A Study of the Optimum Quenching Temperature of Steels with Various Hot Rolling Microstructures after Cold Rolling, Quenching and Partitioning Treatment

Abstract

:1. Introduction

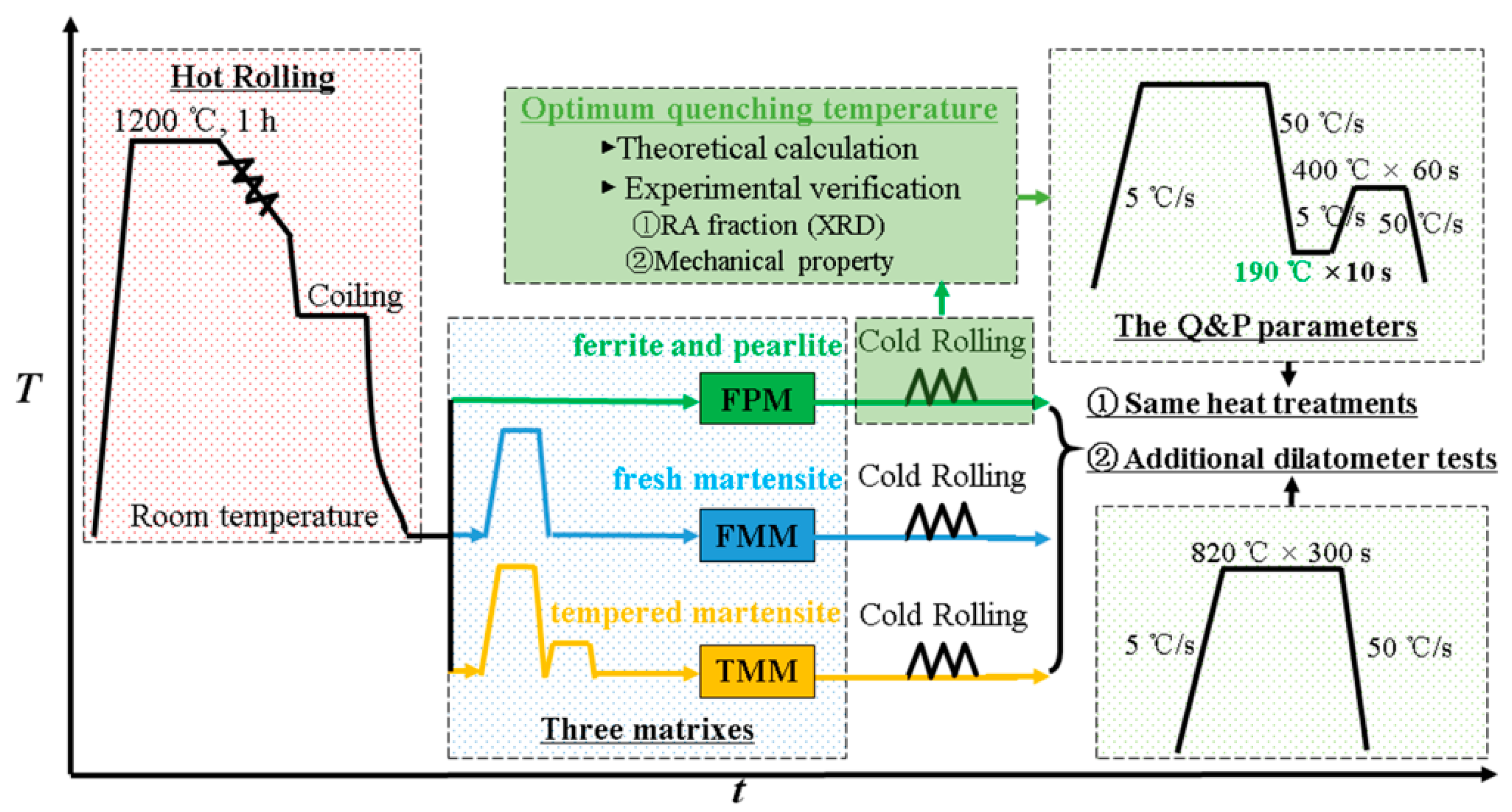

2. Experiment

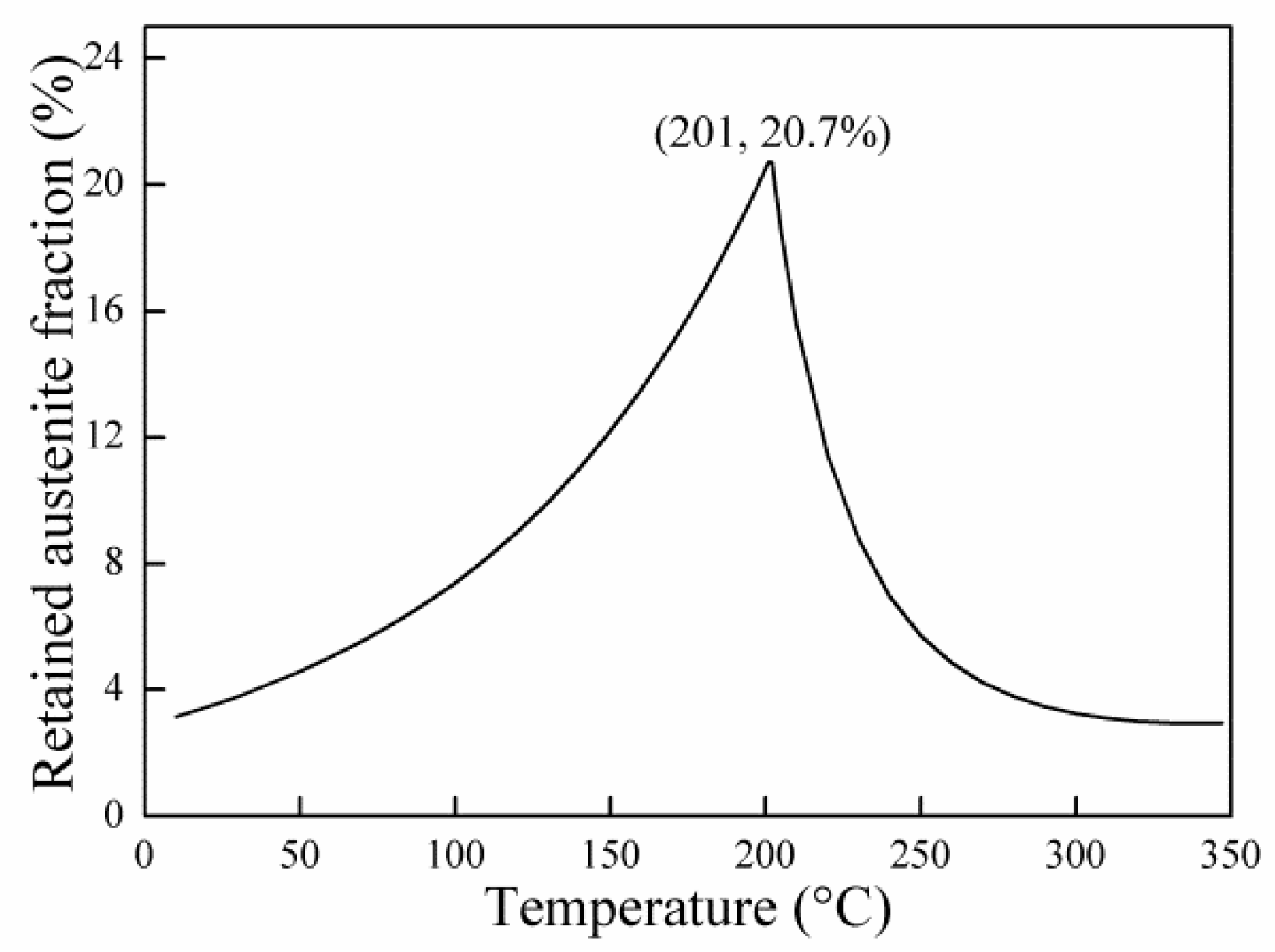

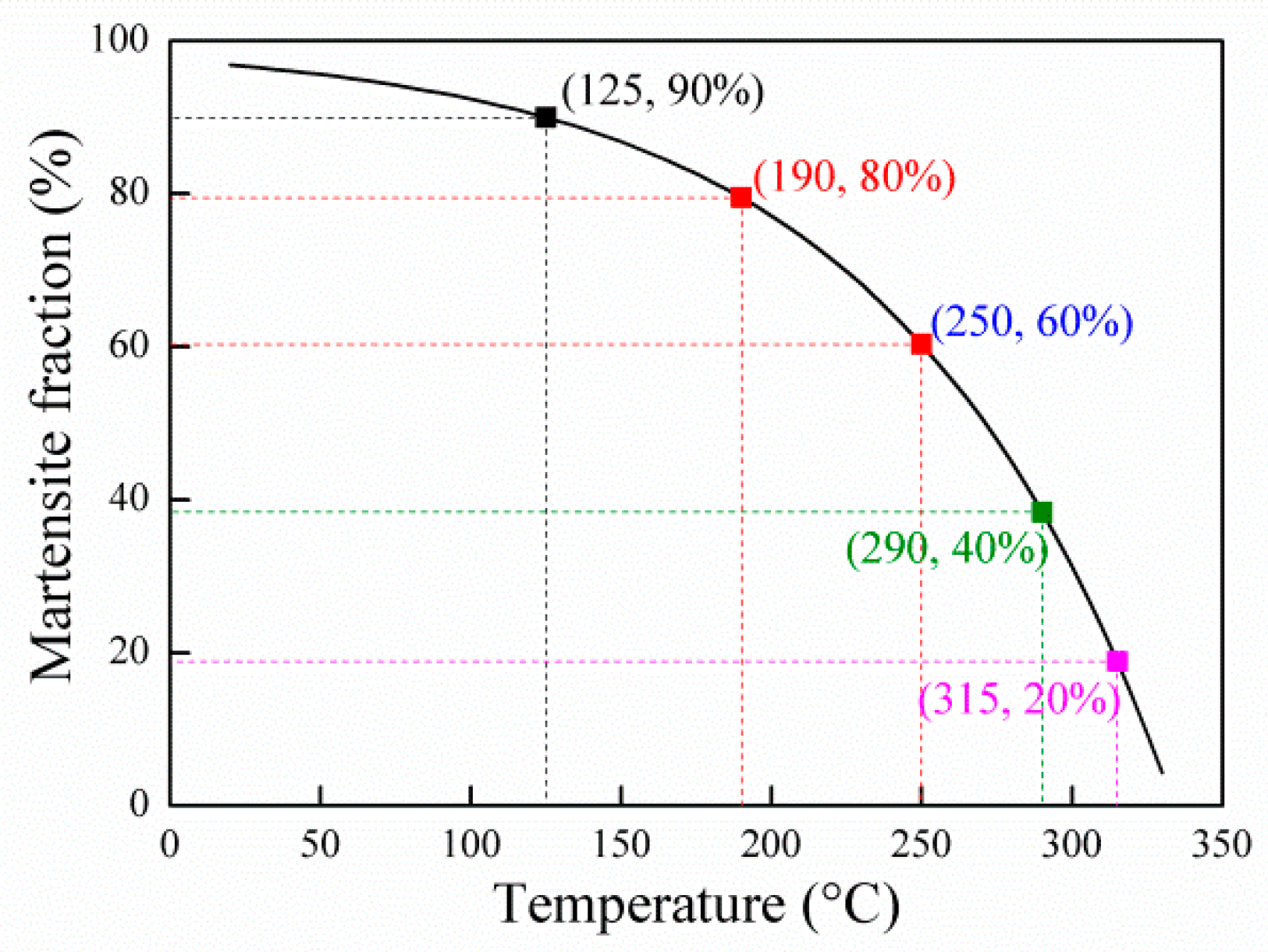

2.1. Optimum Quenching Temperature Selection

2.2. Preparation and Heat Treatment Parameters of the Three Matrixes

2.3. Testing Parameters

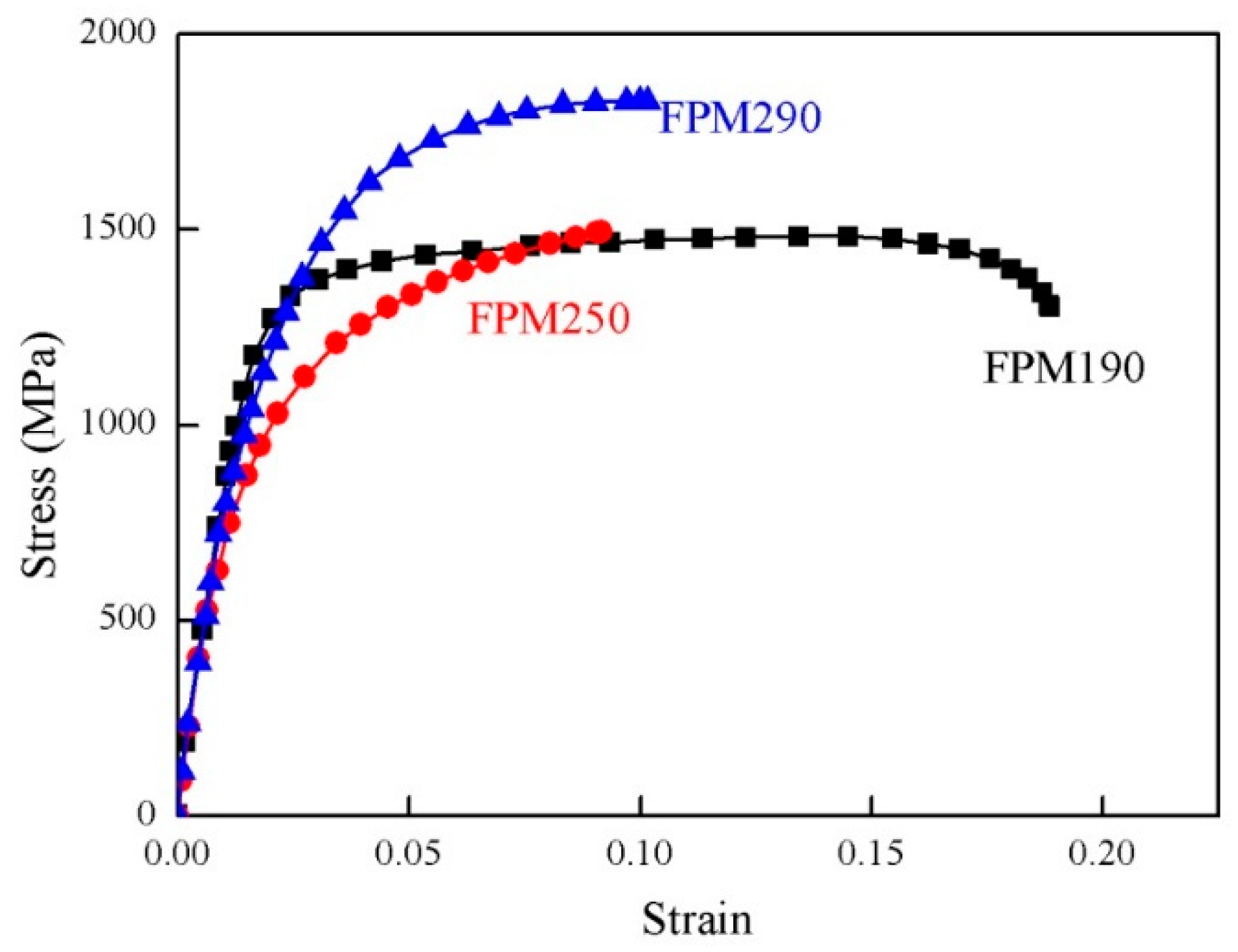

3. Results and Discussion

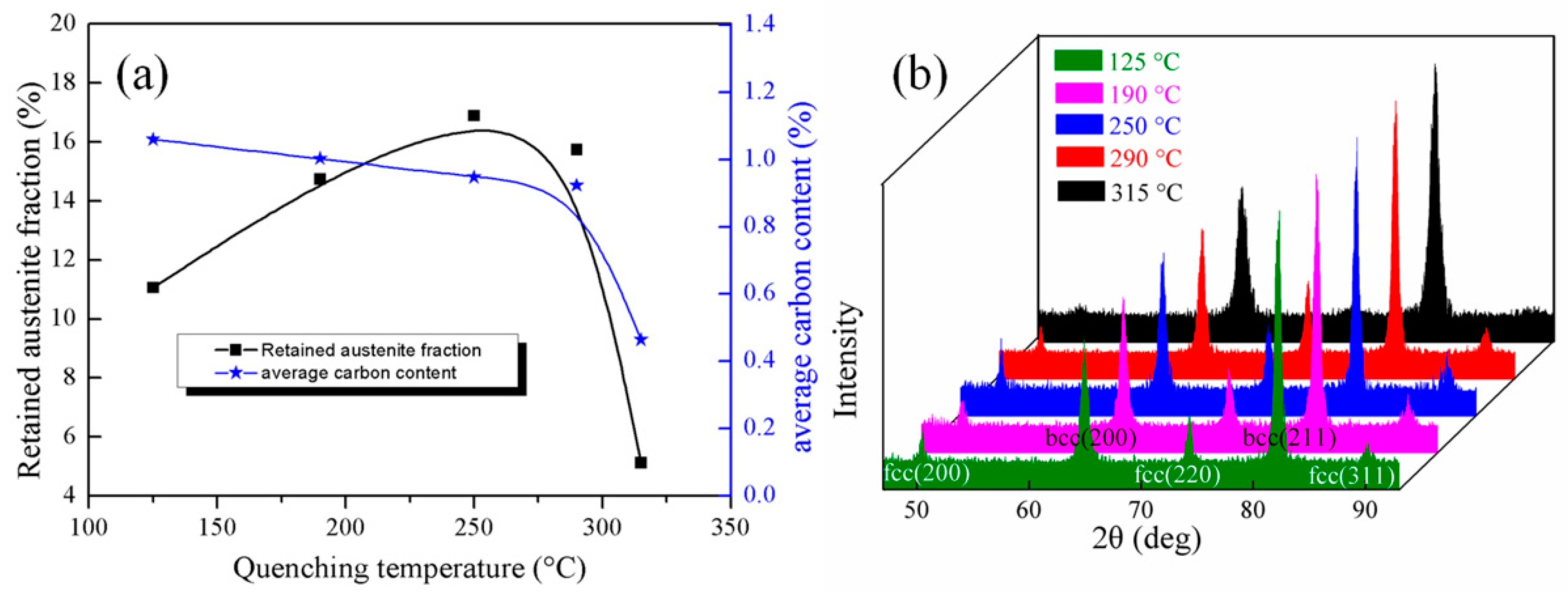

3.1. Optimum Quenching Temperature

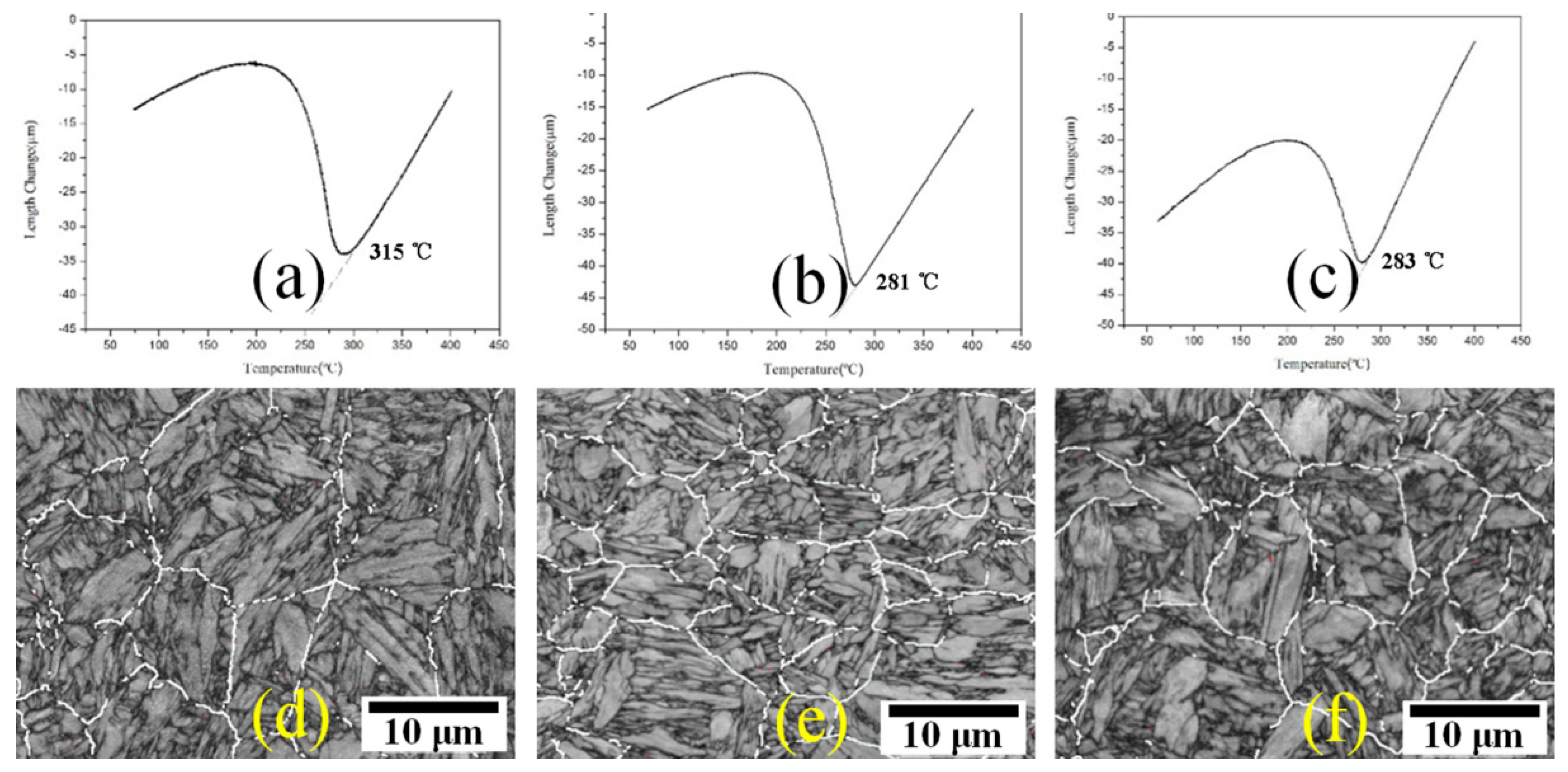

3.2. Ms Temperature and Microstructure Characterization under Different Matrixes

3.3. Modified Empirical Formula

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Speer, J.G.; Edmonds, D.V.; Rizzo, F.C.; Matlock, D.K. Partitioning of carbon from supersaturated plates of ferrite, with application to steel processing and fundamentals of the bainite transformation. Curr. Opin. Solid State Mater. Sci. 2004, 8, 219–237. [Google Scholar] [CrossRef]

- Speer, J.; Hackenberg, R.; Decooman, B.; Matlock, D. Influence of interface migration during annealing of martensite/austenite mixtures. Philos. Mag. Lett. 2007, 87, 379–382. [Google Scholar] [CrossRef]

- Speer, J.; De Moor, E.; Clarke, A. Critical assessment 7: Quenching and partitioning. Mater. Sci. Technol. 2015, 31, 3–9. [Google Scholar] [CrossRef]

- Hsu, T.Y.; Jin, X.J.; Rong, Y.H. Strengthening and toughening mechanisms of quenching-partitioning-tempering (Q-P-T) steels. J. Alloys Compd. 2013, 577, 568–571. [Google Scholar]

- Santofimia, M.J.; Zhao, L.; Sietsma, J. Overview of mechanisms involved during the quenching and partitioning process in steels. Metall. Mater. Trans. A 2011, 42, 3620–3626. [Google Scholar] [CrossRef]

- Santofimia, M.J.; Zhao, L.; Petrov, R.; Kwakernaak, C.; Sloof, W.G.; Sietsma, J. Microstructural development during the quenching and partitioning process in a newly designed low-carbon steel. Acta Mater. 2011, 59, 6059–6068. [Google Scholar] [CrossRef]

- Sun, J.; Yu, H.; Wang, S.Y.; Fan, Y.F. Study of microstructural evolution, microstructure-mechanical properties correlation and collaborative deformation-transformation behavior of quenching and partitioning (Q&P) steel. Mater. Sci. Eng. A 2014, 596, 89–97. [Google Scholar]

- De Moor, E.; Speer, J.G.; Matlock, D.K.; Kwak, J.H.; Lee, S.B. Effect of carbon and manganese on the quenching and partitioning response of CMnSi steels. ISIJ Int. 2011, 51, 137–144. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; De Cooman, B.C. Application of quenching and partitioning processing to medium Mn steel. Metall. Mater. Trans. A 2015, 46, 27–31. [Google Scholar] [CrossRef]

- Kim, J.H.; Seo, E.J.; Kwon, M.H.; Kang, S.; De Cooman, B.C. Effect of quenching temperature on stretch flangeability of a medium Mn steel processed by quenching and partitioning. Mater. Sci. Eng. A 2018, 729, 276–284. [Google Scholar] [CrossRef]

- Hou, Z.; Zhao, X.; Zhang, W.; Liu, H.; Yi, H. A medium manganese steel designed for water quenching and partitioning. Mater. Sci. Technol. 2018, 1–8. [Google Scholar] [CrossRef]

- De Moor, E.; Speer, J.G.; Matlock, D.K.; Kwak, J.H.; Lee, S.B. Quenching and partitioning of CMnSi steels containing elevated manganese levels. Steel Res. Int. 2012, 83, 322–327. [Google Scholar] [CrossRef]

- Huyghe, P.; Malet, L.; Caruso, M.; Georges, C.; Godet, S. On the relationship between the multiphase microstructure and the mechanical properties of a 0.2C quenched and partitioned steel. Mater. Sci. Eng. A 2017, 701, 254–263. [Google Scholar] [CrossRef]

- Clarke, A.J.; Speer, J.G.; Miller, M.K.; Hackenberg, R.E.; Edmonds, D.V.; Matlock, D.K.; Rizzo, F.C.; Clarke, K.D.; De Moor, E. Carbon partitioning to austenite from martensite or bainite during the quench and partition (Q&P) process: A critical assessment. Acta Mater. 2008, 56, 6–22. [Google Scholar]

- Pierce, D.T.; Coughlin, D.R.; Williamson, D.L.; Clarke, K.D.; Clarke, A.J.; Speer, J.G.; De Moor, E. Characterization of transition carbides in quench and partitioned steel microstructures by Mossbauer spectroscopy and complementary techniques. Acta Mater. 2015, 90, 417–430. [Google Scholar] [CrossRef]

- Pierce, D.T.; Coughlin, D.R.; Clarke, K.D.; De Moor, E.; Poplawsky, J.; Williamson, D.L.; Mazumder, B.; Speer, J.G.; Hood, A.; Clarke, A.J. Microstructural evolution during quenching and partitioning of 0.2C-1.5Mn-1.3Si steels with Cr or Ni additions. Acta Mater. 2018, 151, 454–469. [Google Scholar] [CrossRef]

- Thomas, G.A.; Speer, J.G. Interface migration during partitioning of Q&P steel. Mater. Sci. Technol. 2014, 30, 998–1007. [Google Scholar]

- De Knijf, D.; Santofimia, M.J.; Shi, H.; Bliznuk, V.; Fojer, C.; Petrov, R.; Xu, W. In situ austenite-martensite interface mobility study during annealing. Acta Mater. 2015, 90, 161–168. [Google Scholar] [CrossRef]

- Yang, H.S.; Suh, D.W.; Bhadeshia, H.K.D.H. More Complete Theory for the Calculation of the Martensite-Start Temperature in Steels. ISIJ Int. 2012, 52, 164–166. [Google Scholar] [CrossRef]

- Wang, M.M.; Hell, J.C.; Tasan, C.C. Martensite size effects on damage in quenching and partitioning steels. Scr. Mater. 2017, 138, 1–5. [Google Scholar] [CrossRef]

- Liang, J.; Zhao, Z.; Tang, D.; Ye, N.; Yang, S.; Liu, W. Improved microstructural homogeneity and mechanical property of medium manganese steel with Mn segregation banding by alternating lath matrix. Mater. Sci. Eng. A 2018, 711, 175–181. [Google Scholar] [CrossRef]

- Zhao, Z.; Liang, J.; Zhao, A.; Liang, J.; Tang, D.; Gao, Y. Effects of the austenitizing temperature on the mechanical properties of cold-rolled medium-Mn steel system. J. Alloys Compd. 2017, 691, 51–59. [Google Scholar] [CrossRef] [Green Version]

- Cho, L.; Seo, E.J.; De Cooman, B.C. Near-Ac3 austenitized ultra-fine-grained quenching and partitioning (Q&P) steel. Scr. Mater. 2016, 123, 69–72. [Google Scholar]

- Andrews, K.W. Empirical formulae for the calculation of some transformation temperatures. J. Iron Steel Inst. 1965, 721–727. [Google Scholar]

- Ishida, K. Calculation of the effect of alloying elements on the Ms temperature in steels. J. Alloys Compd. 1995, 220, 126–131. [Google Scholar] [CrossRef]

- Mahieu, J.; De Cooman, B.C.; Maki, J. Phase transformation and mechanical properties of Si-free CMnAl transformation-induced plasticity-aided steel. Metall. Mater. Trans. A 2002, 33, 2573–2580. [Google Scholar] [CrossRef]

- Dyson, D.J. Effect of alloying additions on the lattice parameter of austenite. J. Iron. Steel. Inst. 1970, 208, 469–474. [Google Scholar]

- Van Dijk, N.H.; Butt, A.M.; Zhao, L.; Sietsma, J.; Offerman, S.E.; Wright, J.P.; van der Zwaag, S. Thermal stability of retained austenite in TRIP steels studied by synchrotron X-ray diffraction during cooling. Acta Mater. 2005, 53, 5439–5447. [Google Scholar] [CrossRef]

- Liu, L.; He, B.B.; Cheng, G.J.; Yen, H.W.; Huang, M.X. Optimum properties of quenching and partitioning steels achieved by balancing fraction and stability of retained austenite. Scr. Mater. 2018, 150, 1–6. [Google Scholar] [CrossRef]

- Xiong, X.C.; Chen, B.; Huang, M.X.; Wang, J.F.; Wang, L. The effect of morphology on the stability of retained austenite in a quenched and partitioned steel. Scr. Mater. 2013, 68, 321–324. [Google Scholar] [CrossRef]

- Wang, C.Y.; Zhang, Y.J.; Cao, W.Q.; Shi, J.; Wang, M.Q.; Dong, H. Austenite/martensite structure and corresponding ultrahigh strength and high ductility of steels processed by Q&P techniques. Sci. Chin. Technol. Sci. 2012, 55, 1844–1851. [Google Scholar]

- Heinze, C.; Pittner, A.; Rethmeier, M.; Babu, S.S. Dependency of martensite start temperature on prior austenite grain size and its influence on welding-induced residual stresses. Comput. Mater. Sci. 2013, 69, 251–260. [Google Scholar] [CrossRef]

- Van Bohemen, S.M.C.; Morsdorf, L. Predicting the Ms temperature of steels with a thermodynamic based model including the effect of the prior austenite grain size. Acta Mater. 2017, 125, 401–415. [Google Scholar] [CrossRef]

- Zhu, K.; Magar, C.; Huang, M.X. Abnormal relationship between Ms temperature and prior austenite grain size in Al-alloyed steels. Scr. Mater. 2017, 134, 11–14. [Google Scholar] [CrossRef]

- Ryde, L. Application of EBSD to analysis of microstructures in commercial steels. Mater. Sci. Technol. 2006, 22, 1297–1306. [Google Scholar] [CrossRef]

| Phase Transformation Parameters | Ac1/°C | Ac3/°C | Ms/°C |

|---|---|---|---|

| value | 723 | 803 | 334 |

| Dilatometric Method | Empirical Formula | ||||

|---|---|---|---|---|---|

| Sampling Source | Steel Ingots | FPM Cold-Rolled | FMM Cold-Rolled | TMM Cold-Rolled | |

| Ms/°C | 334 | 315 | 281 | 283 | 347 |

| ΔT/°C | 13 | 32 | 66 | 64 | 0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Liang, J.; Kang, T.; Cao, R.; Li, C.; Liang, J.; Li, F.; Zhao, Z.; Tang, D. A Study of the Optimum Quenching Temperature of Steels with Various Hot Rolling Microstructures after Cold Rolling, Quenching and Partitioning Treatment. Metals 2018, 8, 579. https://doi.org/10.3390/met8080579

Chen B, Liang J, Kang T, Cao R, Li C, Liang J, Li F, Zhao Z, Tang D. A Study of the Optimum Quenching Temperature of Steels with Various Hot Rolling Microstructures after Cold Rolling, Quenching and Partitioning Treatment. Metals. 2018; 8(8):579. https://doi.org/10.3390/met8080579

Chicago/Turabian StyleChen, Bin, Juhua Liang, Tao Kang, Ronghua Cao, Cheng Li, Jiangtao Liang, Feng Li, Zhengzhi Zhao, and Di Tang. 2018. "A Study of the Optimum Quenching Temperature of Steels with Various Hot Rolling Microstructures after Cold Rolling, Quenching and Partitioning Treatment" Metals 8, no. 8: 579. https://doi.org/10.3390/met8080579