New Process with Argon Injected into Ladle around the Tapping Hole for Controlling Slag Carry-over during Continuous Casting Ladle

Abstract

:1. Introduction

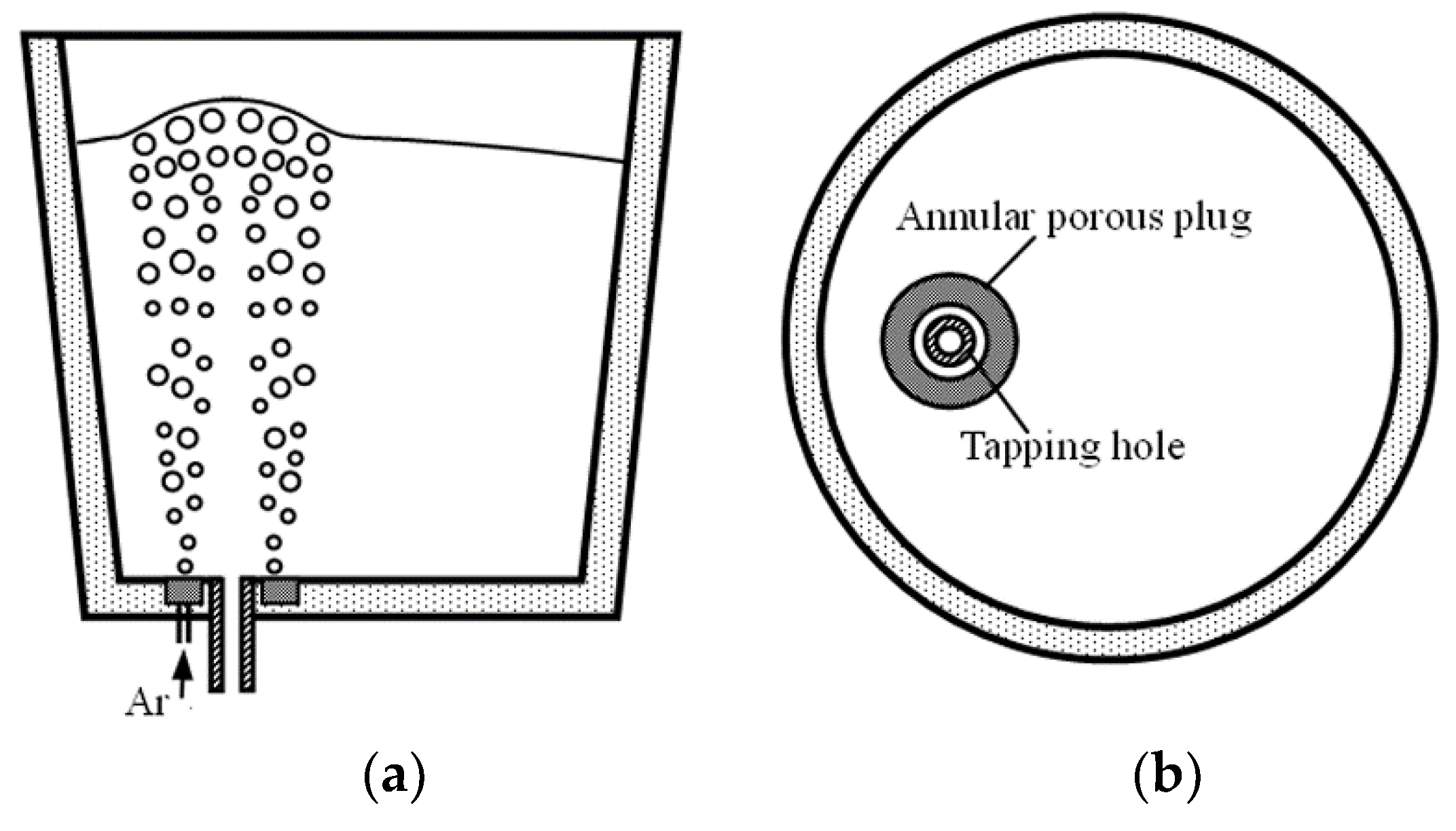

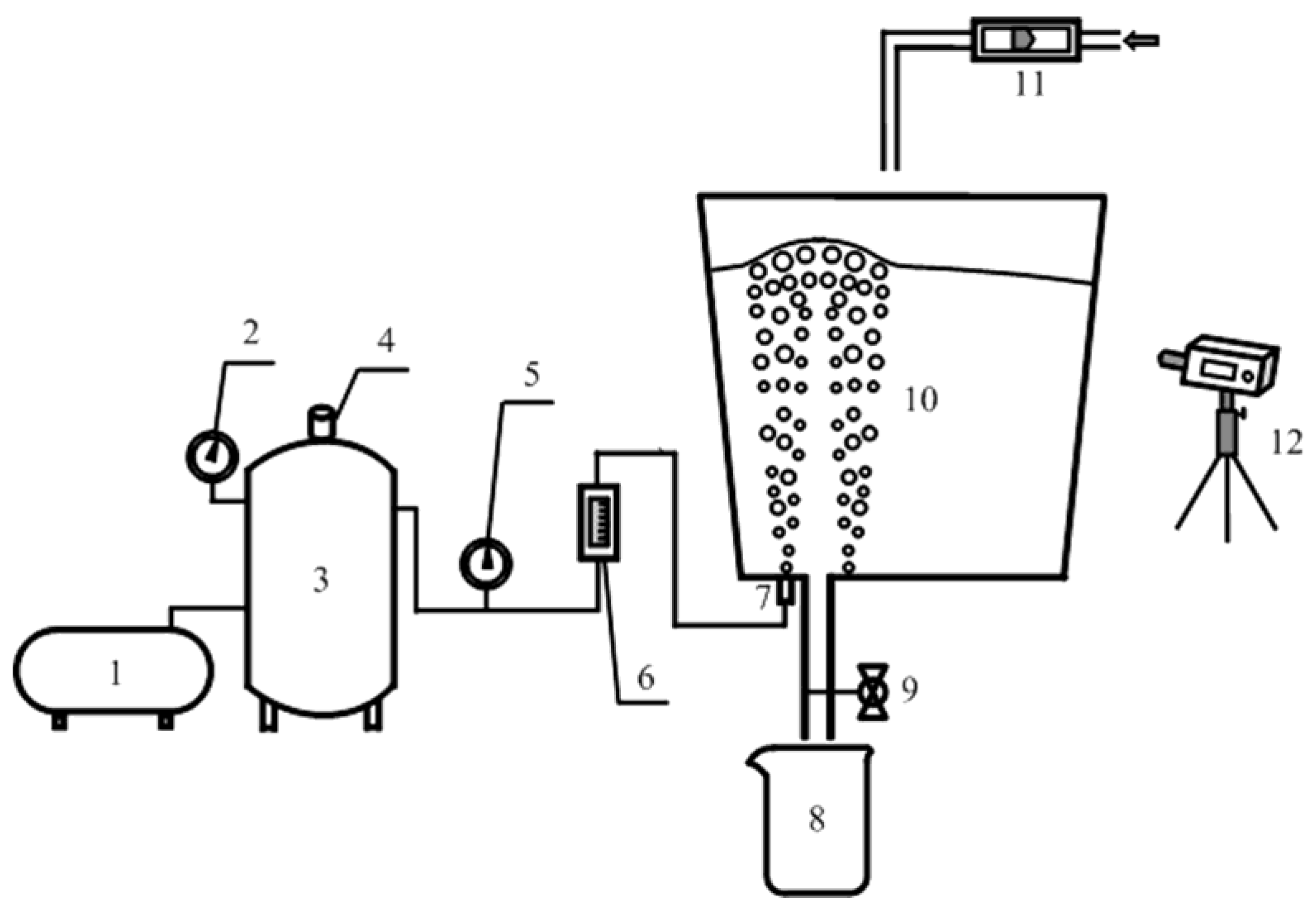

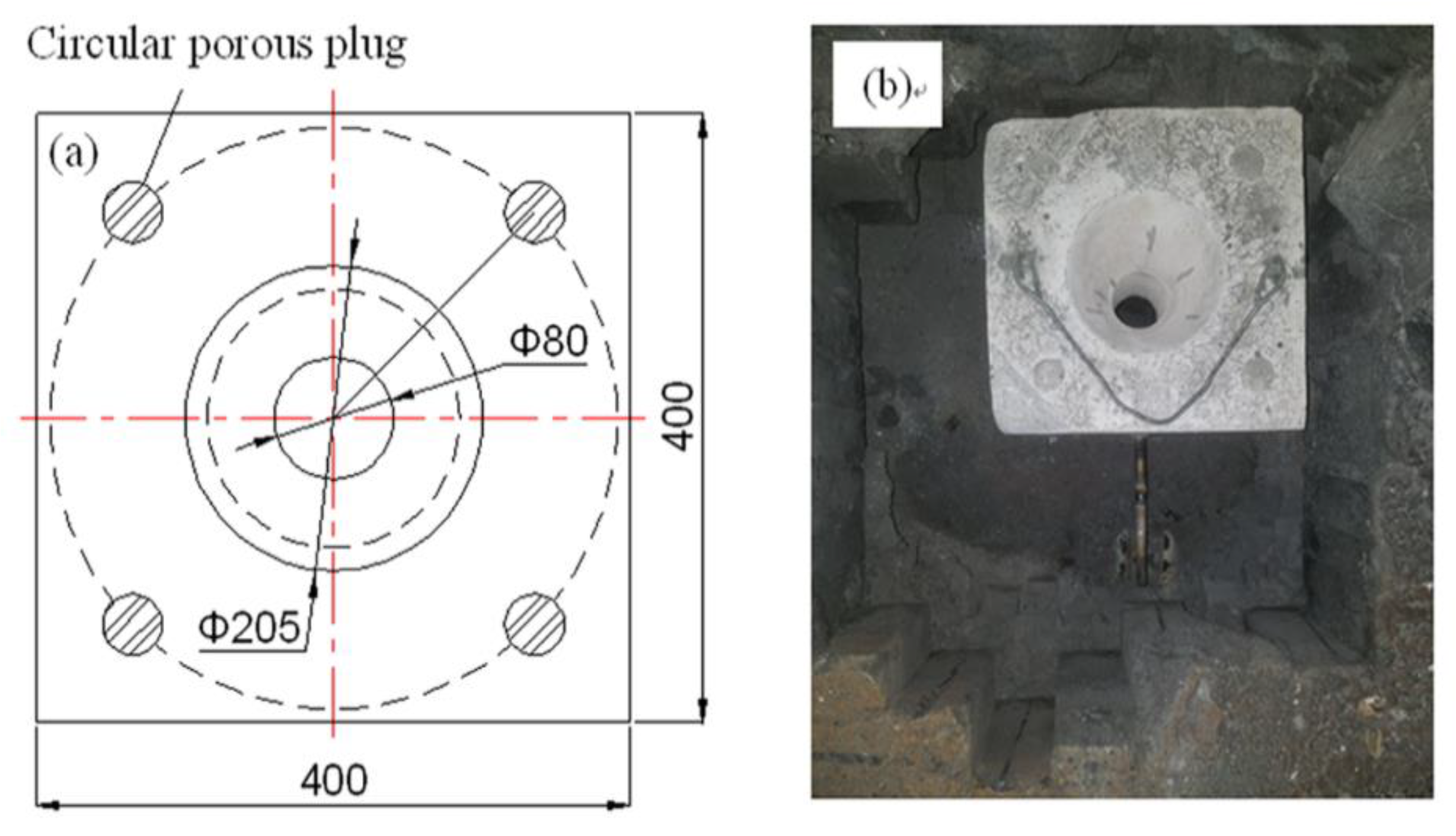

2. Experimental

3. Results and Discussion

3.1. Behavior of Slag Carry-over during the Ladle Teeming Process

3.2. Behavior of Controlling Slag Carry-over of the New Process

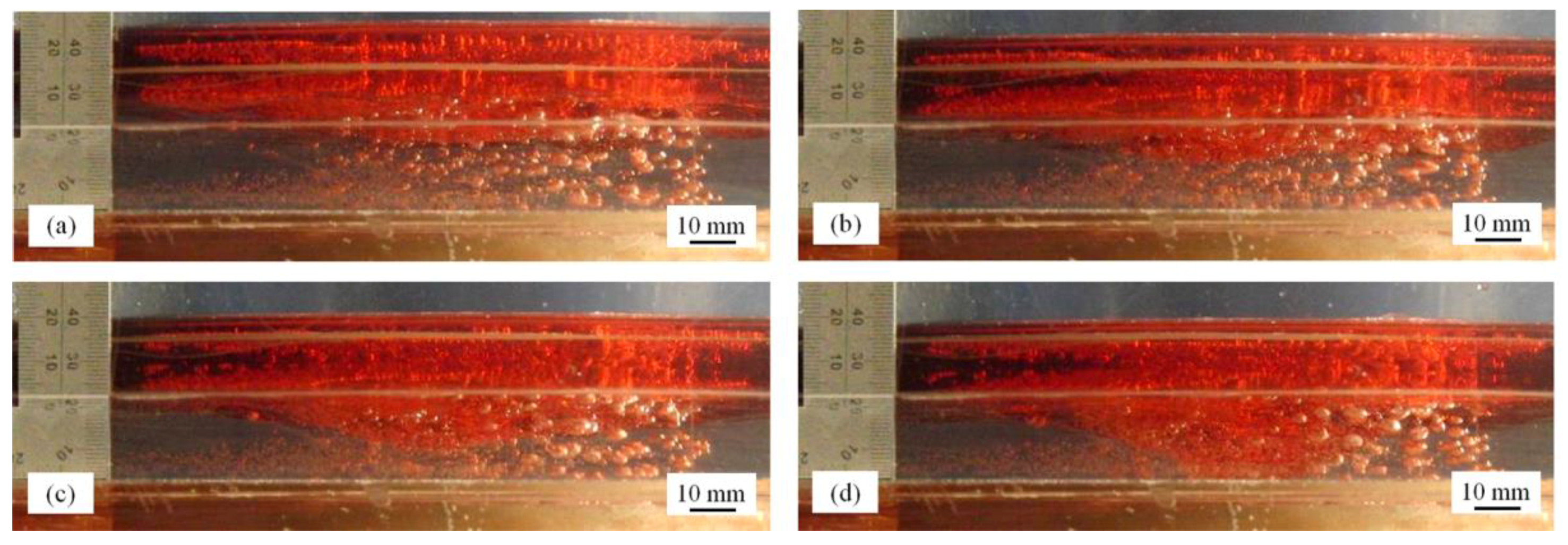

3.3. Metal/Slag Interface Behavior under the New Process

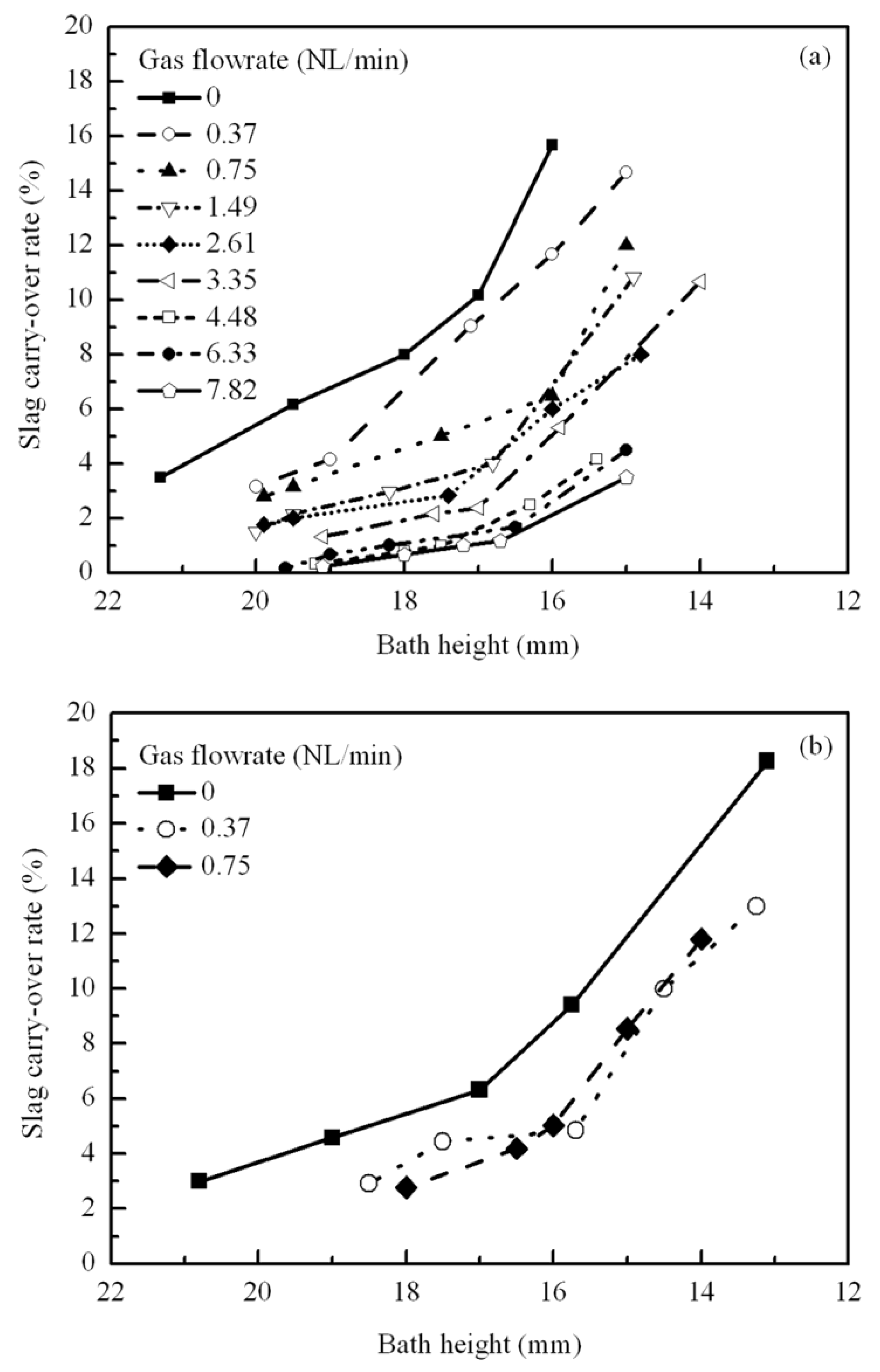

3.4. Effects of Operation Parameters on Controlling the Slag Carry-over under the New Process

4. Trial Application

5. Conclusions

- (1)

- During a continuous casting ladle teeming process, vortex is derived from the dimple at the water/oil interface and quickly develops from the one with a short vibrating tail to a fully developed vortex with a non-vibrating tail. As teeming continues to a certain bath height, the stable vortex begins converting to drain sink gradually. Finally, a fully developed drain sink forms and becomes stronger and stronger. The critical bath heights for the formation of a fully developed vortex and drain sink in a water model are 26.0 mm and 23.5 mm, respectively.

- (2)

- By the new process with argon injected into the ladle around the tapping hole, an argon ring is formed, and the rotating angular velocity of the melt close to the tapping hole can be reduced dramatically, and even vanished, when the melt is passing through the argon ring. Therefore, the slag carry-over caused by vortex can be eliminated. With argon blowing, the velocity of the radial melt flow toward the tapping hole is reduced due to the bubble buoyancy as the melt is passing through the argon ring, decreasing the outflow capacity of the nozzle. Then, the critical bath height for drain sink formation is lowered. So, the slag carry-over caused by drain sink can be suppressed, obviously.

- (3)

- As the model slag thickness is smaller than 20 mm, the bubbles can pass through the slag layer under smaller gas flow rates, and slag eyes are formed over the nozzle under bigger gas flow rates. Under those model slags with thicknesses larger than 20 mm, unreasonable argon blowing can cause foam slag beneath the slag layer, resulting in the slag carry-over in the high bath height.

- (4)

- Under the thin slag, the quantity of slag carry-over during the ladle teeming process decreases with the increase of gas flow rate, and large gas flow rates show good efficiency on controlling the slag carry-over. When the gas flow rates are smaller than the maximum one for avoiding foam slag, they have a small effect on the slag carry-over under the thick slag.

- (5)

- By the plant trials, compared with the original process, the steel residual reduces by 40% with the new controlling slag carry-over process. Therefore, the new controlling slag carry-over process show good efficiency on decreasing the steel residual in the poured ladle.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hammerschmid, P.; Tacke, K.H.; Popper, H.; Weber, L.; Dubke, M.; Schwerdtfeger, K. Vortex formation during drainage of metallurgical vessels. Ironmak. Steelmak. 1984, 11, 332–339. [Google Scholar]

- Sankaranarayanan, R.; Guthrie, R.I.L. Slag entraining vortexing funnel formation during ladle teeming: Similarity criteria and scale-up relationships. Ironmak. Steelmak. 2002, 29, 147–153. [Google Scholar] [CrossRef]

- Davila, O.; Garcia-Demedices, L.; Morales, R.D. Mathematical simulation of fluid dynamics during steel draining operations from a ladle. Metall. Mater. Trans. B 2006, 37, 71–87. [Google Scholar] [CrossRef]

- Mazzaferro, G.M.; Piva, M.; Ferro, S.P.; Bissio, P.; Lglesias, M.; Calvo, A.; Goldschmit, M.B. Experimental and numerical analysis of ladle teeming process. Ironmak. Steelmak. 2004, 31, 503–508. [Google Scholar] [CrossRef]

- Koria, S.C.; Kanth, U. Model studies of slag carry-over during drainage of metallurgical vessels. Steel Res. Int. 1994, 65, 8–14. [Google Scholar] [CrossRef]

- Andrzejewski, P.; Diener, A.; Pluschkell, W. Model investigations of slag flow during last stages of ladle teeming. Steel Res. Int. 1987, 58, 547–552. [Google Scholar] [CrossRef]

- Morales, R.D.; Dávila-Maldonado, O.; Calderón, I.; Morales-Higa, K. Physical and mathematical models of vortex flows during the last stages of steel draining operations from a ladle. ISIJ Int. 2013, 53, 782–791. [Google Scholar] [CrossRef]

- Dubke, M.; Schwerdtfeger, K. Phenomena occurring during drainage of metallurgical vessels. Effect of stopper rod on vortex formation and development of surface waves. Ironmak. Steelmak. 1990, 17, 184–192. [Google Scholar]

- Sucker, D.; Reinecke, J.; Hage-Jewainski, H. Evaluation of melting behaviour of slags containing nonferrous metals. Stahl. Eisen. 1985, 105, 765–769. [Google Scholar]

- Lin, R.; Yan, Z.G.; Yu, J.K. Physical modeling test of vortex during teeming from ladle. J. Northeast. Univ. 2010, 31, 1287–1291. [Google Scholar]

- Zhou, L.; Cao, C.H.; Dai, W.; He, X. Physical simulation of sink-vortex slag entrainment in 120 t ladle. Steelmaking 2012, 28, 56–59. [Google Scholar]

- Huang, Y.; Ye, S.F.; Tao, Y.P.; Li, M.M.; Huang, Z.M. Influence of slag thickness and outlet shape on the vortex sink carrying slag. J. Iron Steel Res. 1995, 7, 9–14. [Google Scholar]

- Lin, R.; Yan, Z.G.; Liu, T.; Yu, J.K. Modeling formation mechanism of vortex during steel casting in a 60 t ladle. Chin. J. Process Eng. 2010, 10, 655–659. [Google Scholar]

- Hassall, G.J.; Jackaman, D.P.; Hawkins, R.J. Phosphorus and sulphur removal from liquid steel in ladle steelmaking processes. Ironmak. Steelmak. 1991, 18, 359–369. [Google Scholar]

- Sankaranarayanan, R.; Guthrie, R.I.L. A laboratory study of slag entrainment during the emptying of metallurgical vessels. In Proceedings of the Steelmaking Conference, Toronto, Canada, 5–8 April 1992; pp. 655–664. [Google Scholar]

- Kojola, N.; Takagi, S.; Yokoya, S.; Jönsson, P. Prediction and disarming of drain sink formation during unsteady-state bottom teeming. ISIJ Int. 2009, 49, 1–9. [Google Scholar] [CrossRef]

- Huang, Y.; Ye, S.F.; Li, M.M. Technology of preventing slag carry-over during casting process. Steelmaking 1996, 12, 26–31. [Google Scholar]

- Idstein, D.J.; Hoffman, J.P.; Witek, E.T.; Hogan, J.L. Development of an improved ladle nozzle system. Iron Steelmak. 1994, 21, 79–81. [Google Scholar]

- Qiu, D.M. A novel continuous casting slag detection system using a single-coil sensor. Scand. J. Metall. 1997, 26, 178–182. [Google Scholar]

- Tan, D.P.; Li, P.Y.; Pan, X.H. Application of improved HMM algorithm in slag detection system. J. Iron Steel Res. Int. 2009, 16, 1–6. [Google Scholar] [CrossRef]

- Trotter, D.J.; Duncan, G.; Camplin, J.M. Development of a ladle/tundish slag detector. Iron Steelmak. 1991, 18, 57–60. [Google Scholar]

- Walker, D.I.; Dawson, S.; Mountford, N.D.G.; Sommerville, I.D.; Mclean, A. Development of ultrasonic sensors for the early detection of slag carryover. Iron Steelmak. 1990, 17, 59–64. [Google Scholar]

- Zhu, M.Y.; Xiao, Z.Q. Maths-Physical Modeling of Steel Refining Process, 1st ed.; Metallurgical Industry Press: Beijing, China, 1998; pp. 124–125. [Google Scholar]

- Zheng, S.G.; Zhu, M.Y. Physical modelling of inclusion behavior in secondary refining with argon blowing. Steel Res. Int. 2008, 79, 685–690. [Google Scholar] [CrossRef]

| Parameters | Prototype | Model |

|---|---|---|

| Ladle top diameter (mm) | 3160 | 632 |

| Ladle bottom diameter (mm) | 2820 | 564 |

| Ladle depth (mm) | 3850 | 770 |

| Tapping hole diameter (mm) | 90 | 18 |

| Inner diameter of annular porous plug (mm) | 380 | 76 |

| Width of annular porous plug (mm) | 150 | 30 |

| Slag thickness (mm) | 50–120 | 10–24 |

| Gas flow rate (NL/min) | 0–653.69 | 0–7.82 |

| Gas density 1 (kg/m3) | 1.784(Ar) | 1.205(Air) |

| Process | Steel Grade | Heat Number | Steel Residual (Kg/heat) |

|---|---|---|---|

| The original process | SPHC (Steel Plate Hot Commercial) | 33 | 535 |

| The new controlling slag carry-over process | SPHC | 22 | 323 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, S.; Zhu, M. New Process with Argon Injected into Ladle around the Tapping Hole for Controlling Slag Carry-over during Continuous Casting Ladle. Metals 2018, 8, 624. https://doi.org/10.3390/met8080624

Zheng S, Zhu M. New Process with Argon Injected into Ladle around the Tapping Hole for Controlling Slag Carry-over during Continuous Casting Ladle. Metals. 2018; 8(8):624. https://doi.org/10.3390/met8080624

Chicago/Turabian StyleZheng, Shuguo, and Miaoyong Zhu. 2018. "New Process with Argon Injected into Ladle around the Tapping Hole for Controlling Slag Carry-over during Continuous Casting Ladle" Metals 8, no. 8: 624. https://doi.org/10.3390/met8080624