A Comparative Study on the Effect of Welding Parameters of Austenitic Stainless Steels Using Artificial Neural Network and Taguchi Approaches with ANOVA Analysis

Abstract

:1. Introduction

2. Materials and Methods

3. Results

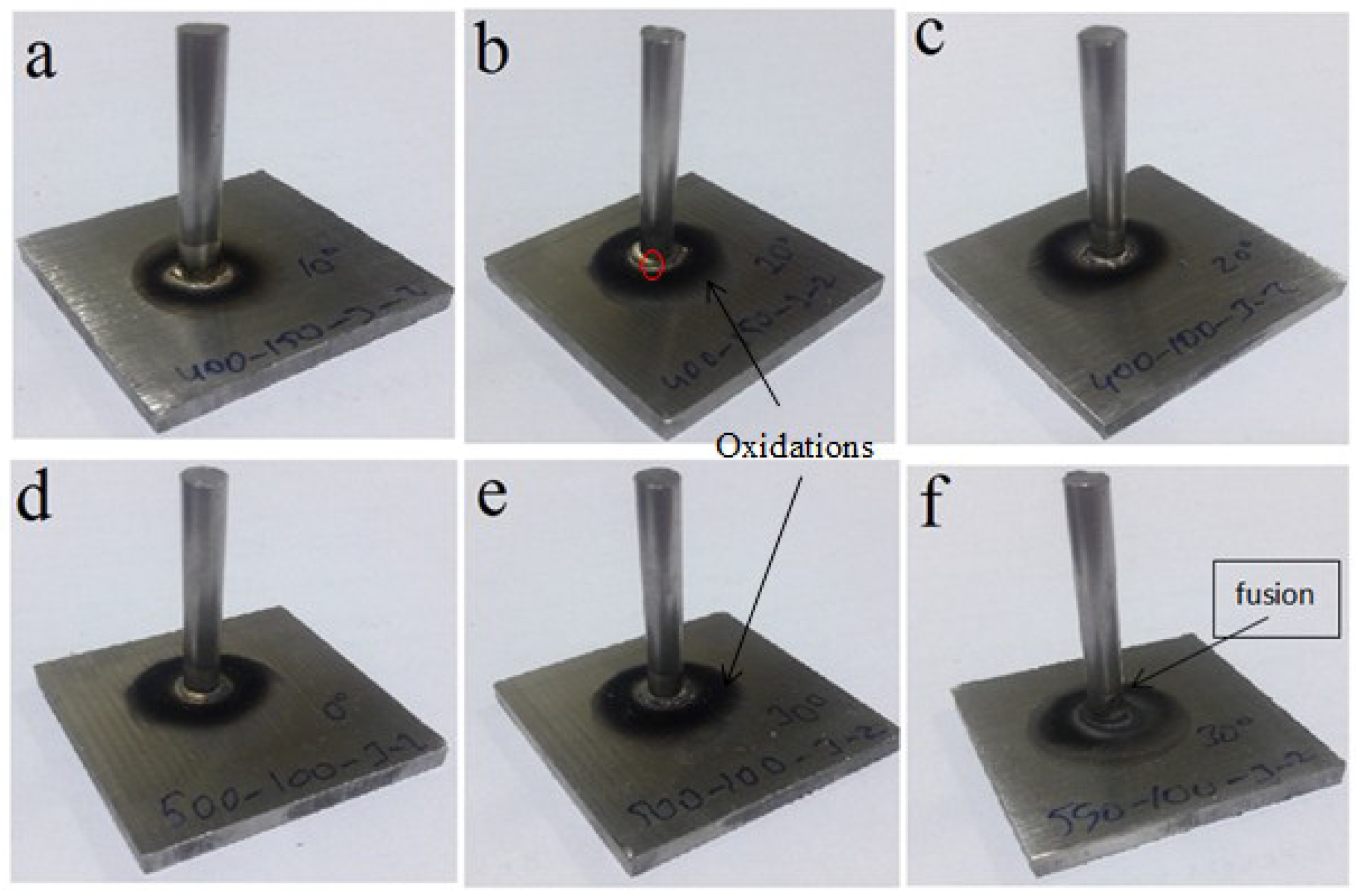

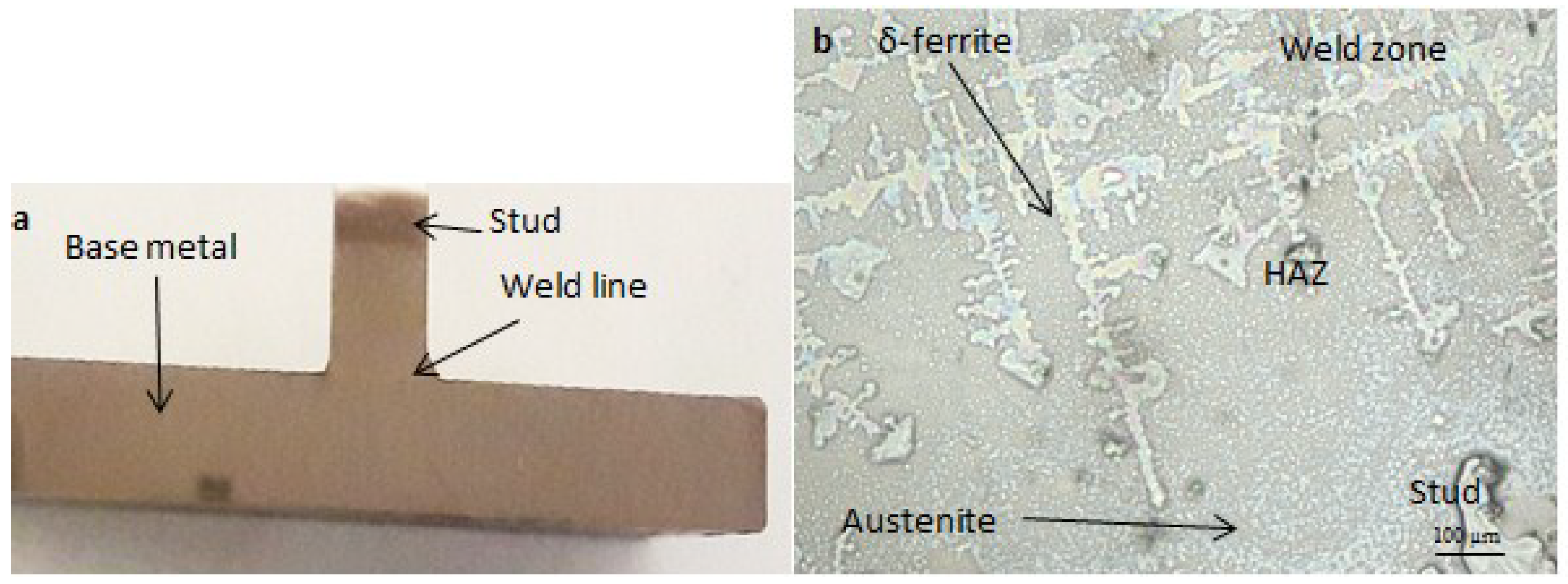

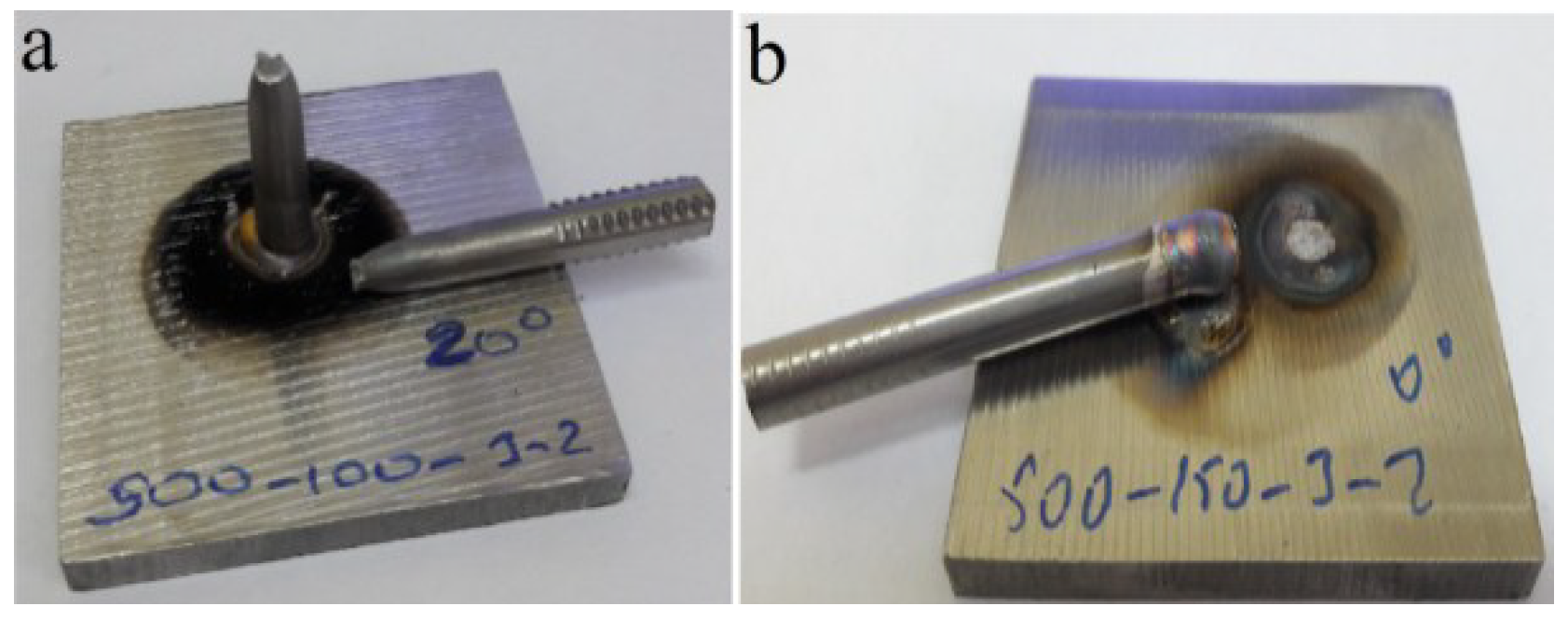

3.1. Macro-Micro Structures of Welds

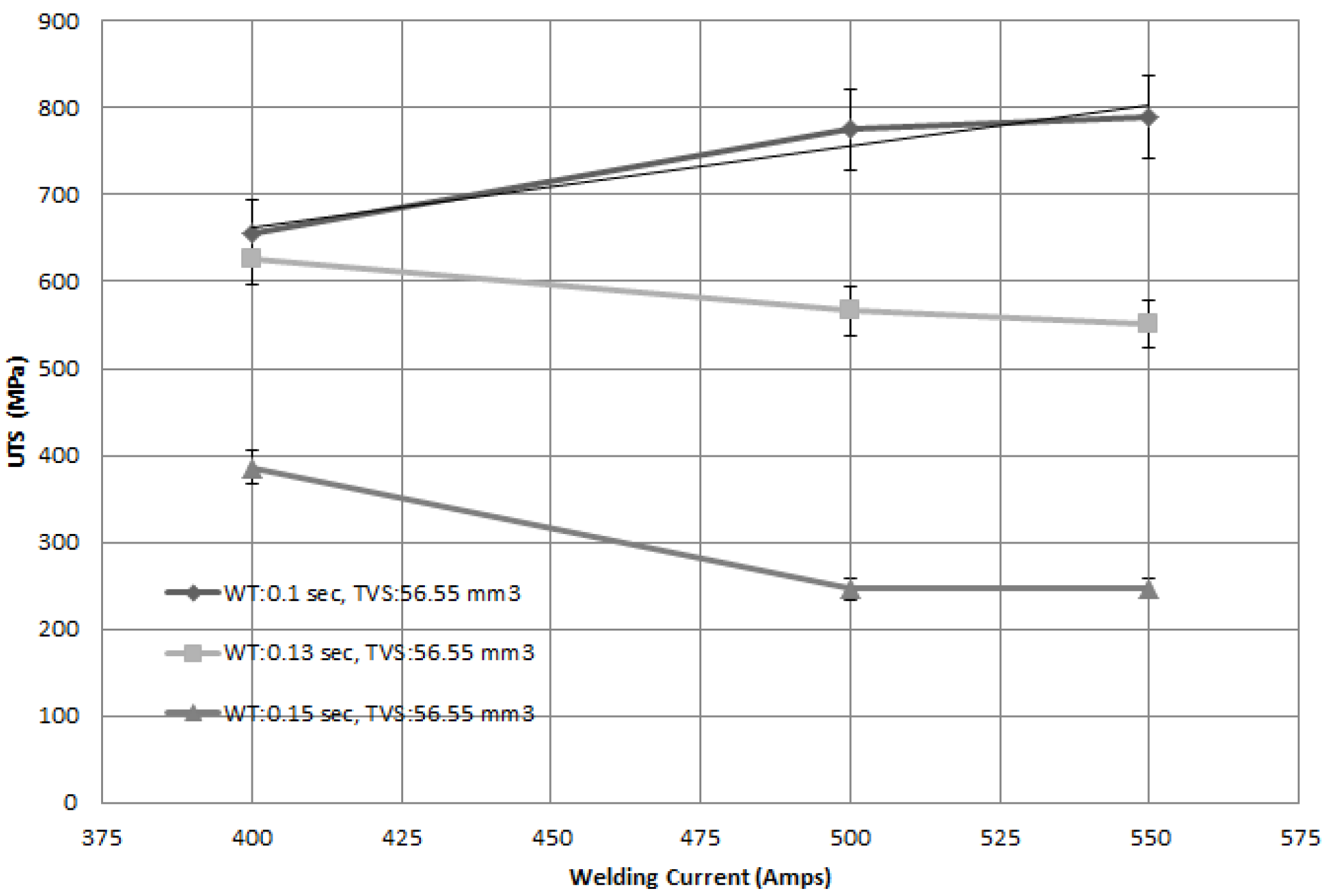

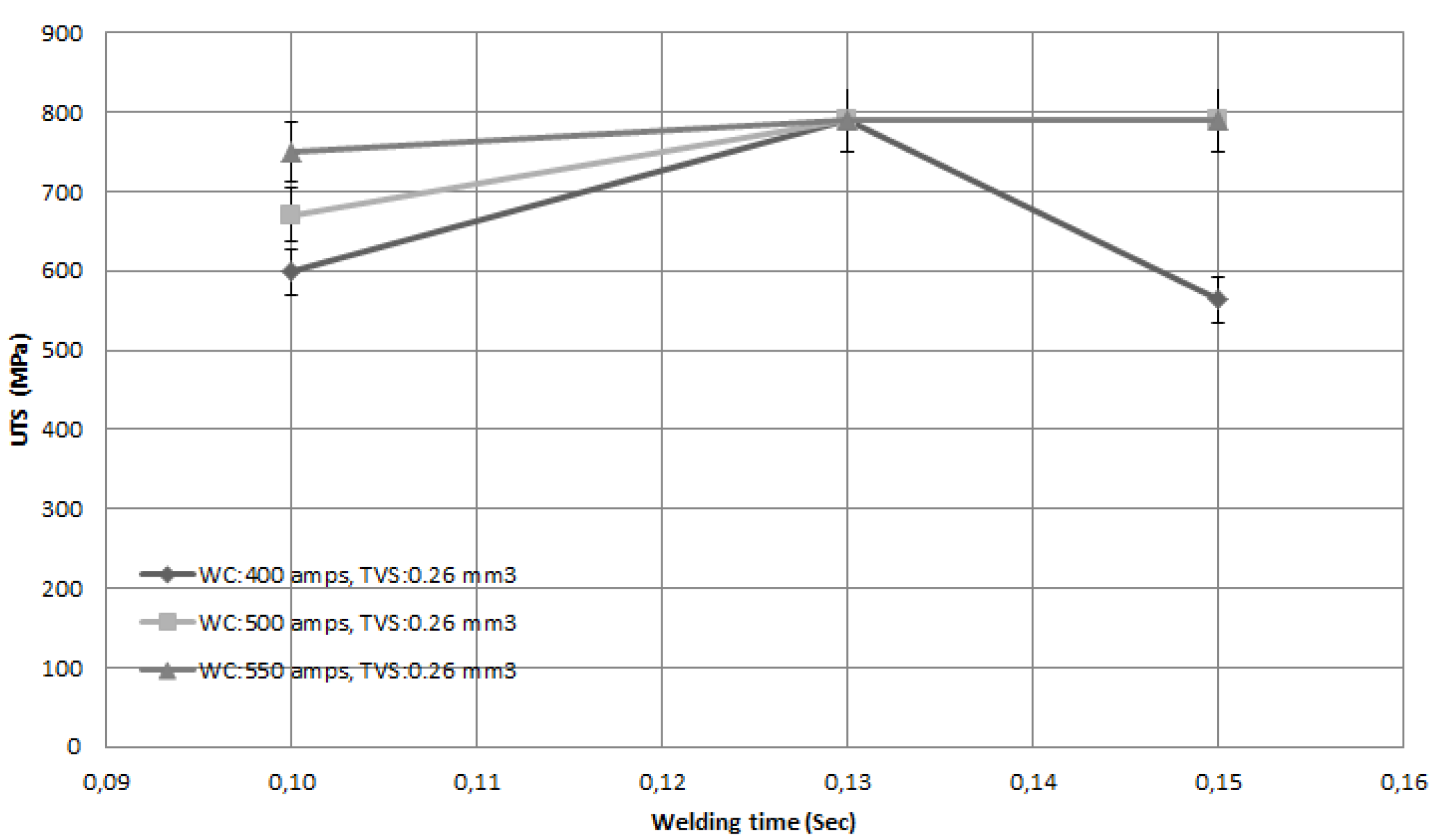

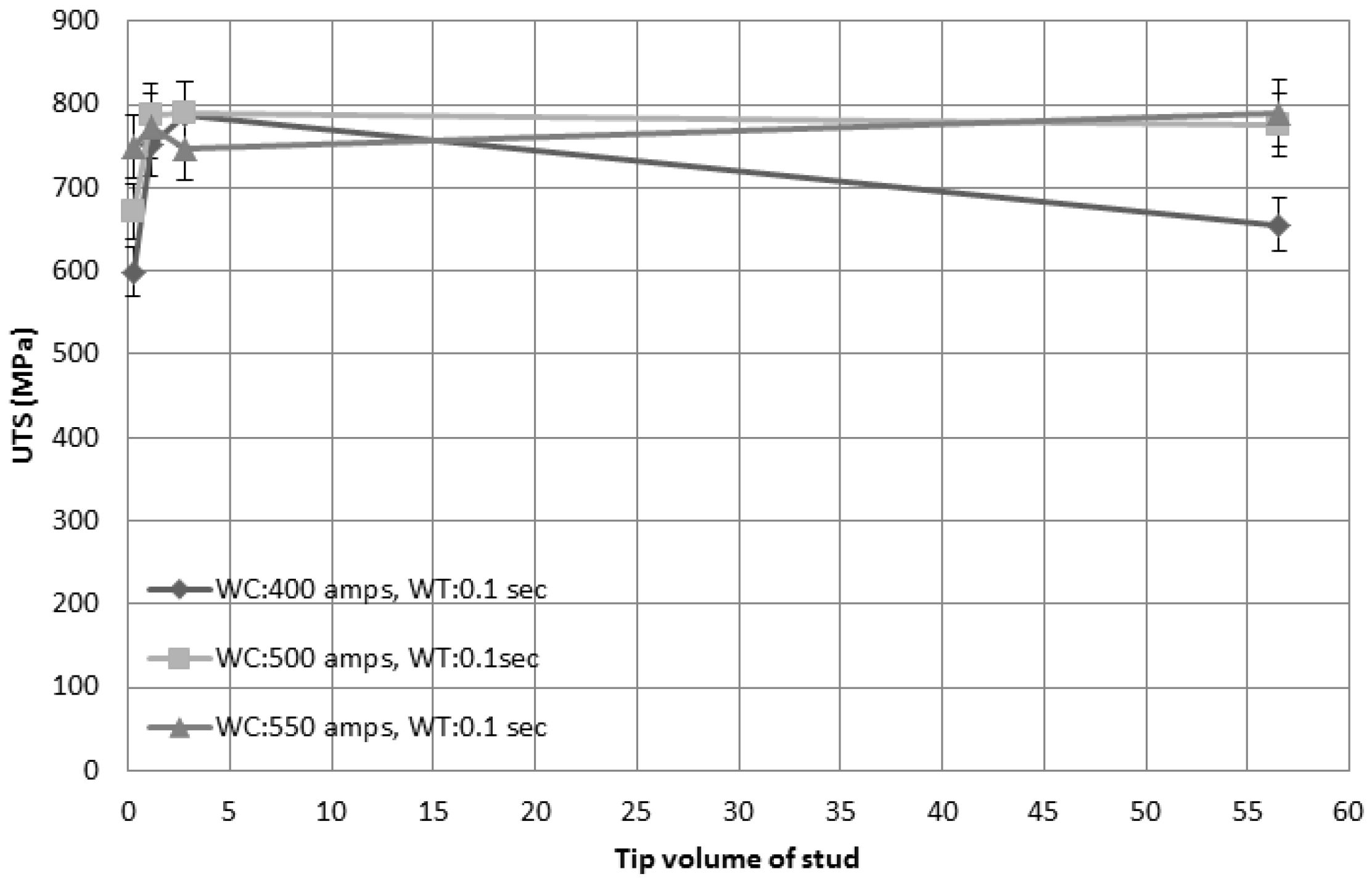

3.2. Mechanical Properties

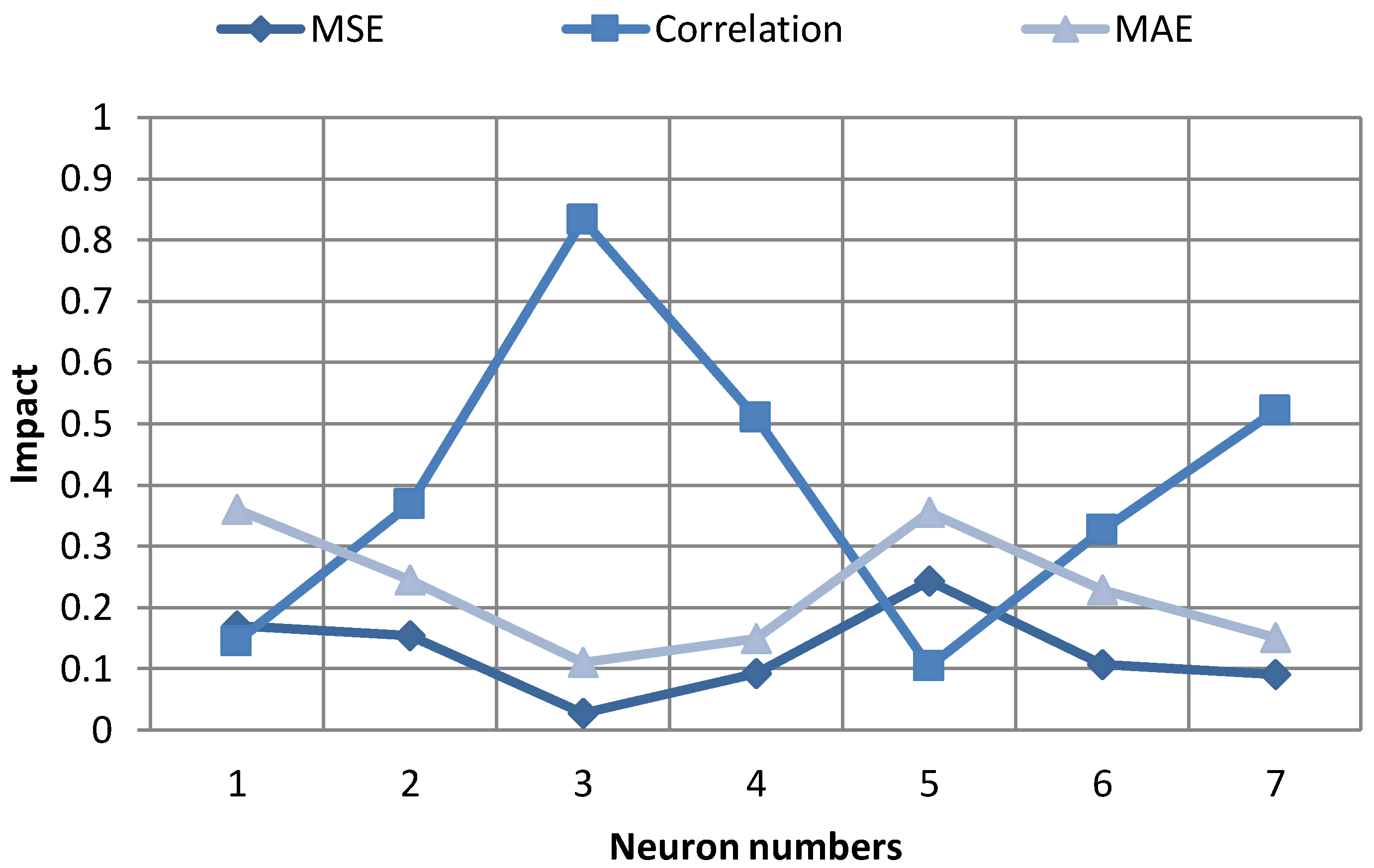

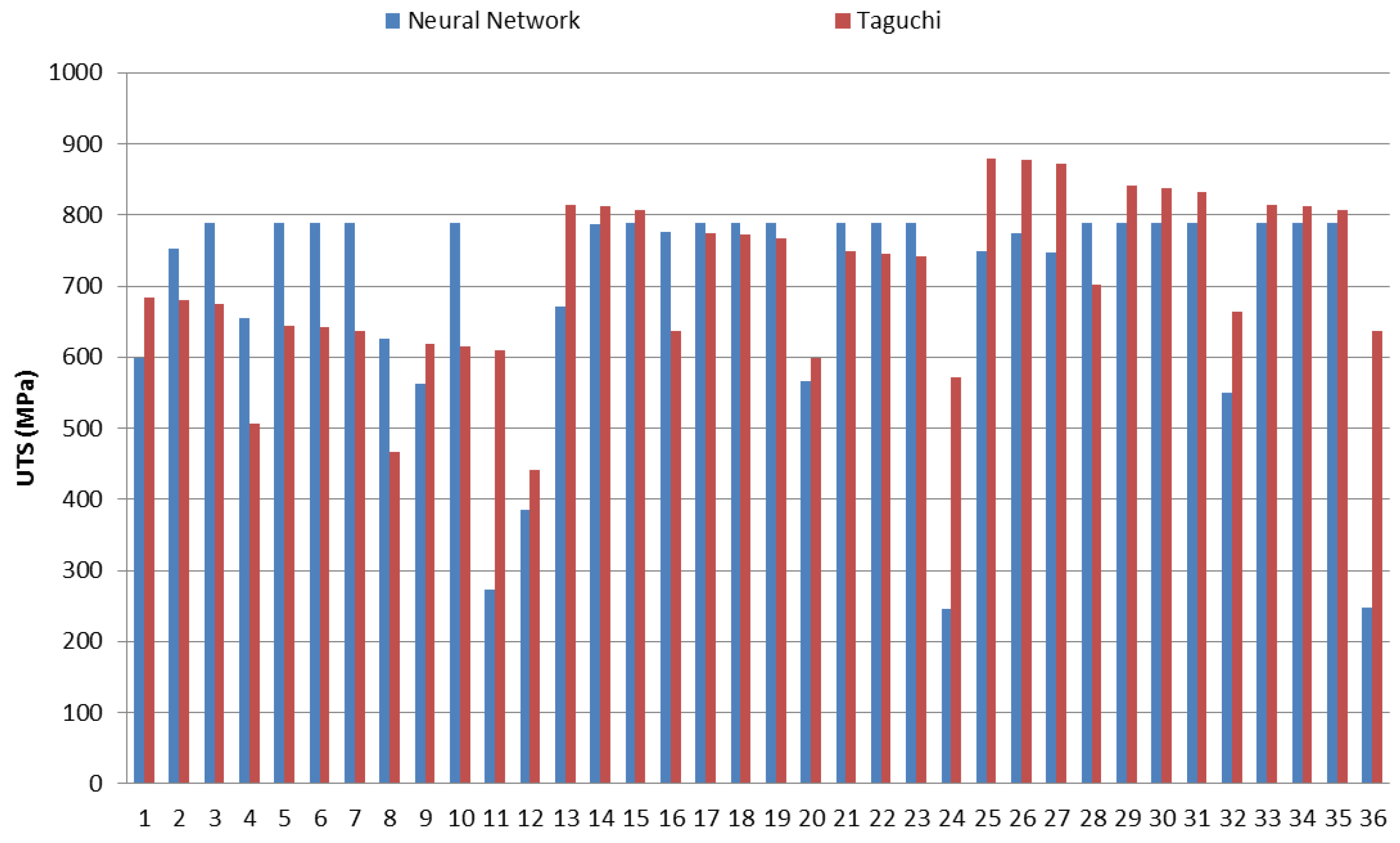

3.2.1. Neural Network Approach

- u1 = (((1.0/(1.0 + exp(−1.0 × (((x) × (14.0987)) + ((y) × (−10.1375)) + ((z) × (−22.6694)) + (10.7274))))) × (25.5146)))

- u2 = (((1.0/(1.0 + exp(−1.0 × (((x) × (−1.5550)) + ((y) × (−7.7413)) + ((z) × (−11.2698)) + (2.0932))))) × (−19.3582)))

- u3 = (((1.0/(1.0 + exp(−1.0 × (((x) × (2.1121)) + ((y) × (6.3599)) + ((z) × (−7.9340)) + (−0.2742))))) × (−13.6633)))

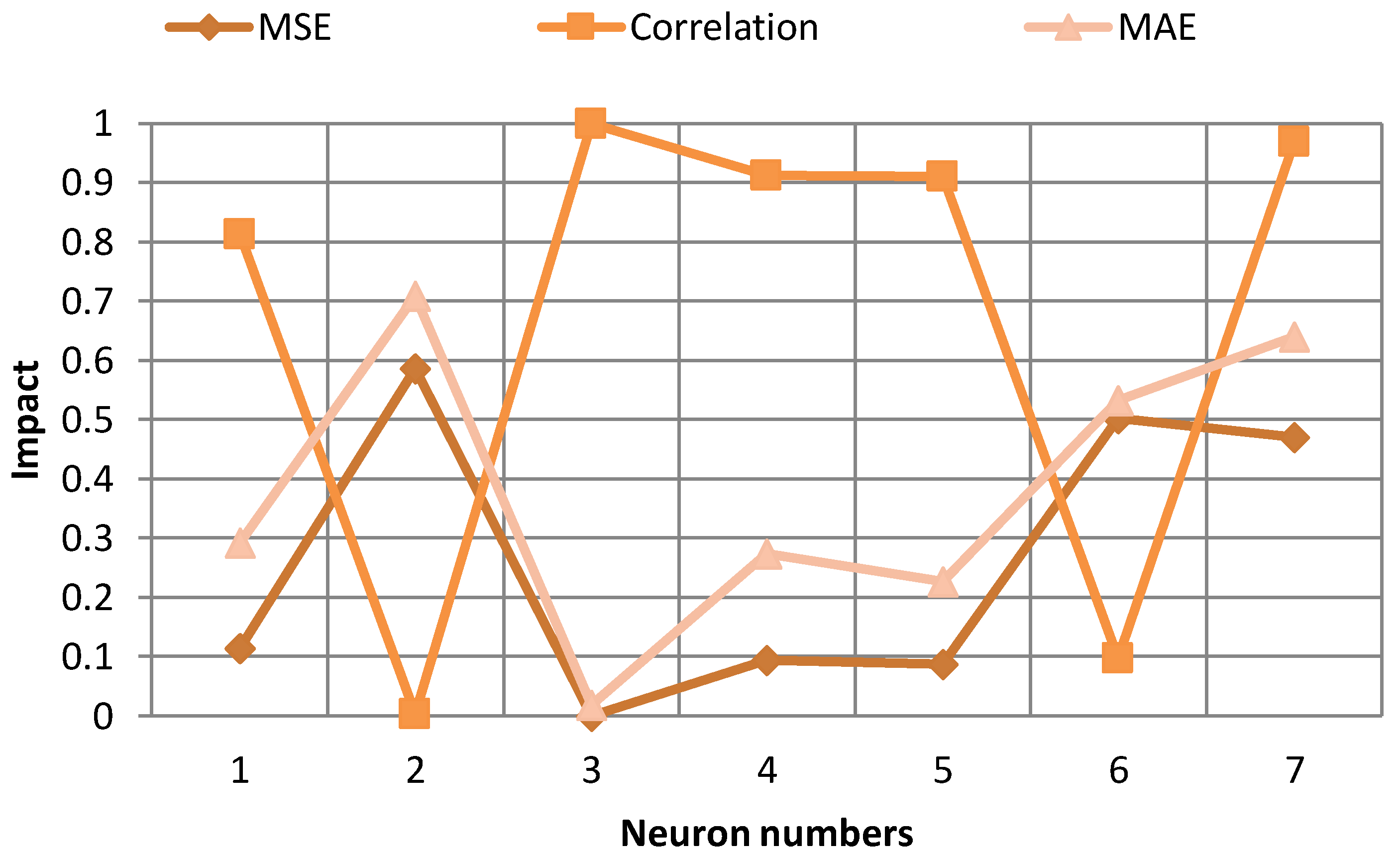

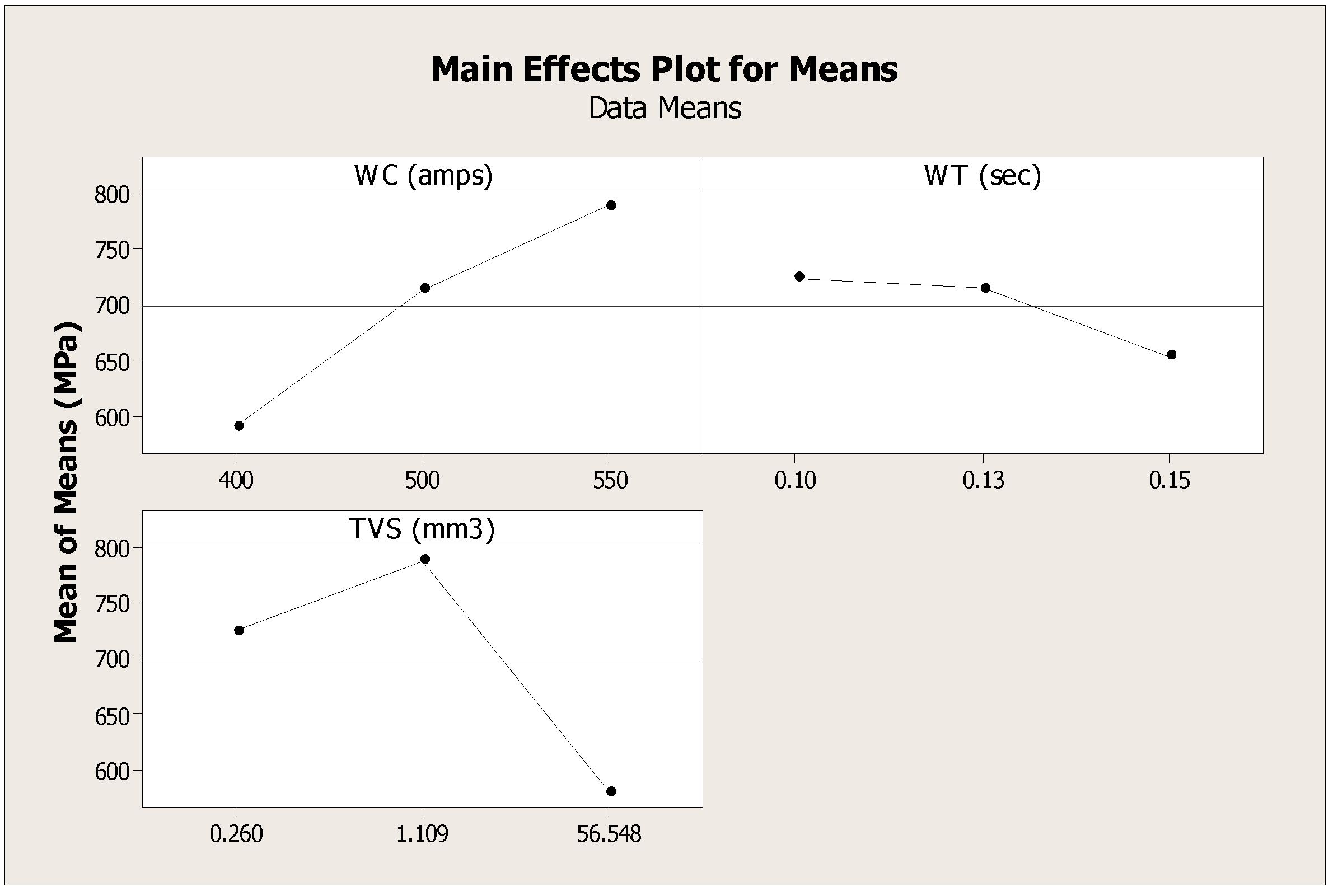

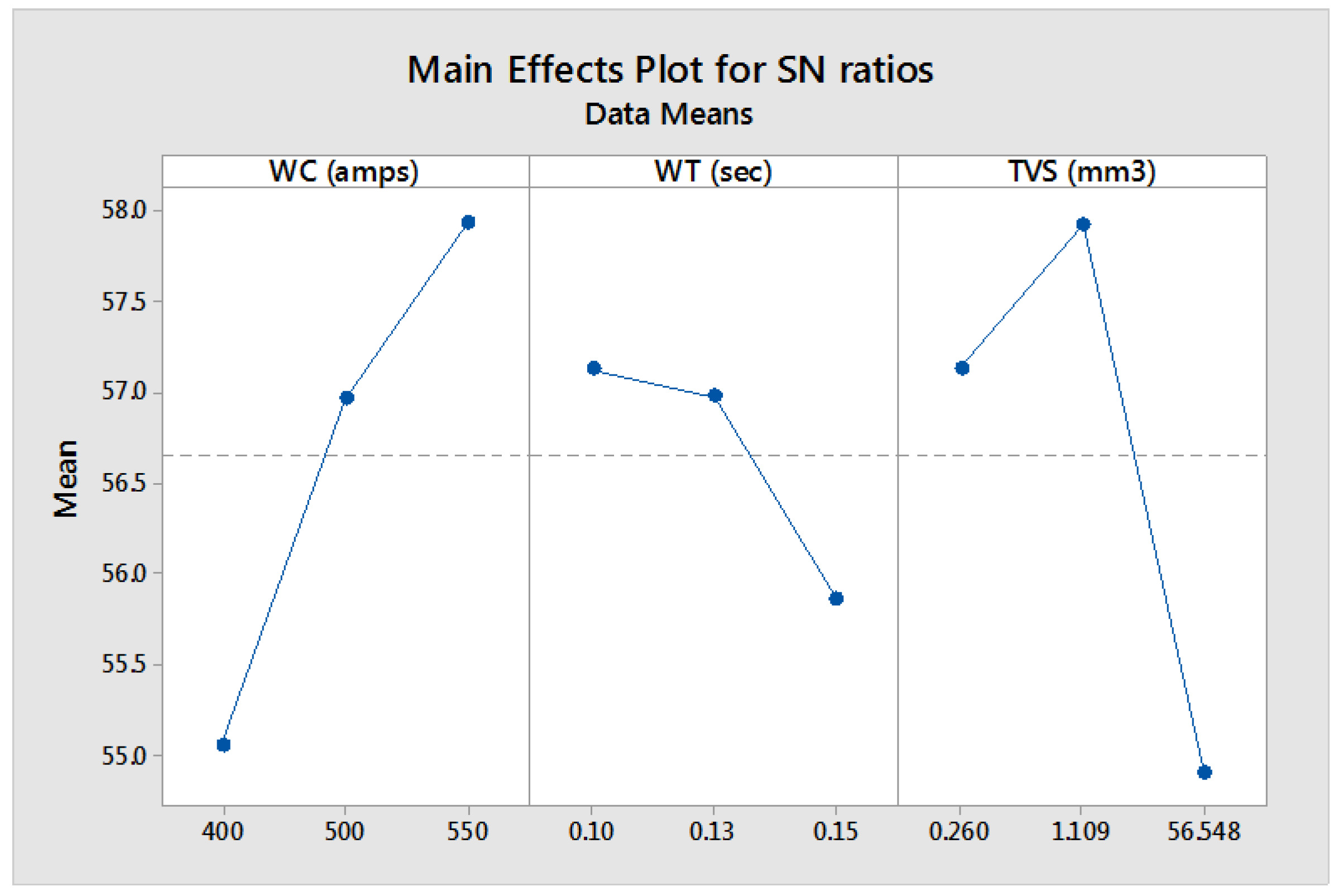

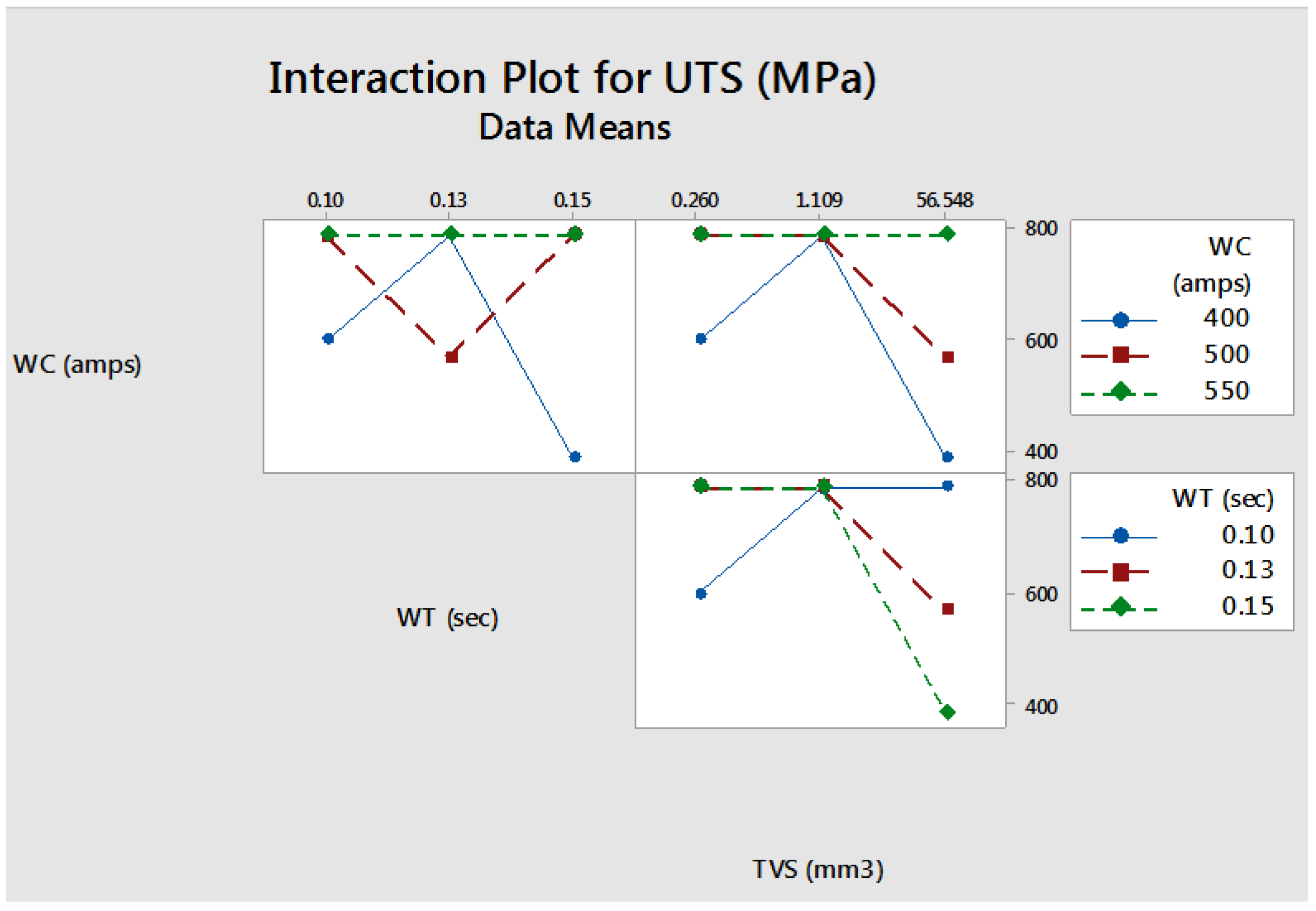

3.2.2. Taguchi Approach

4. Discussion

- The methods are extensively used to optimize engineering processes.

- The Taguchi method has a significant advantage in the design of experiments, which can also be applied to a variety of quantitative tests; by using this method, time and cost can be saved and a much higher number of assays can be reduced.

- ANOVA in the Taguchi approach can be used for analysis and is an alternative and efficient approach for fast, low-cost assay optimization. The Taguchi method incorporates one primary experiment to study the main effects of each factor, modeling some of the important interactions.

- The ANN model is popular in predicting the field that is used to solve the problem by rebuilding any function with arbitrary precision and has good adaptive and self-learning ability.

- The average relative uncertainty values of ANN and Taguchi approaches are 3.86% and 56.37, respectively. The ANN has rapid overlearning, more accuracy (~3%), and precision (±24 MPa); however, the Taguchi method has more low accuracy (~21%) and precision (±389 MPa) in predicting the ultimate tensile strength of the welds.

- A high p-value (0.066) of regression in the Taguchi method indicates that the equation used here has a low accuracy for estimating the ultimate tensile strength of welds.

- It was observed that the average percentage error value decreased and the correlation coefficient value was significantly improved with the neural network approach compared to the Taguchi approach. In other words, results of the neural network approach are in better agreement with the test results, which may be attributed to the high learning rate of the ANN method.

- Increasing the welding current and time raises the local heat, which can probably cause some deformations on the stud, which in turn diminishes the ultimate tensile strength values.

- The grain growth in the weld zone through external heat energy can cause a reduction in strength.

- Decreasing the cross-sectional area of the stud with a high welding current and time enhances the heat intensity distribution and deteriorates the mechanical properties of the welded joints.

- A higher welding current or higher welding time can increase the chance of defect formations in the weld areas, which can also significantly affect the mechanical properties and quality of the welded metal.

- A high learning rate and high correlation coefficient indicate the effectiveness of the neural network model, which may be used for the mechanical predictions of welded materials in many industries.

5. Conclusions

- Test results showed that a dendritic structure was formed during welding, which mainly contained a δ-ferrite and austenitic structure.Improper welding parameters significantly deteriorate the ultimate tensile strength of the welds.

- Tensile test results were statistically studied using artificial neural network and Taguchi approaches. Neural network results were in good agreement with the test results, and the formulation has a high reliability with low error rates. The UTS of the joints using the ANN and Taguchi methods were estimated with an accuracy of 96.97% and 78.31%, respectively. More studies may be needed to obtain closer matching in the future. Hence, it was concluded that the neural network model was fairly successful and has analytical virtue for specifying the ultimate tensile strength of welds under different welding processing cases.

- Welding parameters such as welding current, time, and tip volume of the stud are the most significant parameters in the ASW process. Thus, these parameters should be properly adjusted to maximize the mechanical properties of the welds because any change in any of the parameters can significantly affect all other parameters as well. For example, if a high level of welding current or welding time is selected during welding, then this leads to more fusion/melting and forms necking at the joined region due to grain coarsening effects and other structural changes.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cabibbo, M.; Forcellese, A.; Simoncini, M.; Pieralisi, M.; Ciccarelli, D. Effect of welding motion and pre-/post-annealing of friction stir welded AA5754 joints. Mater. Des. 2016, 93, 146–159. [Google Scholar] [CrossRef]

- Wahba, M.; Mizutani, M.; Katayama, S. Single pass hybrid laser-arc welding of 25 mm thick square groove butt joints. Mater. Des. 2016, 97, 1–6. [Google Scholar] [CrossRef]

- Trzepiecinski, T.; Malinowski, T.; Pieja, T. Experimental and numerical analysis of industrial warm forming of stainless steel sheet. J. Manuf. Process. 2017, 30, 532–540. [Google Scholar] [CrossRef]

- Zhao, D.; Zhao, K.; Ren, D.; Guo, X. Ultrasonic welding of magnesium–titanium dissimilar metals: A study on influences of welding parameters on mechanical property by experimentation and artificial neural network. J. Manuf. Sci. Eng. 2017, 139, 031019. [Google Scholar] [CrossRef]

- Huang, L.; Wu, D.; Hua, X.; Liu, S.; Jiang, Z.; Li, F.; Wang, H.; Shi, S. Effect of the welding direction on the microstructural characterization in fiber laser-GMAW hybrid welding of 5083 aluminum alloy. J. Manuf. Process. 2018, 31, 514–522. [Google Scholar] [CrossRef]

- Habibi, M.; Hashemi, R.; Fallah Tafti, M.; Assempour, A. Experimental investigation of mechanical properties, formability and forming limit diagrams for tailor-welded blanks produced by friction stir welding. J. Manuf. Process. 2018, 31, 310–323. [Google Scholar] [CrossRef]

- Yang, J.; Yu, Z.; Li, Y.; Zhang, H.; Zhou, N. Laser welding/brazing of 5182 aluminium alloy to ZEK100 magnesium alloy using a nickel interlayer. Sci. Technol. Weld. Join. 2018, 1–8. [Google Scholar] [CrossRef]

- Kumar, V.; Hussain, M.; Raza, M.S.; Das, A.K.; Singh, N.K. Fiber laser welding of thin nickel sheets in air and water medium. Arabian J. Sci. Eng. 2017, 42, 1765–1773. [Google Scholar] [CrossRef]

- Krasnowski, K. Experimental study of FSW t-joints of EN-AW 6082-T6 and their behaviour under static loads. Arabian J. Sci. Eng. 2014, 39, 9083–9092. [Google Scholar] [CrossRef]

- Kumar, S.S.; Murugan, N.; Ramachandran, K.K. Microstructure and mechanical properties of friction stir welded AISI 316l austenitic stainless steel joints. J. Mater. Process. Technol. 2018, 254, 79–90. [Google Scholar] [CrossRef]

- Samardžić, I.; Kladarić, I.; Klarić, Š. The influence of welding parameters on weld characteristics in electric arc stud welding. Metalurgija 2009, 48, 181–185. [Google Scholar]

- Chi, Q.; Zhang, J.; Zhang, Y. Study on the autocontrol of stud plunge depth in stepping arc stud welding. J. Appl. Sci. 2006, 6, 362–365. [Google Scholar]

- Harada, Y.; Sada, Y.; Kumai, S. Dissimilar joining of AA2024 aluminum studs and AZ80 magnesium plates by high-speed solid-state welding. J. Mater. Process. Technol. 2014, 214, 477–484. [Google Scholar] [CrossRef]

- Feng, Y.; Luo, Z.; Liu, Z.; Li, Y.; Luo, Y.; Huang, Y. Keyhole gas tungsten arc welding of AISI 316l stainless steel. Mater. Des. 2015, 85, 24–31. [Google Scholar] [CrossRef]

- Ye, Z.; Huang, J.; Cheng, Z.; Gao, W.; Zhang, Y.; Chen, S.; Yang, J. Combined effects of mig and tig arcs on weld appearance and interface properties in al/steel double-sided butt welding-brazing. J. Mater. Process. Technol. 2017, 250, 25–34. [Google Scholar] [CrossRef]

- Shackelford, J.F.; Alexander, W. CRC Materials Science and Engineering Handbook, 3rd ed.; Taylor & Francis: Abingdon, UK, 2001. [Google Scholar]

- Kurt, H.I. Influence of hybrid ratio and friction stir processing parameters on ultimate tensile strength of 5083 aluminum matrix hybrid composites. Compos. Part B Eng. 2016, 93, 26–34. [Google Scholar] [CrossRef]

- Kurt, H.I.; Oduncuoglu, M. Formulation of the effect of different alloying elements on the tensile strength of the in situ Al-Mg2Si composites. Metals 2015, 5, 371–382. [Google Scholar] [CrossRef]

- Kurt, H.I.; Oduncuoglu, M.; Asmatulu, R. Wear behavior of aluminum matrix hybrid composites fabricated through friction stir welding process. J. Iron Steel Res. Int. 2016, 23, 1119–1126. [Google Scholar] [CrossRef]

- Rama, R.S.; Padmanabhan, G. Application of Taguchi methods and ANOVA in optimization of process parameters for metal removal rate in electrochemical machining of AL/5% SIC composites. Int. J. Eng. Res. Appl. 2012, 2, 192–197. [Google Scholar]

- Roy, R.K. A Primer on the Taguchi Method; Society of Manufacturing Engineers: Dearborn, MI, USA, 2010. [Google Scholar]

- Pandey, A.; Khan, M.; Moeed, K. Optimization of resistance spot welding parameters using Taguchi method. Int. J. Eng. Sci. Technol. 2013, 5, 234–241. [Google Scholar]

- Padilha, A.F.; Rios, P. Decomposition of austenite in austenitic stainless steels. ISIJ Int. 2002, 42, 325–327. [Google Scholar] [CrossRef]

- Janovec, J.; Sustarsic, B.; Medved, J.; Jenko, M. Phases in austenitic stainless steels. Mater. Technol. 2003, 37, 307–312. [Google Scholar]

- Lai, J.; Haigh, J. Delta-Ferrite Transformations in a Type 316 Weld Metal; Central Electricity Research Labs.: Leatherhead, UK, 1978. [Google Scholar]

- Radisavljevic, I.; Zivkovic, A.; Radovic, N.; Grabulov, V. Influence of FSW parameters on formation quality and mechanical properties of AL 2024-T351 butt welded joints. Trans. Nonferrous Met. Soc. China 2013, 23, 3525–3539. [Google Scholar] [CrossRef]

- Dorbane, A.; Ayoub, G.; Mansoor, B.; Hamade, R.F.; Kridli, G.; Shabadi, R.; Imad, A. Microstructural observations and tensile fracture behavior of FSW twin roll cast AZ31 mg sheets. Mater. Sci. Eng. A 2016, 649, 190–200. [Google Scholar] [CrossRef]

- Fisher, R.A. The Design of Experiments, 5th ed.; Macmillan Pub Co.: Oxford, UK, 1949. [Google Scholar]

- Al-Abdullah, K.I.A.-L.; Abdi, H.; Lim, C.P.; Yassin, W.A. Force and temperature modelling of bone milling using artificial neural networks. Measurement 2018, 116, 25–37. [Google Scholar] [CrossRef]

- Gajate, A.; Haber, R.; del Toro, R.; Vega, P.; Bustillo, A. Tool wear monitoring using neuro-fuzzy techniques: A comparative study in a turning process. J. Intell. Manuf. 2012, 23, 869–882. [Google Scholar] [CrossRef] [Green Version]

| Materials | C | Si | Mn | P | S | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Plate (304 SS) | 0.08 | 1 | 2 | 0.045 | 0.03 | 18–20 | 8–10.5 | - | Balance |

| Stud (316 SS) | 0.08 | 1 | 2 | 0.045 | 0.03 | 16–18 | 10–14 | 2–3 | Balance |

| Materials | UTS (MPa) | El. (%) | Hardness (HV) |

|---|---|---|---|

| Plate (304) | 515 - | 55 | 275 |

| Stud (316) | 515 - | 55 | 275 |

| Level | Welding Current (amps) | Welding Time (s) | Lift (mm) | Plunge (mm) |

|---|---|---|---|---|

| Min | 400 | 0.10 | 3 | 2 |

| Max | 550 | 0.15 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurt, H.I.; Oduncuoglu, M.; Yilmaz, N.F.; Ergul, E.; Asmatulu, R. A Comparative Study on the Effect of Welding Parameters of Austenitic Stainless Steels Using Artificial Neural Network and Taguchi Approaches with ANOVA Analysis. Metals 2018, 8, 326. https://doi.org/10.3390/met8050326

Kurt HI, Oduncuoglu M, Yilmaz NF, Ergul E, Asmatulu R. A Comparative Study on the Effect of Welding Parameters of Austenitic Stainless Steels Using Artificial Neural Network and Taguchi Approaches with ANOVA Analysis. Metals. 2018; 8(5):326. https://doi.org/10.3390/met8050326

Chicago/Turabian StyleKurt, Halil Ibrahim, Murat Oduncuoglu, Necip Fazil Yilmaz, Engin Ergul, and Ramazan Asmatulu. 2018. "A Comparative Study on the Effect of Welding Parameters of Austenitic Stainless Steels Using Artificial Neural Network and Taguchi Approaches with ANOVA Analysis" Metals 8, no. 5: 326. https://doi.org/10.3390/met8050326

APA StyleKurt, H. I., Oduncuoglu, M., Yilmaz, N. F., Ergul, E., & Asmatulu, R. (2018). A Comparative Study on the Effect of Welding Parameters of Austenitic Stainless Steels Using Artificial Neural Network and Taguchi Approaches with ANOVA Analysis. Metals, 8(5), 326. https://doi.org/10.3390/met8050326