Simple Fabrication and Characterization of an Aluminum Nanoparticle Monolayer with Well-Defined Plasmonic Resonances in the Far Ultraviolet

Abstract

:1. Introduction

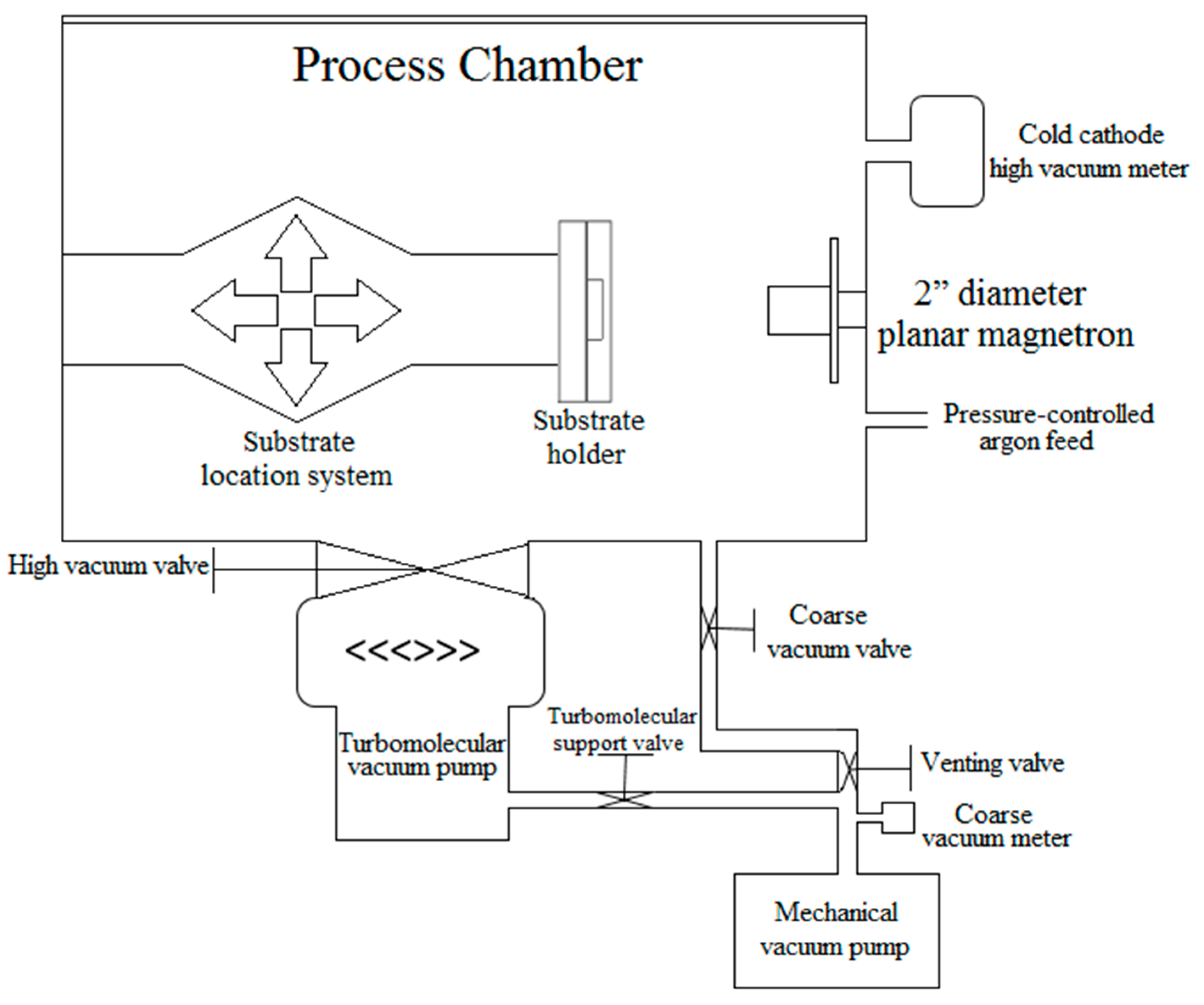

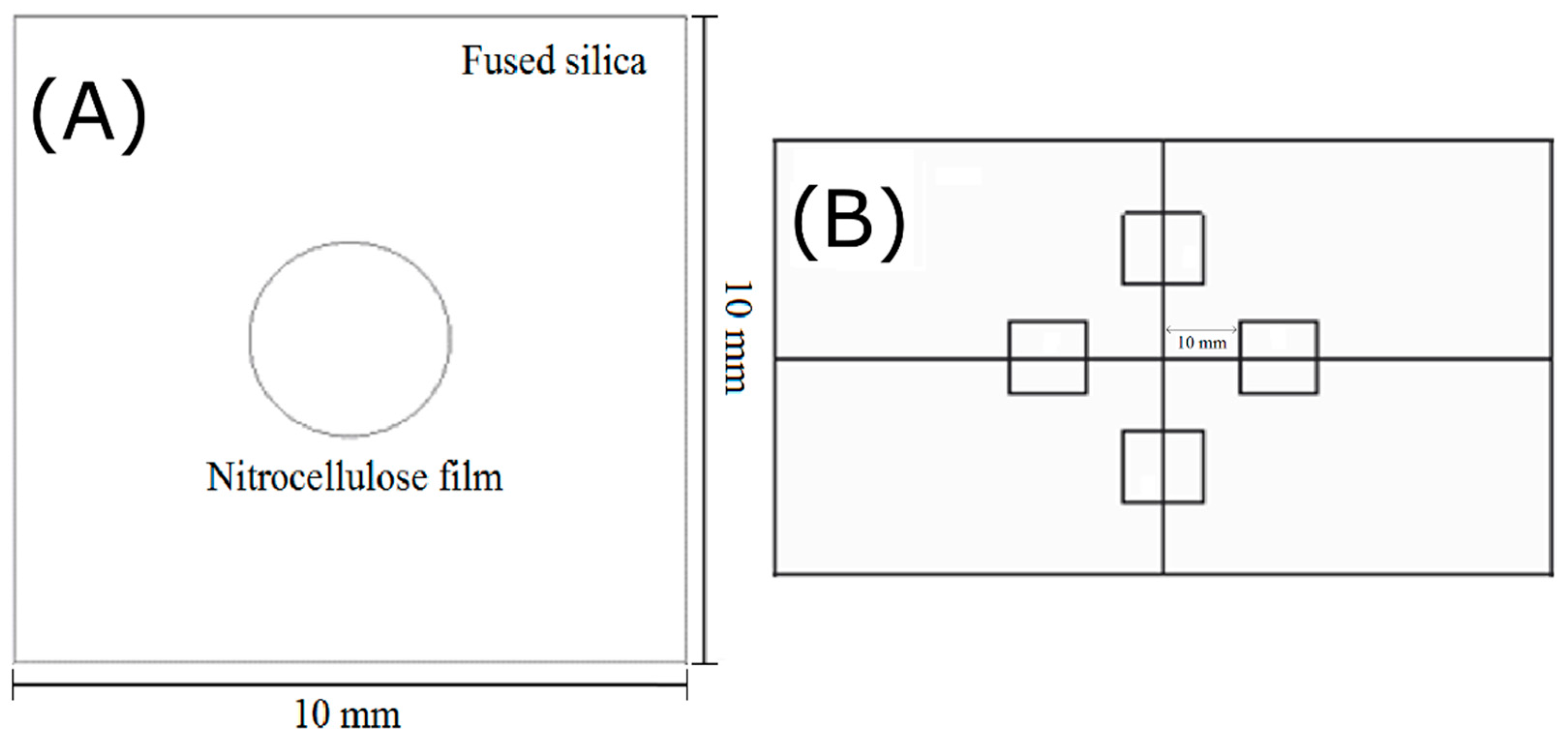

2. Experimental Details

3. Results and Discussion

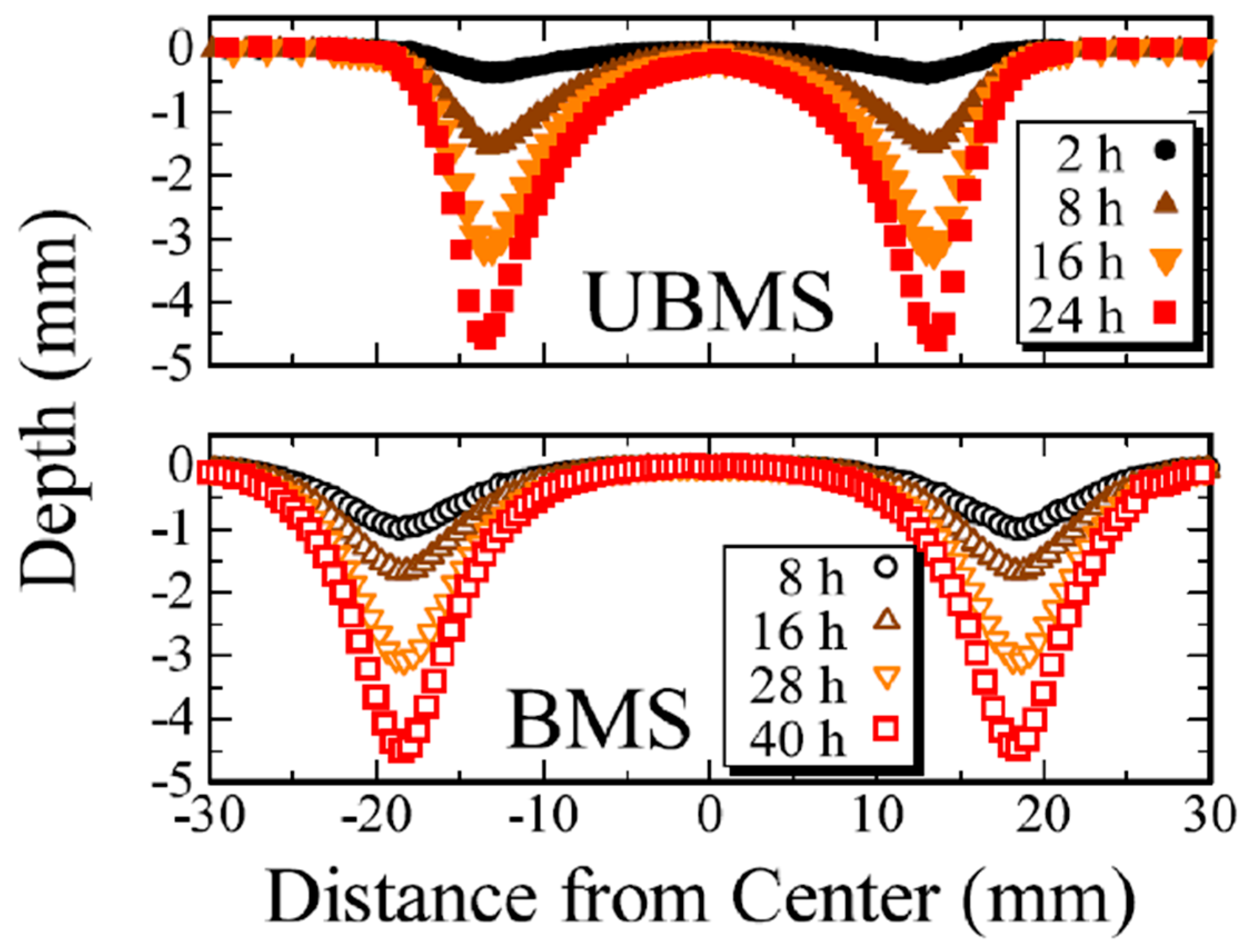

3.1. Determination of Deposition Parameters

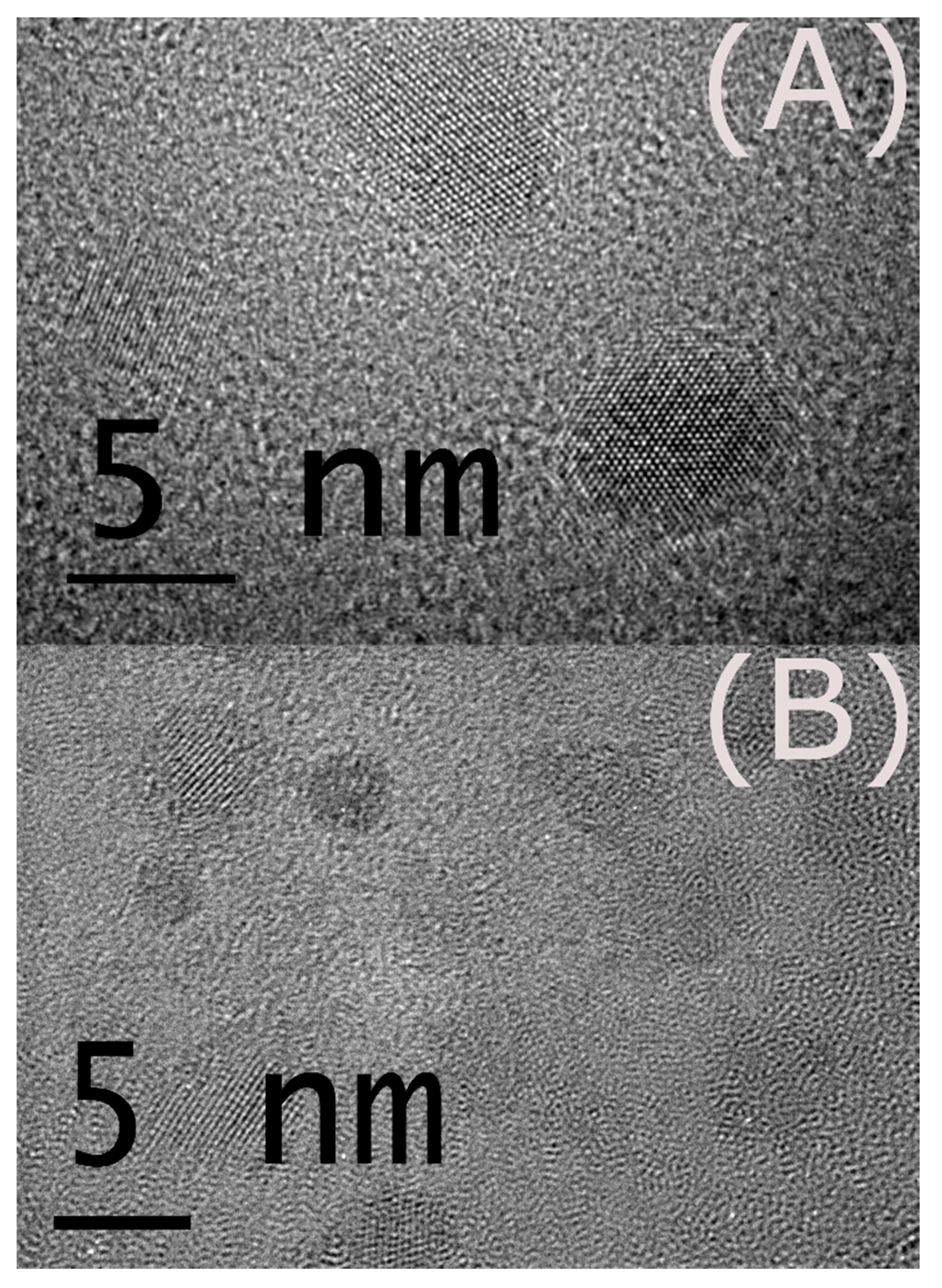

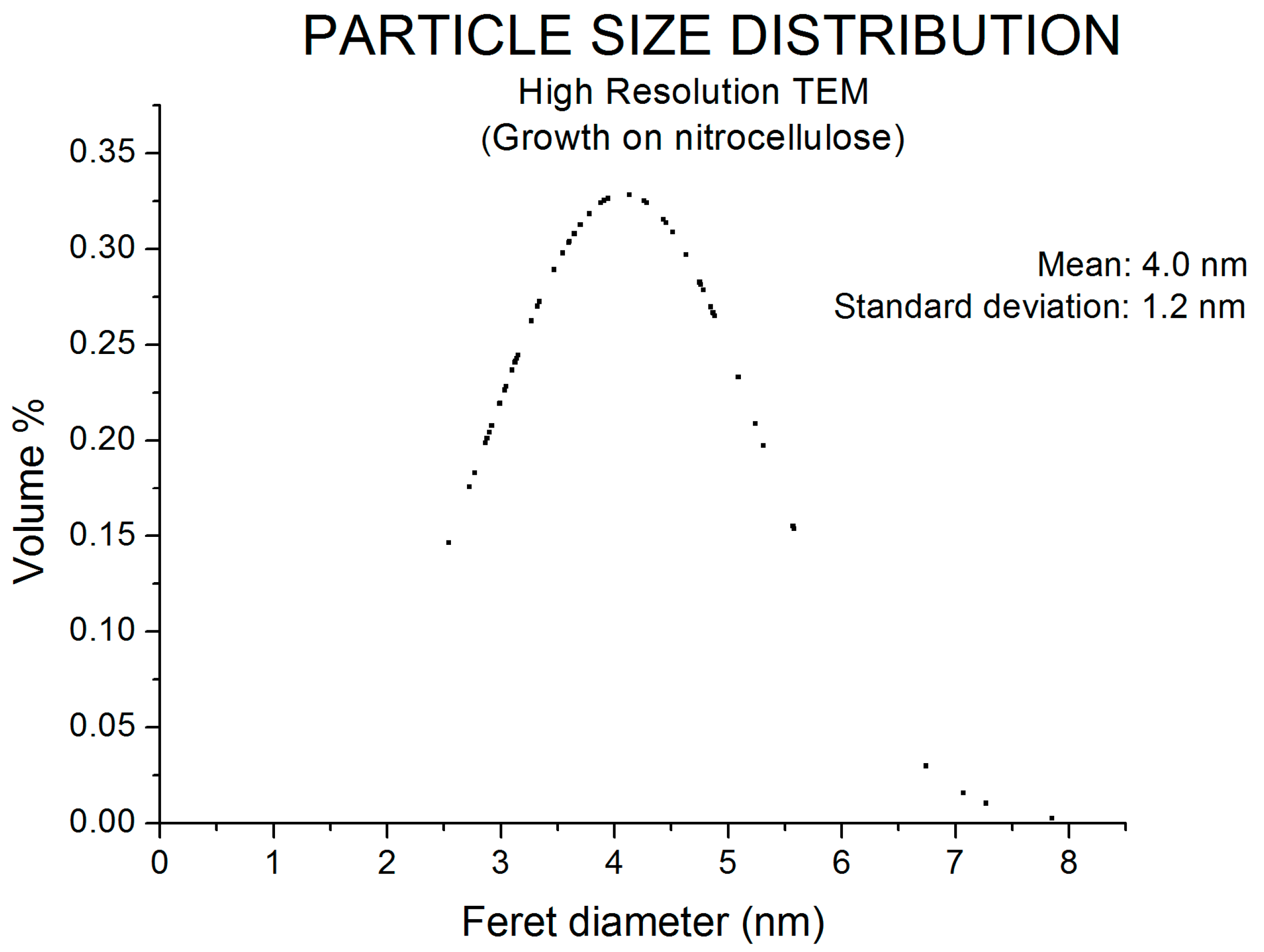

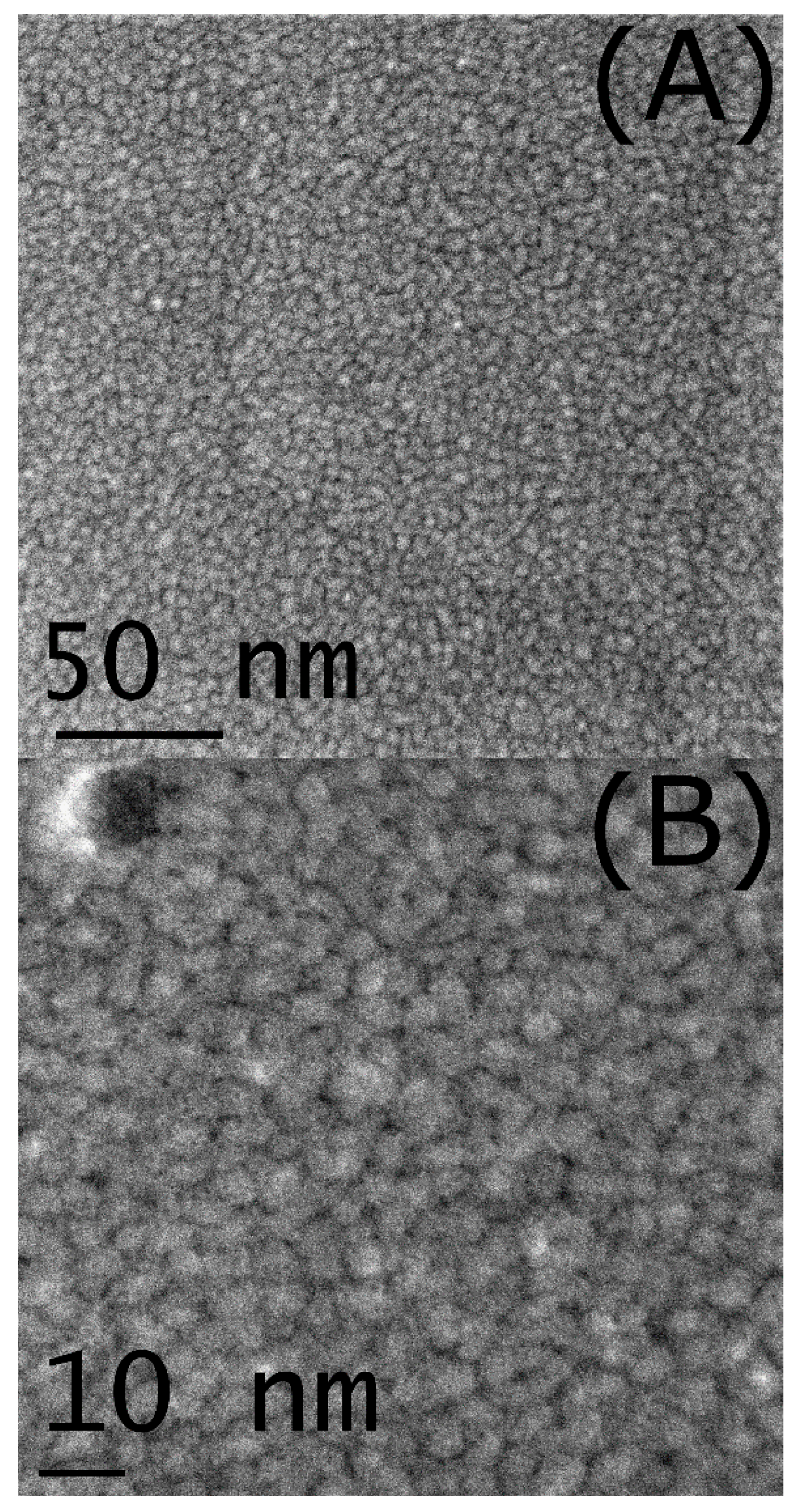

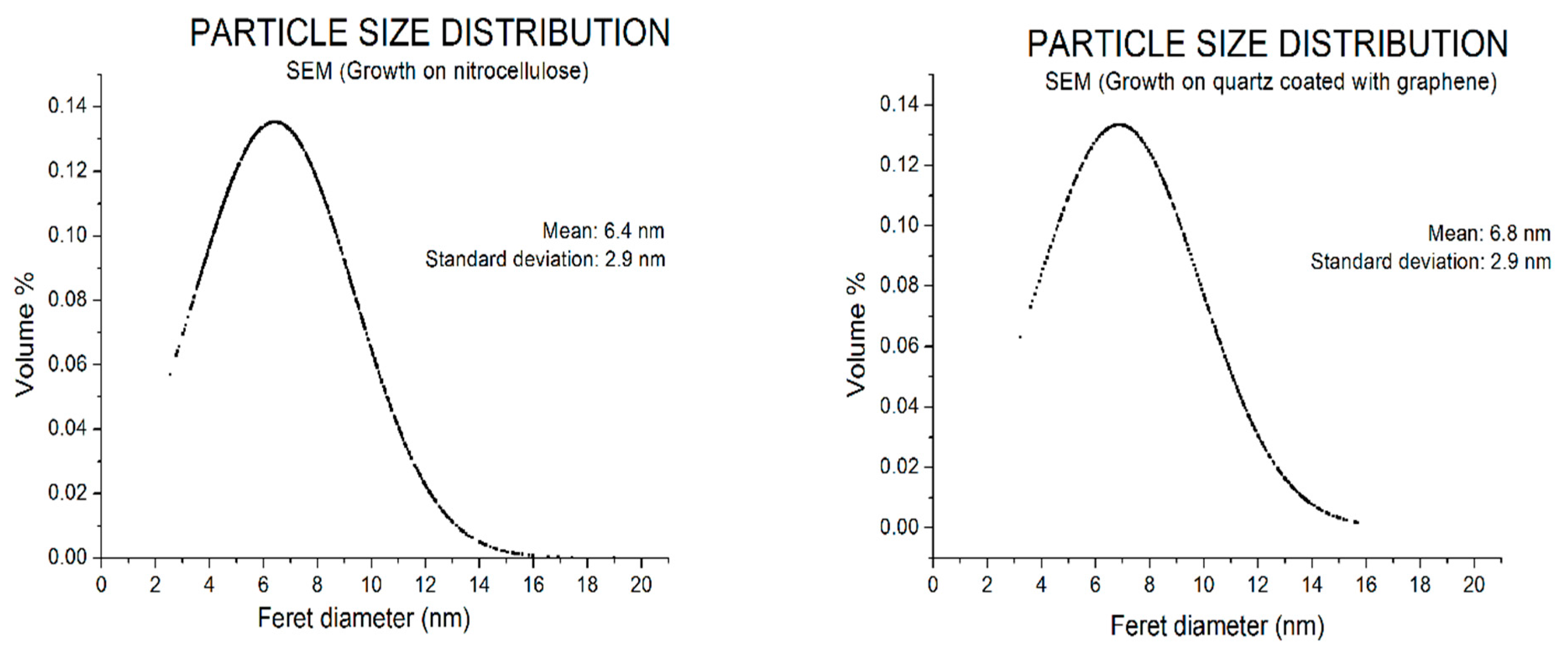

3.2. Nanostructural Characterization

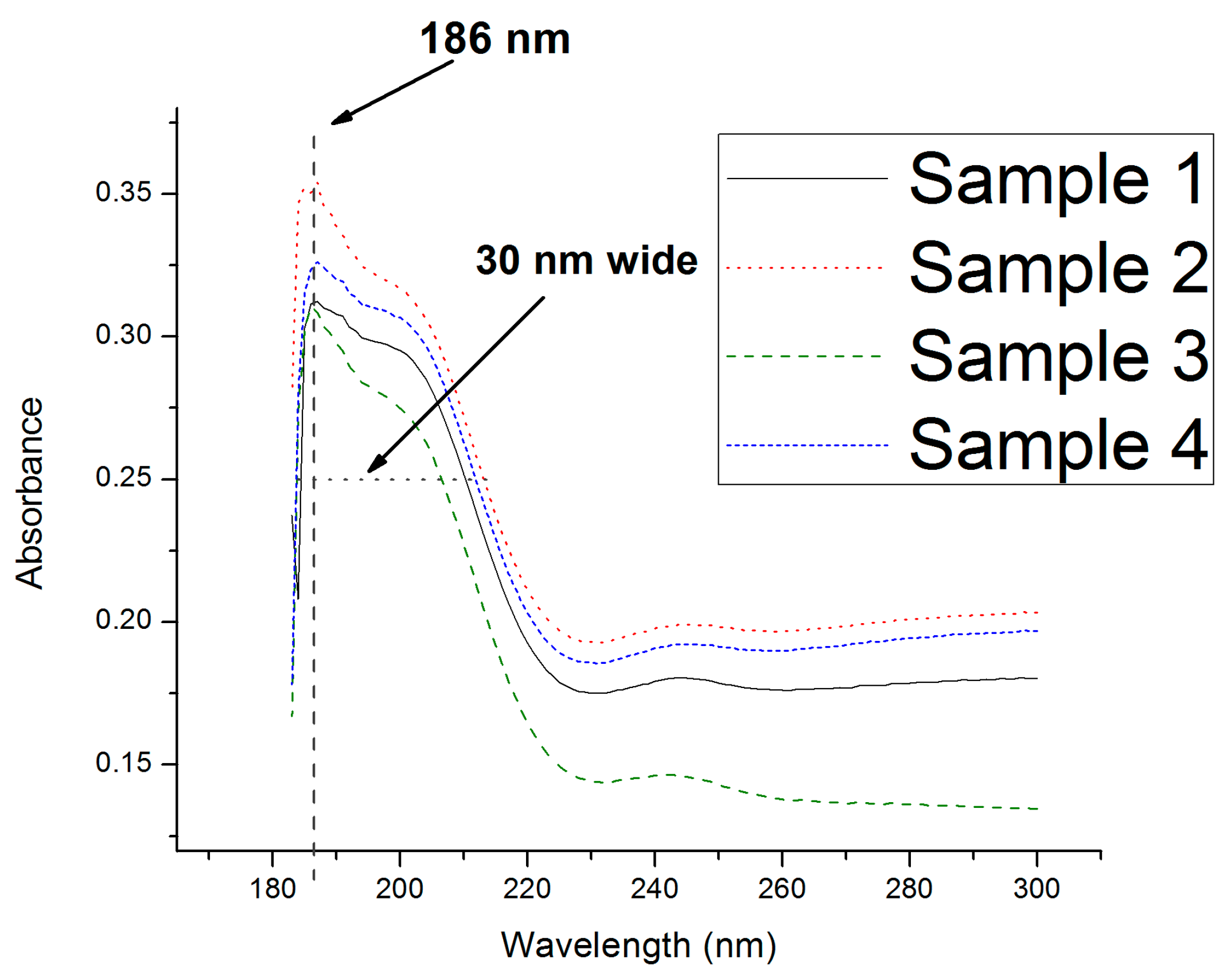

3.3. Optical Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface plasmon resonance sensors: Review. Sens. Actuators B Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, Q.; Zhang, L.; Wang, L.; Zeng, Y.; Huang, H. Combined detection of breast cancer biomarkers based on plasmonic sensor of gold nanorods. Sens. Actuators B Chem. 2015, 221, 1391–1397. [Google Scholar] [CrossRef]

- Tao, H.; Lin, Y.; Yan, J.; Di, J. A plasmonic mercury sensor based on silver-gold alloy nanoparticles electrodeposited on indium tin oxide glass. Electrochem. Commun. 2014, 40, 75–79. [Google Scholar] [CrossRef]

- Naik, G.V.; Shalaev, V.M.; Boltasseva, A. Alternative plasmonic materials: Beyond gold and silver. Adv. Mater. 2013, 25, 3264–3294. [Google Scholar] [CrossRef] [PubMed]

- Knight, M.W.; King, N.S.; Liu, L.; Everitt, H.O.; Nordlander, P.; Halas, N.J. Aluminum for plasmonics. ACS Nano 2014, 8, 834–840. [Google Scholar] [CrossRef] [PubMed]

- Rakić, A.D. Algorithm for the determination of intrinsic optical constants of metal films: Application to aluminum. Appl. Opt. 1995, 34, 4755–4767. [Google Scholar] [CrossRef] [PubMed]

- Ekinci, Y.; Solak, H.H.; Löffler, J.F. Plasmon resonances of aluminum nanoparticles and nanorods. J. Appl. Phys. 2008, 104, 083107. [Google Scholar] [CrossRef]

- Taguchi, A.; Saito, Y.; Watanabe, K.; Yijian, S.; Kawata, S. Tailoring plasmon resonances in the deep-ultraviolet by size-tunable fabrication of aluminum nanostructures. Appl. Phys. Lett. 2012, 101, 081110. [Google Scholar] [CrossRef]

- Hu, J.; Chen, L.; Lian, Z.; Cao, M.; Li, H.; Sun, W.; Tong, N.; Zeng, H. Deep-ultraviolet-blue-light surface plasmon resonance of Al and Alcore/Al2O3shell in spherical and cylindrical nanostructures. J. Phys. Chem. C 2012, 116, 15584–15590. [Google Scholar] [CrossRef]

- Langhammer, C.; Schwind, M.; Kasemo, B.; Zoric, I. Localized surface plasmon resonances in aluminum nanodisks. Nano Lett. 2008, 8, 1461–1471. [Google Scholar] [CrossRef] [PubMed]

- Ekinci, Y.; Solak, H.H.; David, C.; Sigg, H. Bilayer Al wire-grids as broadband and high-performance polarizers. Opt. Express 2006, 14, 2323–2334. [Google Scholar] [CrossRef] [PubMed]

- Jha, S.K.; Ahmed, Z.; Agio, M.; Ekinci, Y.; Löffler, J.F. Deep-UV surface-enhanced resonance Raman scattering of adenine on aluminum nanoparticle arrays. J. Am. Chem. Soc. 2012, 134, 1966–1969. [Google Scholar] [CrossRef] [PubMed]

- Thyagarajan, K.; Rivier, S.; Lovera, A.; Martin, O.J.F. Enhanced second-harmonic generation from double resonant plasmonic antennae. Opt. Express 2012, 20, 12860–12865. [Google Scholar] [CrossRef] [PubMed]

- Kochergin, V.; Neely, L.; Jao, C.Y.; Robinson, H.D. Aluminum plasmonic nanostructures for improved absorption in organic photovoltaic devices. Appl. Phys. Lett. 2011, 98, 133305. [Google Scholar] [CrossRef]

- Langhammer, C.; Zorić, I.; Kasemo, B.; Clemens, B.M. Hydrogen storage in Pd nanodisks characterized with a novel nanoplasmonic sensing scheme. Nano Lett. 2007, 7, 3122–3127. [Google Scholar] [CrossRef] [PubMed]

- Schwind, M.; Langhammer, C.; Kasemo, B.; Zorić, I. Nanoplasmonic sensing and QCM-D as ultrasensitive complementary techniques for kinetic corrosion studies of aluminum nanoparticles. Appl. Surf. Sci. 2011, 257, 5679–5687. [Google Scholar] [CrossRef]

- Meziani, M.J.; Bunker, C.E.; Lu, F.; Li, H.; Wang, W.; Guliants, E.A.; Quinn, R.A.; Sun, Y.P. Formation and properties of stabilized aluminum nanoparticles. ACS Appl. Mater. Interfaces 2009, 1, 703–709. [Google Scholar] [CrossRef] [PubMed]

- Thornton, J.A. Magnetron sputtering: Basic physics and application to cylindrical magnetrons. J. Vac. Sci. Technol. 1978, 15, 171–177. [Google Scholar] [CrossRef]

- Ray, K.; Chowdhury, M.H.; Lakowicz, J.R. Aluminum nanostructured films as substrates for enhanced fluorescence in the ultraviolet-blue spectral region. Anal. Chem. 2007, 79, 6480–6487. [Google Scholar] [CrossRef] [PubMed]

- Stratakis, E.; Barberoglou, M.; Fotakis, C.; Viau, G.; Garcia, C.; Shafeev, G.A. Generation of Al nanoparticles via ablation of bulk Al in liquids with short laser pulses. Opt. Express 2009, 17, 12650–12659. [Google Scholar] [CrossRef] [PubMed]

- Sanz, J.M.; Ortiz, D.; Alcaraz De La Osa, R.; Saiz, J.M.; González, F.; Brown, A.S.; Losurdo, M.; Everitt, H.O.; Moreno, F. UV plasmonic behavior of various metal nanoparticles in the near- and far-field regimes: Geometry and substrate effects. J. Phys. Chem. C 2013, 117, 19606–19615. [Google Scholar] [CrossRef]

- Maidecchi, G.; Gonella, G.; Proietti Zaccaria, R.; Moroni, R.; Anghinolfi, L.; Giglia, A.; Nannarone, S.; Mattera, L.; Dai, H.L.; Canepa, M.; et al. Deep ultraviolet plasmon resonance in aluminum nanoparticle arrays. ACS Nano 2013, 7, 5834–5841. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Zhang, X.; Yonzon, C.R.; Haes, A.J.; Van Duyne, R.P. Localized surface plasmon resonance biosensors. Nanomedicine 2006, 1, 219–228. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-Rosas, A.L.; Rodríguez-Gómez, A.; Arenas-Alatorre, J.A.; Alonso-Huitrón, J.C. Photoluminescence enhancement from silicon quantum dots located in the vicinity of a monolayer of gold nanoparticles. RSC Adv. 2015, 5, 92923–92931. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; DeZonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinform. 2017, 18, 529. [Google Scholar] [CrossRef] [PubMed]

- Nakano, T.; Saitou, Y.; Oya, K. Transient evolution of the target erosion profile during magnetron sputtering: Dependence on gas pressure and magnetic configuration. Surf. Coat. Technol. 2017, 326, 436–442. [Google Scholar] [CrossRef]

- Shearer, C.J.; Slattery, A.D.; Stapleton, A.J.; Shapter, J.G.; Gibson, C.T. Accurate thickness measurement of graphene. Nanotechnology 2016, 27, 125704. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez, Y.; Ortiz, D.; Sanz, J.M.; Saiz, J.M.; Gonzalez, F.; Everitt, H.O.; Moreno, F. How an oxide shell affects the ultraviolet plasmonic behavior of Ga, Mg, and Al nanostructures. Opt. Express 2016, 24, 20621–20631. [Google Scholar] [CrossRef] [PubMed]

- Tehuacanero-Cuapa, S.; Reyes-Gasga, J.; Rodríguez-Gómez, A.; Bahena, D.; Hernández-Calderón, I.; García-García, R. The low-loss EELS spectra from radiation damaged gold nanoparticles. J. Appl. Phys. 2016, 120, 164302. [Google Scholar] [CrossRef]

- Tehuacanero-Cuapa, S.; Reyes-Gasga, J.; Brès, E.F.; Palomino-Merino, R.; García-García, R. Holes drilling in gold and silver decahedral nanoparticles by the convergent beam electron diffraction electron beam. Radiat. Eff. Defects Solids 2014, 169, 838–844. [Google Scholar] [CrossRef]

- Stöckli, T.; Bonard, J.-M.; Stadelmann, P.-A.; Châtelain, A. EELS investigation of plasmon excitations in aluminum nanospheres and carbon nanotubes. Z. Phys. D 1997, 40, 425–428. [Google Scholar] [CrossRef]

- Brown, R.N.; Kahan, A. Optical absorption of irradiated quartz in the near IR. J. Phys. Chem. Solids 1975, 36, 467–476. [Google Scholar] [CrossRef]

- Anker, J.N.; Hall, W.P.; Lyandres, O.; Shah, N.C.; Zhao, J.; Van Duyne, R.P. Biosensing with plasmonic nanosensors. Nat. Mater. 2008, 7, 442–453. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguilar-Del-Valle, M.D.P.; Cruz-Manjarrez, H.D.J.; Rodríguez-Gómez, A. Simple Fabrication and Characterization of an Aluminum Nanoparticle Monolayer with Well-Defined Plasmonic Resonances in the Far Ultraviolet. Metals 2018, 8, 67. https://doi.org/10.3390/met8010067

Aguilar-Del-Valle MDP, Cruz-Manjarrez HDJ, Rodríguez-Gómez A. Simple Fabrication and Characterization of an Aluminum Nanoparticle Monolayer with Well-Defined Plasmonic Resonances in the Far Ultraviolet. Metals. 2018; 8(1):67. https://doi.org/10.3390/met8010067

Chicago/Turabian StyleAguilar-Del-Valle, María Del Pilar, Héctor De Jesús Cruz-Manjarrez, and Arturo Rodríguez-Gómez. 2018. "Simple Fabrication and Characterization of an Aluminum Nanoparticle Monolayer with Well-Defined Plasmonic Resonances in the Far Ultraviolet" Metals 8, no. 1: 67. https://doi.org/10.3390/met8010067

APA StyleAguilar-Del-Valle, M. D. P., Cruz-Manjarrez, H. D. J., & Rodríguez-Gómez, A. (2018). Simple Fabrication and Characterization of an Aluminum Nanoparticle Monolayer with Well-Defined Plasmonic Resonances in the Far Ultraviolet. Metals, 8(1), 67. https://doi.org/10.3390/met8010067