3.2. Pull-Out Force

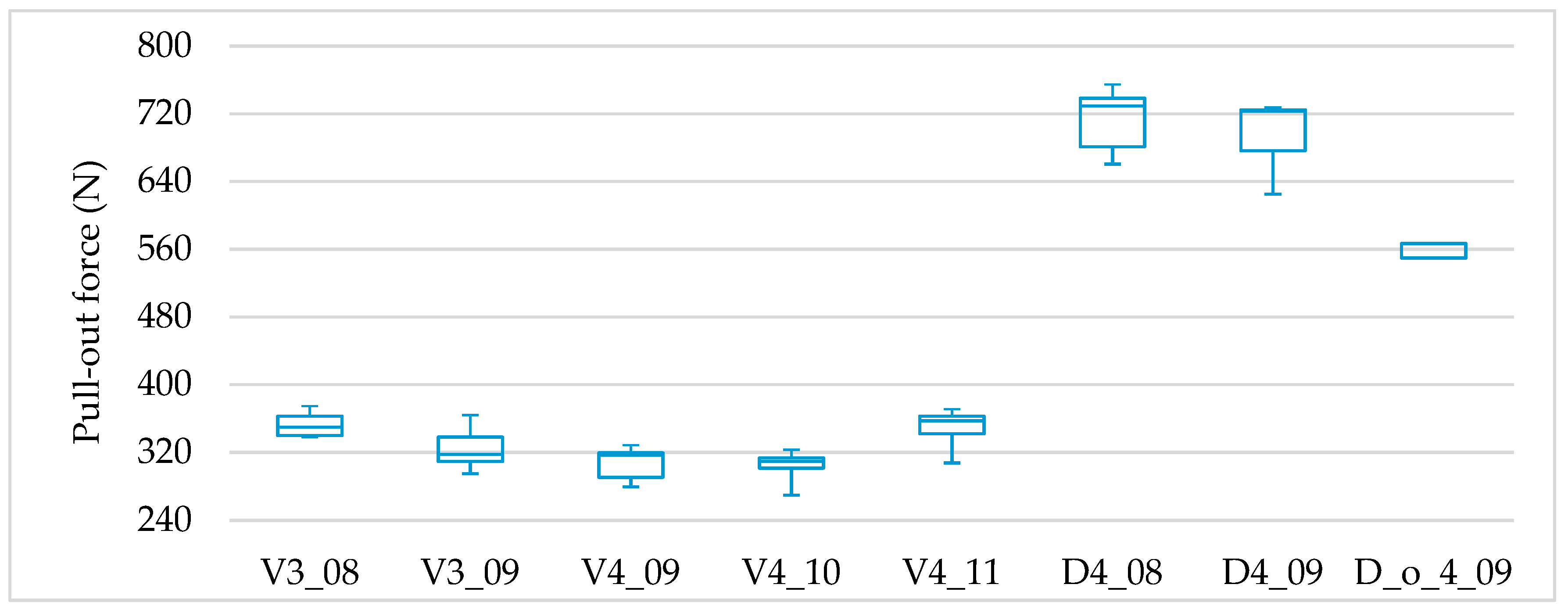

To determine the pull-out forces, the manufactured cups were stripped from the cavities after being press-fitted into the artificial bone cavity. The results are shown in

Figure 5 and

Table 4.

The results of the experiments carried out according to the measuring methodology reveal differences that are related to the structural elements used. Whereas the combined structures achieve the highest results (D4_08 = 708 N; D4_09 = 704 N), the pull-out forces for the twisted structures (Max: V3_08 = 351 N; Min: V4_10 = 308 N) are significantly lower. The combined open structure (550 N) lies between the two combined variants and the cups with the twisted structures.

After carrying out a statistical significance test using one-way Anova with Dunnett’s T3 post-hoc test (multiple comparisons), the following relationships become clear. The two combined structures do not differ significantly from each other. However, the combined open structure is significantly below the combined structure (D4_08 to D_o_4_09/

p = 0.00438; D4_09 to D_o_4_09/

p = 0.00193). The differences in the twisted structures are consistently significant (values see

Table 4). In the twisted structures only version V3_08 deviates significantly from version V4_10 (

p = 0.0242). The differences between the combined open and twisted structures can mainly be explained by the existing differences in press-fit volume. The press-fit volumes of the combined (D4_08 = 0.91 cm

3; D4_09 = 0.97 cm

3) and the combined open structure with 0.77 cm

3 clearly differ from the twisting structures (<0.54 cm

3). However, this relationship is not identifiable in the twisting structures, since despite clear differences in the press-fit volume between the twisting structures, a significant difference could only be determined between the variants V3_08 and V4_10. It seems that in addition to the press-fit volume, other influencing factors such as the surface quality (roughness and manufacturing accuracy) of the struts of the structure and their dimensions (length, diameter, surface area) could play a role [

55,

59].

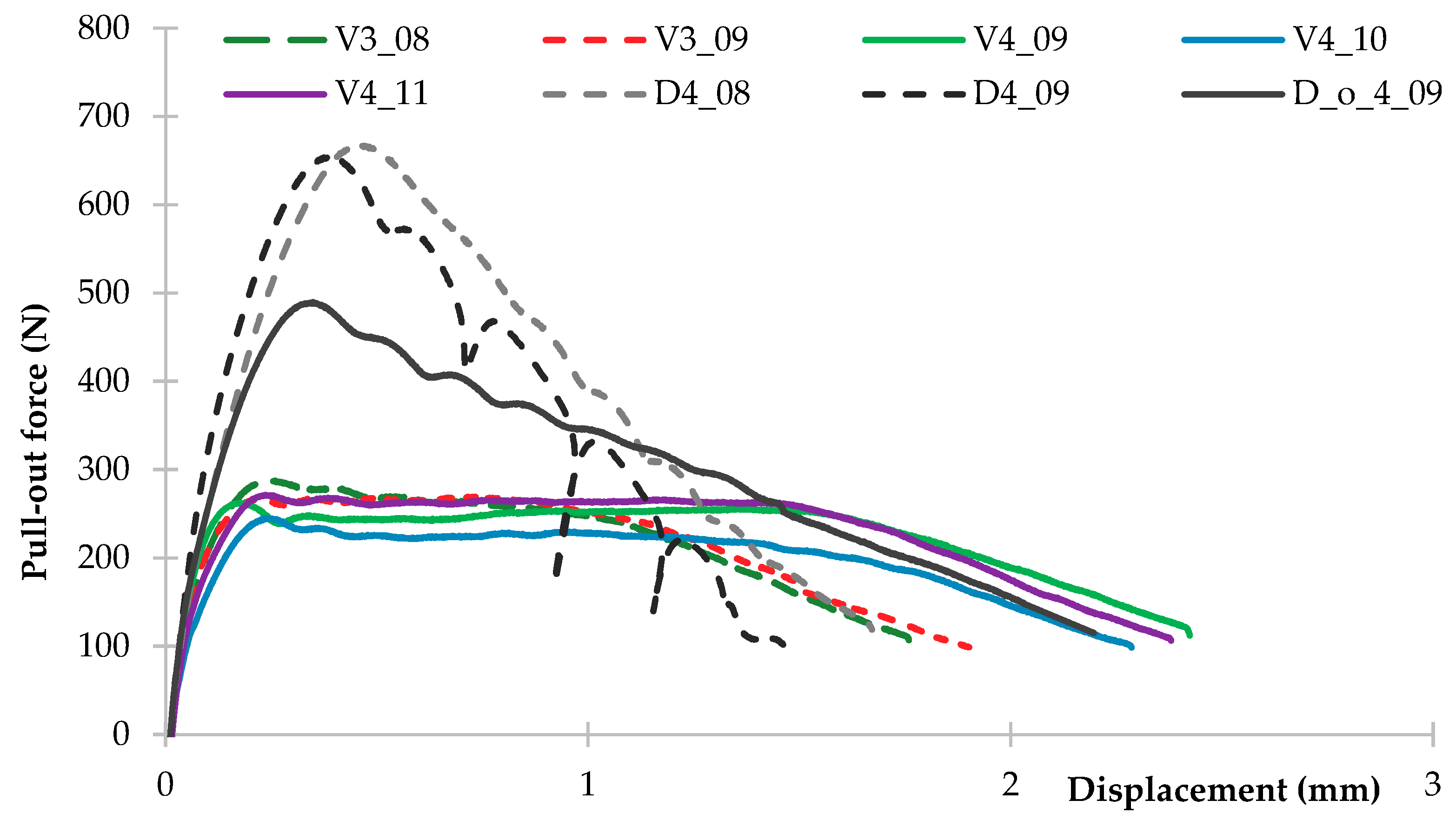

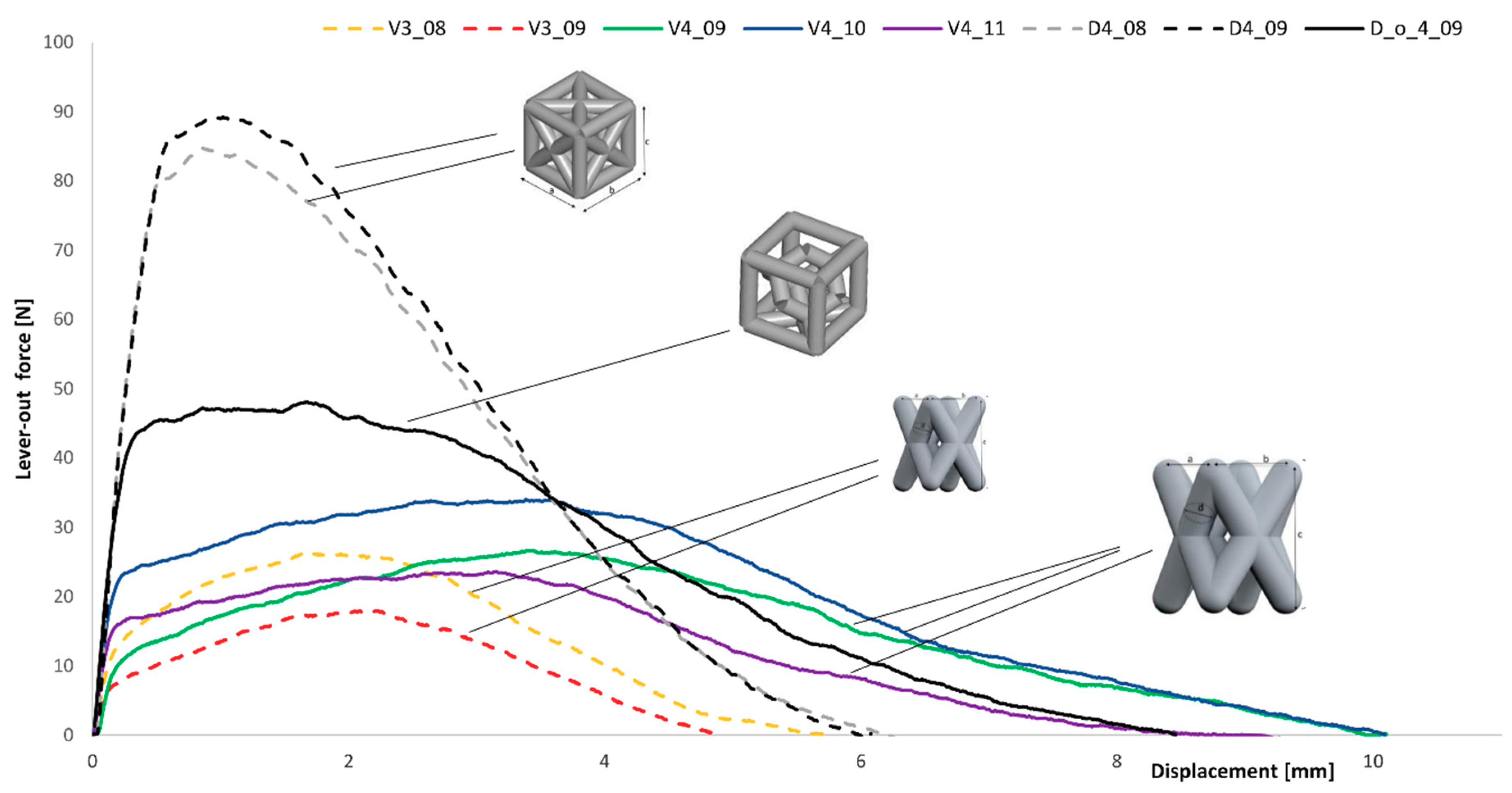

The pull-out behavior of the different cup models is shown in

Figure 6. The representation of the force profiles over cup displacement in the artificial bone cavity additionally offers the possibility to evaluate the measured maximum force in relation to the reached cup displacement at that time. The curves show characteristic differences.

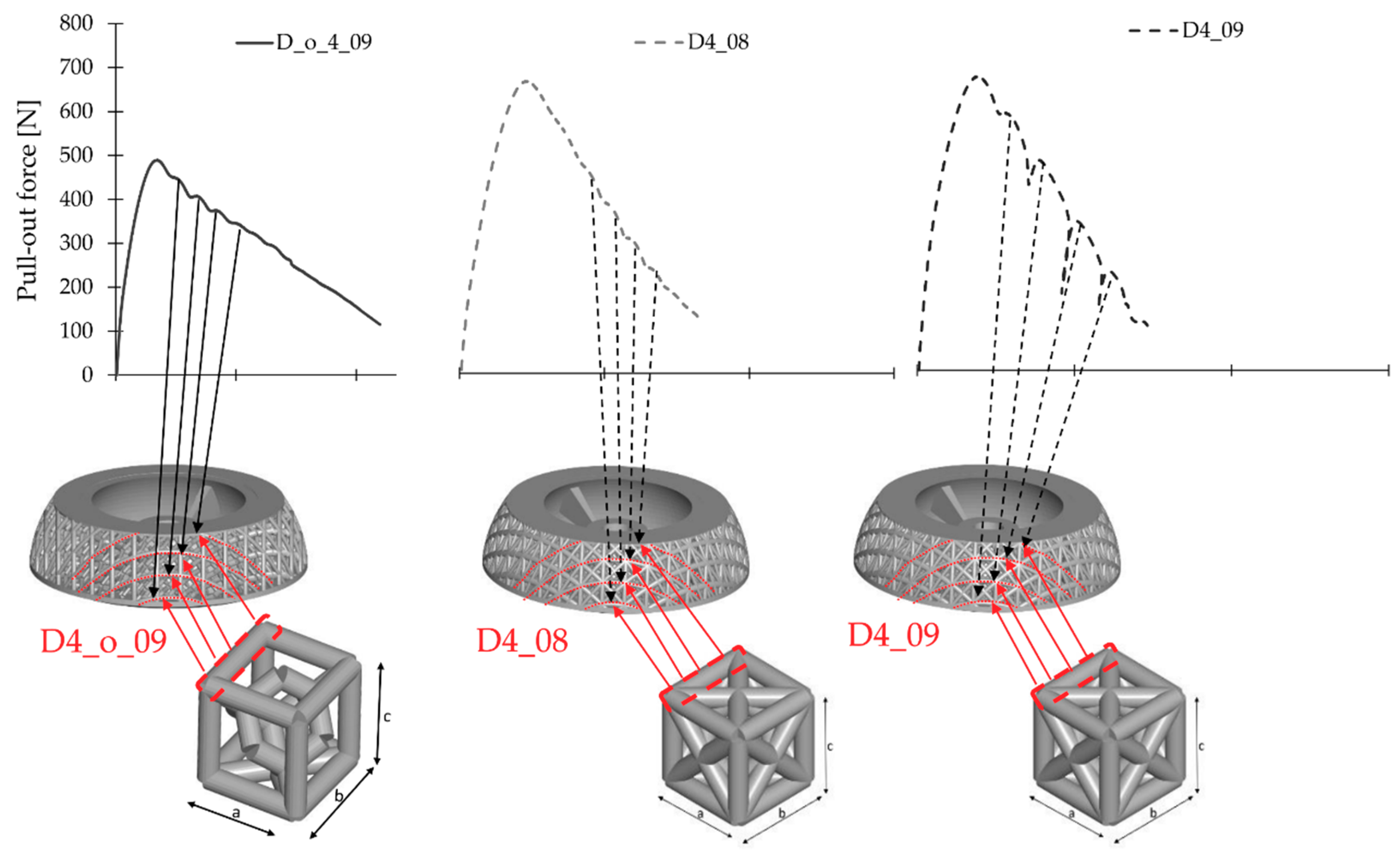

The curve for the cups with a combined structure differs clearly from the curves for the cups with a combined open or twisting structure. The most striking feature here is the cascading force decrease after a maximum force has been exceeded. This cascade is characterized in that a renewed force increase is determined after a drop in force. This course reflects the loosening and re-jamming of the cup in the artificial bone cavity. These cascades are most pronounced in version D4_09. This cascade development is also evident in the combined open structure version D4_08, though weaker. Apparently, this cascade is due to the larger space between the individual struts or the greater porosity. Here, the material of the artificial bone cavity has the possibility to fill more space. The necessary release from this room requires force again.

This cascade is characterized in that a renewed force increase is determined after a drop in force. This course reflects the loosening and re-jamming of the cup in the artificial bone cavity. These cascades are most pronounced in version D4_09. This cascade development is also evident in the combined open structure version D4_08, though weaker. Apparently, this cascade is due to the larger space between the individual struts or the greater porosity. Here, the material of the artificial bone cavity has the possibility to fill more space. The necessary release from this room requires force again.

The number of cascades obviously results from the number of superficial, continuous struts (

Figure 7—red lines). The maximum peak (and thus the first peak of force) results from overcoming the edge of the hip cup. The second to fifth peak results from the strut contours. Starting at the highest point of the continuous strut lines. The differences in cascade intensity of the cup variants are caused by the differences in the strut diameter. The strut with a rod diameter of 0.9 mm has a larger contact surface to the artificial bone bed. This requires more force to loosen from the artificial bone cavity. The differences between the open and closed variants (D_o_4_09 and D4_09) are due to the varying degrees of free space in the surface of the hip cups. More free space (D_o_4_09) requires less force than with the closed variant (D4_09).

The press-fit cups with the twisted structure show a completely different behavior. After reaching the force maximum, the corresponding force path continues at a uniform level of force. This applies to the twisted structure with a height of 3 mm as well as to the structure with a height of 4 mm. It is clearly shown here; however, that the versions in the 4 mm height maintain this level of force significantly longer. A weakening of the cup anchoring takes place here only after about 1.5 mm compared to about 1 mm in the variants with a height of 3 mm. Here, the cups with the structural elements whose individual elements have a height of 4 mm and an associated spacing of the bars of 2.83 mm, provide the artificial bone cavity material more space for anchoring than the variant of 3 mm height and a spacing of 2.12 mm. As a result, the force is maintained longer at one level.

In view of later desired ingrowth of the bone into the structural area as well as the formation of blood vessels, larger open areas have advantages over the smaller areas [

22,

25,

60]. Here it is important to carefully observe the interaction of the geometric conditions (unit cell and macro-porosity) and the component properties influenced by the additive manufacturing process (e.g., roughness or micro-porosity, surface finish at intersections) [

61,

62,

63].

While the diamond structures reach the maximum force required to pull out at approx. 0.6 to 0.7 mm, these values for the twisted structures are approx. 0.2 to 0.3 mm. The open combined structure shows a maximum at approx. 0.35 mm. In addition, it can be seen that the twisted version with a height of 3 mm as well as the combined structure D4_08 still require approximately 100 N after about 1.6 to 1.8 mm displacement for a further release.

In the case of the twisted versions with a height of 4 mm and the open combined structure, the cups have already experienced a displacement of approximately 2.5 mm at a force of 100 N. The progression curves of the press-fit cups are very similar. This value probably reflects the interaction between the artificial bone cavity and the surface of the additively manufactured cup.

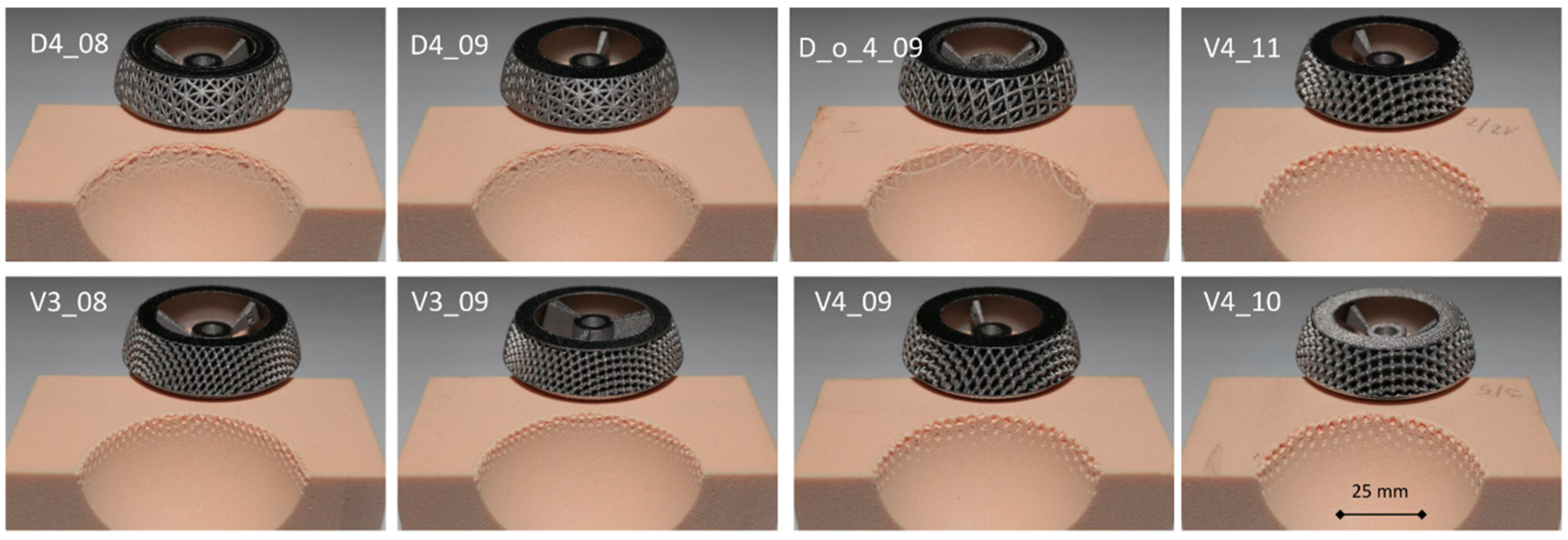

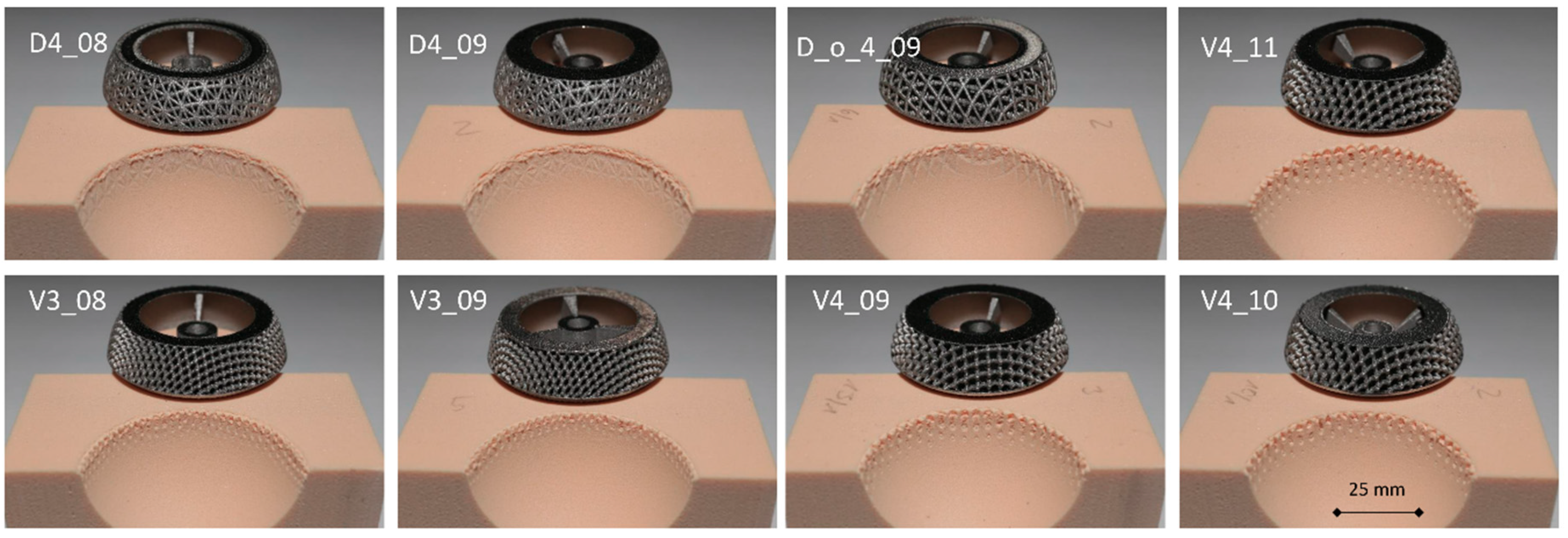

As can be seen from

Figure 8, all cups leave clear traces of an impression on the entire circumference of the artificial bone bed. The evaluation of these traces using this visual assessment of the contact surface has been described, for example, by Le Cann et al. to characterize how the roughness of a cup affects primary stability [

33].

All cups left distinct positioning traces in the press-fit region. The artificial bone cavity remained intact. The artificial bone cavities shown in

Figure 8 exhibit clear marks of an anchorage. The damage patterns of the artificial bone cavity differ optically from each other.

All twisted versions show dot-like impressions in the cavity area. The cavity edges remain sharply intact. Differences caused by the different bar diameters (3 and 4 mm) and bar distances (2.83 and 2.12 mm) are optically present. With increasing bar diameter, the damage in the bone bed also increases. Variant V4_11 shows clearer and stronger traces than versions V4_10, V4_09, V3_08 and V3_09.

The combined structures (D4_08, D4_09) show rather flat impressions on the artificial bone cavity areas. The cavity edges tend to blur slightly, as a representation of slight material detachments. These detachments are much less pronounced in the diamond open structure.

The forces determined in the pull-out test and the traces in the bone bearing also allow the following conclusion to be drawn. The twisting structure already destroys the corresponding area in the bone bearing during the press fitting. Because of that, less force is required when pulling out of the bearing because the resistances against loosening are lower than with intact material. The combined structure, on the other hand, only damages the bone bearing when it is pulled out. Here, the resistance of predominantly intact material must be overcome. This leads to a higher power requirement.

In addition, the contacting of the structures with the bone bed takes place differently. The contact of the twisting structure is made punctually. The combined and combined open structure creates a two-dimensional contact to the surface of the bone bed. To overcome the press fit, more force is required for the two-dimensional contacts than for the punctual contacts.

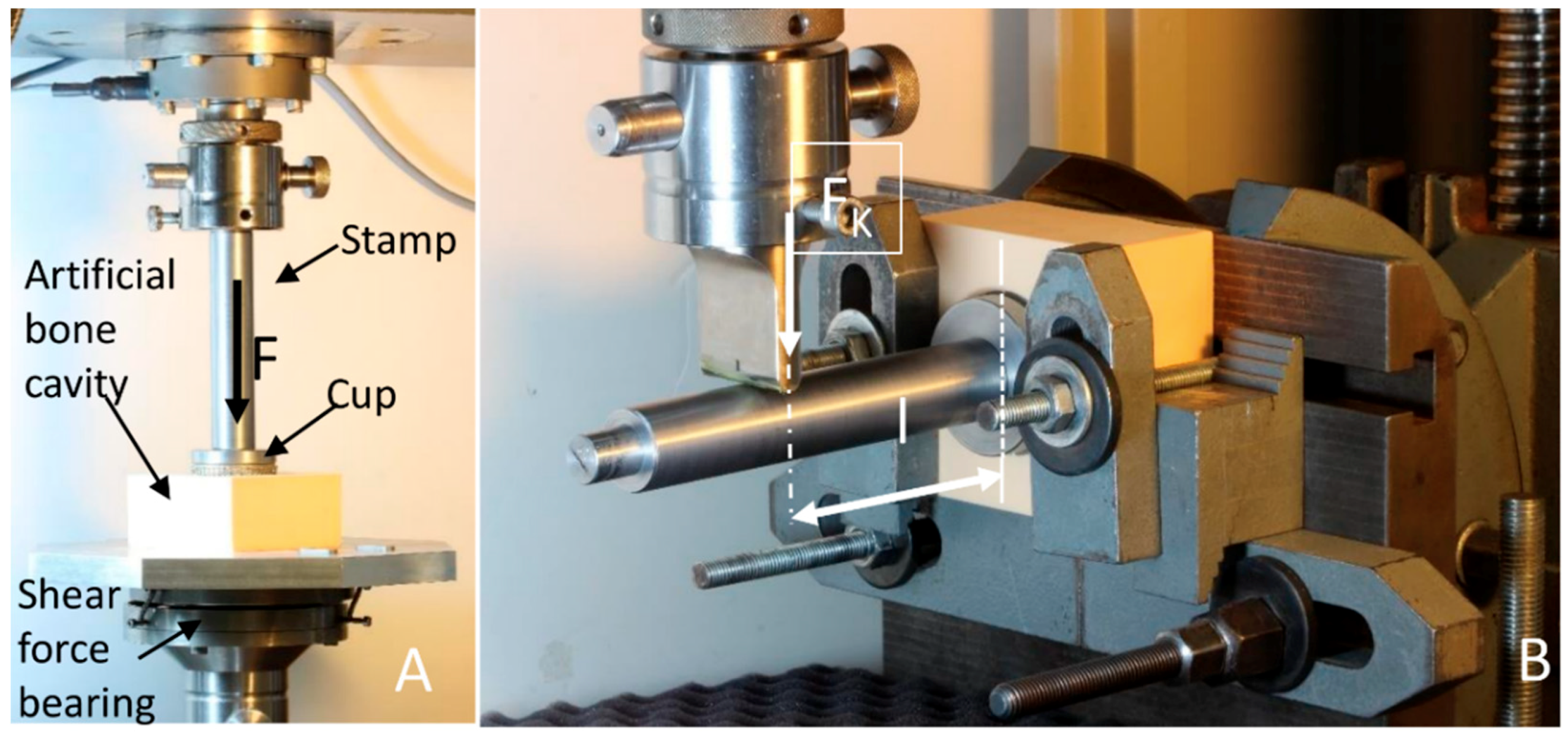

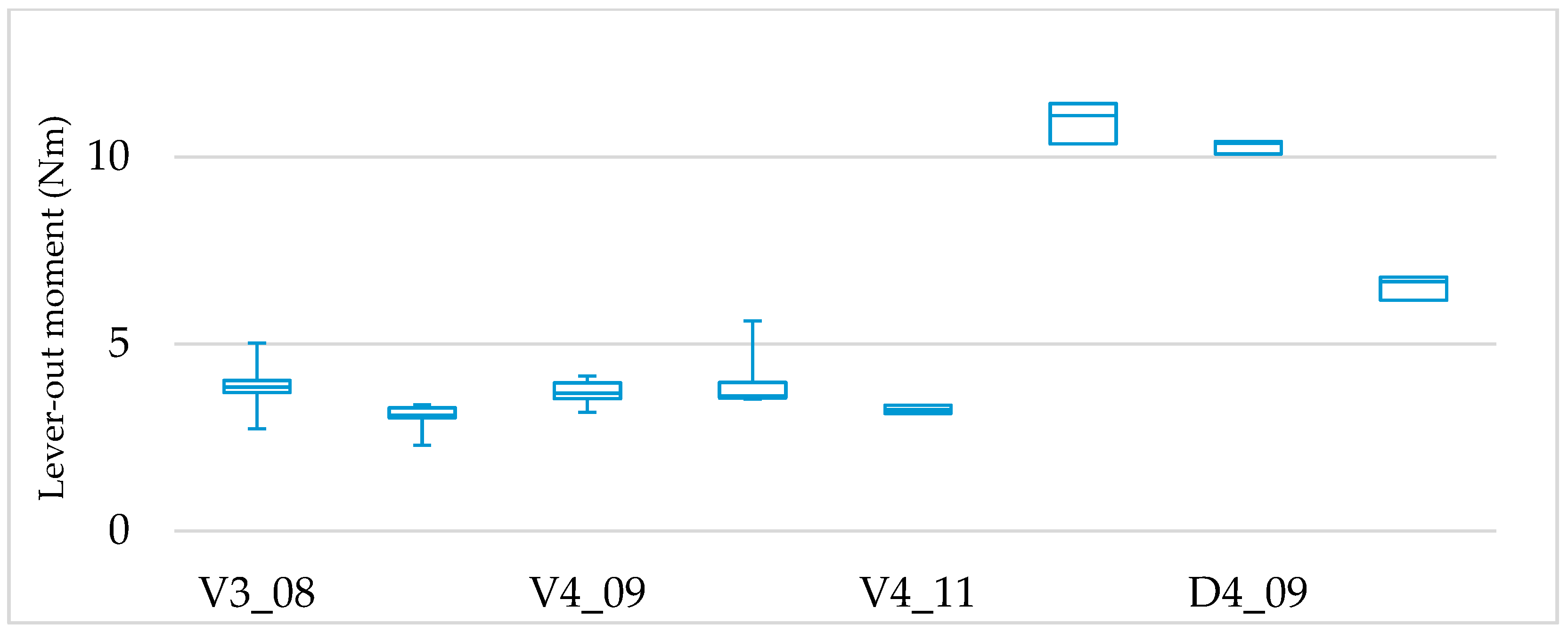

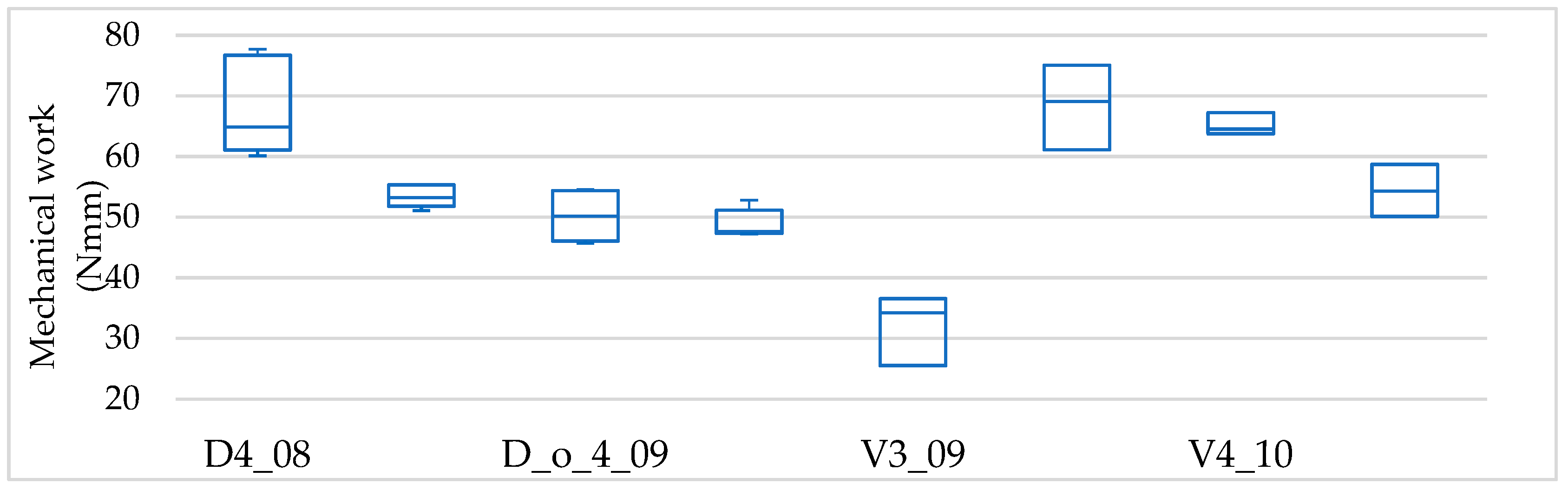

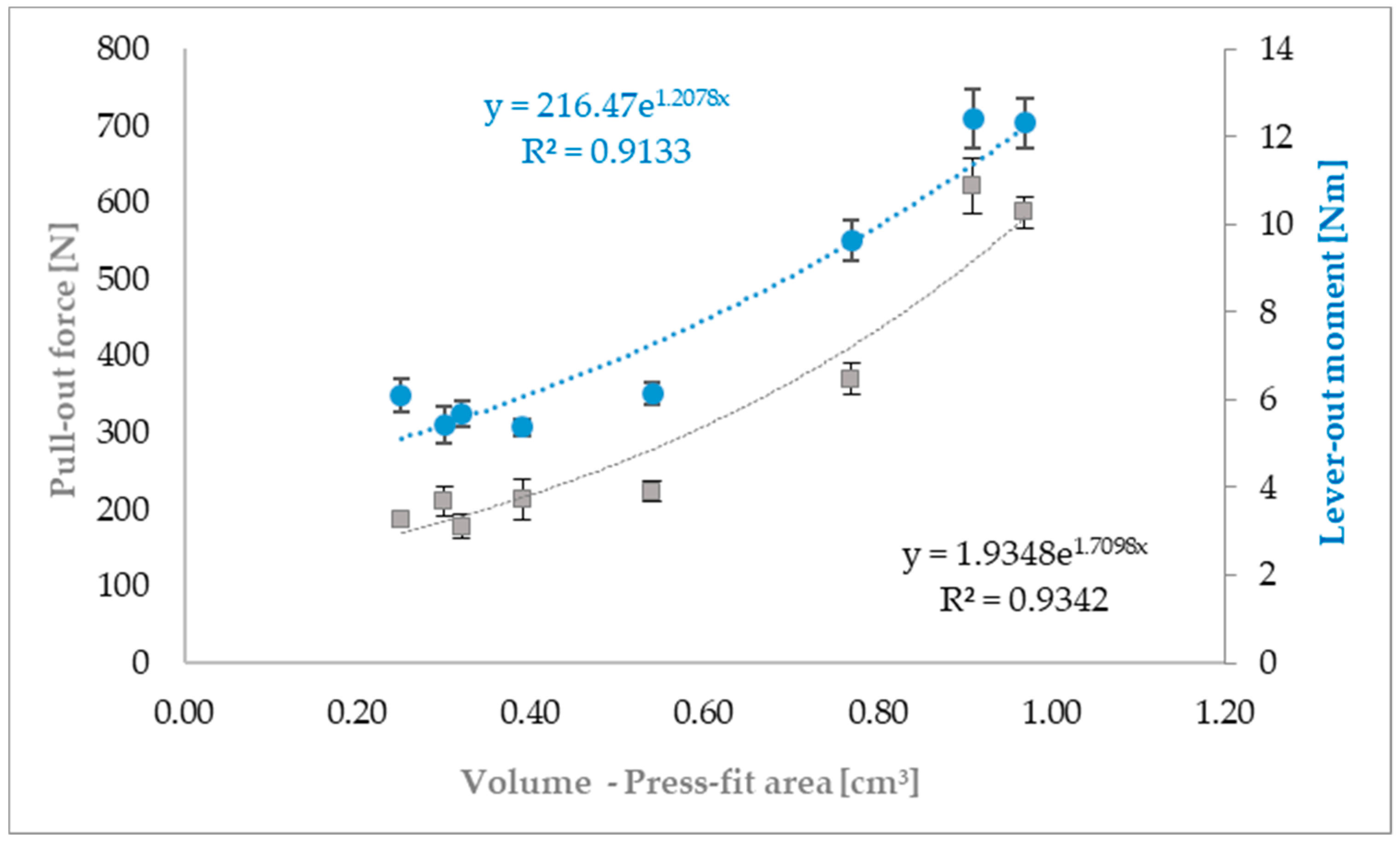

3.3. Lever-Out Moment

After being press-fitted into the artificial bone cavities, all cup models were levered out from the cavities to determine the lever-out moments as described in 0. The results are shown in

Figure 9 and

Table 5. The course of the forces required to lever out the cups over the displacement is shown in

Figure 10.

The influence of the applied structural elements on the behavior of the press-fit cups in the lever-out test can be clearly established on the basis of the experimentally determined lever-out moments. The best results were achieved by the combined structure (D4_08 = 10.9 Nm, D4_09 = 10.3 Nm), followed by the combined open structure (6.5 Nm) and the twisted structure (Max: V3_08 = 3.9 Nm; Min: V3_09 = 3.1 Nm).

By carrying out a statistical significance test using one-way Anova with Dunnett’s T3 post-hoc test (multiple comparisons) it is possible to describe the following relationships. The two combined structures do not differ significantly from each other. However, the combined open structure is significantly below the combined structure (D4_08 and D4_09 to D_o_4_09/p < 0.001).

The differences of the experimentally determined lever-out moments shown between the combined structures, the combined open structures and the twisted structures are significant in all cases (p < 0.001). For the twisted structures, only the version V3_08 deviates significantly from both version V3_09 (p = 0.04619) and version V4_11 (p = 0.04649). Similar to the pull-out tests, the differences between the combined and the combined open structures to the twisted structures can be explained by the existing differences in press-fit volume. The differences between the structure V3_08 and V3_09 and V4_11 also result from the differences in the press-fit volumes (V3_08 = 0.54 cm3; V3_09 = 0.32 cm3; V4_11 = 0.25 cm3). The fact that variant V4_09 does not deviate significantly from variant V3_8 despite a lower press-fit volume (0.3 cm3) is additional evidence that other factors are notoriously influencing the anchoring strength.

The lever-out behavior of the tested cup models is shown in

Figure 10. All additively manufactured cups show curves which are characteristic for the structural elements used.

All models were preloaded with an initial moment of 0.62 Nm by the self-weight of the test setup. The representation of lever-out forces over displacement displays for the combined structure a maximum lever-out force (mean values: D4_08 = 90.3 N; D4_09 = 85 N) at a displacement of approx. 1 mm and then a decrease of the moment up to a displacement of 6 mm. The combined open structure reaches a lever-out force maximum (mean value: 51.6 N) after approx. 1.8 mm. This cup variant reduces the force to zero after a displacement of about 8.3 mm. The twisted structures show differences depending on the size of the structure. The twisted structures with dimensions of 3 mm height reach a lever-out force maximum (mean values: V3_08 = 29 N; V3_09 = 22 N) after about 1.8 to 2.2 mm. The twisted structures with dimensions of 4 mm height reach force maximums (mean values: V4_09 = 27.1 N; V4_10 = 27.5 N; V4_11 = 23.2 N) after about 3.5 to 3.7 mm. The force reduction continues in the V3-versions up to a displacement of approx. 4.8 to 5.8 mm. The V4 versions run to zero at about 9 to 10.5 mm.

Similar to the pull-out tests, it can be seen that, following a steep rise, the cups with the combined structure show a continuous force drop after reaching a lever-out force maximum. The combined open structure and the twisted structures behave differently. Here the maximum force is only reached after passing through a plateau phase. This plateau phase is much longer for the V4-variants than for the V3-variants.

This functional difference is related to the geometric design of the individual structures. As shown in

Table 1, the combined structures are structures that produce a relatively uniformly shaped surface whose interstices engage only weakly in the bone bed. Here the press-fit is in the foreground.

In the combined open structure and the twisted structures, the shaped surface of the cups is much more open. These structures engage more clearly in the artificial bone stock. The differences between the V3 and V4 variants are due to the geometric dimensions of the individual rods. The larger-sized rods of the V4 variant have larger gaps than the V3-variants (V4-2.83 mm and V3-2.12 mm). Thus, a hooking of the structural elements in the bone cavity in the V4-variant is possible across a longer distance than in the V3 variant.

This leads to differences in the height of the moments determined due to the structure design. In addition, it becomes clear that the twisted structures in the artificial bone bed produce deeper punctual impressions. During the lever-out test, the struts move along these impressions. This behavior is recognizable for all twisted structure variants by traces between the punctual impressions. The illustrations of the bone beds after the pull-out test (

Figure 8) do not show these traces. Therefore, due to the already damaged surface, less force is required to lever-out. The twisted structures thereby show overall lower moments than the combined and combined open structure due to the different nature of the unit cell.

A larger structural design is helpful in terms of the positive effects for bone ingrowth [

25]. In addition to good primary stability, the bone-like properties of the load-bearing structural layer are an essential prerequisite for good secondary stability of the implant [

64]. Secondary stability is essentially characterized by the ability of bone to grow onto the implant surface and thereby firmly anchor the implant. The use of open-pore structures enlarges the implant surface and thus improves the prerequisite for the formation of sufficiently high secondary stability. In addition, a high primary anchoring strength is the prerequisite for creating a sufficiently high secondary stiffness, since only then is sufficient growth of the bone on the surface possible. Only if a load transfer via the implant into the surrounding bone is possible without stress-shielding can a successful use of the implants be ensured. With regard to the geometric selection of structural elements, this circumstance must be taken into account [

65]. The combined structures, which are more direction-independent in their properties, show slight advantages here [

52,

66].

The artificial bone cavities show distinct traces left by the lever-out of the cups. In the following

Figure 11 the cup models are shown with representative examples of the artificial bone cavity. The artificial bone cavity is intact despite clear traces of anchoring. The damage patterns of the bone cavities differ optically from each other, as in the case of the pull-out experiments. The twisted versions show, as expected, punctually impressions in the bone cavities. The edge of the cavity remains sharp. The different strut diameters and spaces of the struts in the structure produce visually recognizable representative patterns (dot-like impressions). The combined structures leave flat traces on the bone cavities. The edge of the bone cavities tends to blur slightly, as a representation of slight material detachments. These detachments are significantly less pronounced in the combined open structure.

The use of an artificial bone cavity has a positive effect on the characterization of primary stability. This speaks in favor of the experimental results determined here since possible property variations, as they occur in the use of cadaveric models, have been omitted. Goldman et al. compared the effect of component surface roughness at the bone implant interface and the quality of the bone on initial press-fit stability [

67]. They found no significant differences between the bending moment at 150 m for two kind of press-fit cups with different coefficients of friction. They made clear in the discussion that the results from the use of the cadaveric models represent a realistic representation of surgical interventions, but are also associated with corresponding scatter of the results. For the purpose of this study, which is to evaluate structurally differently designed press-fit cups, the artificial bone bed is the better choice. The uniform mechanical properties of the artificial bone bed provide a much better basis for a comparative consideration of the different cup designs.