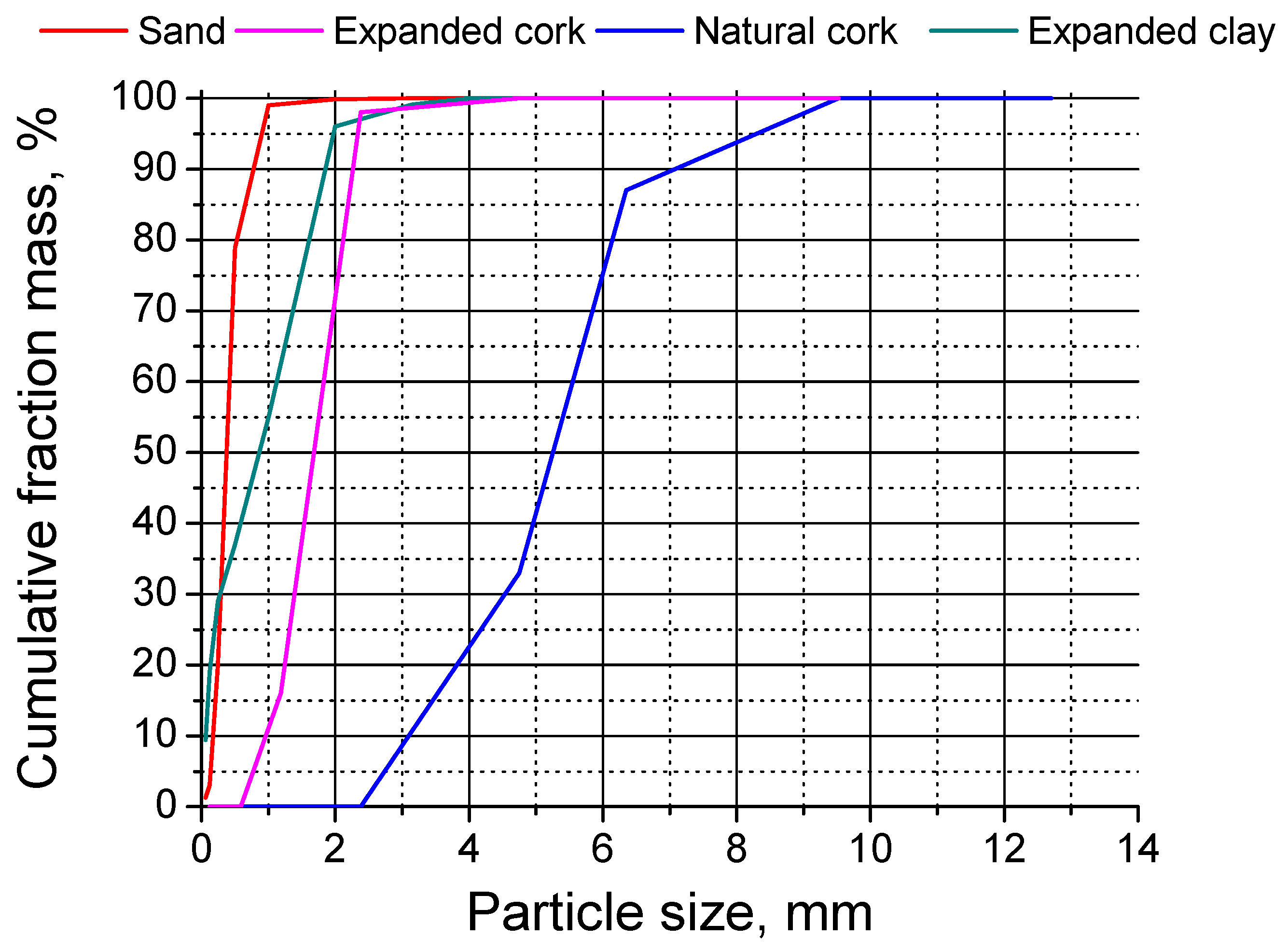

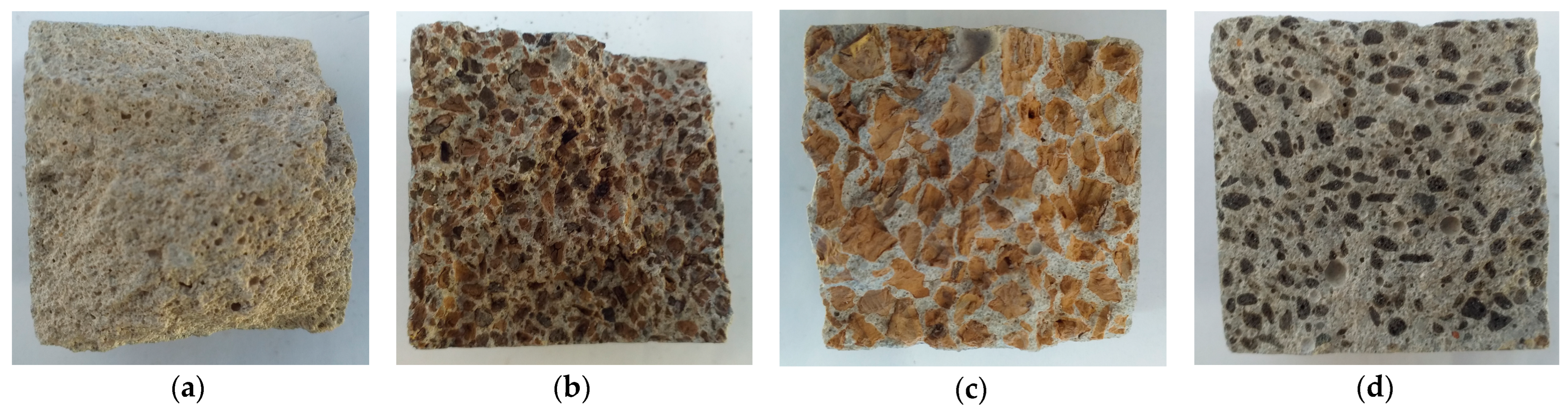

2.1. Sample Preparation and Materials

2.2. Gel and Capillary Pores

2.3. Absorption, Density and Volume of Permeable Pore Space

2.4. Water Absorption by Immersion after 48 H

2.5. Drying Kinetics Assessment

3. Results and Discussion

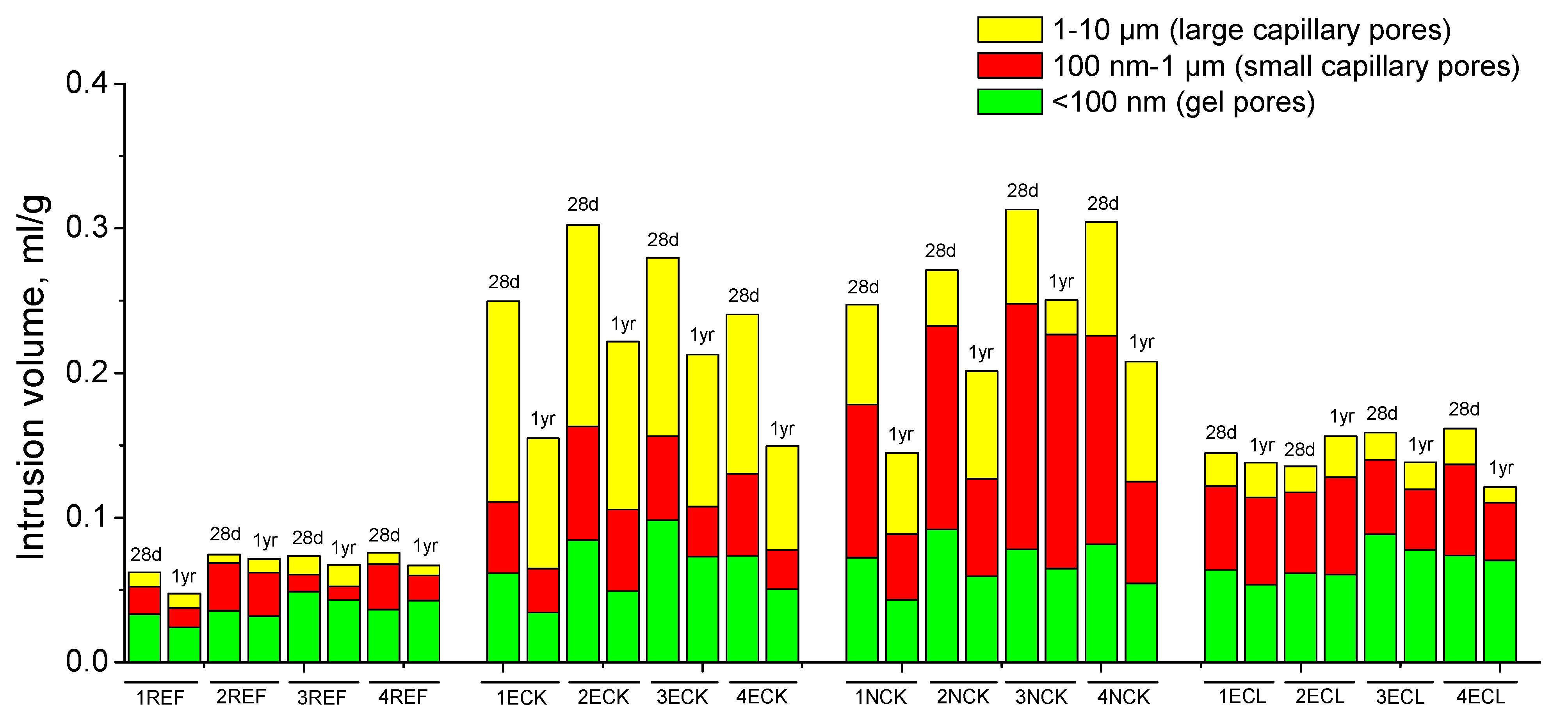

3.1. Gel and Capillary Pores

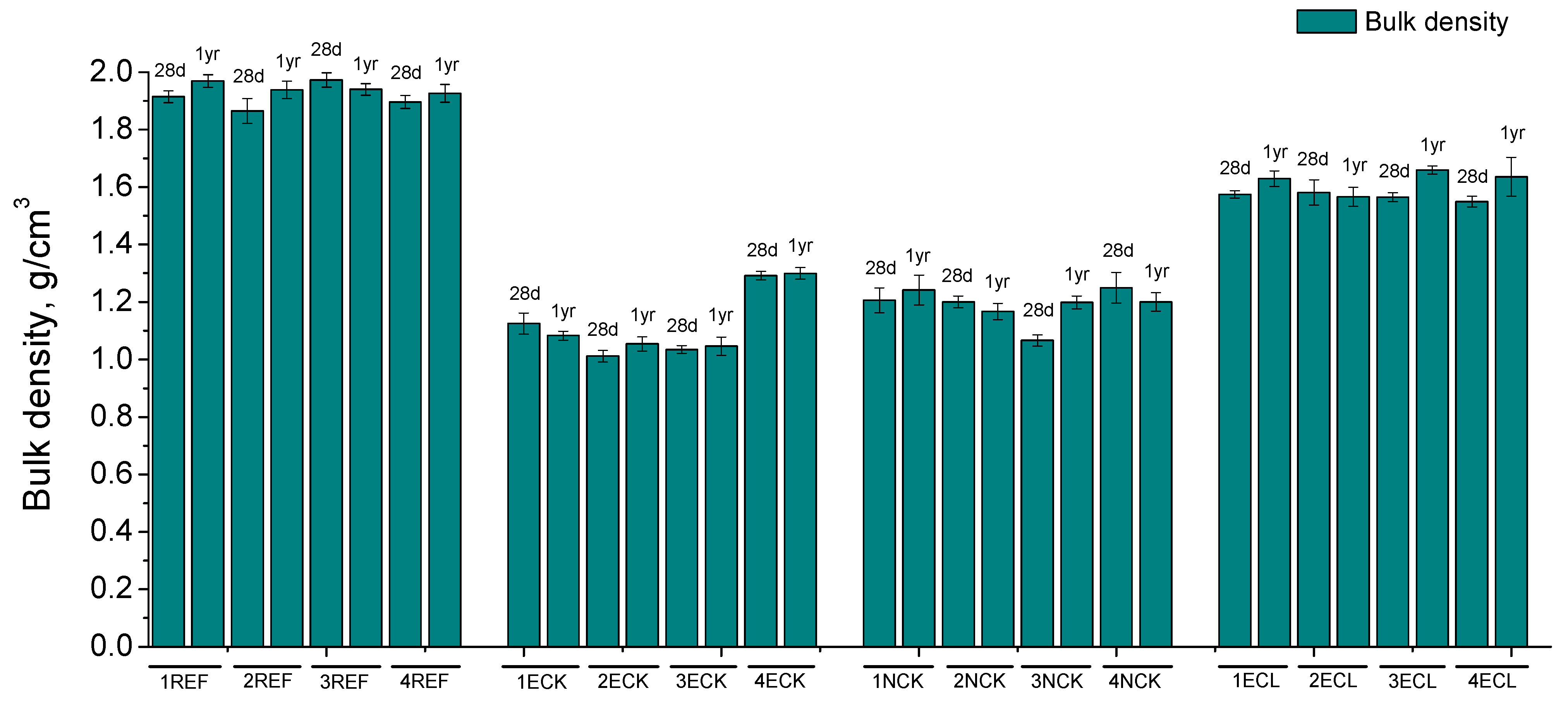

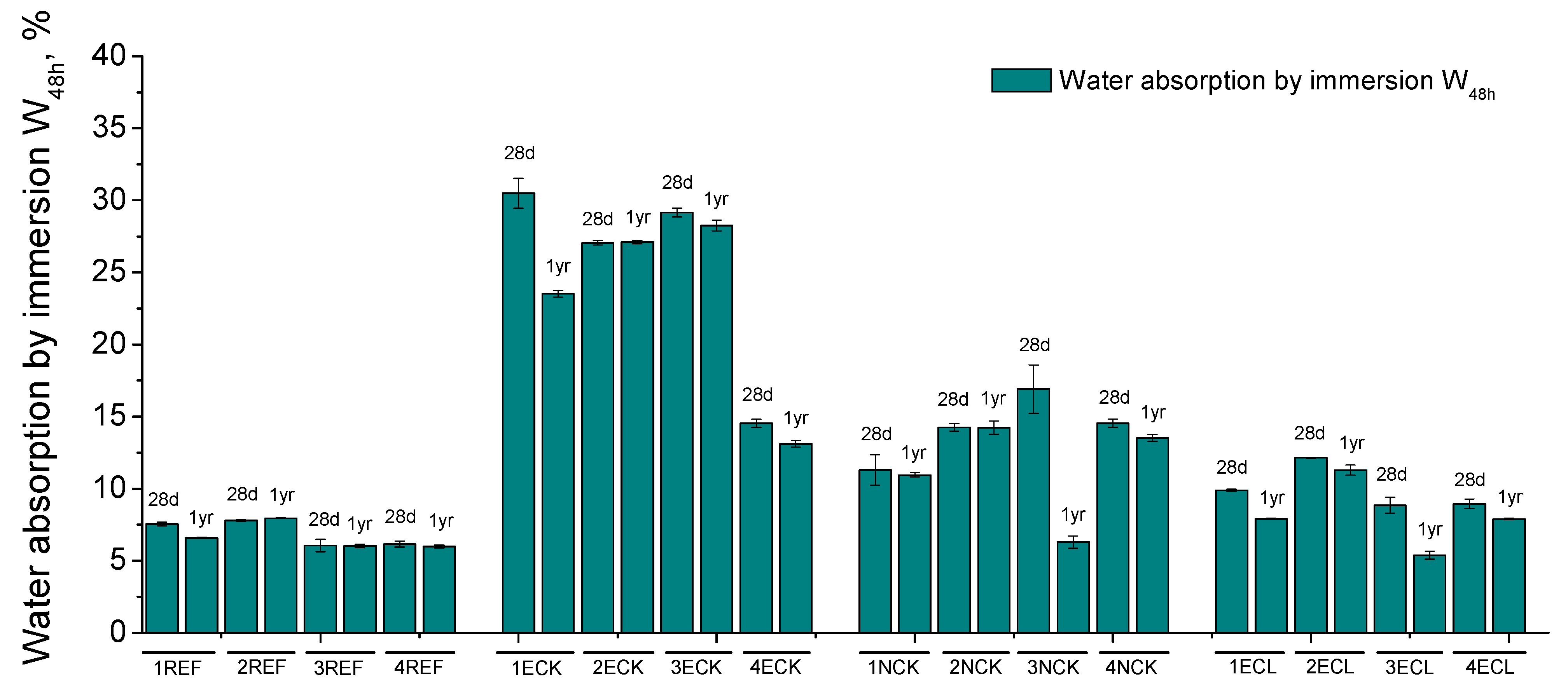

3.2. Absorption, Density and Volume of Permeable Pore Space

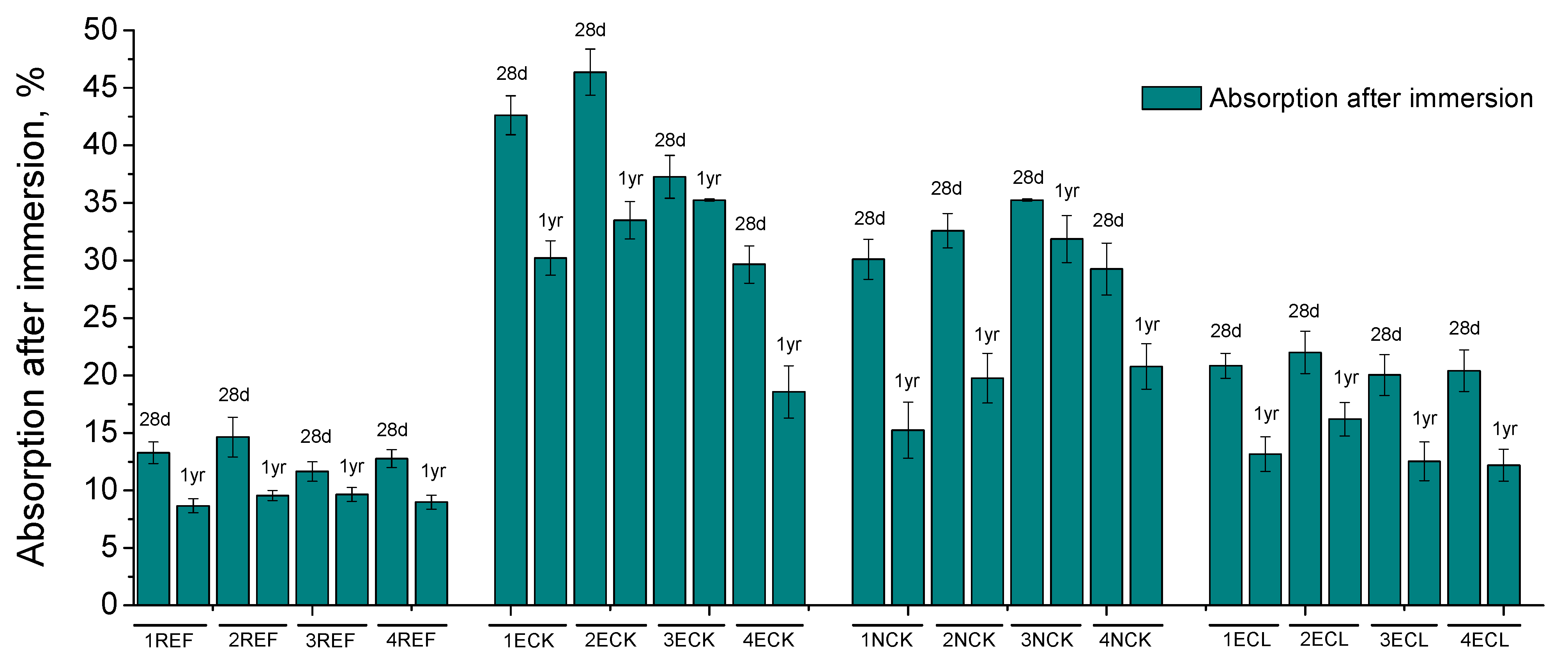

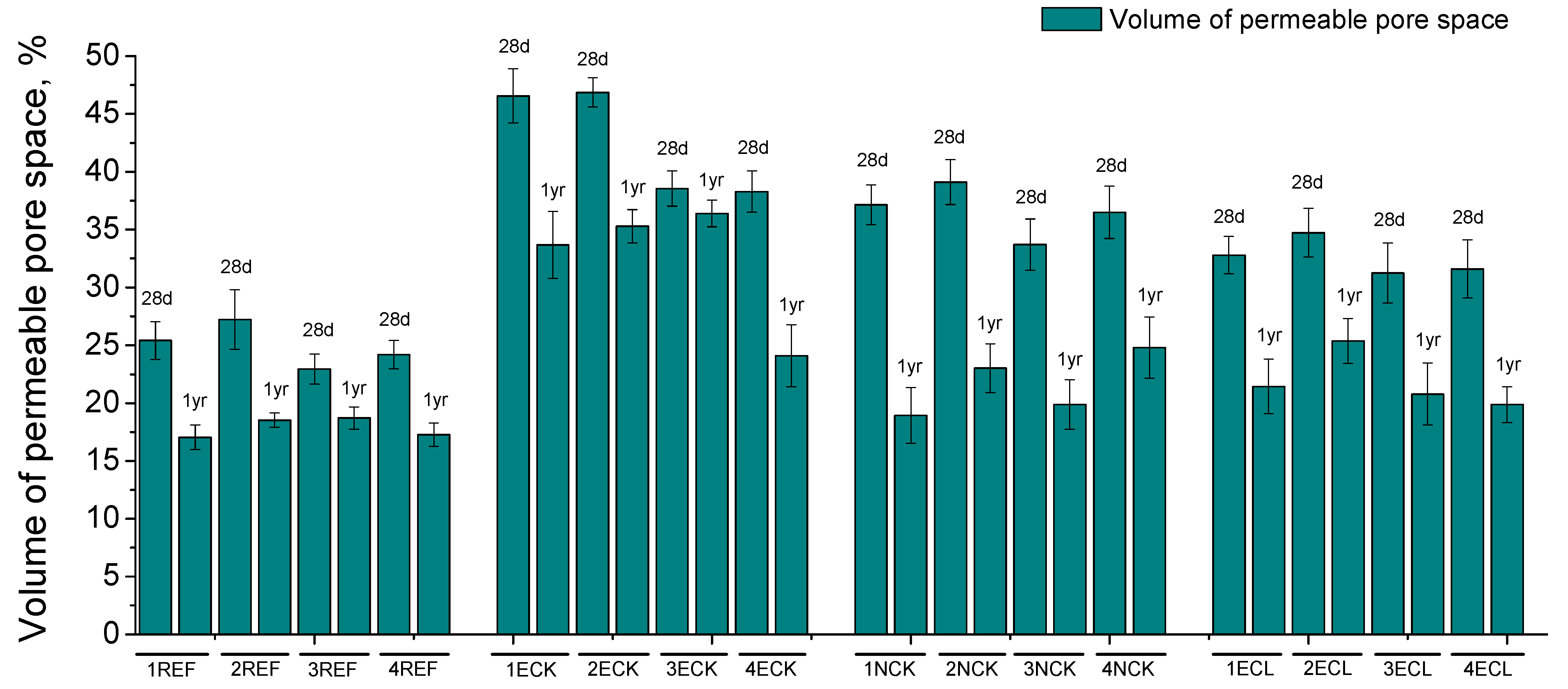

3.3. Water Absorption by Immersion after 48 H

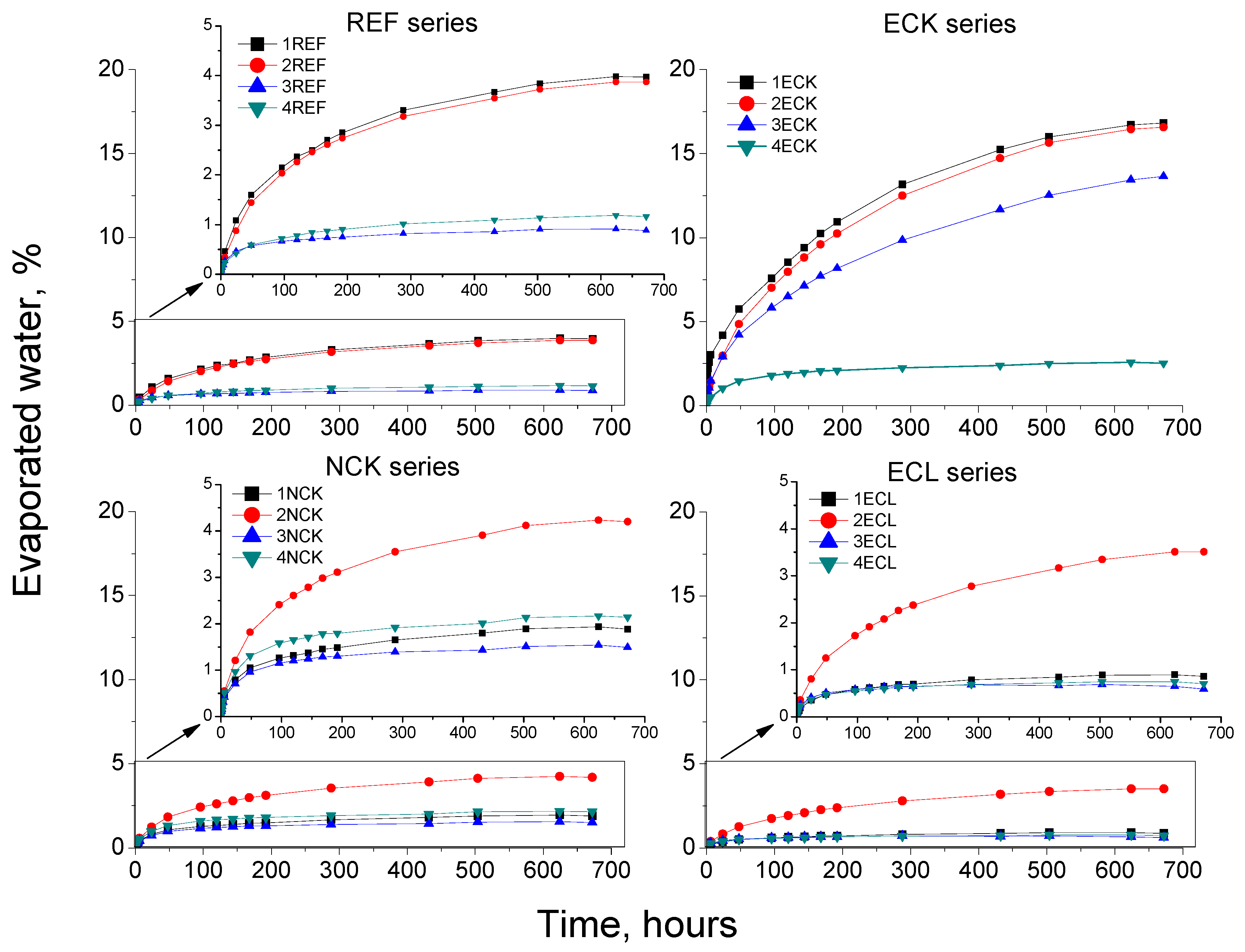

3.4. Drying Kinetics Assessment

4. Conclusions

- A decrease with time in the total volume of gel and capillary pores was observed for most of the mortar series studied, regardless of the aggregate used. This may be related to the progressive formation of solid phases as products of clinker and slag hydration and fly ash pozzolanic reactions.

- The abovementioned reduction in the proportion of gel and capillary pores had an influence on the water absorption and the volume of permeable pore space, which showed a decrease in the long term.

- For each of the lightweight aggregates studied, a good behavior has been generally observed in the mortars when an addition was incorporated to the binder, especially when slag or fly ash were used.

- Regarding the new non-standardized lightweight cork aggregates, mortars with natural cork showed lower water absorption and lower volume of permeable pore space in the long term than mortars with expanded cork. Therefore, in the context of this research, the use of lightweight natural cork aggregate would be more advisable than expanded cork in terms of protection against water ingress.

- At one year, natural cork mortars had an adequate behavior regarding the water absorption by immersion after 48 h and the volume of permeable pore space compared to mortars with expanded clay, which may be due to the high volume of small capillary pores (100 nm–1 µm) in natural cork mortars.

- The drying capacity and the internal water evaporation were higher for mortars with expanded cork. This could be related to their high volume of large capillary pores (1–10 µm), which would make the drying process of the material easier. Scarce differences in this property were observed between reference mortars and those with natural cork and expanded clay.

- In accordance with the results obtained in this work, the use of binders with additions did not produce a noticeably worsening or even improved performance related to water ingress of the mortars with the analyzed lightweight aggregates, in comparison with those with Portland cement without additions. These results would be relevant because the combination of new cork lightweight aggregates and blended cements would provide new solutions for eco-friendly cement-based materials, which could be used in specific applications, contributing to sustainability in several ways.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Benhelal, E.; Shamsaei, E.; Rashid, M.I. Challenges against CO2 abatement strategies in cement industry: A review. J. Environ. Sci. 2021, 104, 84–101. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.-Y.; Yu, B.; Chen, J.-M.; Wei, Y.-M. Green transition pathways for cement industry in China. Resour. Conserv. Recycl. 2021, 166, 105355. [Google Scholar] [CrossRef]

- Wan, J.; Han, T.; Li, K.; Shu, S.; Hu, X.; Gan, W.; Chen, Z. Effect of Phosphogypsum Based Filler on the Performance of Asphalt Mortar and Mixture. Materials 2023, 16, 2486. [Google Scholar] [CrossRef] [PubMed]

- Al-Bared, M.A.M.; Harahap, I.S.H.; Marto, A.; Mohamad, H.; Alavi Nezhad Khalil Abad, S.V.; Mustaffa, Z. Cyclic behavior of RT-cement treated marine clay subjected to low and high loading frequencies. Geomech. Eng. 2020, 21, 433–445. [Google Scholar] [CrossRef]

- Jusoh, S.N.; Mohamad, H.; Marto, A.; Yunus, N.Z.M.; Kasim, F. Segment’s joint in precast tunnel lining design. J. Teknol. 2015, 77, 91–98. [Google Scholar] [CrossRef] [Green Version]

- Křížová, K.; Bubeník, J.; Sedlmajer, M. Use of Lightweight Sintered Fly Ash Aggregates in Concrete at High Temperatures. Buildings 2022, 12, 2090. [Google Scholar] [CrossRef]

- Meglio, E.; Davino, A.; Formisano, A. Experimental Tests on Lightweight Cement Mortar and Concrete with Recycled Plastic Wastes. Buildings 2023, 13, 1181. [Google Scholar] [CrossRef]

- Rodríguez, G.; Medina, C.; Alegre, F.J.; Asensio, E.; Sánchez de Rojas, M.I. Assessment of Construction and DemolitionWaste plant management in Spain: In pursuit of sustainability and eco-efficiency. J. Clean. Prod. 2015, 90, 16–24. [Google Scholar] [CrossRef]

- Valipour, M.; Shekarchi, M.; Arezoumandi, M. Chlorine diffusion resistivity of sustainable green concrete in harsh marine environments. J. Clean. Prod. 2017, 142, 4092–4100. [Google Scholar] [CrossRef]

- Taghipoor, H.; Sadeghian, A. Experimental investigation of single and hybrid-fiber reinforced concrete under drop weight test. Structures 2022, 43, 1073–1083. [Google Scholar] [CrossRef]

- Sadeghian, A.; Moradi Shaghaghi, T.; Mohammadi, Y.; Taghipoor, H. Performance Assessment of Hybrid Fibre-Reinforced Concrete (FRC) under Low-Speed Impact: Experimental Analysis and Optimized Mixture. Shock Vib. 2023, 2023, 7110987. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Bijen, J. Benefits of slag and fly ash. Constr. Build. Mater. 1996, 10, 309–314. [Google Scholar] [CrossRef]

- Demirboğa, R. Thermal conductivity and compressive strength of concrete incorporation with mineral admixtures. Build. Environ. 2007, 42, 2467–2471. [Google Scholar] [CrossRef]

- Ponikiewski, T.; Gołaszewski, J. The effect of high-calcium fly ash on selected properties of self-compacting concrete. Arch. Civ. Mech. Eng. 2014, 14, 455–465. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Influence of environmental conditions on durability of slag cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010. [Google Scholar]

- Papadakis, V.G. Effect of fly ash on Portland cement systems. Cem. Concr. Res. 1999, 29, 1727–1736. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, C.; Sun, W. Fly ash effects. Cem. Concr. Res. 2004, 34, 2057–2060. [Google Scholar] [CrossRef]

- Glinicki, M.; Jóźwiak-Niedźwiedzka, D.; Gibas, K.; Dąbrowski, M. Influence of Blended Cements with Calcareous Fly Ash on Chloride Ion Migration and Carbonation Resistance of Concrete for Durable Structures. Materials 2016, 9, 18. [Google Scholar] [CrossRef] [Green Version]

- Letelier, V.; Ortega, M.; Tarela, E.; Muñoz, P.; Henríquez-Jara, B.I.; Moriconi, G. Mechanical Performance of Eco-Friendly Concretes with Volcanic Powder and Recycled Concrete Aggregates. Sustainability 2018, 10, 3036. [Google Scholar] [CrossRef] [Green Version]

- Wedding, P.; Manmohan, D.; Mehta, P. Influence of Pozzolanic, Slag, and Chemical Admixtures on Pore Size Distribution and Permeability of Hardened Cement Pastes. Cem. Concr. Aggreg. 1981, 3, 63. [Google Scholar] [CrossRef]

- Bouikni, A.; Swamy, R.N.; Bali, A. Durability properties of concrete containing 50% and 65% slag. Constr. Build. Mater. 2009, 23, 2836–2845. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Durability related transport properties of OPC and slag cement mortars hardened under different environmental conditions. Constr. Build. Mater. 2012, 27, 176–183. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M.; Kaladharan, G.; Ramanathan, S. Towards ternary binders involving limestone additions—A review. Cem. Concr. Res. 2021, 143, 106396. [Google Scholar] [CrossRef]

- Hadji, T.; Guettala, S.; Quéneudec, M. Mix design of high performance concrete with different mineral additions. World J. Eng. 2021, 18, 767–779. [Google Scholar] [CrossRef]

- Marchetti, G.; Irassar, E.F.; Rahhal, V.F. Effects of packing density and water film thickness on fresh and hardened properties of ternary cement pastes. Adv. Cem. Res. 2020, 32, 444–455. [Google Scholar] [CrossRef]

- Branco, F.G.; Godinho, L. On the use of lightweight mortars for the minimization of impact sound transmission. Constr. Build. Mater. 2013, 45, 184–191. [Google Scholar] [CrossRef]

- De Lurdes Belgas Da Costa, M.; Branco, F.G. Cork concrete mechanical behavior under high temperatures. Int. J. Hous. Sci. Its Appl. 2013, 37, 207–215. [Google Scholar]

- Souza, N.S.L.D.; Anjos, M.A.S.D.; Sá, M.D.V.V.A.D.; Farias, E.C.D.; Souza, M.M.D.; Branco, F.G.; Pereira, A. Evaluation of sugarcane bagasse ash for lightweight aggregates production. Constr. Build. Mater. 2021, 271, 121604. [Google Scholar] [CrossRef]

- Branco, F.G.; Tadeu, A.; Belgas, M. de L. Can cork be used as a concrete aggregate? Int. J. Hous. Sci. Its Appl. 2007, 31, 1–11. [Google Scholar]

- de Oliveira, V.C.; Godinho, J.P.; Grings, K.J.O.; de Oliveira, R.A.; dos Santos, E.G.F. Performance as for watertightness f rendering mortars using admixtures. J. Build. Pathol. Rehabil. 2021, 6, 2. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V. Water vapour sorption experiments on hardened cementitious materials. Cem. Concr. Res. 2007, 37, 414–437. [Google Scholar] [CrossRef]

- Ren, F.; Zhou, C.; Zeng, Q.; Zhang, Z.; Angst, U.; Wang, W. Quantifying the anomalous water absorption behavior of cement mortar in view of its physical sensitivity to water. Cem. Concr. Res. 2021, 143, 106395. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, X.; Wang, Z.; Yang, Z. Water sensitivity of cement-based materials. J. Am. Ceram. Soc. 2021, 104, 4279–4296. [Google Scholar] [CrossRef]

- Angelin, A.F.; Lintz, R.C.C.; Gachet-Barbosa, L.A.; Osório, W.R. The effects of porosity on mechanical behavior and water absorption of an environmentally friendly cement mortar with recycled rubber. Constr. Build. Mater. 2017, 151, 534–545. [Google Scholar] [CrossRef]

- Brazão Farinha, C.; de Brito, J.; Veiga, R. Influence of forest biomass bottom ashes on the fresh, water and mechanical behaviour of cement-based mortars. Resour. Conserv. Recycl. 2019, 149, 750–759. [Google Scholar] [CrossRef]

- EN 197-1:2011; Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: Brussels, Belgium, 2011; p. 30.

- EN 196-1:2016; Methods of Testing Cement-Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016; p. 33.

- Diamond, S. Mercury porosimetry. Cem. Concr. Res. 2000, 30, 1517–1525. [Google Scholar] [CrossRef]

- Ouellet, S.; Bussière, B.; Aubertin, M.; Benzaazoua, M. Microstructural evolution of cemented paste backfill: Mercury intrusion porosimetry test results. Cem. Concr. Res. 2007, 37, 1654–1665. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Ho, L.S.; Nakarai, K.; Duc, M.; Kouby, A.L.; Maachi, A.; Sasaki, T. Analysis of strength development in cement-treated soils under different curing conditions through microstructural and chemical investigations. Constr. Build. Mater. 2018, 166, 634–646. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Raksachon, Y. Role of fly ash on strength and microstructure development in blended cement stabilized silty clay. Soils Found. 2009, 49, 85–98. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.; Ye, G. The pore structure of cement paste blended with fly ash. Constr. Build. Mater. 2013, 45, 30–35. [Google Scholar] [CrossRef]

- Nakarai, K.; Ishida, T.; Kishi, T.; Maekawa, K. Enhanced thermo dynamic analysis coupled with temperature-dependent microstructures of cement hydrates. Cem. Concr. Res. 2007, 37, 139–150. [Google Scholar] [CrossRef]

- ASTM. ASTM C642—06 Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2006; p. 3. [Google Scholar]

- Laboratorio Nacional de Engenharia Civil Especificações LNEC E 394. Betões–Determinação da Absorção de Água Por Imersão; LNEC: Lisboa, Portugal, 1993. [Google Scholar]

- Branco, F.G.; Belgas, M.L.; Mendes, C.; Pereira, L.; Ortega, J.M. Characterization of fresh and durability properties of different lime mortars for being used as masonry coatings in the restoration of ancient constructions. Sustainability 2021, 13, 4909. [Google Scholar] [CrossRef]

- Pavão, J.M. Estudo da Influência da Dosagem de Ligante no Desempenho de Rebocos Para Edifícios Antigos. Master’s Thesis, Universidade Técnica de Lisboa, Lisboa, Portugal, 2010. [Google Scholar]

- Gomes, F.A.C.M. Argamassas Pré-Doseadas Para Rebocos de Edificios Antigos. Master’s Thesis, Universidade Técnica de Lisboa, Lisboa, Portugal, 2009. [Google Scholar]

- Adhikary, S.K.; Rudžionis, Ž.; Tučkutė, S. Characterization of novel lightweight self-compacting cement composites with incorporated expanded glass, aerogel, zeolite and fly ash. Case Stud. Constr. Mater. 2022, 16, e00879. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions in the microstructure development of OPC and slag cement mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

- Duan, P.; Shui, Z.; Chen, W.; Shen, C. Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete. Constr. Build. Mater. 2013, 44, 1–6. [Google Scholar] [CrossRef]

- Çakır, Ö.; Aköz, F. Effect of curing conditions on the mortars with and without GGBFS. Constr. Build. Mater. 2008, 22, 308–314. [Google Scholar] [CrossRef]

- Ibáñez-Gosálvez, J.; Real-Herraiz, T.; Ortega, J.M. Microstructure, durability and mechanical properties of mortars prepared using ternary binders with addition of slag, fly ash and limestone. Appl. Sci. 2021, 11, 6388. [Google Scholar] [CrossRef]

- Mounanga, P.; Khokhar, M.I.A.; El Hachem, R.; Loukili, A. Improvement of the early-age reactivity of fly ash and blast furnace slag cementitious systems using limestone filler. Mater. Struct. Constr. 2011, 44, 437–453. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions on th microstructure development of sustainable fly ash cement mortars. Materials 2017, 10, 1130. [Google Scholar] [CrossRef] [Green Version]

- Fernandez, A.; Alonso, M.C.; García-Calvo, J.L.; Lothenbach, B. Influence of the synergy between mineral additions and Portland cement in the physical-mechanical properties of ternary binders. Mater. Constr. 2016, 66, e097. [Google Scholar] [CrossRef] [Green Version]

- Meddah, M.S.; Lmbachiya, M.C.; Dhir, R.K. Potential use of binary and composite limestone cements in concrete production. Constr. Build. Mater. 2014, 58, 193–205. [Google Scholar] [CrossRef]

- Xue, S.; Zhang, P.; Wang, J.; Bao, J.; Han, S.; He, L. Influences of thermal damage on water transport in heat-treated cement mortar: Experimental and theoretical analyses. Constr. Build. Mater. 2021, 288, 123100. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Tayeh, B.A.; Yusuf, M.O. Strength and transport characteristics of volcanic pumice powder basedhigh strength concrete. Constr. Build. Mater. 2019, 216, 314–324. [Google Scholar] [CrossRef]

| Designation | Binder (EN 197-1 [37]) | Description (Percentages in Weight) |

|---|---|---|

| 1 | CEM I 42.5 R | Commercial cement consisting of ≥95% clinker and ≤5% minority components |

| 2 | CEM II/B-L 32.5 N | Commercial cement with 65–79% clinker, 21–35% limestone and ≤5% minority components |

| 3 | CEM III/B 32.5 N/SR | Commercial cement consisting of 70% blast furnace slag, 25% clinker and 5% minority components |

| 4 | Equivalent to CEM II/A-V | Binder prepared with 20% fly ash and 80% cement CEM I 42.5 R |

| Designation | Binder | Aggregate (Percentage in Volume) | |||

|---|---|---|---|---|---|

| Sand | Expanded Cork | Natural Cork | Expanded Clay | ||

| 1REF | CEM I 42.5 R | 100% | - | - | - |

| 2REF | CEM II/B-L 32.5 N | 100% | - | - | - |

| 3REF | CEM III/B 32.5 N/SR | 100% | - | - | - |

| 4REF | Equiv. to CEM II/A-V | 100% | - | - | - |

| 1ECK | CEM I 42.5 R | 50% | 50% | - | - |

| 2ECK | CEM II/B-L 32.5 N | 50% | 50% | - | - |

| 3ECK | CEM III/B 32.5 N/SR | 50% | 50% | - | - |

| 4ECK | Equiv. to CEM II/A-V | 50% | 50% | - | - |

| 1NCK | CEM I 42.5 R | 50% | - | 50% | - |

| 2NCK | CEM II/B-L 32.5 N | 50% | - | 50% | - |

| 3NCK | CEM III/B 32.5 N/SR | 50% | - | 50% | - |

| 4NCK | Equiv. to CEM II/A-V | 50% | - | 50% | - |

| 1ECL | CEM I 42.5 R | 50% | - | - | 50% |

| 2ECL | CEM II/B-L 32.5 N | 50% | - | - | 50% |

| 3ECL | CEM III/B 32.5 N/SR | 50% | - | - | 50% |

| 4ECL | Equiv. to CEM II/A-V | 50% | - | - | 50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega, J.M.; Branco, F.G.; Pereira, L. Long-Term Behavior Related to Water Ingress in Mortars Which Combine Expanded and Natural Cork Lightweight Aggregates and Eco-Friendly Cements. Buildings 2023, 13, 1651. https://doi.org/10.3390/buildings13071651

Ortega JM, Branco FG, Pereira L. Long-Term Behavior Related to Water Ingress in Mortars Which Combine Expanded and Natural Cork Lightweight Aggregates and Eco-Friendly Cements. Buildings. 2023; 13(7):1651. https://doi.org/10.3390/buildings13071651

Chicago/Turabian StyleOrtega, José Marcos, Fernando G. Branco, and Luís Pereira. 2023. "Long-Term Behavior Related to Water Ingress in Mortars Which Combine Expanded and Natural Cork Lightweight Aggregates and Eco-Friendly Cements" Buildings 13, no. 7: 1651. https://doi.org/10.3390/buildings13071651