Resilient Capabilities to Tackle Supply Chain Risks: Managing Integration Complexities in Construction Projects

Abstract

:1. Introduction

- What complexities are involved in integrating critical risks related to SC management and RCs?

- How to enable a resilient SC in the construction industry?

- To identify the risks associated with the construction SC in developing countries.

- To identify the RCs necessary for construction SC, tailoring risks associated with SC management.

- To establish the interconnectivity and functionality amongst the identified factors in SC management through ST.

- To assess the complexity and evaluate the integrated effect of SC risks and RCs for a resilient SC through the SD approach.

2. Literature Review

2.1. Construction Supply Chain Risks

2.2. Supply Chain Resilient Capabilities of Construction Organizations

2.3. Construction Complexity and System Dynamics

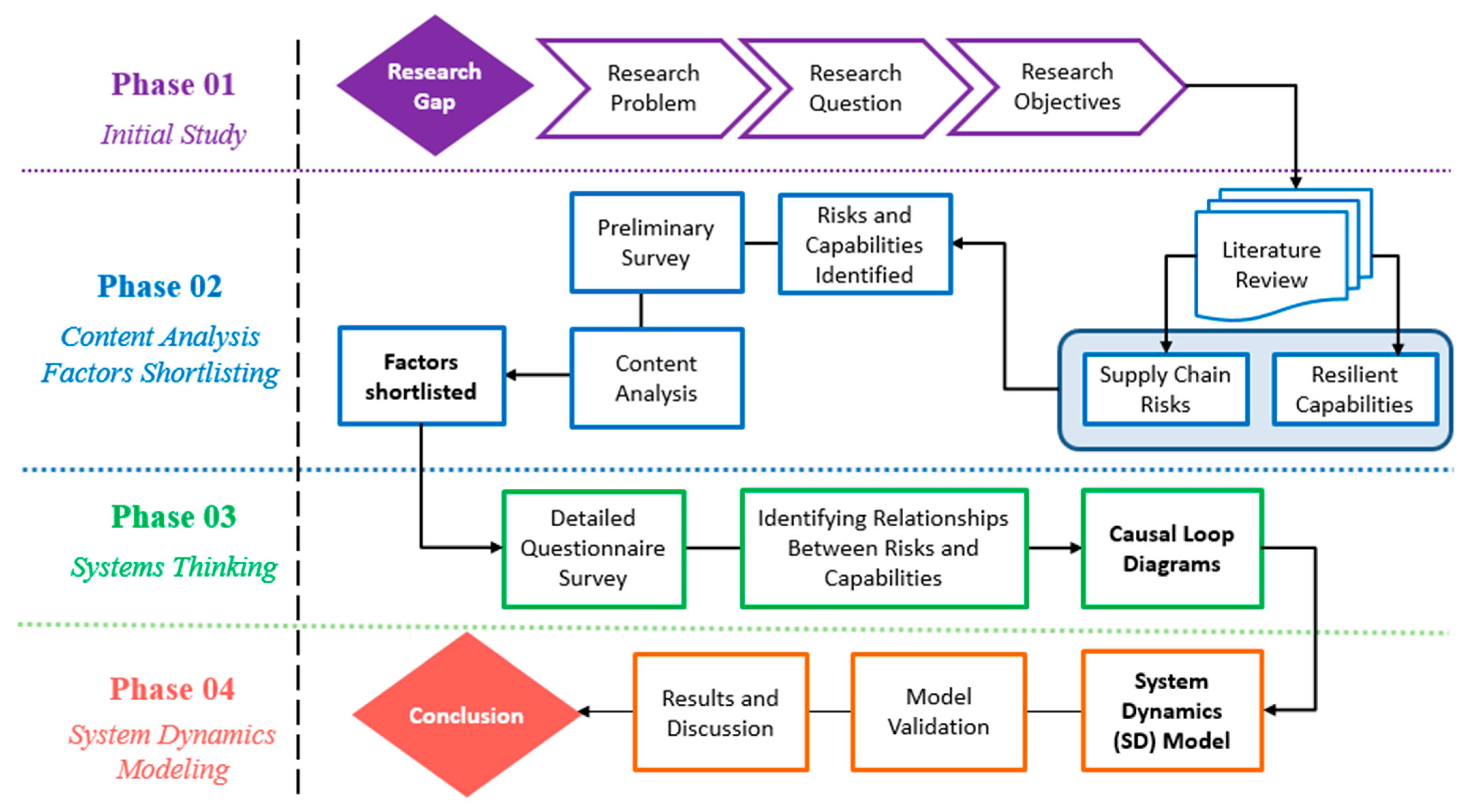

3. Research Methodology

3.1. Initial Study

3.2. Literature Review and Content Analysis

3.3. Data Analysis

- A = maximum weight assigned on the scale (i.e., 3 in this research),

- N = total number of respondents (i.e., 60 in this research).

3.4. Demographic Details of the Survey Respondents

3.5. System Dynamics Model Development and Validation

4. Results and Analyses

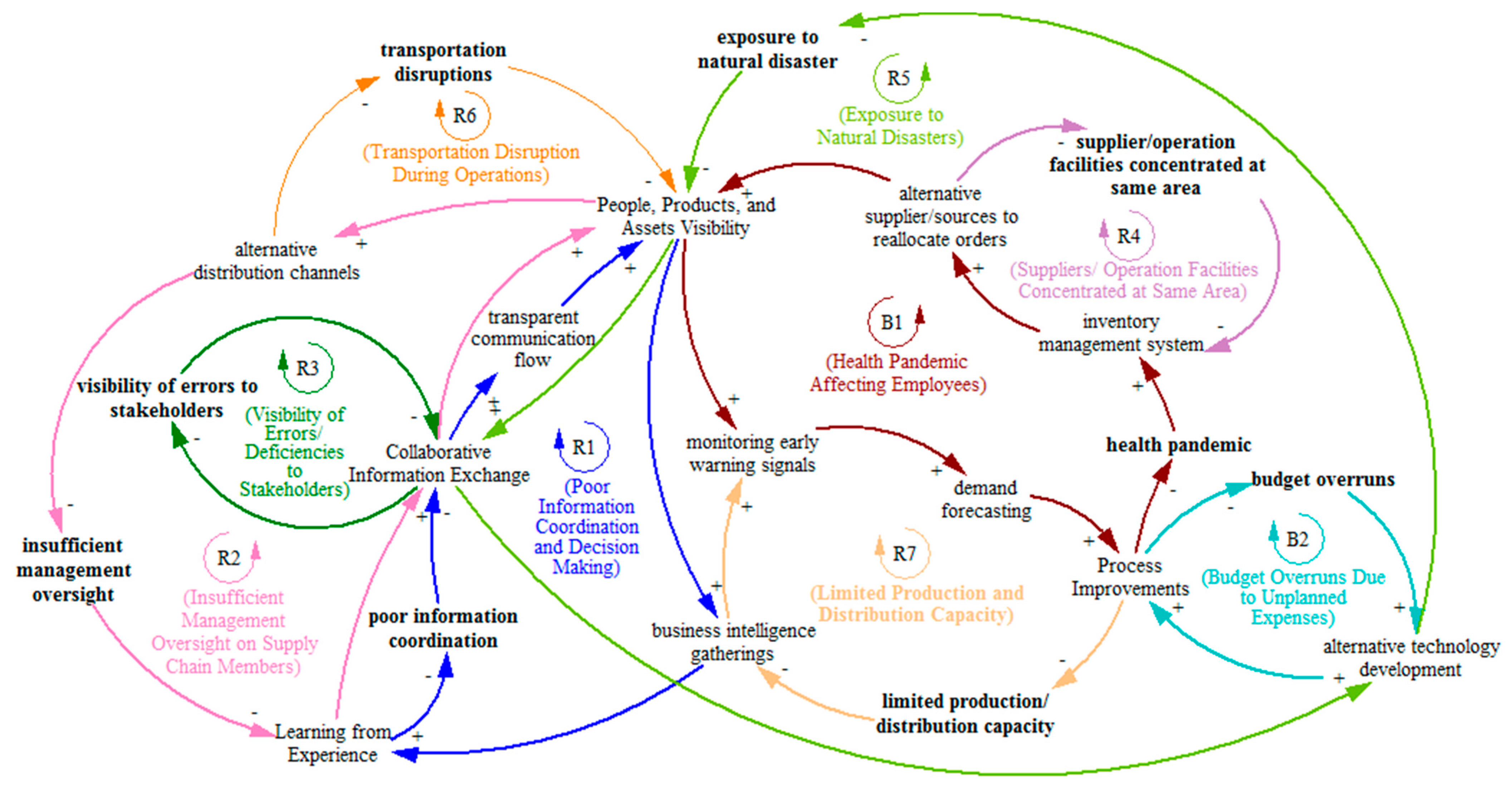

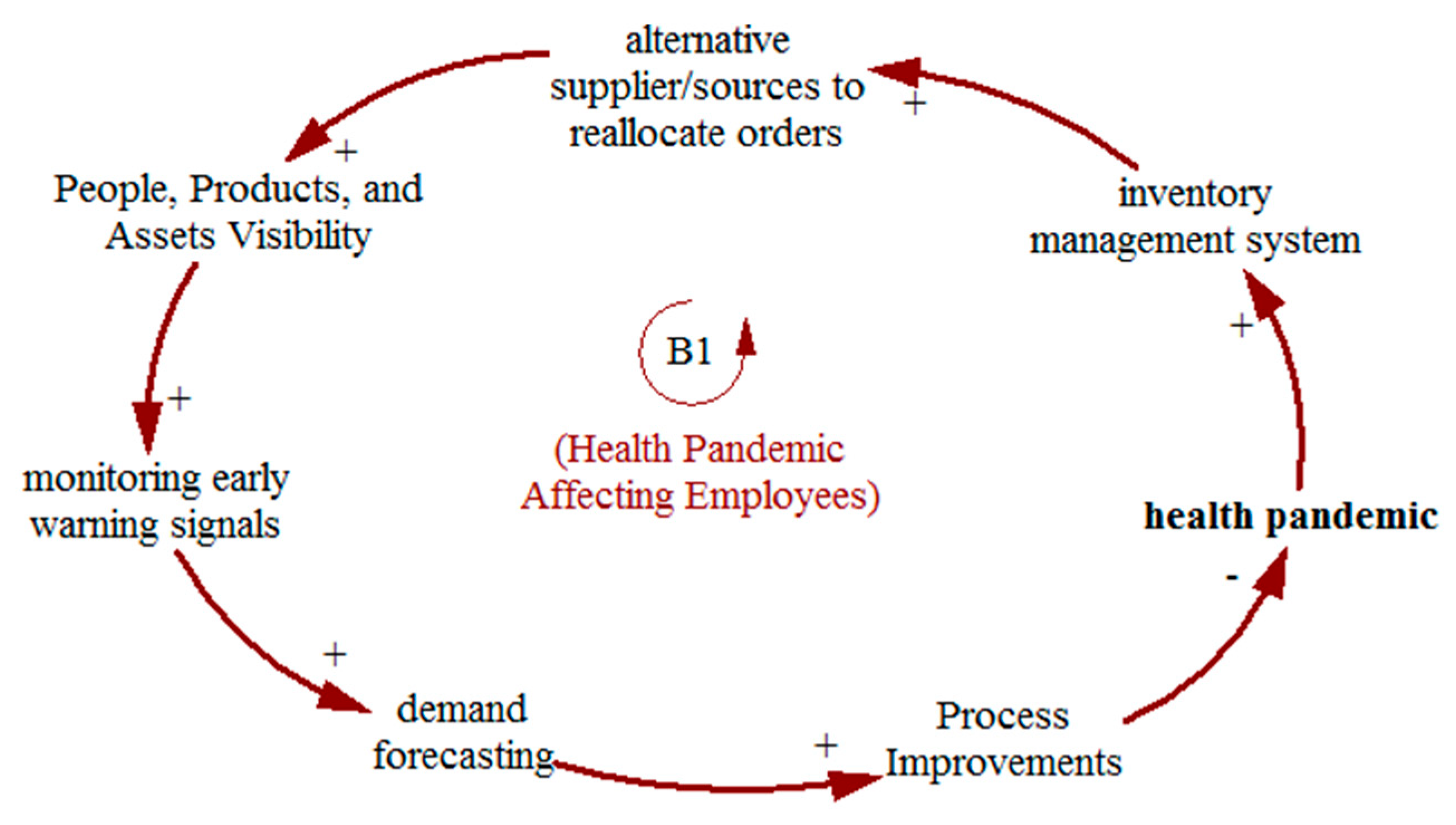

4.1. Balancing Loop B1 (Health Pandemic Affecting Employees)

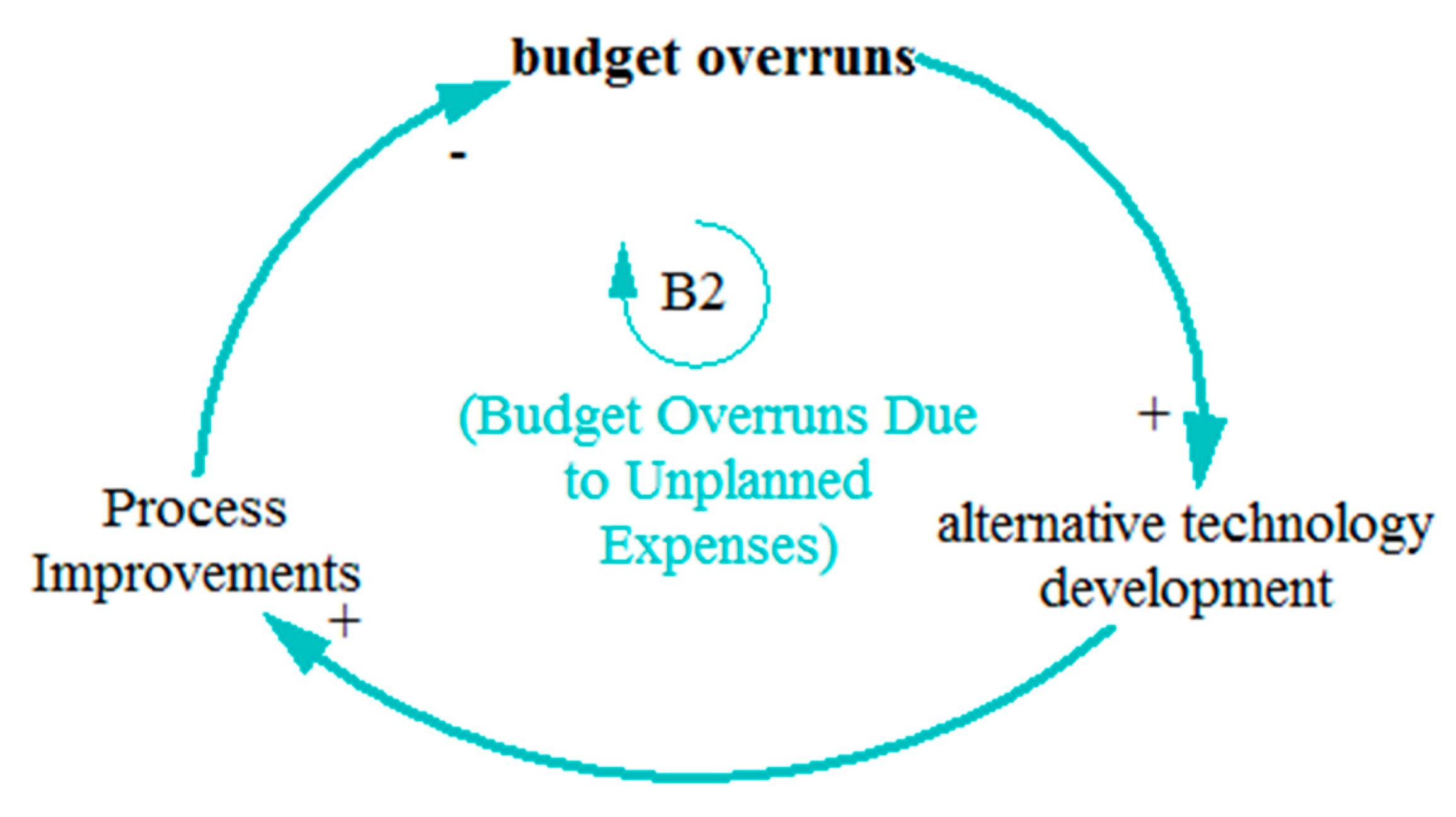

4.2. Balancing Loop B2 (Budget Overruns Due to Unplanned Expenses)

4.3. Reinforcing Loop R1 (Poor Information Coordination and Decision Making)

4.4. Reinforcing Loop R2 (Insufficient Management Oversight on Supply Chain Members)

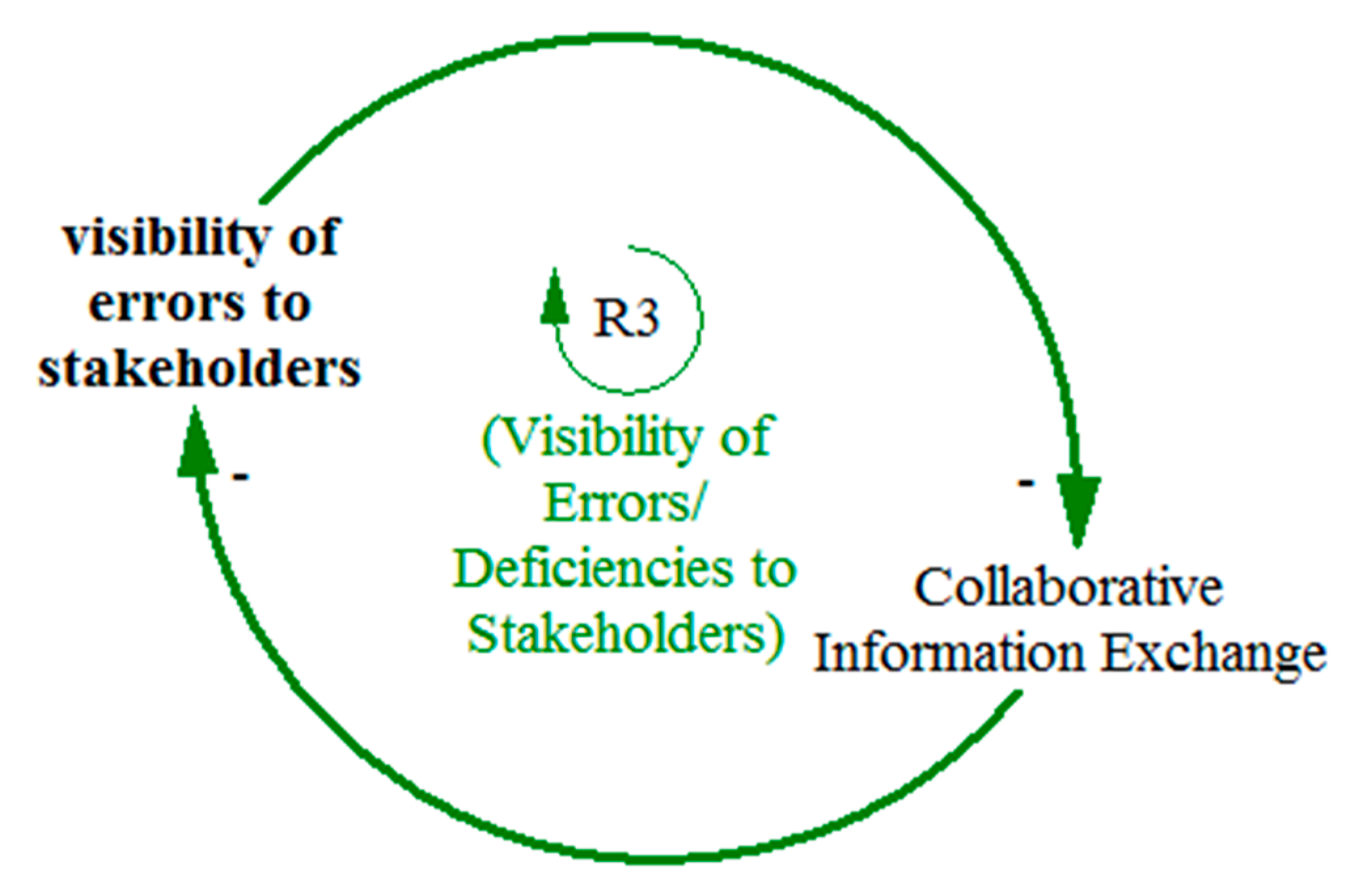

4.5. Reinforcing Loop R3 (Visibility of Errors/Deficiencies to Stakeholders)

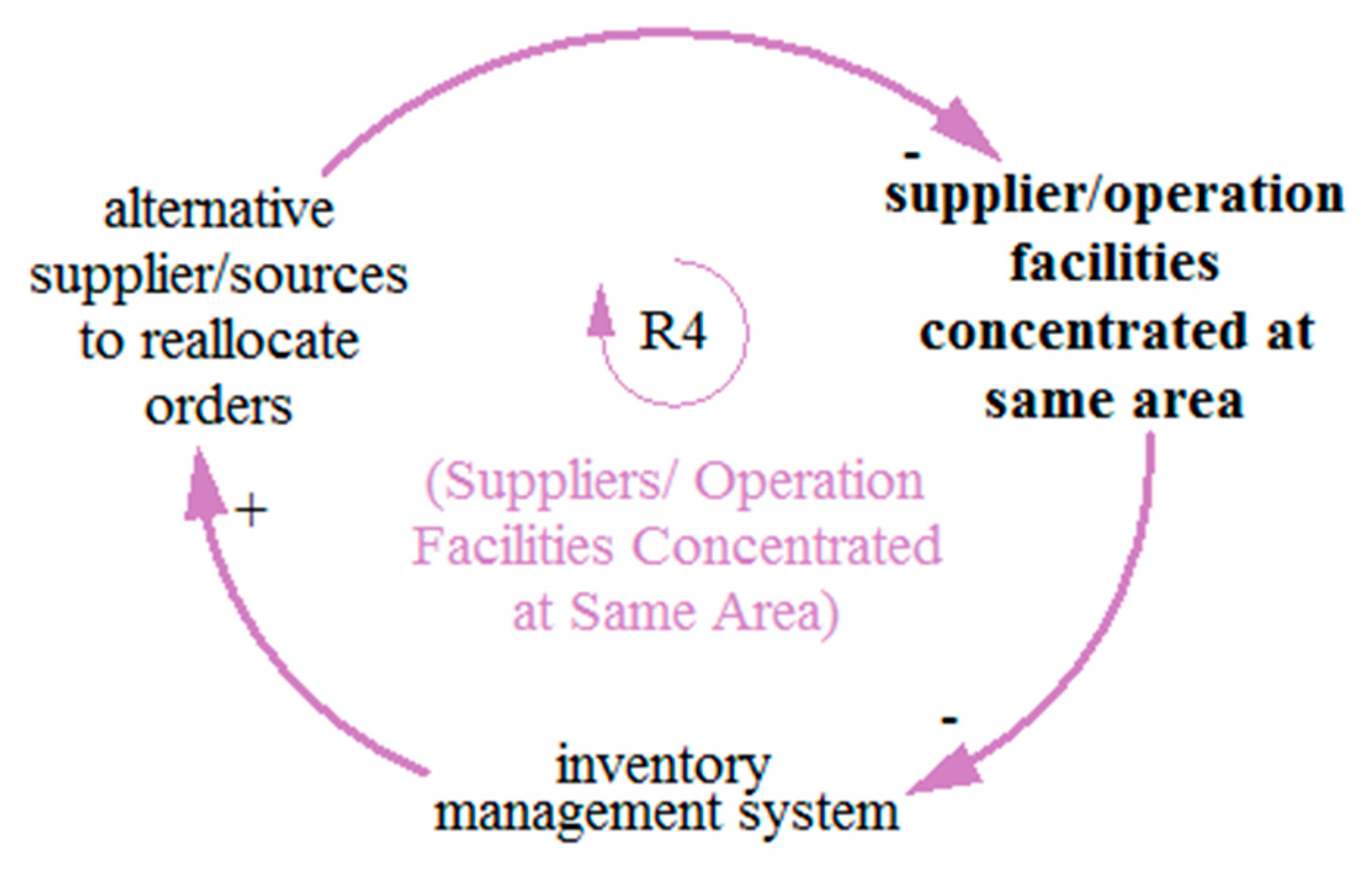

4.6. Reinforcing Loop R4 (Suppliers/Operation Facilities Concentrated at Same Area)

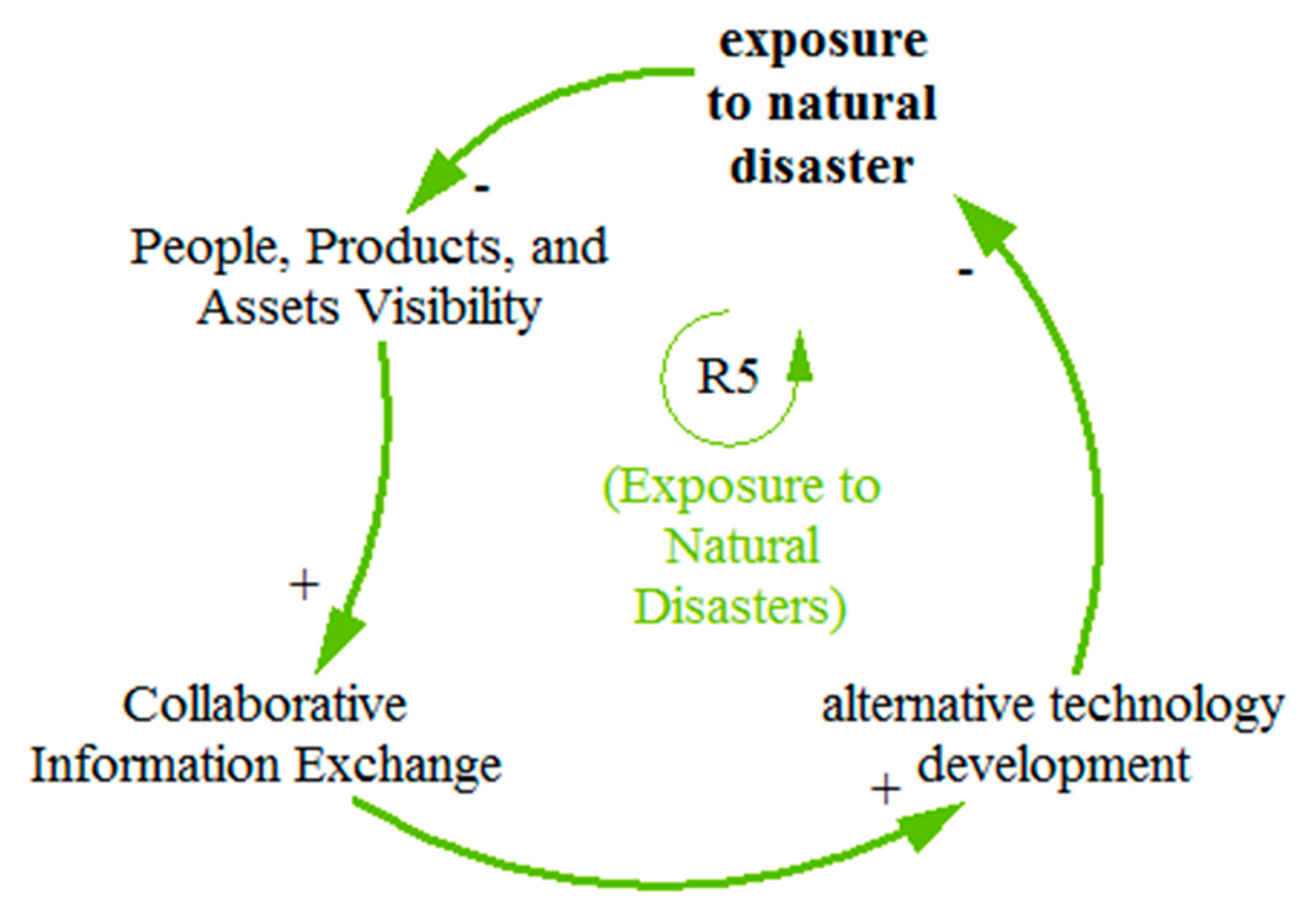

4.7. Reinforcing Loop R5 (Exposure to Natural Disasters)

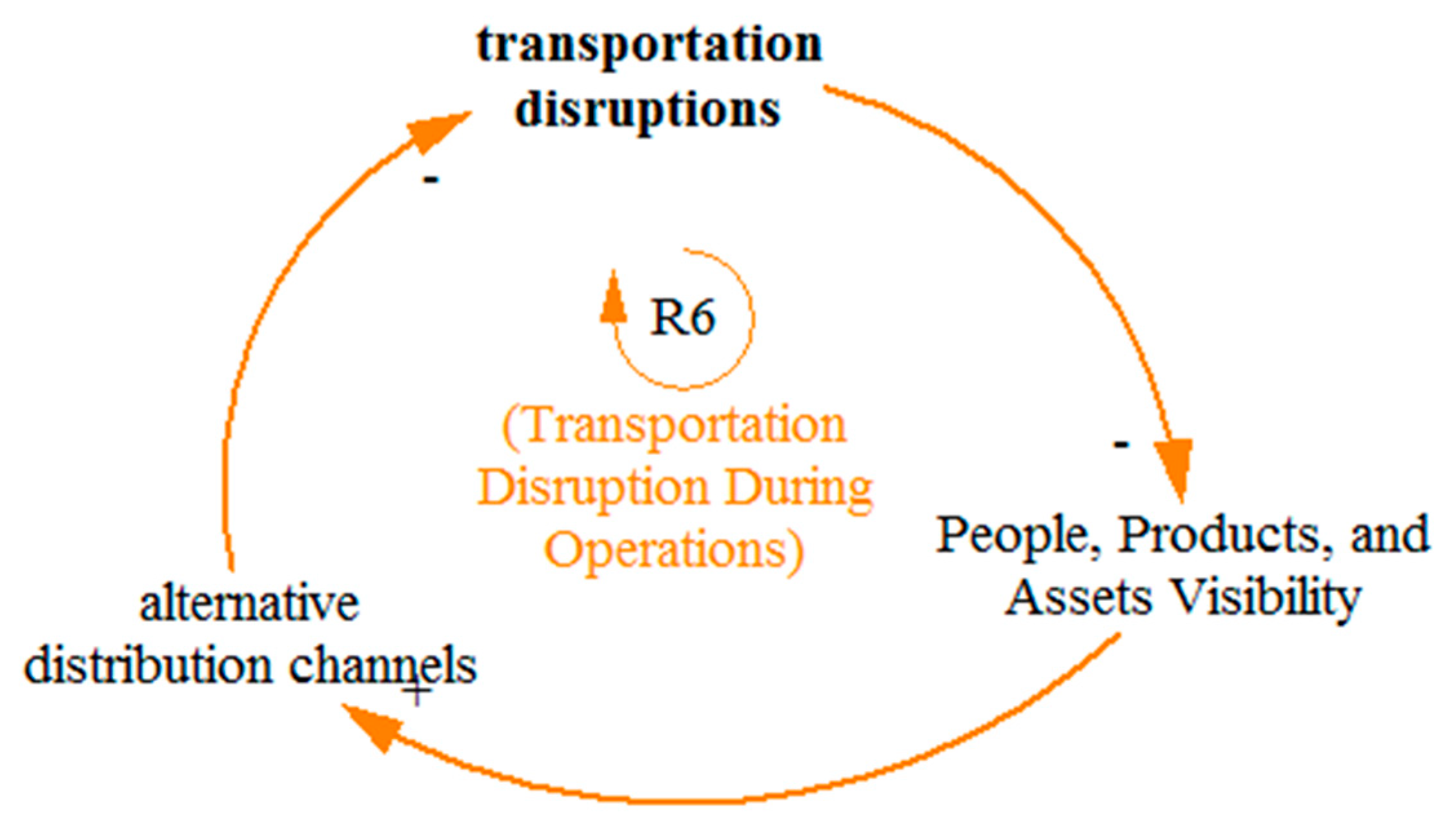

4.8. Reinforcing Loop R6 (Transportation Disruption during Operations)

4.9. Reinforcing Loop R7 (Limited Production and Distribution Capacity)

4.10. System Dynamics Modeling and Simulations

5. Discussion and Implications

6. Conclusions

- Set up an effective communication system with suppliers to improve trust.

- A risk management team can integrate suppliers with other parties and inform them about expected risks during the project. In addition, previous project reviews, particularly the risks, can assist the existing project with preventive and corrective actions.

- A relevant problem-solving strategy should be exercised to set apart the problem and its source and seek workable solutions.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abidin, N.A.Z.; Ingirige, B. The dynamics of vulnerabilities and capabilities in improving resilience within Malaysian construction supply chain. Constr. Innov. 2018, 18, 412–432. [Google Scholar] [CrossRef]

- Kosansky, A.; Taus, M. Managing for Catastrophes: Building a Resilient Supply Chain. Supply Chain Manag. Rev. 2014. Available online: https://www.scmr.com/article/managing_for_catastrophes_building_a_resilient_supply_chain (accessed on 25 August 2022).

- Ofori, G. New Perspectives on Construction in Developing Countries; Routledge: London, UK, 2012. [Google Scholar]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Abdul-Rahman, H.; Rahim, F.A.M.; Mohd, M.S. A study on quality management during the pre-construction stage of design-and-build projects. In Proceedings of the CME 25 Conference Construction Management and Economics—‘Past, Present and Future’, Reading, UK, 16–18 July 2007; p. 753. [Google Scholar]

- Swedberg, R. The structure of confidence and the collapse of Lehman Brothers. In Markets on Trial: The Economic Sociology of the US Financial Crisis: Part A; Emerald Group Publishing Limited: Bradford, UK, 2010. [Google Scholar]

- Wildgoose, N. Avoiding the Pitfalls of Supply Chain Disruptions; Zurich: Zurich, Switzerland, 2011. [Google Scholar]

- Le-Hoai, L.; Lee, Y.D.; Lee, J.Y. Delay and Cost Overruns in Vietnam Large Construction Projects: A Comparison with Other Selected Countries. KSCE J. Civ. Eng. 2008, 12, 367–377. [Google Scholar] [CrossRef]

- Mehdi Riazi, S.; Skitmore, M.; Cheung, F. The use of supply chain management to reduce delays: Malaysian public sector construction projects. In Proceedings of the 6th Nordic Conference on Construction Economics and Organisation—Shaping the Construction/Society Nexus, Volume 2: Transforming Practices; Widen, K., Klakegg, O.J., Lindahl, G.A., Gottlieb, S.C., Kahkonen, K.E., Haugbolle, K., Eds.; Danish Building Research Institute, Aalborg University: Aalborg, Denmark, 2011; pp. 403–414. [Google Scholar]

- Maqsoom, A.; Zahoor, I.; Ashraf, H.; Ullah, F.; Alsulami, B.T.; Salman, A.; Alqurashi, M. Nexus between Leader–Member Exchange, Paternalistic Leadership, and Creative Behavior in the Construction Industry. Sustainability 2022, 14, 7211. [Google Scholar] [CrossRef]

- Loosemore, M.; Teo, M.M.M. Crisis preparedness of construction companies. J. Manag. Eng. 2000, 16, 60–65. [Google Scholar] [CrossRef]

- Ghufran, M.; Khan, K.I.A.; Ullah, F.; Nasir, A.R.; Al Alahmadi, A.A.; Alzaed, A.N.; Alwetaishi, M. Circular Economy in the Construction Industry: A Step towards Sustainable Development. Buildings 2022, 12, 1004. [Google Scholar] [CrossRef]

- Abas, M.; Khattak, S.B.; Habib, T.; Nadir, U. Assessment of critical risk and success factors in construction supply chain: A case of Pakistan. Int. J. Constr. Manag. 2020, 1–9. [Google Scholar] [CrossRef]

- Jüttner, U.; Peck, H.; Christopher, M. Supply chain risk management: Outlining an agenda for future research. Int. J. Logist. Res. Appl. 2003, 6, 197–210. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring Supply Chain Resilience: Development of a Conceptual Framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Olsson, N.O. Management of flexibility in projects. Int. J. Proj. Manag. 2006, 24, 66–74. [Google Scholar] [CrossRef]

- Pettit, T.J. Supply Chain Resilience: Development of a Conceptual Framework, an Assessment Tool and an Implementation Process; Ohio State University: Columbus, OH, USA, 2008. [Google Scholar]

- Maqsoom, A.; Khan, M.U.; Khan, M.T.; Khan, S.; Ullah, F. Factors influencing the construction time and cost overrun in projects: Empirical evidence from Pakistani construction industry. In Proceedings of the 21st International Symposium on Advancement of Construction Management and Real Estate; Springer: Singapore, 2018; pp. 769–778. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Chan, A.P.C. Factors attracting private sector investments in public-private partnerships in developing countries A survey of international experts. J. Financial Manag. Prop. Constr. 2017, 22, 92–111. [Google Scholar] [CrossRef]

- Mandal, S. An empirical investigation into supply chain resilience. IUP J. Supply Chain. Manag. 2012, 9, 46. [Google Scholar]

- McManus, S.T. Organisational Resilience in New Zealand. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2008. [Google Scholar]

- Zsidisin, G.A.; Wagner, S.M. Do Perceptions Become Reality? The Moderating Role of Supply Chain Resiliency on Disruption Occurrence. J. Bus. Logist. 2010, 31, 1–20. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. Ensuring Supply Chain Resilience: Development and Implementation of an Assessment Tool. J. Bus. Logist. 2013, 34, 46–76. [Google Scholar] [CrossRef]

- Ullah, F.; Thaheem, M.J. Concession period of public private partnership projects: Industry–academia gap analysis. Int. J. Constr. Manag. 2018, 18, 418–429. [Google Scholar] [CrossRef]

- Siang, L.C.; Ali, A.S. Implementation of risk management in the Malaysian construction industry. J. Surv. Constr. Prop. 2012, 3, 1–15. [Google Scholar] [CrossRef]

- Goh, C.S.; Abdul-Rahman, H.; Samad, Z.A. Applying Risk Management Workshop for a Public Construction Project: Case Study. J. Constr. Eng. Manag. 2013, 139, 572–580. [Google Scholar] [CrossRef]

- Camerer, C.F.; Kunreuther, H. Decision processes for low probability events: Policy implications. J. Policy Anal. Manag. 1989, 8, 565–592. [Google Scholar] [CrossRef]

- IEC 31010:2019; Risk Management—Risk Assessment Techniques. ISO (International Organization for Standardization): Geneva, Switzerland, 2019.

- Wedawatta, G.; Ingirige, B. A conceptual framework for understanding resilience of construction SMEs to extreme weather events. Built Environ. Proj. Asset Manag. 2016, 6, 428–443. [Google Scholar] [CrossRef]

- Juttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. Int. J. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Kinman, B. Building a risk-resilient organisation. Resil. Win. Risk 2012, 1. Available online: https://www.pwc.com/gx/en/services/advisory/consulting/risk/resilience/publications/building-a-risk-resilient-organisation.html (accessed on 25 August 2022).

- Stephenson, A.V. Benchmarking the Resilience of Organisations. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2010. [Google Scholar]

- Ullah, F.; Sepasgozar, S.M.; Shirowzhan, S.; Davis, S. Modelling users’ perception of the online real estate platforms in a digitally disruptive environment: An integrated KANO-SISQual approach. Telemat. Inform. 2021, 63, 101660. [Google Scholar] [CrossRef]

- Sterman, J.D. Business Dynamics: Systems Thinking and Modeling for a Complex World; McGraw-Hill, Inc.: New York, NY, USA, 2000; 982p. [Google Scholar]

- Li, C.Y.; Ren, J.; Wang, H.Y. A system dynamics simulation model of chemical supply chain transportation risk management systems. Comput. Chem. Eng. 2016, 89, 71–83. [Google Scholar] [CrossRef]

- Peng, M.; Peng, Y.; Chen, H. Post-seismic supply chain risk management: A system dynamics disruption analysis approach for inventory and logistics planning. Comput. Oper. Res. 2014, 42, 14–24. [Google Scholar] [CrossRef]

- Keilhacker, M.L.; Minner, S. Supply chain risk management for critical commodities: A system dynamics model for the case of the rare earth elements. Resour. Conserv. Recycl. 2017, 125, 349–362. [Google Scholar] [CrossRef]

- Oliveira, J.B.; Jin, M.; Lima, R.S.; Kobza, J.E.; Montevechi, J.A.B. The role of simulation and optimization methods in supply chain risk management: Performance and review standpoints. Simul. Model. Pract. Theory 2019, 92, 17–44. [Google Scholar] [CrossRef]

- Sheffi, Y.; Rice, J.B., Jr. A supply chain view of the resilient enterprise. MIT Sloan Manag. Rev. 2005, 47, 41. [Google Scholar]

- Berg, E.; Knudsen, D.; Norrman, A. Assessing performance of supply chain risk management programmes: A tentative approach. Int. J. Risk Assess. Manag. 2008, 9, 288–310. [Google Scholar] [CrossRef]

- Alkhaleel, B.A.; Liao, H.; Sullivan, K.M. Risk and resilience-based optimal post-disruption restoration for critical infrastructures under uncertainty. Eur. J. Oper. Res. 2022, 296, 174–202. [Google Scholar] [CrossRef]

- Svensson, G. A conceptual framework for the analysis of vulnerability in supply chains. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 731–750. [Google Scholar] [CrossRef]

- Kleindorfer, P.R.; Saad, G.H. Managing disruption risks in supply chains. Prod. Oper. Manag. 2009, 14, 53–68. [Google Scholar] [CrossRef]

- Hendricks, K.B.; Singhal, V.R.; Zhang, R. The effect of operational slack, diversification, and vertical relatedness on the stock market reaction to supply chain disruptions. J. Oper. Manag. 2009, 27, 233–246. [Google Scholar] [CrossRef]

- Craighead, C.W.; Blackhurst, J.; Rungtusanatham, M.J.; Handfield, R.B. The severity of supply chain disruptions: Design characteristics and mitigation capabilities. Decis. Sci. 2007, 38, 131–156. [Google Scholar] [CrossRef]

- Fiksel, J.; Polyviou, M.; Croxton, K.L.; Pettit, T.J. From Risk to Resilience: Learning to Deal with Disruption. MIT Sloan Manag. Rev. 2015, 56, 79–86. [Google Scholar]

- Wagner, S.M.; Neshat, N. Assessing the vulnerability of supply chains using graph theory. Int. J. Prod. Econ. 2010, 126, 121–129. [Google Scholar] [CrossRef]

- Benton, W.; McHenry, L.F. Construction Purchasing & Supply Chain Management; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

- Blos, M.F.; Quaddus, M.; Wee, H.; Watanabe, K. Supply chain risk management (SCRM): A case study on the automotive and electronic industries in Brazil. Supply Chain Manag. Int. J. 2009, 14, 247–252. [Google Scholar] [CrossRef]

- Perez-Franco, R.; Singh, M.; Sheffi, Y. Expressing a Firm’s Supply Chain Strategy: A Framework and a Method. Manuscr. Draft. Mass. Inst. Technol. 2010. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.399.3040&rep=rep1&type=pdf (accessed on 25 August 2022).

- Chowdhury, M.; Hossan, M.; Dewan, M.N.A.; Quaddus, M. Supply chain resilience to mitigate disruptions: A QFD approach. In Proceedings of the 16th Pacific Asia Conference on Information Systems, Ho Chi Minh City, Vietnam, 11–15 July 2012. [Google Scholar]

- Einarsson, S.; Rausand, M. An approach to vulnerability analysis of complex industrial systems. Risk Anal. 1998, 18, 535–546. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the resilient supply chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Badea, A.; Prostean, G.; Goncalves, G.; Allaoui, H. Assessing risk factors in collaborative supply chain with the analytic hierarchy process (AHP). Procedia-Soc. Behav. Sci. 2014, 124, 114–123. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Darko, A.; Olanipekun, A.O.; Ameyaw, E.E. Critical barriers to green building technologies adoption in developing countries: The case of Ghana. J. Clean. Prod. 2018, 172, 1067–1079. [Google Scholar] [CrossRef]

- Peck, H. Drivers of supply chain vulnerability: An integrated framework. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 210–232. [Google Scholar] [CrossRef]

- Meng, X. The effect of relationship management on project performance in construction. Int. J. Proj. Manag. 2012, 30, 188–198. [Google Scholar] [CrossRef]

- Ryciuk, U. Identification of factors related to trust formation in construction supply chains. Procedia Eng. 2017, 182, 627–634. [Google Scholar] [CrossRef]

- Luo, W.; Shi, Y.; Venkatesh, V. Exploring the factors of achieving supply chain excellence: A New Zealand perspective. Prod. Plan. Control. 2018, 29, 655–667. [Google Scholar] [CrossRef]

- Rasul, N.; Malik, M.S.A.; Bakhtawar, B.; Thaheem, M.J. Risk assessment of fast-track projects: A systems-based approach. Int. J. Constr. Manag. 2021, 21, 1099–1114. [Google Scholar] [CrossRef]

- Bertelsen, S. Complexity–Construction in a New Perspective; IGLC-11: Blacksburg, VA, USA, 2003; Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.509.5436&rep=rep1&type=pdf (accessed on 25 August 2022).

- Forrester, J.W. System dynamics: The foundation under systems thinking. Sloan Sch. Management. Mass. Inst. Technol. 1999, 10, 1–3. Available online: http://static.clexchange.org/ftp/documents/system-dynamics/SD2011-01SDFoundationunderST.pdf (accessed on 28 August 2022).

- Sterman, J.D. System dynamics modeling: Tools for learning in a complex world. Calif. Manag. Rev. 2001, 43, 8–25. [Google Scholar] [CrossRef]

- Feng, Y. System dynamics modeling for supply chain information sharing. Phys. Procedia 2012, 25, 1463–1469. [Google Scholar] [CrossRef]

- Khan, K.I.A.; Flanagan, R.; Lu, S.-L. Managing information complexity using system dynamics on construction projects. Constr. Manag. Econ. 2016, 34, 192–204. [Google Scholar] [CrossRef]

- Lee, S.; Peña-Mora, F.; Park, M. Web-enabled system dynamics model for error and change management on concurrent design and construction projects. J. Comput. Civ. Eng. 2006, 20, 290–300. [Google Scholar] [CrossRef]

- Naveed, F.; Khan, K.I.A. Investigating the influence of information complexity on construction quality: A systems thinking approach. Eng. Constr. Archit. Manag. 2021, 29, 1427–1448. [Google Scholar] [CrossRef]

- Ghufran, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R.; Ullah, F. Adoption of Sustainable Supply Chain Management for Performance Improvement in the Construction Industry: A System Dynamics Approach. Architecture 2021, 1, 161–182. [Google Scholar] [CrossRef]

- Amin, F.; Khan, K.I.A.; Ullah, F.; Alqurashi, M.; Alsulami, B.T. Key Adoption Factors for Collaborative Technologies and Barriers to Information Management in Construction Supply Chains: A System Dynamics Approach. Buildings 2022, 12, 766. [Google Scholar] [CrossRef]

- Hsieh, H.-F.; Shannon, S.E. Three approaches to qualitative content analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef] [PubMed]

- Ullah, F.; Ayub, B.; Siddiqui, S.Q.; Thaheem, M.J. A review of public-private partnership: Critical factors of concession period. J. Financial Manag. Prop. Constr. 2016, 21, 269–300. [Google Scholar] [CrossRef]

- Jahan, S.; Khan, K.I.A.; Thaheem, M.J.; Ullah, F.; Alqurashi, M.; Alsulami, B.T. Modeling Profitability-Influencing Risk Factors for Construction Projects: A System Dynamics Approach. Buildings 2022, 12, 701. [Google Scholar] [CrossRef]

- Ahmad, Z. BIM Driven Project Risk Management: A Causal Evolution. Master’s Thesis, National University of Science and Technology, Islamabad, Pakistan, 2017. [Google Scholar]

- Watkins, M.W. A Step-by-Step Guide to Exploratory Factor Analysis with SPSS; Routledge: London, UK, 2021. [Google Scholar]

- Wang, J.; Yu, B.; Tam, V.W.; Li, J.; Xu, X. Critical factors affecting willingness of design units towards construction waste minimization: An empirical study in Shenzhen, China. J. Clean. Prod. 2019, 221, 526–535. [Google Scholar] [CrossRef]

- Hossen, M.M.; Kang, S.; Kim, J. Construction schedule delay risk assessment by using combined AHP-RII methodology for an international NPP project. Nucl. Eng. Technol. 2015, 47, 362–379. [Google Scholar] [CrossRef]

- Muneeswaran, G.; Manoharan, P.; Awoyera, P.; Adesina, A. A statistical approach to assess the schedule delays and risks in Indian construction industry. Int. J. Constr. Manag. 2020, 20, 450–461. [Google Scholar] [CrossRef]

- Rooshdi, R.R.R.M.; Abd Majid, M.Z.; Sahamir, S.R.; Ismail, N.A.A. Relative importance index of sustainable design and construction activities criteria for green highway. Chem. Eng. Trans. 2018, 63, 151–156. [Google Scholar]

- Qudrat-Ullah, H.; Seong, B.S. How to do structural validity of a system dynamics type simulation model: The case of an energy policy model. Energy Policy 2010, 38, 2216–2224. [Google Scholar] [CrossRef]

| RAT80/20 | RAT70/30 | RAT60/40 | RAT50/50 | RAT40/60 | RAT30/70 | RAT20/80 | ||

|---|---|---|---|---|---|---|---|---|

| Correlation | RAT80/20 | 1.000 | 0.970 | 0.925 | 0.886 | 0.855 | 0.830 | 0.810 |

| RAT70/30 | 0.970 | 1.000 | 0.989 | 0.972 | 0.955 | 0.940 | 0.928 | |

| RAT60/40 | 0.925 | 0.989 | 1.000 | 0.996 | 0.988 | 0.980 | 0.972 | |

| RAT50/50 | 0.886 | 0.972 | 0.996 | 1.000 | 0.998 | 0.994 | 0.990 | |

| RAT40/60 | 0.855 | 0.955 | 0.988 | 0.998 | 1.000 | 0.999 | 0.997 | |

| RAT30/70 | 0.830 | 0.940 | 0.980 | 0.994 | 0.999 | 1.000 | 0.999 | |

| RAT20/80 | 0.810 | 0.928 | 0.972 | 0.990 | 0.997 | 0.999 | 1.000 | |

| Sr# | Risk Factors Affecting Construction SCs | Respondent’s Normalized Score | Literature’s Normalized Score | 60/40 | Cumulative Score |

|---|---|---|---|---|---|

| 0.6*RS + 0.4*LS | |||||

| 1 | Health pandemic affecting employees | 0.03472 | 0.03827 | 0.036285143 | 0.036285143 |

| 2 | Budget overruns/unplanned expenses | 0.02778 | 0.04783 | 0.03591587 | 0.072201013 |

| 3 | Poor information coordination and decision making | 0.02778 | 0.04783 | 0.03591587 | 0.108116883 |

| 4 | Insufficient management oversight (on SC members) | 0.02778 | 0.04783 | 0.03591587 | 0.144032753 |

| 5 | Visibility of errors to stakeholders | 0.02778 | 0.04783 | 0.03591587 | 0.179948623 |

| 6 | Outsourcing to different suppliers | 0.02778 | 0.04145 | 0.033364849 | 0.213313472 |

| 7 | Decentralization of suppliers/operation facilities | 0.02778 | 0.04145 | 0.033364849 | 0.246678322 |

| 8 | Severe price fluctuations in the market | 0.03472 | 0.02870 | 0.032458613 | 0.279136934 |

| 9 | Exposure to natural disasters | 0.02778 | 0.03827 | 0.032089339 | 0.311226274 |

| 10 | Pressure from public opinion | 0.02778 | 0.03827 | 0.032089339 | 0.343315613 |

| 11 | Poor utilities (electrical power, water, sewer) availability | 0.02778 | 0.03827 | 0.032089339 | 0.375404952 |

| 12 | Products quality problems | 0.02778 | 0.03827 | 0.032089339 | 0.407494291 |

| 13 | Transportation disruption during operations | 0.02778 | 0.03827 | 0.032089339 | 0.439583631 |

| 14 | Limited production and distribution capacity | 0.02778 | 0.03827 | 0.032089339 | 0.47167297 |

| 15 | Exposure to political disruptions | 0.02778 | 0.03508 | 0.030813829 | 0.502486799 |

| Sr# | Resilient Capabilities | Respondent’s Normalized Score | Literature’s Normalized Score | 60/40 | Cumulative Score |

|---|---|---|---|---|---|

| 0.6*RS + 0.4*LS | |||||

| 1 | People, products, and assets visibility (real-time data on location) | 0.02273 | 0.05064 | 0.033892227 | 0.033892227 |

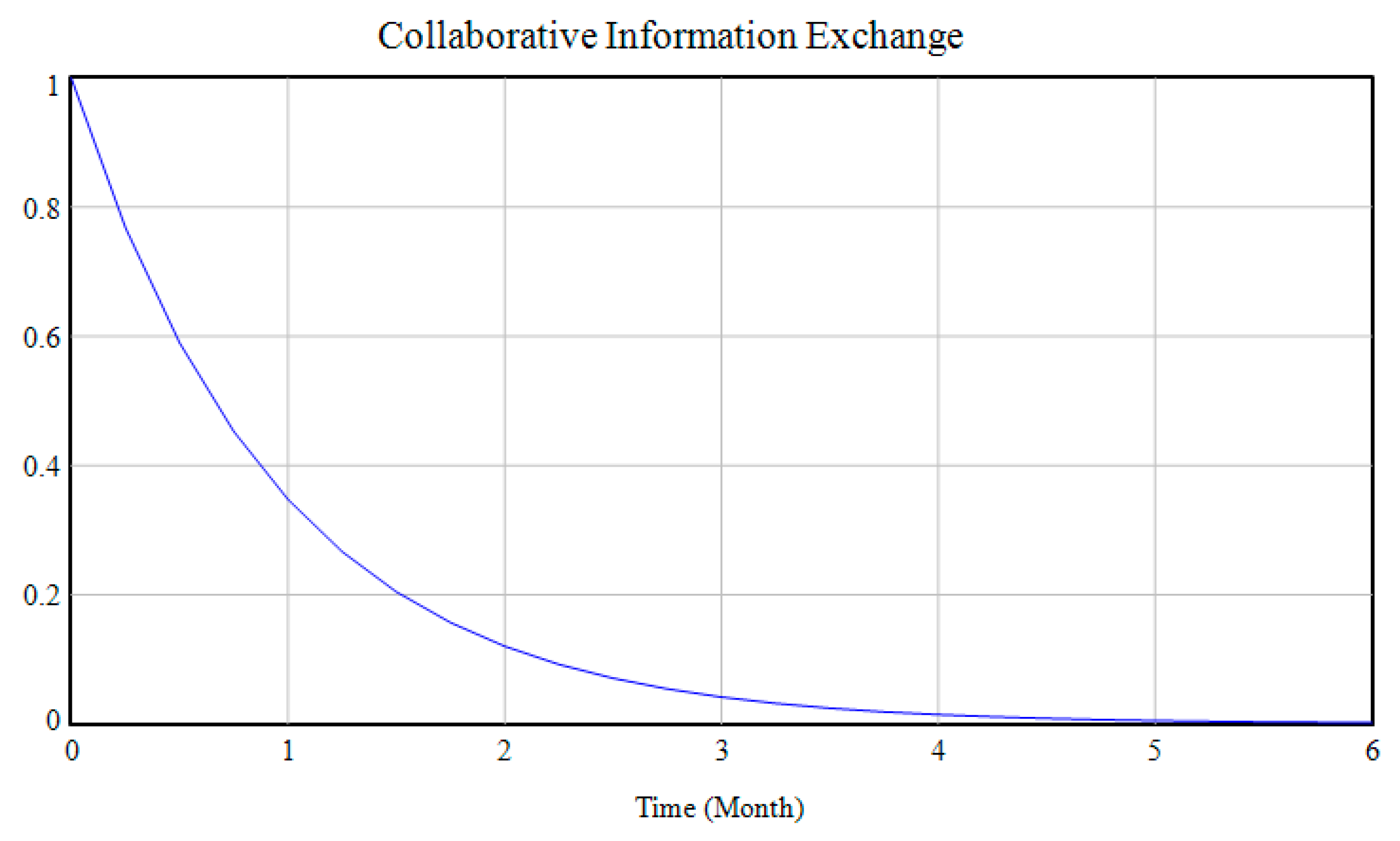

| 2 | Collaborative information exchange among stakeholders | 0.02273 | 0.05064 | 0.033892227 | 0.067784454 |

| 3 | Business intelligence gatherings (modern trends and technology awareness) | 0.02273 | 0.05064 | 0.033892227 | 0.101676682 |

| 4 | Alternative suppliers/sources to quickly reallocate orders | 0.02273 | 0.04531 | 0.031760031 | 0.133436713 |

| 5 | Inventory management system (fast rerouting of requirements) | 0.02273 | 0.04531 | 0.031760031 | 0.165196744 |

| 6 | Alternate distribution channels (modes of transportation) | 0.02273 | 0.04531 | 0.031760031 | 0.196956775 |

| 7 | Product commonality (flexible design) | 0.02273 | 0.04531 | 0.031760031 | 0.228716806 |

| 8 | Mode of communication (external, internal) | 0.02273 | 0.04531 | 0.031760031 | 0.260476837 |

| 9 | Order postponement willingly by clients due to disruption | 0.02273 | 0.04531 | 0.031760031 | 0.292236868 |

| 10 | Risk management/business continuity planning | 0.02273 | 0.04531 | 0.031760031 | 0.323996899 |

| 11 | Alternative technology development | 0.02273 | 0.03998 | 0.029627835 | 0.353624733 |

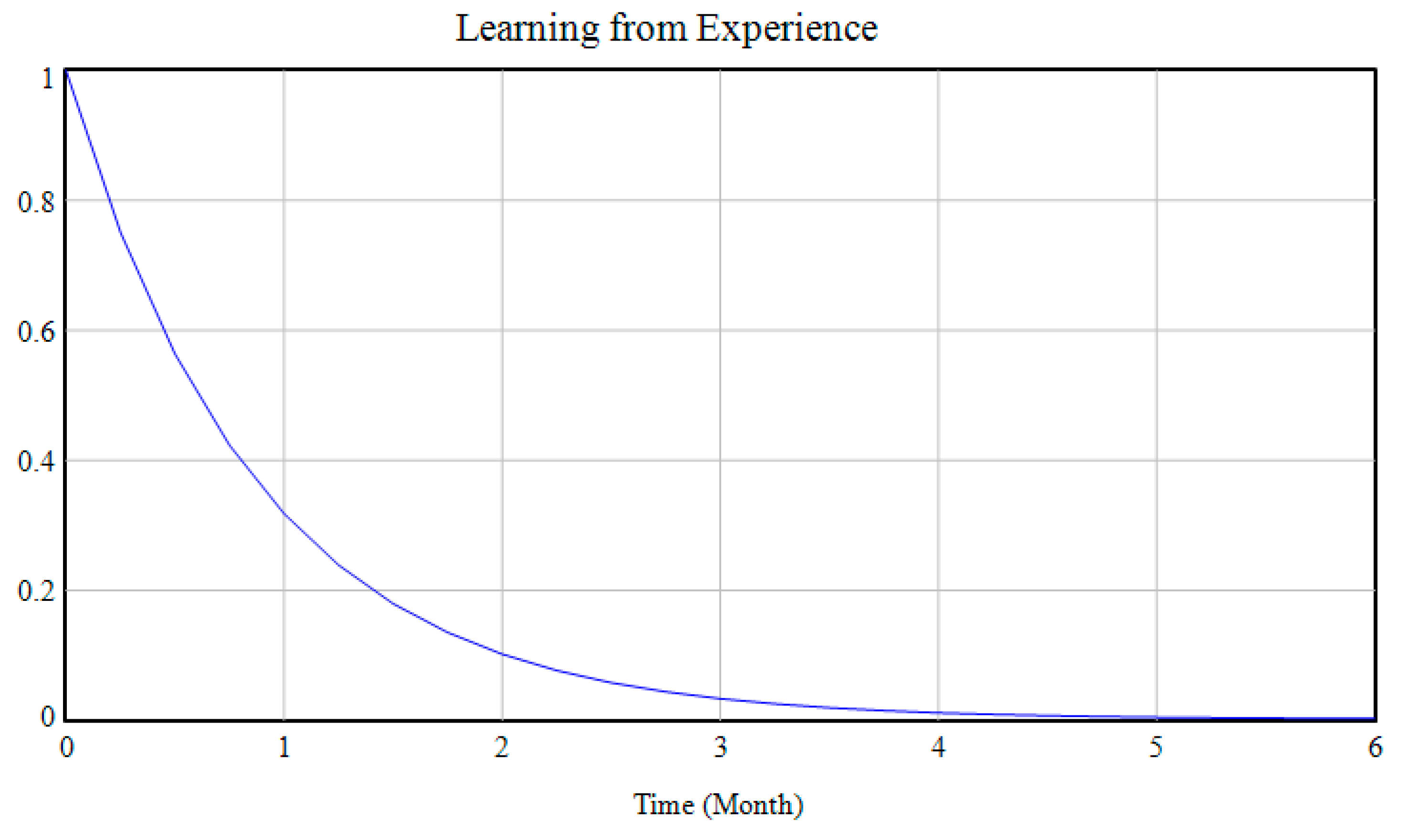

| 12 | Learning from experience | 0.02273 | 0.03998 | 0.029627835 | 0.383252568 |

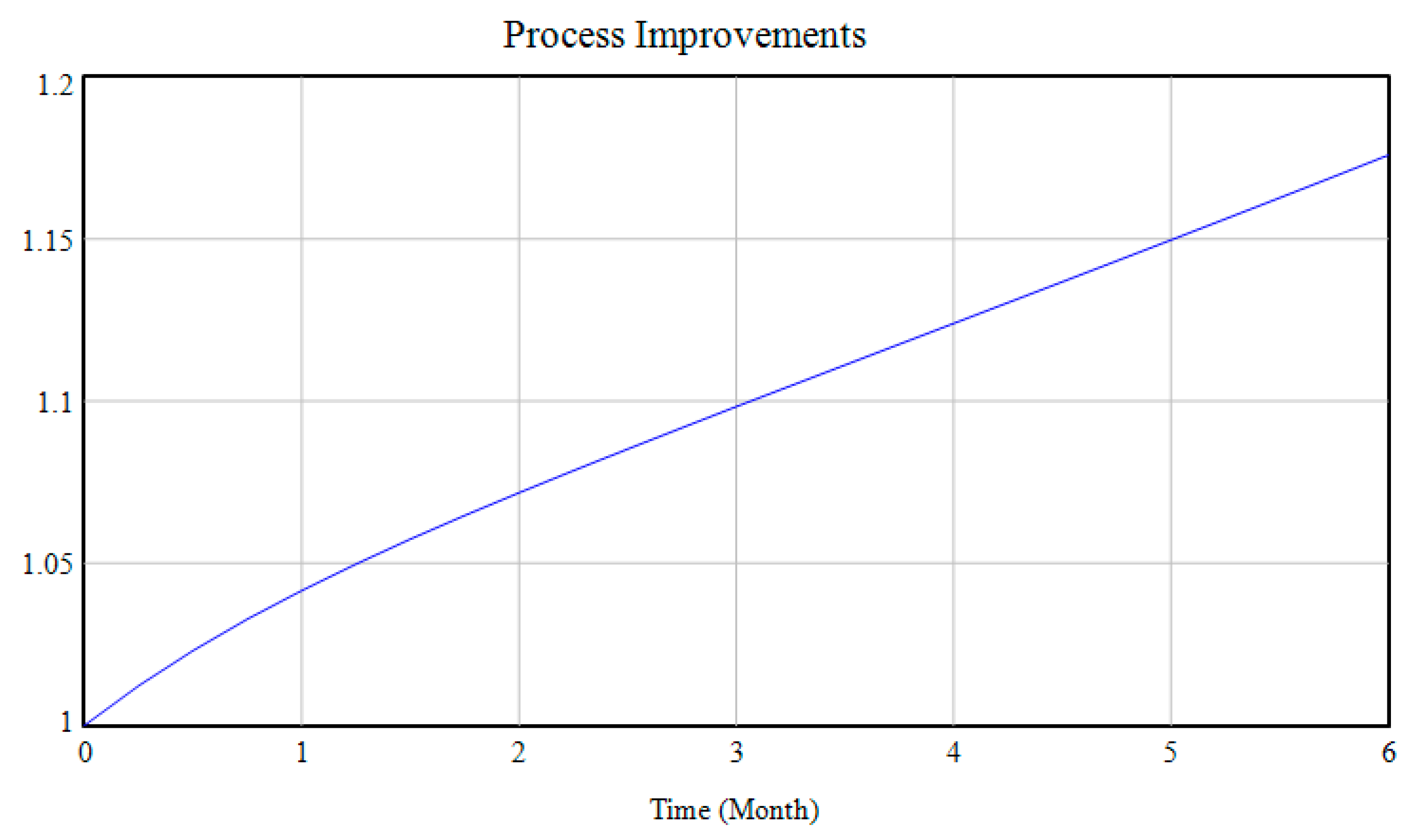

| 13 | Process improvements (to reduce lead-times) | 0.02273 | 0.03998 | 0.029627835 | 0.412880403 |

| 14 | Monitoring early warning signals (near miss analysis) | 0.02273 | 0.03198 | 0.026429541 | 0.439309944 |

| 15 | Customers demand forecasting | 0.02273 | 0.03198 | 0.026429541 | 0.465739484 |

| 16 | Contingency planning (drills, training) | 0.02273 | 0.03198 | 0.026429541 | 0.492169025 |

| Risks | Resilient Capabilities | Polarity | Weighted RII Score |

|---|---|---|---|

| Health pandemic | People, products, and assets visibility (real-time data on location) | − | 0.75 |

| Alternative suppliers/sources to quickly reallocate order | − | 0.79 | |

| Inventory management system (Fast rerouting of requirements | + | 0.76 | |

| Process improvements (to reduce lead times) | − | 0.76 | |

| Monitoring early warning signals (deviations near misses’ analysis) | − | 0.75 | |

| Customers demand forecasting | − | 0.75 | |

| Budget overruns/unplanned expenses | Process improvement | − | 0.75 |

| Alternative technology development | + | 0.75 | |

| Poor information coordination and decision making | People, products, and assets visibility (real-time data on location) | − | 0.77 |

| Collaborative information exchange (among stakeholders) | − | 0.81 | |

| Business intelligence gatherings (modern trends and technology awareness). | − | 0.76 | |

| Mode of communication (external and internal) | − | 0.75 | |

| Learning from experience | − | 0.75 | |

| Insufficient management oversight of SC members | People, products, and assets visibility (real-time data on location) | − | 0.75 |

| Collaborative information exchange (among stakeholders) | − | 0.77 | |

| Alternate distribution channels (modes of transportation | − | 0.76 | |

| Learning from experience | − | 0.76 | |

| Visibility of errors/deficiencies to stakeholders | Collaborative information exchange (among stakeholders) | − | 0.78 |

| Decentralization of suppliers/operation facilities | Alternative suppliers/sources to quickly reallocate order | − | 0.76 |

| Inventory management system (Fast rerouting of requirements | − | 0.76 | |

| Exposure to natural disasters | People, products, and assets visibility (real-time data on location) | − | 0.77 |

| Collaborative information exchange (among stakeholders) | − | 0.77 | |

| Alternative technology development | − | 0.76 | |

| Transportation disruption during operations | Asset visibility | − | 0.75 |

| Alternate distribution channels (modes of transportation | − | 0.78 | |

| Limited production and distribution capacity | Business intelligence gatherings (Awareness of modern trends & technology). | − | 0.77 |

| Process improvements (to reduce lead times) | − | 0.76 | |

| Monitoring early warning signals (deviations near misses’ analysis) | − | 0.81 | |

| Customers demand forecasting | − | 0.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malik, A.; Khan, K.I.A.; Qayyum, S.; Ullah, F.; Maqsoom, A. Resilient Capabilities to Tackle Supply Chain Risks: Managing Integration Complexities in Construction Projects. Buildings 2022, 12, 1322. https://doi.org/10.3390/buildings12091322

Malik A, Khan KIA, Qayyum S, Ullah F, Maqsoom A. Resilient Capabilities to Tackle Supply Chain Risks: Managing Integration Complexities in Construction Projects. Buildings. 2022; 12(9):1322. https://doi.org/10.3390/buildings12091322

Chicago/Turabian StyleMalik, Afia, Khurram Iqbal Ahmad Khan, Siddra Qayyum, Fahim Ullah, and Ahsen Maqsoom. 2022. "Resilient Capabilities to Tackle Supply Chain Risks: Managing Integration Complexities in Construction Projects" Buildings 12, no. 9: 1322. https://doi.org/10.3390/buildings12091322