1. Introduction

The energy consumption of the building sector accounts for around 40% of final energy use and 25% of total carbon dioxide emissions globally [

1,

2]. With continuous economic development and improving living standards, the energy demand of the building sector in China has been steadily growing since the beginning of the 21st century [

3]. Since the end of 2015, all newly designed buildings in urban areas have been required to implement the government’s building energy-saving standard. Public buildings have the highest energy use intensity among all building types [

4]. A huge number of existing public buildings in China were designed before the end of 2015, most with very high energy consumption [

5]. Retrofitting existing buildings is recognized as the most feasible and cost-effective way to achieve green buildings, and it has less environmental impact than demolishing and reconstructing a new building [

6]. Energy retrofitting existing public buildings is a priority for energy saving, mitigating the environmental impact of the building sector, and sustainably developing China [

7].

Energy retrofitting existing buildings employs efficient energy-saving measures to reduce energy consumption while meeting the thermal comfort needs of people [

8]. Since [

9] China has a very large land area with distinct regional climates, bespoke measures are needed in different climate regions to meet the thermal comfort and living habits of the residents [

9]. Building retrofit measures in China vary according to the five distinct climate regions defined by the “Thermal Design Standard for Civic Building (GB50176-2016)”, which are: Warm Winter and Hot Summer climate region, Temperate climate region, Hot Summer and Cold Winter (HSCW) climate region, Cold climate region, and Severe Cold climate region [

10]. This research focuses on the HSCW climate region.

China’s HSCW climate region consists of 14 provinces and two municipalities, involving an area of 1,800,000 km

2 with a population of more than 500 million [

11]. The typical climate in this area is that of a tropical monsoon, with hot, humid summers and mild winters. The GDP of this area totals about 40% the GDP of the whole of China [

12]. Because of the developed economy, the area has a relatively high-income population, with higher expectations of indoor thermal comfort. People rely on using heating, ventilation, and air conditioning (HVAC) systems to fulfil the indoor thermal conditions of buildings [

13]. HVAC systems account for the largest proportion of energy consumption of public buildings in the HSCW climate region of China [

14]. Measures that reduce the energy consumption of existing public buildings in the HSCW climate region need to be investigated.

The heating and cooling demands of buildings are affected by heat transfer through the building envelope. The building envelope separates the indoor environment from the exterior environment and directly attenuates the impact of the natural climate. Enhancing the thermal performance of the building envelope to mitigate the energy demand of a building is recognized as one of the most sustainable methods of building energy retrofitting [

15]. The main building thermal envelope includes the external walls, roof, and windows. In earlier years, because of low comfort demand and low cost, buildings were constructed without any insulation. When existing uninsulated buildings are conditioned with heating and cooling systems, there is a huge waste of energy due to poor envelopes [

16]. Insulation is recognized as one of the most vital parameters of energy conservation in buildings. In recognition of this importance, all energy regulations for buildings judge efficiency using the Heat Transfer Coefficient (U-value) of a building envelope, including the external walls, roof, and windows [

17]. The main objective of the U-value is to measure heat transfer through the envelope, where a smaller U-value indicates better insulation [

18]. External windows account for a substantial portion of the envelope and affect indoor space heating and cooling demand. Besides U-value, the Solar Heat Gain Coefficient (SHGC) is a primary parameter used to judge the energy performance of a window. SHGC is the fraction of the external solar radiation transmitted through a window and absorbed in the glazing [

19]. Due to its importance, the SHGC value of windows is restricted in all the energy regulations for buildings [

20]. The lower the SHGC, the more solar radiation is blocked from the window.

China’s first national standard of building energy efficiency for public buildings, “Design Standard for Energy Efficiency of Public Buildings (GB50189-2005)”, was implemented in 2005 to guide the design of new construction projects [

21]. Compared with public buildings designed before 2005, the buildings that complied with the standard saved about 50% on energy consumption annually [

22]. As building materials and technologies then rapidly developed after China’s “11th Five Year Plan (2006–2010)”, old standards and technical codes started to show limitations and lagged behind on design and technological developments. Consequently, the new version of GB50189-2015 was launched at the end of 2015 (MOHURD, 2015) [

23]. The building envelope baseline thermal properties, including the U-Values and SHGCs of the external walls, roof, and windows, are improved in GB50189-2015 compared with GB50189-2005. A comparison of the parameters of GB50189-2005 and GB50189-2015 for the HSCW climate region is shown in

Table 1.

Previous studies have analyzed energy retrofit measures for building envelopes to minimize the energy consumption of existing buildings in China’s HSCW climate region. Peng et al. (2014) studied the energy performance of a building after adding an insulation layer inside the external wall and replacing the windows with Low-E glassing [

24]. Xu et al. (2016) assessed different energy retrofit measures in three different climate zones of China through simulation [

25]. Ge et al. (2018) studied the energy performance of the building envelope energy retrofitting of a university building in Hangzhou through simulation [

26]. Li et al. (2019) simulated the partial horizontal and vertical green roof and wall of an existing public building in a HSCW climate region of China [

27]. Liu et al. (2021) simulated the insulation of building envelopes based on the Passivhaus EnerPHit standard for a suburban building in the HSCW region of China [

28]. It is evident that previous studies focused on energy reduction using different retrofitting measures on the building envelope of existing buildings. Meanwhile, the Chinese government has required the energy thermal performance of existing public building retrofitting to be improved based on the public building energy efficiency standard GB50189-2015. However, few studies have investigated the influence of GB50189-2015 on the thermal energy performance of retrofitted existing public buildings [

29].

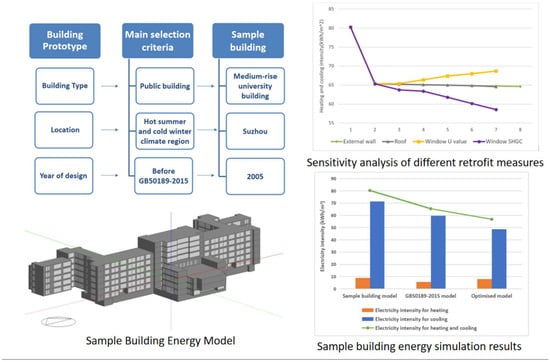

The goals of this study are: the creation of a baseline model for the public building energy efficiency standard GB50189-2015 to assess the energy performance of existing buildings; the application of sensitivity analysis to assess the parameters of the thermal standard of the envelope for a typical public building prototype based on the GB50189-2015 standard; and the adoption of optimized parameters to assess energy performance. The findings of this study could provide a valuable reference to local governments and practitioners eager to improve the energy efficient retrofitting of existing public buildings.

6. Conclusions

This research provides energy retrofit optimization strategies for existing public buildings in China’s HSCW climate region through a case study. The public building used as a case study was in Suzhou, which is a typical city in China’s HSCW climate region. The sample building model and a corresponding standard GB50189-2015 baseline model were created using the simulation tool DesignBuilder. The thermal and energy performance of the envelope of the sample building was assessed using the standard GB50189-2015 baseline model. Based on this baseline model, the study adopted sensitivity analyses for the building envelope, including the U-value of external walls, the U-value of the roof, and U-value and SHGC value of external windows, to further assess the parameters and identify their significance in affecting the energy consumption for indoor space heating and cooling. In comparison with the sample building, the total energy use of the GB50189-2015 baseline model was 18.94% lower. The optimized parameters could reduce the heating and cooling load by 11.49% compared with the GB50189-2015 baseline model, and by 28.26% compared with the existing sample building. The following conclusions are drawn from this research.

For existing public buildings constructed before the implementation of the energy efficiency standard GB50189-2015, thermal properties and energy performance could effectively be assessed by using the baseline model of the energy efficiency standard. If an existing public building already meets the baseline value of the latest energy efficiency standard, further improvement of the insulation of external walls and the roof cause little energy reduction for heating and cooling. Hence, it is not recommended to consider installing insulation with a lower U-value as a retrofit measure for external walls and roofs. Instead of insulation, green roofs prove a better solution for energy retrofitting for a roof, as they reduce heat gain in summer and heat loss in winter. Using a lower SHGC value for windows could greatly reduce the energy consumption compared with other parameters of an envelope. Improved shading and lower SHGC values are the most effective measures for public building envelope energy retrofitting in China’s HSCW climate region.

The findings of this study could provide a valuable reference for local government and practitioners to improve energy efficiency when retrofitting existing public buildings in China’s HSCW climate region. The methodology of this research could also be adopted to investigate existing building energy retrofitting for other climate regions in China and around the world. Since lack of funds and high cost is one of the barriers for energy retrofit projects, the cost-effectiveness of retrofitting measures and the return rates could be analyzed in future studies. The embodied emissions caused by energy retrofitting could also be assessed to investigate the tradeoff between operational energy and embodied energy of a public building retrofit project.