Predicting the Microstructure of a Valve Head during the Hot Forging of Steel 21-4N

Abstract

:1. Introduction

2. Experimental Program and Analysis

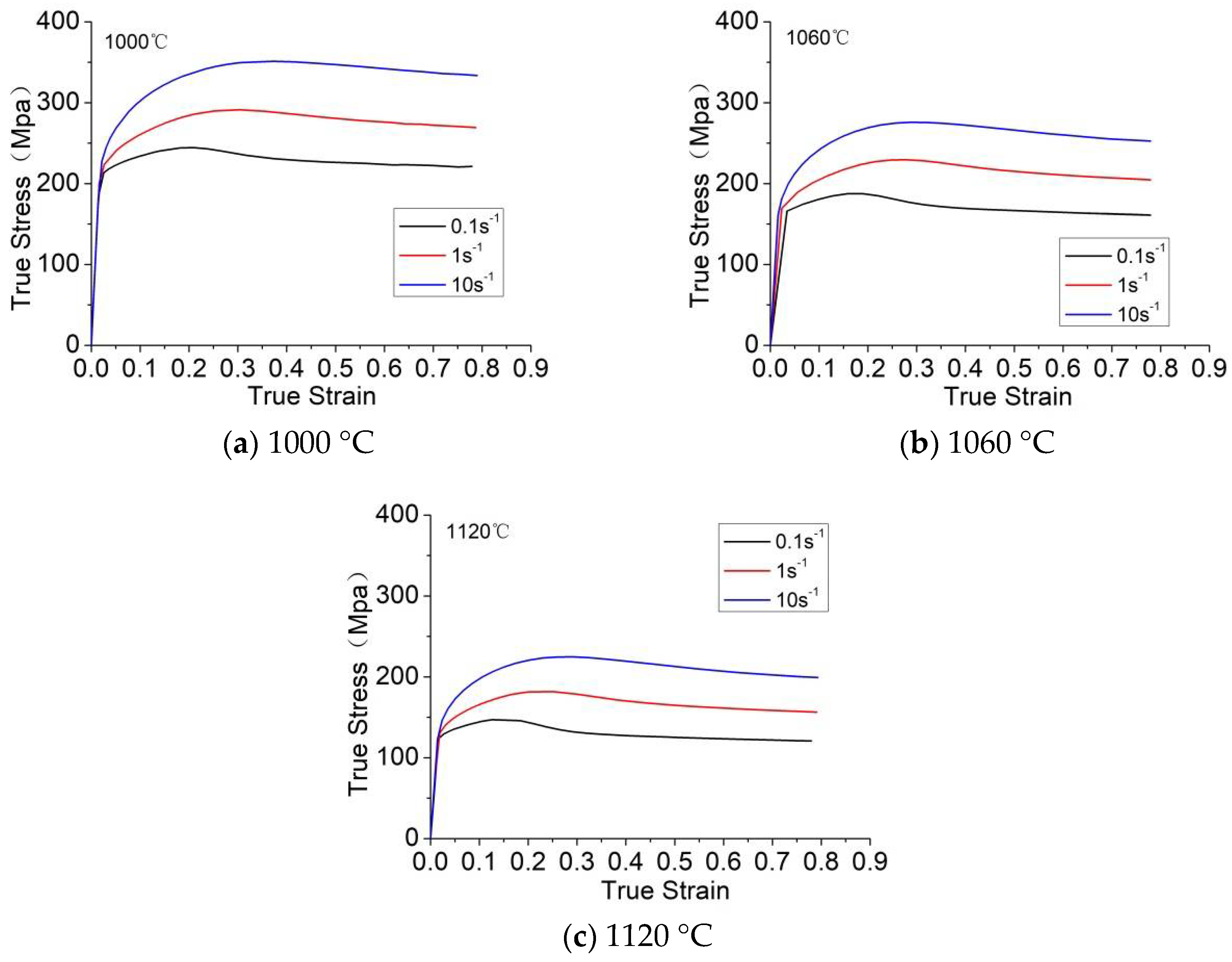

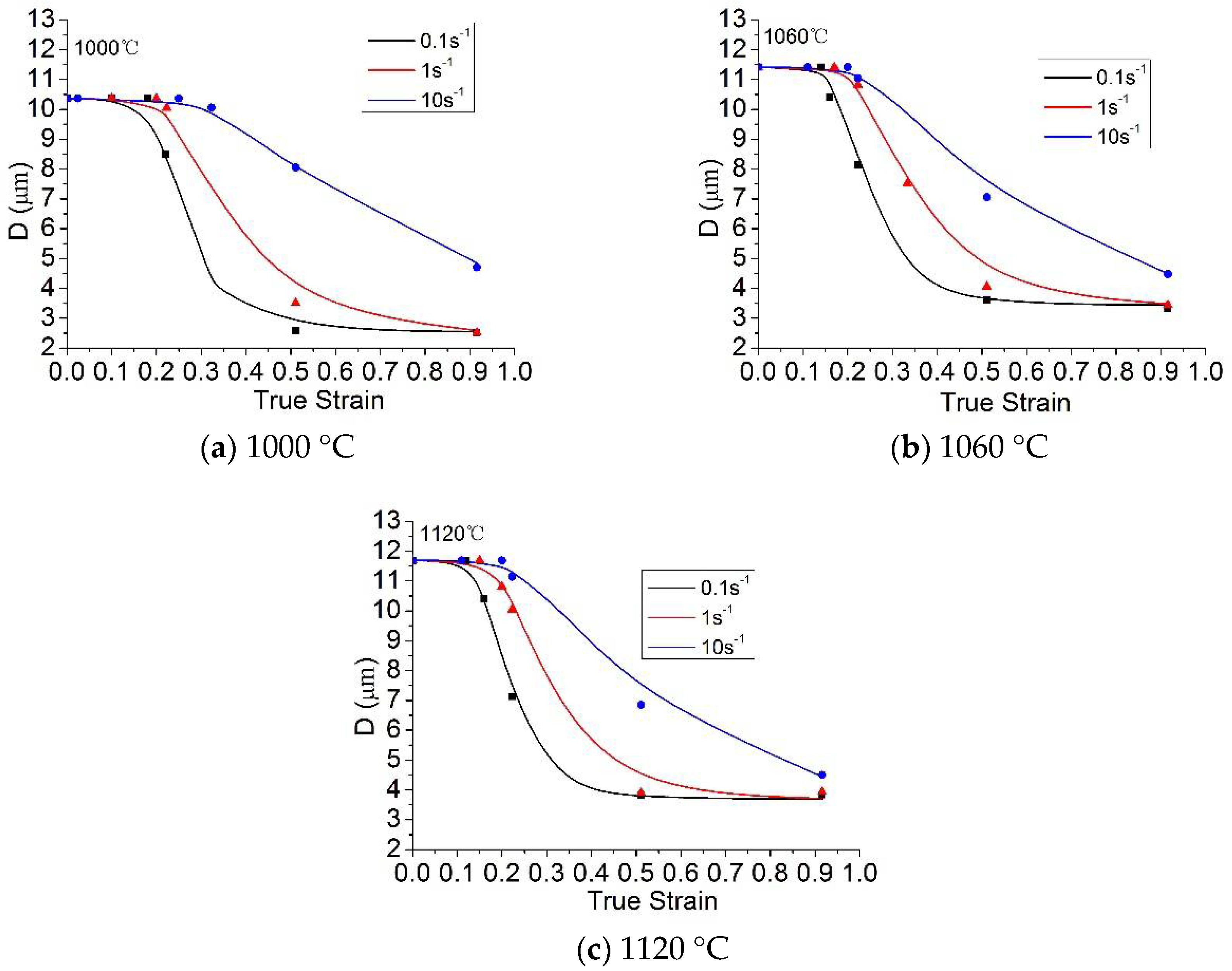

2.1. Compression Tests

2.2. Static-State Grain Growth Tests

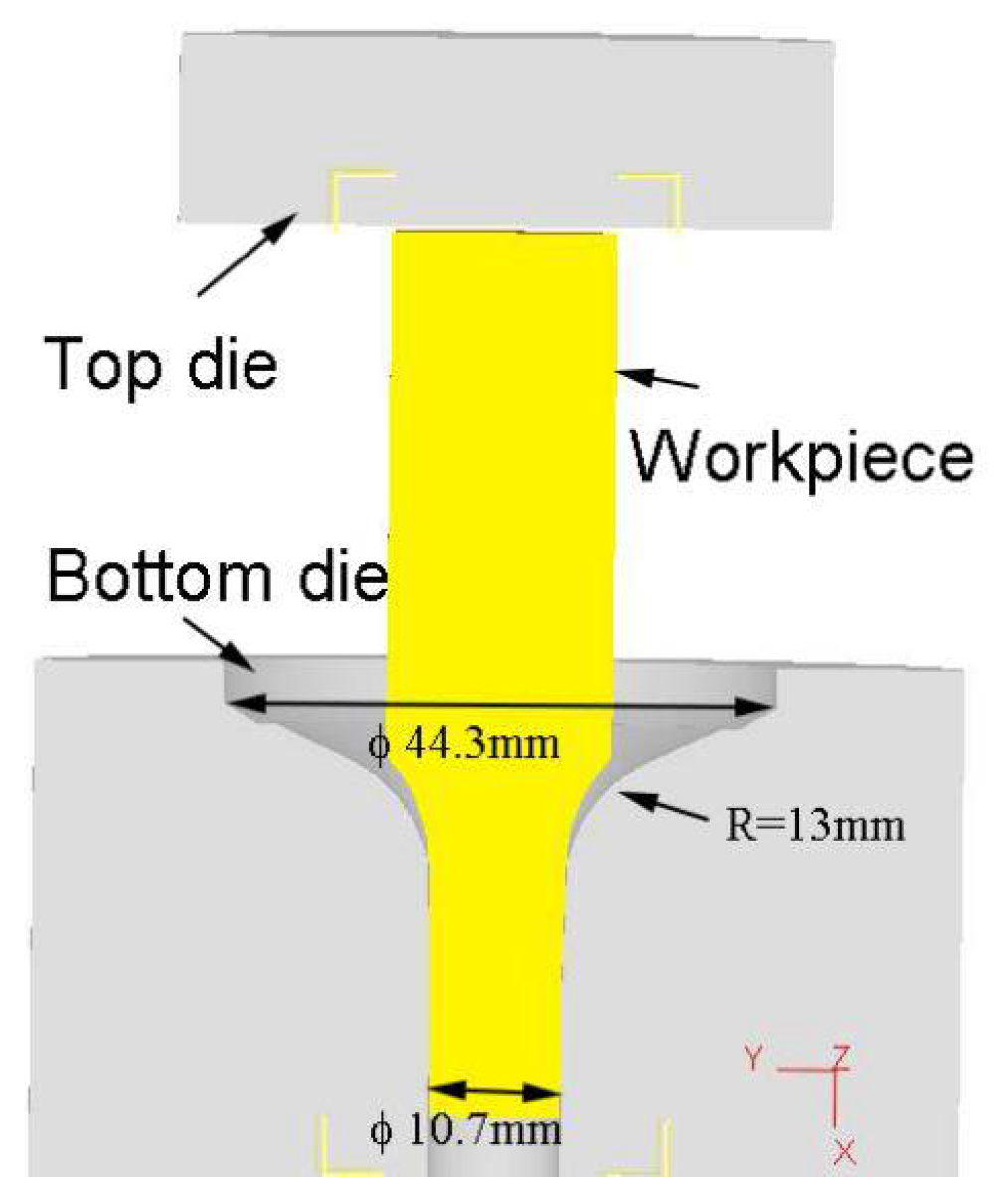

3. FE Modeling of the Hot Forging Process

4. Hot Forging of Valves

5. Constitutive Equations and Microstructural Model of 21-4N

6. Microstructure Evolution of 21-4N in the Forging Process

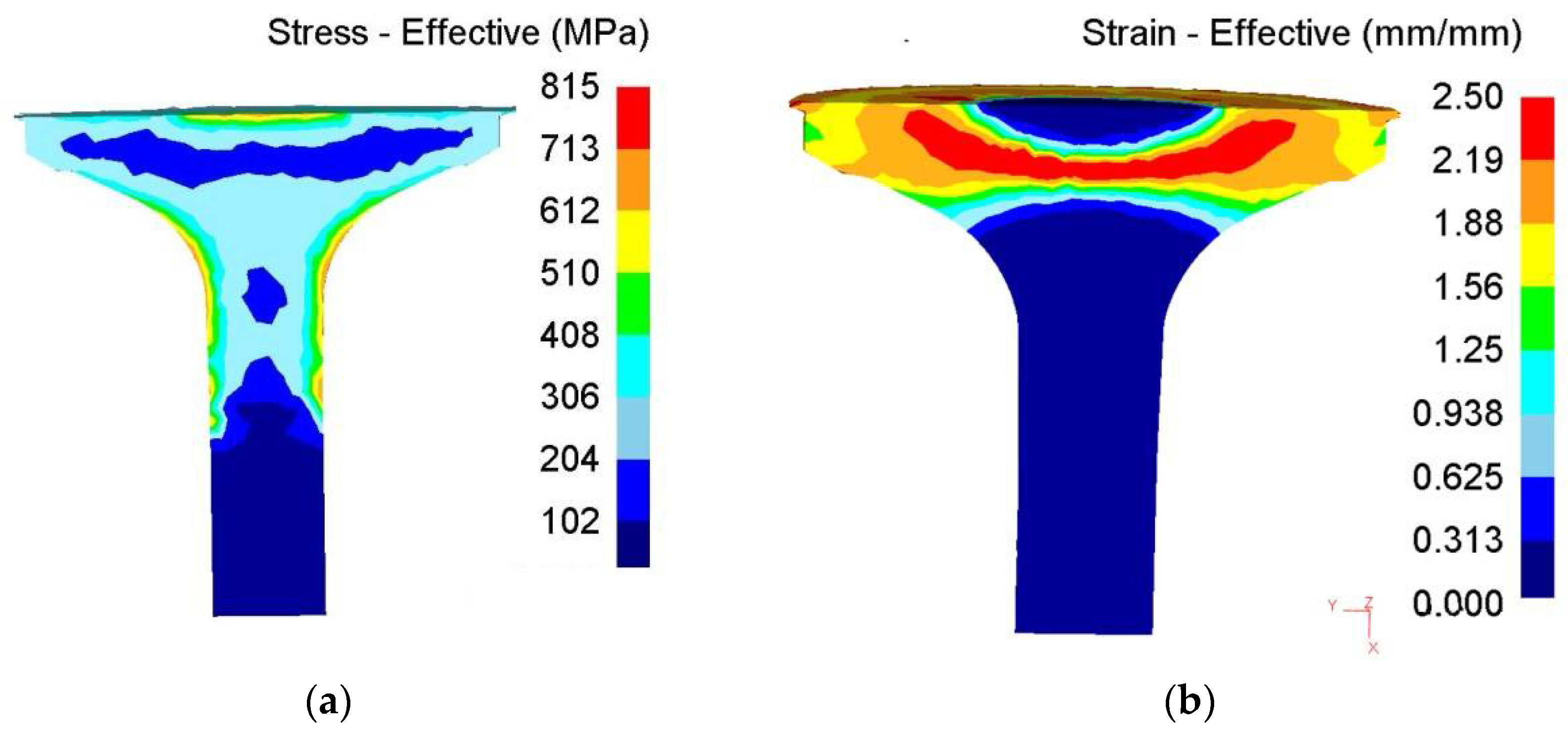

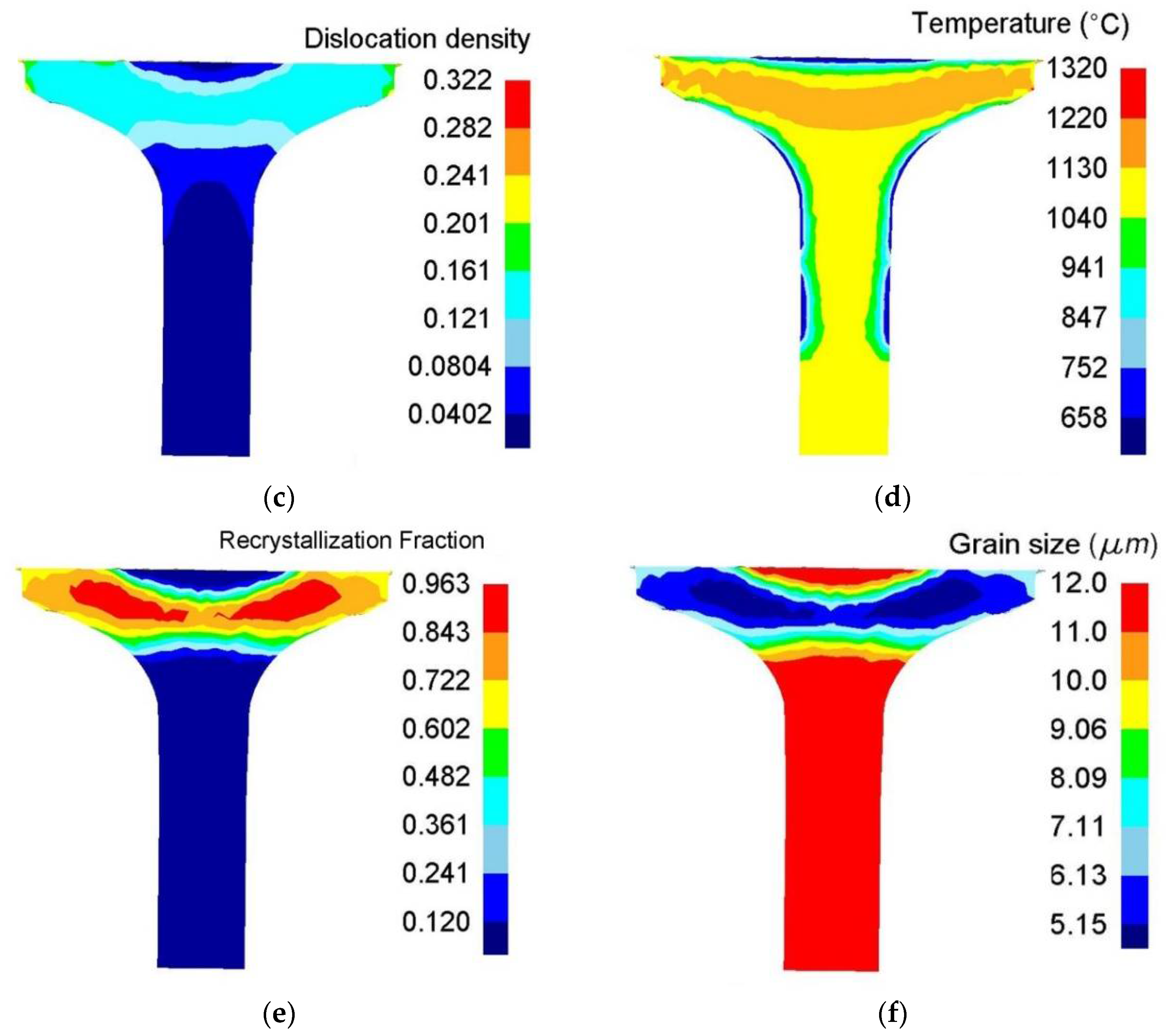

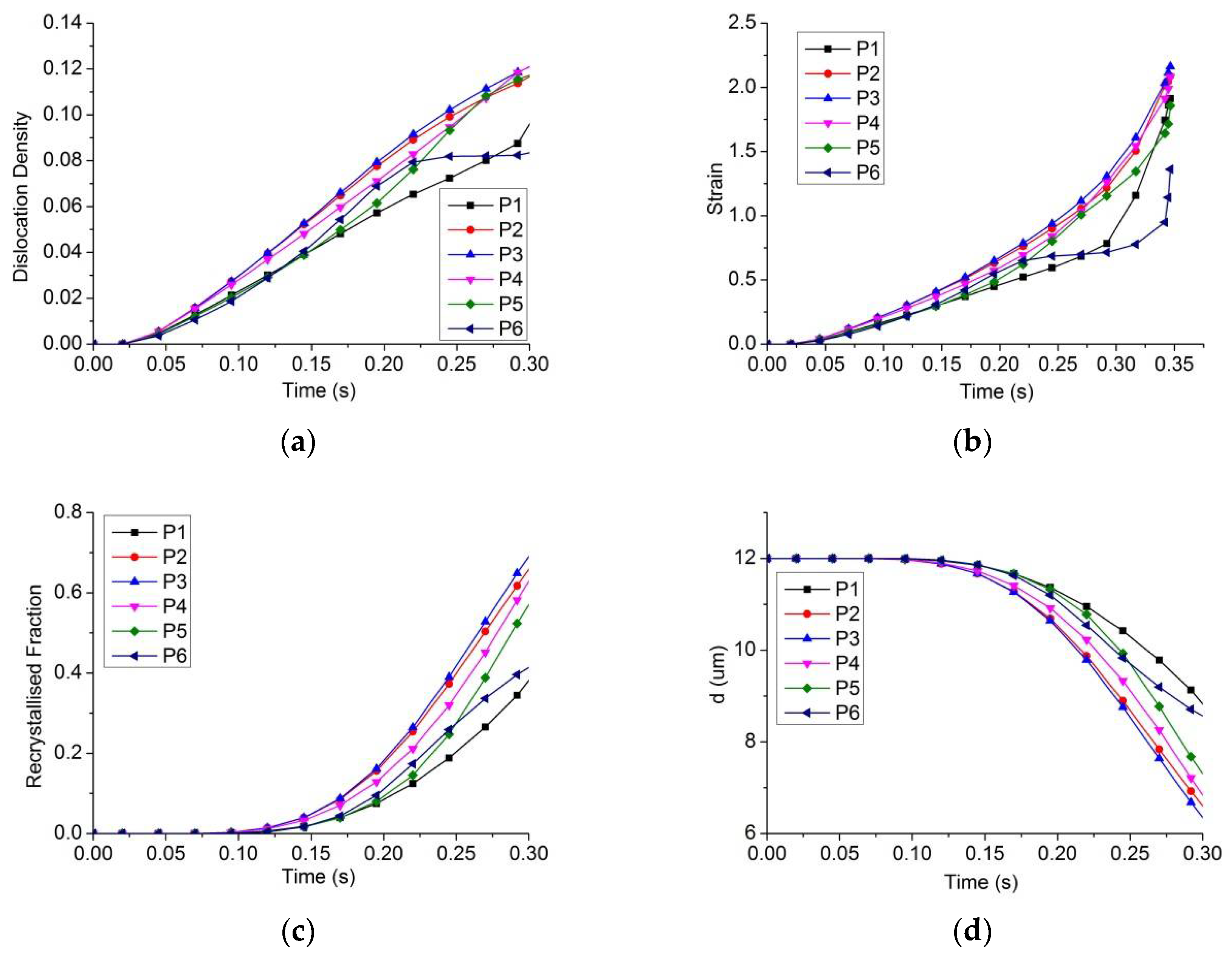

6.1. Predictions of State Variables

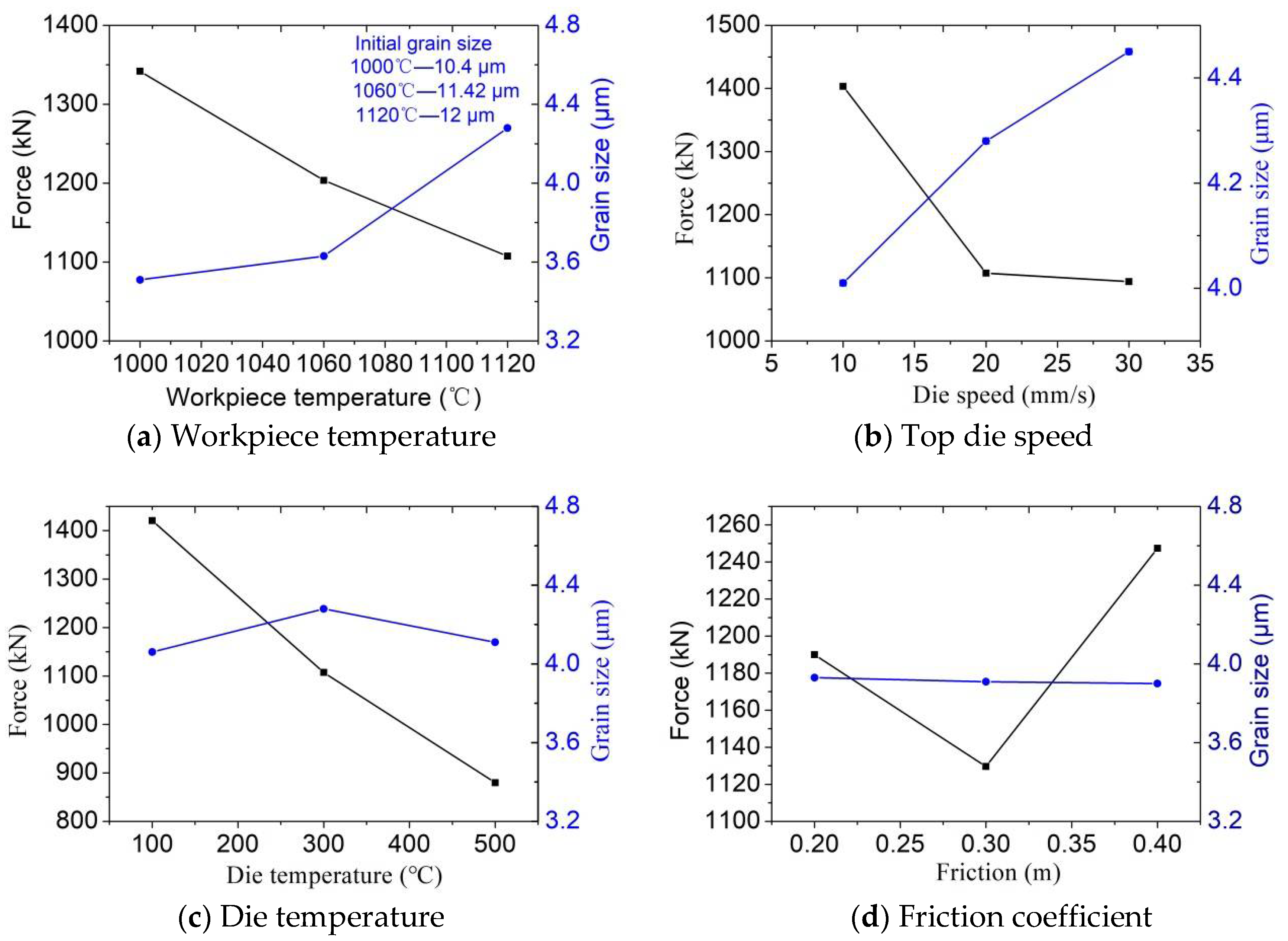

6.2. Effects of Processing Parameters on the Forging Process

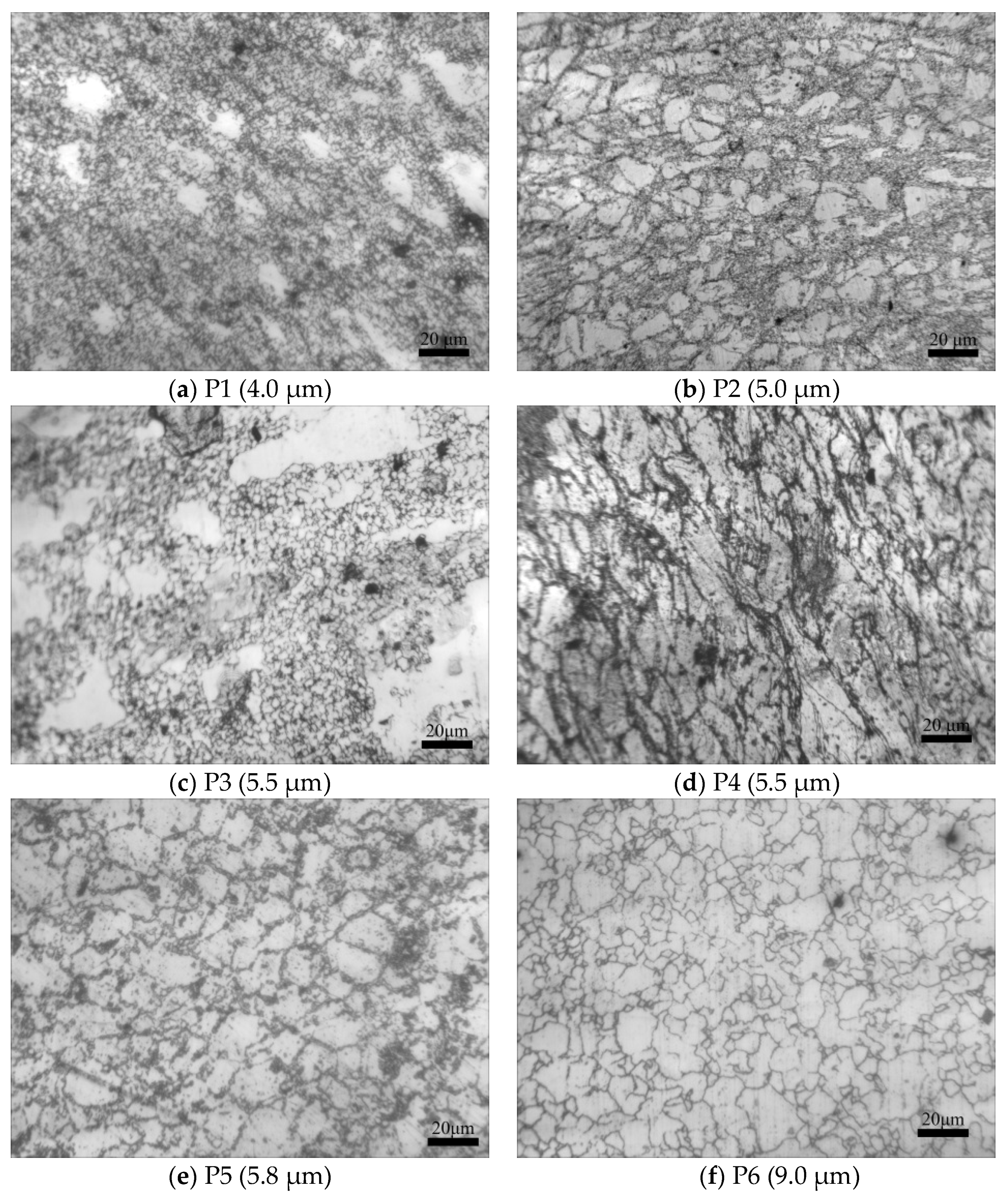

6.3. Average Grain Size by Experiment

7. Conclusions and Future Work

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhu, Y.; Yin, Z.; Xu, J. Microstructural mapping in closed die forging process of superalloy Nimonic 80a valve head. J. Alloys Compd. 2011, 509, 6106–6112. [Google Scholar] [CrossRef]

- Jeong, H.S.; Cho, J.R.; Lee, N.K.; Park, H.C. Simulation of Electric Upsetting and Forging Process for Large Marine Diesel Engine Exhaust Valves. Mater. Sci. Forum 2006, 510–511, 142–145. [Google Scholar] [CrossRef]

- Ji, H.; Liu, J.; Wang, B.; Zhang, Z.; Zhang, T.; Hu, Z. Numerical analysis and experiment on cross wedge rolling and forging for engine valves. J. Mater. Process. Technol. 2015, 221, 233–242. [Google Scholar] [CrossRef]

- Voorwald, H.J.C.; Coisse, R.C.; Cioffi, M.O.H. Fatigue Strength of X45CrSi93 stainless steel applied as internal combustion engine valves. Procedia Eng. 2011, 10, 1256–1261. [Google Scholar] [CrossRef]

- Yu, Z.W.; Xu, X.L. Failure analysis and metallurgical investigation of diesel engine exhaust valves. Eng. Fail. Anal. 2006, 13, 673–682. [Google Scholar] [CrossRef]

- Biba, N.; Lishnij, A.; Vlasov, A. Simulation of coupled problem of electric upsetting. J. Mater. Process. Technol. 1998, 80, 184–187. [Google Scholar] [CrossRef]

- Jeong, H.S.; Cho, J.R.; Park, H.C. Microstructure prediction of Nimonic 80A for large exhaust valve during hot closed die forging. J. Mater. Process. Technol. 2005, 162–163, 504–511. [Google Scholar] [CrossRef]

- Chun, K.J.; Kim, J.H.; Hong, J.S. A study of exhaust valve and seat insert wear depending on cycle numbers. Wear 2007, 263, 1147–1157. [Google Scholar] [CrossRef]

- Ji, H.; Liu, J.; Wang, B.; Fu, X.; Xiao, W.; Hu, Z. A new method for manufacturing hollow valves via cross wedge rolling and forging: Numerical analysis and experiment validation. J. Mater. Process. Technol. 2017, 240, 1–11. [Google Scholar] [CrossRef]

- Jiang, H.; Yang, L.; Dong, J.; Zhang, M.; Yao, Z. The recrystallization model and microstructure prediction of alloy 690 during hot deformation. Mater. Des. 2016, 104, 162–173. [Google Scholar] [CrossRef]

- Wang, C.; Shi, D.; Yang, X.; Li, S.; Dong, C. An improved viscoplastic constitutive model and its application to creep behavior of turbine blade. Mater. Sci. Eng. 2017, 707, 344–355. [Google Scholar] [CrossRef]

- Sun, C.; Liu, G.; Zhang, Q.; Li, R.; Wang, L. Determination of hot deformation behavior and processing maps of IN 028 alloy using isothermal hot compression test. Mater. Sci. Eng. 2014, 595, 92–98. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, S.; Fan, S.; Yan, G. Study on the material characteristic and process parameters of the open-die warm extrusion process of spline shaft with 42CrMo steel. J. Alloys Compd. 2013, 571, 12–20. [Google Scholar] [CrossRef]

- Xiao, J.; Li, D.S.; Li, X.Q.; Deng, T.S. Constitutive modeling and microstructure change of Ti–6Al–4V during the hot tensile deformation. J. Alloys Compd. 2012, 541, 346–352. [Google Scholar] [CrossRef]

- Lin, Y.C.; Deng, J.; Jiang, Y.; Wen, D.; Liu, G. Effects of initial δ phase on hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy. Mater. Sci. Eng. A 2014, 598, 251–262. [Google Scholar] [CrossRef]

- Chai, R.; Su, W.; Guo, C.; Zhang, F. Constitutive relationship and microstructure for 20CrMnTiH steel during warm deformation. Mater. Sci. Eng. A 2012, 556, 473–478. [Google Scholar] [CrossRef]

- Xiao, Y.; Guo, C. Constitutive modelling for high temperature behavior of 1Cr12Ni3Mo2VNbN martensitic steel. Mater. Sci. Eng. A 2011, 528, 5081–5087. [Google Scholar] [CrossRef]

- Chen, X.; Lin, Y.C.; Chen, M.; Li, H.; Wen, D.; Zhang, J.; He, M. Microstructural evolution of a nickel-based superalloy during hot deformation. Mater. Des. 2015, 77, 41–49. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.; Zhong, J. Effect of temperature and strain rate on the compressive deformation behavior of 42CrMo steel. J. Mater. Process. Technol. 2008, 205, 308–315. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 2008, 42, 470–477. [Google Scholar] [CrossRef]

- Tang, X.; Wang, B.; Ji, H.; Fu, X.; Xiao, W. Behavior and modeling of microstructure evolution during metadynamic recrystallization of a Ni-based superalloy. Mater. Sci. Eng. A 2016, 675, 192–203. [Google Scholar] [CrossRef]

- Tang, X.; Wang, B.; Zhang, H.; Fu, X.; Ji, H. Study on the microstructure evolution during radial-axial ring rolling of IN718 using a unified internal state variable material model. Int. J. Mech. Sci. 2017, 128–129, 235–252. [Google Scholar] [CrossRef]

- Quan, G.; Mao, A.; Luo, G.; Liang, J.; Wu, D.; Zhou, J. Constitutive modeling for the dynamic recrystallization kinetics of as-extruded 3Cr20Ni10W2 heat-resistant alloy based on stress–strain data. Mater. Des. 2013, 52, 98–107. [Google Scholar] [CrossRef]

- Ji, H.; Liu, J.; Wang, B.; Tang, X.; Lin, J.; Huo, Y. Microstructure evolution and constitutive equations for the high-temperature deformation of 5Cr21Mn9Ni4N heat-resistant steel. J. Alloys Compd. 2017, 693, 674–687. [Google Scholar] [CrossRef]

- Li, N.; Sun, C.; Guo, N.; Mohamed, M.; Lin, J.; Matsumoto, T.; Liu, C. Experimental investigation of boron steel at hot stamping conditions. J. Mater. Process. Technol. 2016, 228, 2–10. [Google Scholar] [CrossRef]

- Huo, Y.; Bai, Q.; Wang, B.; Lin, J.; Zhou, J. A new application of unified constitutive equations for cross wedge rolling of a high-speed railway axle steel. J. Mater. Process. Technol. 2015, 223, 274–283. [Google Scholar] [CrossRef]

- Ma, W.; Wang, B.; Bian, J.; Tang, X.; Yang, L.; Huo, Y. A New Damage Constitutive Model for Thermal Deformation of AA6111 Sheet. Metall. Mater. Trans. A 2015, 46, 2748–2757. [Google Scholar] [CrossRef]

- Yang, L.; Wang, B.; Liu, G.; Zhao, H.; Xiao, W. Behavior and modeling of flow softening and ductile damage evolution in hot forming of TA15 alloy sheets. Mater. Des. 2015, 85, 135–148. [Google Scholar] [CrossRef]

- Tang, X.; Wang, B.; Zhang, N.; Huo, Y.; Zhou, J. Modeling of microstructural evolution and flow behavior of superalloy IN718 using physically based internal state variables. Rare Metals. 2015, 1–8. [Google Scholar] [CrossRef]

- Yang, L.; Wang, B.; Liu, G.; Zhao, H.; Zhou, J. Hot Tensile Behavior and Self-consistent Constitutive Modeling of TA15 Titanium Alloy Sheets. J. Mater. Eng. Perform. 2015, 24, 4647–4655. [Google Scholar] [CrossRef]

- Mohamed, M.S.; Foster, A.D.; Lin, J.; Balint, D.S.; Dean, T.A. Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modelling. Int. J. Mach. Tools Manuf. 2012, 53, 27–38. [Google Scholar] [CrossRef]

- Lin, J.; Liu, Y.; Farrugia, D.C.J.; Zhou, M. Development of dislocation-based unified material model for simulating microstructure evolution in multipass hot rolling. Philos. Mag. 2005, 85, 1967–1987. [Google Scholar] [CrossRef]

- Lin, J.; Dean, T.A. Modelling of microstructure evolution in hot forming using unified constitutive equations. J. Mater. Process. Technol. 2005, 167, 354–362. [Google Scholar] [CrossRef]

- Lin, J. A set of unified constitutive equations for modelling microstructure evolution in hot deformation. J. Mater. Process. Technol. 2003, 143–144, 281–285. [Google Scholar] [CrossRef]

- Sun, C.Y.; Guo, N.; Fu, M.W.; Liu, C. Experimental investigation and modeling of ductile fracture behavior of TRIP780 steel in hot working conditions. Int. J. Mech. Sci. 2016, 110, 108–115. [Google Scholar] [CrossRef]

- Gao, P.; Yang, H.; Fan, X.; Zhu, S. Unified modeling of flow softening and globularization for hot working of two-phase titanium alloy with a lamellar colony microstructure. J. Alloys Compd. 2014, 600, 78–83. [Google Scholar] [CrossRef]

- Cao, J.; Lin, J.; Dean, T.A. An implicit unitless error and step-size control method in integrating unified viscoplastic/creep ODE-type constitutive equations. Int. J. Numer. Methods Eng. 2008, 73, 1094–1112. [Google Scholar] [CrossRef]

- Cao, J.; Lin, J. A study on formulation of objective functions for determining material models. Int. J. Mech. Sci. 2008, 50, 193–204. [Google Scholar] [CrossRef]

- Huo, Y.; Lin, J.; Bai, Q.; Wang, B.; Tang, X.; Ji, H. Prediction of microstructure and ductile damage of a high-speed railway axle steel during cross wedge rolling. J. Mater. Process. Technol. 2017, 239, 359–369. [Google Scholar] [CrossRef]

- Ma, W.; Wang, B.; Fu, L.; Zhou, J.; Huang, M. Effect of friction coefficient in deep drawing of AA6111 sheet at elevated temperatures. Trans. Nonferrous Met. Soc. 2015, 25, 2342–2351. [Google Scholar] [CrossRef]

- Zhan, L.; Lin, J.; Dean, T.A. A review of the development of creep age forming: Experimentation, modelling and applications. Int. J. Mach. Tools Manuf. 2011, 51, 1–17. [Google Scholar] [CrossRef]

| C | Cr | Mn | Ni | N | Si | S | P | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.48–0.58 | 20.0–22.0 | 8.0–10.0 | 3.25–4.0 | 0.35–0.50 | ≤0.35 | ≤0.03 | ≤0.04 | Bal. |

| Temperature | Strain Rate (s−1) | Grain Size When Strain Is 0 | Grain Size When Strain Is 0.223 | Grain Size When Strain Is 0.511 | Grain Size When Strain Is 0.916 |

|---|---|---|---|---|---|

| 1000 °C | 0.1 | 10.36 | 7.54 | 4.52 | 3.75 |

| 1 | 10.36 | 8.50 | 4.77 | 3.74 | |

| 10 | 10.36 | 9.36 | 4.99 | 3.88 | |

| 1060 °C | 0.1 | 11.42 | 9.13 | 5.61 | 5.33 |

| 1 | 11.42 | 10.41 | 6.41 | 5.54 | |

| 10 | 11.42 | 11.42 | 7.57 | 5.71 | |

| 1120 °C | 0.1 | 11.69 | 9.33 | 7.30 | 6.23 |

| 1 | 11.69 | 10.04 | 8.03 | 6.44 | |

| 10 | 11.69 | 11.69 | 9.10 | 6.16 |

| Temperature | 0 min | 10 min | 20 min | 30 min | 40 min |

|---|---|---|---|---|---|

| 1000 °C | 9.54 | 9.89 | 9.95 | 10.69 | 11.56 |

| 1060 °C | 9.54 | 10.61 | 11.53 | 11.8 | 12.36 |

| 1120 °C | 9.54 | 12.18 | 13.46 | 14.56 | 14.73 |

| Parameter | Value |

|---|---|

| Speed of top die (mm/s) | 10, 20, 30 |

| Initial temperature of workpiece (°C) | 1.100 |

| Die temperature (°C) | 300 |

| Environment temperature (°C) | 20 |

| Heat transfer coefficient (N/s/mm/°C) | 30 |

| Convection coefficient (N/s/mm/°C) | 0.02 |

| Friction factor (workpiece and die) | 0.3 |

| Mesh elements for billet | 60,000 |

| Die material | 4Cr5MoSiV1 |

| Billet material | 21-4N |

| Material Constants | Values | Material Constants | Values | Material Constants | Values |

|---|---|---|---|---|---|

| 8.771 × 10−37 | 0.325 | 0.041217 | |||

| 14.66 | 45.8748 | 3.7844 | |||

| 1.069918 | 55,787.08 | 1.0432 | |||

| 2.055 × 10−13 | 0.105 | 1 | |||

| 9.89 | 0.11646 | 373,209.6 | |||

| 88,377.82 | 39,824.16 | 73,122.4 | |||

| 384.56 | 1.495 | 1.5637 | |||

| 56,941 | 64,481 | 14.7205 | |||

| 108,140 | 175,610 | 0.5757 | |||

| 0.7788 | 136.54 | 47,869.21 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, H.; Huang, X.; Ma, C.; Pei, W.; Liu, J.; Wang, B. Predicting the Microstructure of a Valve Head during the Hot Forging of Steel 21-4N. Metals 2018, 8, 391. https://doi.org/10.3390/met8060391

Ji H, Huang X, Ma C, Pei W, Liu J, Wang B. Predicting the Microstructure of a Valve Head during the Hot Forging of Steel 21-4N. Metals. 2018; 8(6):391. https://doi.org/10.3390/met8060391

Chicago/Turabian StyleJi, Hongchao, Xiaomin Huang, Chenjun Ma, Weichi Pei, Jinping Liu, and Baoyu Wang. 2018. "Predicting the Microstructure of a Valve Head during the Hot Forging of Steel 21-4N" Metals 8, no. 6: 391. https://doi.org/10.3390/met8060391

APA StyleJi, H., Huang, X., Ma, C., Pei, W., Liu, J., & Wang, B. (2018). Predicting the Microstructure of a Valve Head during the Hot Forging of Steel 21-4N. Metals, 8(6), 391. https://doi.org/10.3390/met8060391