1. Introduction

Automobile manufacturers have started to use new types of high strength steels (HSS, AHSS, and UHSS) at the end of the last century, with the aim of increasing the passive safety of vehicles and to reduce vehicle weight to decrease fuel consumption [

1,

2,

3]. However, these types of steels have a lower formability in comparison with steels used for deep drawing. The main reason for this is the higher values of the yield strength and lower ductility of high strength steels [

2]. In addition, aluminium alloys are now widely used in the automotive industry due to advantages, including the low density, high specific strength, good corrosion resistance, exceptional specific stiffness, and so forth [

1]. The implementation of aluminium alloys in car body production can reduce fuel consumption and emissions [

4]. Both high strength steels and aluminium alloys are more prone to wrinkling and springback than mild steels [

1,

5].

Springback in the present refers to a change of shape which is elastically driven. Springback occurs following a sheet-forming operation when the forming loads are removed from the workpiece—sheet metal blank. It is usually unwanted, causing problems in the next forming operations, in assembly, and in the final product. These problems usually degrade the accuracy, appearance, and quality of the products being manufactured [

2,

3,

6]. The most common counter measurement against the springback of car body parts is to design a forming tool with anticipation of springback, thus compensating springback by die design. However, the amount of compensation is a difficult question even for skilled tool designers. In practice, this compensation of die is still sometimes done by the “trial and error” method. This method can be replaced by FEA (finite element analysis)—numerical simulation. With the use of FEA, it is possible to achieve a more accurate prediction of springback [

6,

7,

8]. There are other counter measurements against springback, for example, the stiffening of pressings (use of beads or embossing), crash forming with pressure pads, the use of variable blank holder force, and so forth [

7].

In general, two types of methods are used for springback prediction—finite element analysis and the analytical model. For example, the analytical model for springback prediction of aluminium alloys can be found in the work by Gau and Kinzel [

9]. Analytical methods usually use simplified models of real processes. Thus, analytical models are usually not as accurate in predicting springback as numerical simulations and their use is limited, especially for stampings with complex geometry [

10]. The finite element method (FEM) is a well-known tool for the prediction and analysis of sheet metal deformation. Springback prediction with the use of numerical simulation is not limited by the geometrical complexity of the stamped part like in the case of the analytical model. However, the numerical simulation of springback is more sensitive to the accuracy of the input data than the analytical method. Thus, it is very important to choose the correct input and numerical parameters in the FEA analysis of springback [

11].

Numerical parameters involve the through-thickness integration scheme (which can be implicit, explicit, or a combination of both), the number of integration points, the used elements (type, size, and count), and so forth. Trzepiecinski and Lemu [

12] studied the effect of a number of integration points and integration rules on the springback amount. Their results indicate that at least 5 integration points must be used to achieve accurate springback prediction. The input parameters involve geometry (sheet thickness, tool and sheet dimensions, and so forth), process conditions (type of forming method, tribology, forming forces, forming temperature and speed, and so forth), and material characteristics (Young’s modulus, yield strength, hardening behaviour, yield function, and so forth) [

10,

11]. Slota, Siser, and Dvorak [

13] studied the effects of yield functions (isotropic and orthotropic) on the springback prediction accuracy of aluminium alloys. Their results showed that the orthotropic yield function is more accurate in predicting springback than the isotropic function. In addition, the effect of the die radius on springback was studied. They found out that the increase of the bending radius caused a higher springback of the bend materials. Seo et al. [

14] conducted a study to evaluate the effect of constitutive equations on the springback prediction accuracy. They used two yield functions, Hill48 and Yld2000, in combination with the Yoshida-Uemori hardening model in the finite element (FE) simulation to predict the springback of the U-bend part and drawn T-shape part. Both parts were made of TRIP steel. They found out that it is essential to choose the right yield function to get an accurate prediction of springback. Mulidran et al. [

15] conducted a numerical simulation of the drawing hat-shaped part made of the DP600 and DC04 steels with the use of two forming methods: drawing with a blank holder and crash forming with a pressure pad. They studied the effect of forming methods and the various process parameters on springback amount. Their results indicated that the higher blank holder and pad pressure have positive effects on reducing springback. Additionally, crash forming with a pressure pad showed lower springback in comparison with drawing with a blank holder. The work by Jung et al. [

16] aimed at studying anisotropic hardening behaviour and the springback of AHSS steels. They proposed the modified isotropic-kinematic hardening model, which they used in the simulation of U-bending. Their model showed better results in the predicting springback in comparison with the isotropic hardening model.

The novelty of this work lies in findings which indicate that the isotropic hardening model is sufficient for predicting the springback of formed parts made of aluminium alloy. This model is simpler, and does not need cyclic shear tests. In addition, isotropic hardening models do not use as many parameters as kinematic hardening models. The accuracy of springback prediction with use of the isotropic hardening model was high. In addition, we found out that the phenomenon of the degradation of Young´s modulus is not present for aluminium alloys which are precipitation hardened, and that the degradation is not as significant as in AHSS steels (max. 2% degradation of Young´s modulus for aluminium alloys). Villuendas et al. [

17] and Roca et al. [

18] studied the effect of plastic deformation on the changes of Young´s modulus of metallic alloys. They reported that, in aluminium alloys, there were no appreciable changes in the E value. This conclusion is consistent with our findings. These changes are related to the dislocation density changes. However, even though the dislocation density is high, the values of parameter l (length of dislocations) are very low, due to the interaction between nanometric precipitates and dislocations in the aluminium alloys. The Mott model then shows that the change of Young´s modulus E is very small. Kinematic hardening models also take into account other phenomena, such as the transient behaviour, work-hardening stagnation, and the permanent softening. These phenomena were not observed in the material studied in this work.

These findings have a significant financial impact. For example, it is not necessary to conduct time-consuming tests on special (expensive) equipment, which are used to determine the parameters for kinematic hardening models.

In addition, the detailed analysis of a complex shaped part made of aluminium alloy with a significant thickness of 3 mm, mainly used in car production, was conducted. In most of the studied literature, the research was done on simply shaped parts.

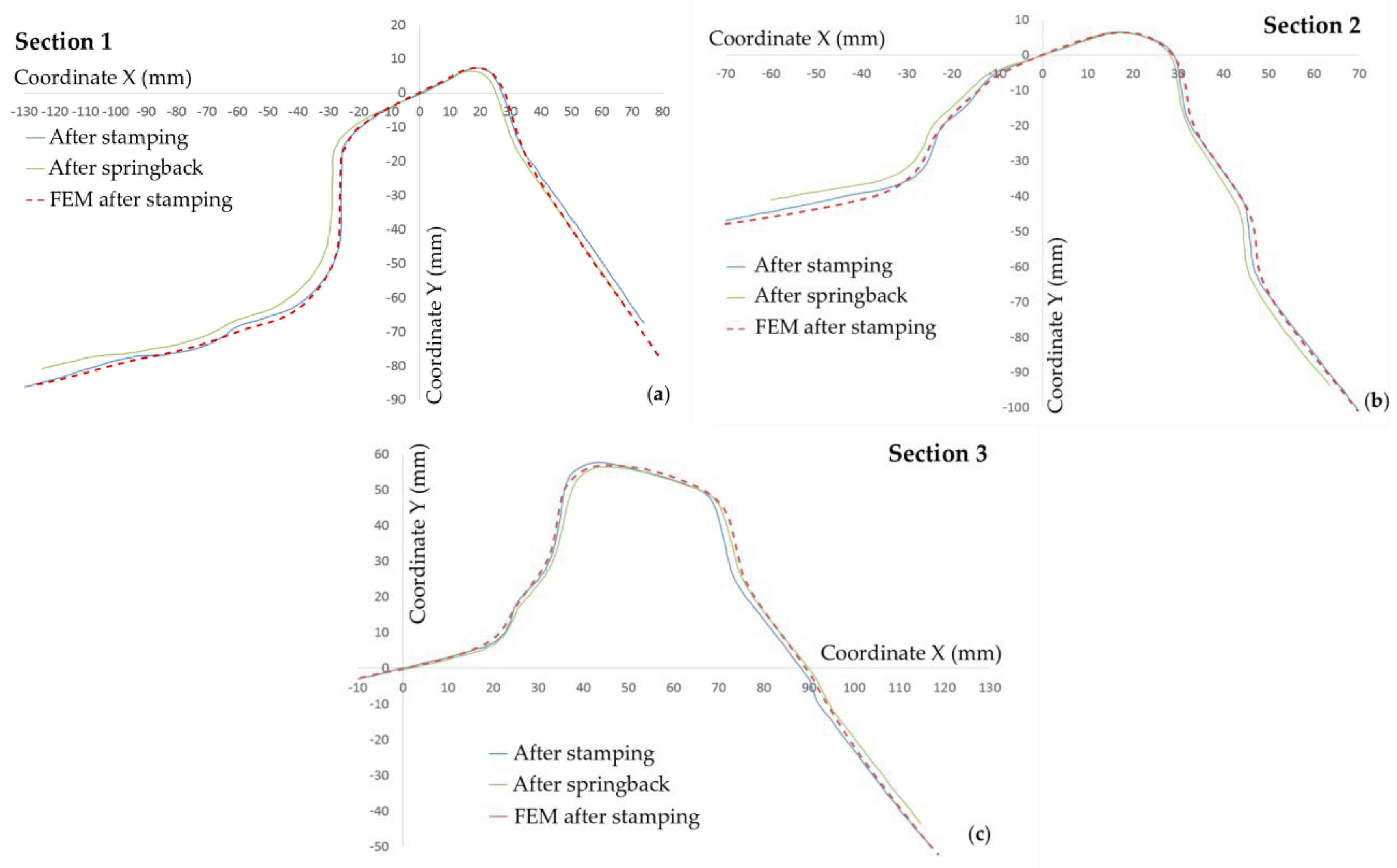

In this research work, a FEM was used to predict the springback of a car body part made of aluminium alloy AA6451-T4. The finite element analysis (FEA) was conducted to investigate the influence of the used yield functions in the numerical simulation on springback prediction accuracy. Three sections were used for springback evaluation; in these sections, the thickness and part profile were measured and compared with the experimental results. The experimental results were given by the automobile manufacturer. Additionally, the computation times for the various yield functions were compared.

3. Numerical Model

The springback computation was performed using the dynamic explicit code in the PAM-Stamp 2G software. The tool setup imported in the simulation software is shown in

Figure 3. The tool consists of punch, blankholder, and die. The tool is aligned with the global z- axis without a plane of symmetry. The blank was positioned between the die and blankholder.

The blank was meshed by the quadrilateral shell elements which were 23 mm in size. The refinement level of the elements was set to 4 so that the smallest elements after refinement had a size of 2.875 mm. The number of integration points was set to 11, which is recommended for springback computation. The friction coefficient was set to 0.08, which responded to the grease lubrication. The initial meshed blank with a rolling direction is illustrated in

Figure 4.

The obtained values of the mechanical properties were used as the basic input for the material model in the FEM simulation. The accuracy of the springback prediction for several yield functions was investigated by the FEM simulation. The yield function describes the material transition from the elastic state to the plastic state. It can be described as a function of the area that limits the elastic area of the multi-axis stress plane. In 1948, Hill introduced the concept of material anisotropy in yield functions. According to Hill’s plasticity conditions [

20], in case of uniaxial load, a local thickness reduction occurs in a direction sensitive to the sample load. Hill assumed that the direction of the compression is in line with the direction of zero extension and, therefore, the deformation of the narrowed areas is only reflected as a reduction in thickness. This is assumed for the plane strain (

σ1—major stress,

σ2—minor stress, and

σ3 = 0). If we assumed that the anisotropy axes are identical with the main guideline strain tensor (

σx =

σ1,

σy =

σ2,

τxy = 0), it is possible to describe the Hill48 yield function by the formula

where

σxx,

σyy, and

σzz are stresses in the RD (

x), TD (

y), and thickness (

z) directions, respectively;

σxy,

σyz, and

σzx are the shear stresses in

xy,

yz, and

zx directions. Parameters

F,

G,

H, and

N are material parameters that describe the anisotropy of the material. If

F =

G =

H = 1, and

N = 3, the Hill48 function is reduced to the von Mises criterion, or as it is called in FEM code, the Hill48 isotropic criterion. A more common description is based on normal anisotropy in the 0°, 45°, and 90° directions to the rolling direction. Then, the material parameters

F,

G,

H, and

N can be described by

For orthotropic hardening law and the values of anisotropy under 1.0, the Hill90 yield function is more suitable. This function is considered to be more suitable for aluminium alloys, and it is based on a non-quadratic transition function. In order to construct this function, the values from the uniaxial tensile test are deficient. For a complete description of this function, the biaxial test data are also required. The function can be described as

where

σ0 is uniaxial tensile stress in the rolling direction,

σ90 is uniaxial tensile stress in the direction normal to the rolling direction,

σb is the stress under the balanced biaxial stress, and the

c,

p, and

q parameters are defined as follows [

21]:

where

R0 is the anisotropy value for the uniaxial tension in the rolling direction and

R90 is the anisotropy value for the uniaxial tension in the in-plane direction, perpendicular to the rolling direction.

The Barlat’s material models describe the plastic behaviour of a material in a more detailed way than Hill’s functions, but the higher number of parameters increases the calculation time. The Barlat89 model needs three parameters for its complete formulation, by which it is possible to describe the plane strain behaviours. Those parameters are defined in

Table 4. The formulation is the following:

where

M is the exponent related to the crystallographic structure of the material, and

k1 and

k2 can be described as

where

a,

h, and

p are the material model parameters.

A more precise function was presented by Barlat in 2003, called Barlat2000, where the linear transformation method was used. In the FEM software, this function is described by the eight parameters shown in

Table 5. The formulation for this model is as follows:

where

a is an exponent related to the crystallographic structure of the material and

and

are two isotropic functions described as follows [

22]:

According to several works [

23,

24,

25], the Vegter yield function should be more suitable for special steels and aluminium alloys due to its more convenient results. The Vegter criterion describes the yield locus more accurately from a series of physically tested points. According to Vegter, it is possible to establish the first quadrant of the yield function on the basis of the basic experimental measurement. To construct the ellipses, the Bezier interpolations between each point need to be performed. Every point requires three parameters to be defined, the main stresses

σ1 and

σ2, and the strain vector ρ = dε

2/dε

1. For a complete description of planar anisotropy, it is necessary to obtain 17 parameters from 9 mechanical tests. The mathematical expression of this function is

where

λ is the parameter for the Bezier interpolation subscript,

i refers to the first reference point,

r and

h refer to a reference point and hinge point, respectively [

26].

It is possible to use a simplified formula—Vegter-Lite. For this optional model, only 7 parameters from three mechanical tests (uniaxial tensile test, hydraulic bulge test, and the measurement of anisotropy) need to be defined. In this model, the second order Bezier interpolation is replaced by the second order NURBS interpolation, and the weight factor w—that controls the position of the curve between the points—is introduced. The formula for this model is

To fully define the material behaviour, the hardening curve of the material is also required. The Voce hardening curve gives the best correlation with the experimental results at an orientation of 0° from the rolling direction. This law provides a sufficient description of the elastic behaviour for aluminium alloys. The Voce hardening law is given by the equation

where

A,

B, and

C are parameters defined in

Table 6.

To determine the failure criteria, Keller´s and Goodwin´s forming limit curve (FLC) model was used [

27]. This empirical formula was obtained from experimental trials, and requires only two parameters: the thickness of the material and the strain hardening coefficient. The formula can be written as follows:

where

t0 is the initial thickness of the sheet and

n is the strain hardening coefficient.

The simulation process consisted of three operations (stamping, trimming, and springback). Stamping was carried out as one continuous process in which the die moved at a speed of 100 mm/s. The blank was positioned between the die and the blankholder during holding. The die movement was set in the −z-direction at 300 mm until the blank was clamped. Subsequently, a blankholding force of 1900 kN was applied. The die and blankholder moved in the −z-direction until the tool was closed. After the part was fully formed, the trimming operation was performed. The trimming curve is shown in

Figure 5.