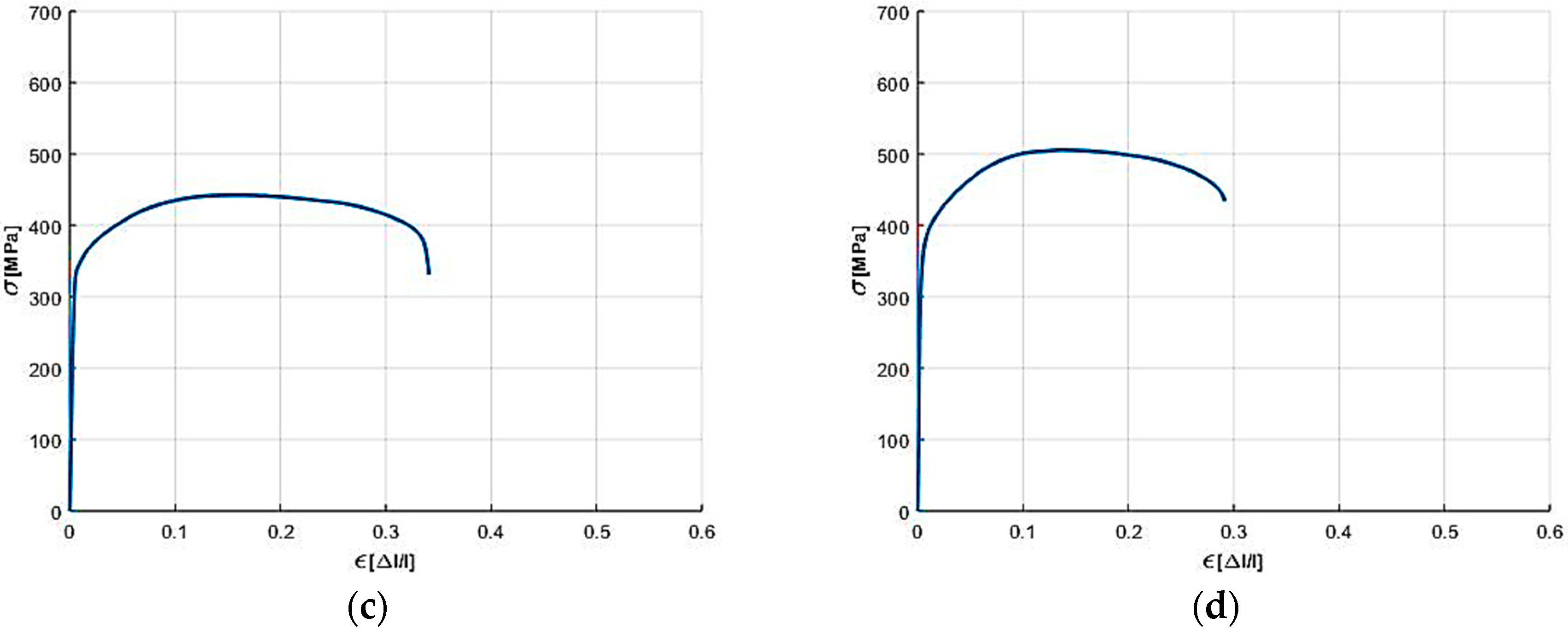

Figure 1.

Examples of experimental stress–strain curves for the considered materials, obtained from tensile tests at room temperature on the pipes for the following grades of stainless steel: (a) AISI 304; (b) AISI 316; (c) AISI 409; and (d) AISI 441.

Figure 2.

Geometry and working parts of the machinery simulated inside the software.

Figure 3.

Typical shape of the formability limit curve (a); example of Nakazima’s experimental test results on the formability limit diagram (FLD) with deformation state points for an AISI 304 stainless steel sheet (b).

Figure 4.

Equivalent stress mapping for diameters of 35 mm (a) and 60 mm (b) for AISI 304, 1.5 mm thickness.

Figure 5.

Trend of maximum equivalent stress according to the diameter for AISI 304, 1.5 mm thickness (a); percent variation of maximum equivalent stress according to the diameter for AISI 304, 1.5 mm thickness (b).

Figure 6.

FLD diagrams of 35 mm (a) and 60 mm (b) for AISI 304, 1.5 mm thickness.

Figure 7.

Equivalent stress mapping for a thickness of 1 mm (a) and 1.8 mm (b) for AISI 304, 50 mm diameter.

Figure 8.

The trend of maximum equivalent stress according to thickness for AISI 304, 50 mm diameter (a); percent variation of maximum equivalent stress according to the thickness for AISI 304, 50 mm diameter (b).

Figure 9.

Trend of maximum thinning according to thickness for AISI 304, 50 mm diameter (a); percent variation of maximum thinning according to thickness for AISI 304, 50 mm diameter (b).

Figure 10.

Trend of maximum equivalent stress according to the curvature radius and the pipe diameter (R/D) ratio for AISI 304 (a); percent variation of maximum equivalent stress according to the R/D ratio for AISI 304 (b).

Figure 11.

Trend of maximum thinning according to the R/D ratio for AISI 304 (a); percent variation of maximum thinning according to the R/D ratio for AISI 304 (b).

Figure 12.

Percentage reached of the formability limit (red dashed line) according to the R/D ratio for AISI 304 (a) and AISI 409 (b).

Figure 13.

Percentage reached of the formability limit for every combination of speed and angle for AISI 304.

Figure 14.

Percentage of formability limit variation in the minimum–maximum speed range as a function of the bending angle for AISI 304 steel.

Figure 15.

Equivalent stress mapping for bending angle of 90° (a); 120° (b); 150° (c); and 180° (d), at 2.7 rad/s for AISI 304.

Figure 16.

Thicknesses measuring grid on the backbone (a,b).

Figure 17.

Thickness trend for the simulation case (blue) and real case (orange) for AISI 304 (a); AISI 316 (b); AISI 409 (c); and AISI 441 (d).

Table 1.

Thickness for the AISI 304 samples.

| Measurement Angle | Sample n° 1 | Sample n° 2 | Sample n° 3 | Sample n° 4 | Sample n° 5 | Sample n° 6 | Mean Value |

|---|

| 0° | 1.169 | 1.200 | 1.180 | 1.124 | 1.250 | 1.235 | 1.108 |

| 22.5° | 1.003 | 1.019 | 1.026 | 1.023 | 1.023 | 1.101 | 1.037 |

| 45° | 0.982 | 0.993 | 1.002 | 1.058 | 1.157 | 1.016 | 1.039 |

| 67.5° | 1.086 | 1.016 | 1.050 | 1.029 | 1.166 | 1.052 | 1.042 |

| 90° | 1.200 | 1.146 | 1.180 | 1.152 | 1.149 | 1.161 | 1.149 |

Table 2.

Thickness for the AISI 316 samples.

| Measurement Angle | Sample n° 1 | Sample n° 2 | Sample n° 3 | Sample n° 4 | Sample n° 5 | Sample n° 6 | Mean Value |

|---|

| 0° | 1.091 | 1.131 | 1.290 | 1.119 | 1.119 | 1.123 | 1.119 |

| 22.5° | 1.023 | 1.010 | 1.028 | 1.014 | 1.048 | 1.032 | 1.026 |

| 45° | 1.016 | 0.999 | 1.004 | 0.986 | 0.987 | 1.021 | 1.002 |

| 67.5° | 1.028 | 1.015 | 1.021 | 1.030 | 1.071 | 1.017 | 1.030 |

| 90° | 1.135 | 1.101 | 1.149 | 1.128 | 1.192 | 1.143 | 1.140 |

Table 3.

Thickness for the AISI 409 samples.

| Measurement Angle | Sample n° 1 | Sample n° 2 | Sample n° 3 | Sample n° 4 | Sample n° 5 | Sample n° 6 | Mean Value |

|---|

| 0° | 1.080 | 1.067 | 1.070 | 1.075 | 1.083 | 1.079 | 1.076 |

| 22.5° | 0.959 | 0.961 | 0.950 | 0.963 | 0.942 | 0.962 | 0.956 |

| 45° | 1.011 | 0.970 | 0.936 | 0.911 | 1.026 | 0.937 | 0.965 |

| 67.5° | 0.987 | 0.971 | 0.968 | 0.990 | 1.010 | 0.989 | 0.986 |

| 90° | 1.200 | 1.092 | 0.097 | 1.107 | 1.079 | 1.096 | 1.112 |

Table 4.

Thickness for the AISI 441 samples.

| Measurement Angle | Sample n° 1 | Sample n° 2 | Sample n° 3 | Sample n° 4 | Sample n° 5 | Sample n° 6 | Mean Value |

|---|

| 0° | 1.169 | 1.200 | 1.180 | 1.124 | 1.250 | 1.235 | 1.193 |

| 22.5° | 1.003 | 1.019 | 1.026 | 1.023 | 1.123 | 1.101 | 1.049 |

| 45° | 0.982 | 0.993 | 1.002 | 1.058 | 1.157 | 1.016 | 1.035 |

| 67.5° | 1.086 | 1.016 | 1.050 | 1.029 | 1.166 | 1.052 | 1.067 |

| 90° | 1.200 | 1.180 | 1.180 | 1.152 | 1.149 | 1.161 | 1.166 |

Table 5.

Thickness for the AISI 304 samples.

| Measurement Angle | Simulation Thickness [mm] | Sample mean Thickness [mm] | Δ Thickness [mm] | Percentage Variation [%] |

|---|

| 0° | 1.138 | 1.108 | 0.031 | 2.80 |

| 22.5° | 0.958 | 1.037 | −0.079 | −7.62 |

| 45° | 0.850 | 1.039 | −0.188 | −18.10 |

| 67.5° | 0.880 | 1.042 | −0.162 | −15.55 |

| 90° | 1.160 | 1.149 | 0.010 | 0.87 |

Table 6.

Thickness for the AISI 316 samples.

| Measurement Angle | Simulation Thickness [mm] | Sample mean Thickness [mm] | Δ Thickness [mm] | Percentage Variation [%] |

|---|

| 0° | 1.135 | 1.118 | 0.007 | 0.62 |

| 22.5° | 0.952 | 1.025 | −0.073 | −7.12 |

| 45° | 0.840 | 1.002 | −0.160 | −16 |

| 67.5° | 0.800 | 1.030 | −0.230 | −22.3 |

| 90° | 1.135 | 1.140 | −0.005 | −0.43 |

Table 7.

Thickness for the AISI 409 samples.

| Measurement Angle | Simulation Thickness [mm] | Sample Mean Thickness [mm] | Δ Thickness [mm] | Percentage Variation [%] |

|---|

| 0° | 1.170 | 1.076 | 0.094 | 8.7 |

| 22.5° | 1.000 | 0.956 | 0.044 | 4.6 |

| 45° | 0.880 | 0.965 | −0.085 | −8.8 |

| 67.5° | 0.200 | 0.986 | −0.786 | −79.7 |

| 90° | 1.170 | 1.112 | 0.058 | 5.2 |

Table 8.

Thickness for the AISI 441 samples.

| Measurement Angle | Simulation Thickness [mm] | Sample Mean Thickness [mm] | Δ Thickness [mm] | Percentage Variation [%] |

|---|

| 0° | 1.166 | 1.193 | −0.027 | −2.26 |

| 22.5° | 1.013 | 1.049 | −0.036 | −3.43 |

| 45° | 0.874 | 1.035 | −0.161 | −15.56 |

| 67.5° | 0.814 | 1.067 | −0.253 | −23.71 |

| 90° | 1.171 | 1.166 | 0.005 | 0.42 |