2. Materials and Methods

To analyze the given Al-Si-Mn alloys, we have applied Thermo-Calc 4.1 [

13] software (using the CALPHAD approach) with TCAl3 (TCS Al-based alloys database v.3) and MOBAl3 (TCS Al-alloys mobility database v.3) databases. Thermo-Calc may be used for a wide variety of applications, including the calculation of stable and metastable heterogeneous phase equilibria, amounts of phases and their compositions as a function of temperature and chemistry, phase transformation temperatures such as liquidus and solidus, binary and ternary phase diagrams, isoplethal and isothermal sections for higher order systems, thermochemical data such as enthalpies, heat capacity and activities, driving force for phase transformations, and solidification applying the Scheil-Gulliver model.

For this study, we used hypoeutectic aluminum alloys with 5, 7 and 9 wt % Si and 0.2, 0.4 and 1.0 wt % Mn prepared from pure components: Al (99.999%, Hydro Aluminium Deutschland GmbH, Bonn, Germany), Si (Crystal Growth Laboratory, Berlin, Germany) and Mn (from Manganese Flake 99.95%, Goodfellow Cambridge Ltd., Huntingdon, UK). These specific values of Si and Mn were chosen to reflect the compositions of common industrial alloys. From the given values of Si and Mn, five samples were created and processed for mushy zone analysis, allowing the effect of each element individually to be analyzed across three different samples.

Specimens with 8 mm diameter and 120 mm length were processed in the Artemis-3 facility (German Aerospace Center, Cologne, Germany), which is similar to a Bridgman furnace, in that it allows directional solidification of metal alloys under controlled conditions [

10,

11,

12]. The specimen is contained within a silica aerogel crucible, held between an upper heater and a lower heater equipped with an active cooling system [

10,

12]. The construction of this furnace allows for solidification with a maximum temperature gradient

G = 3 K/mm and solidification velocity in the range

v = 0.02–0.12 mm/s. In the current study, specimens were solidified with a temperature gradient

G = 3 K/mm and solidification velocity

v = 0.04 mm/s in order to allow an extended period of melt stirring to affect the mushy zone. In order to investigate flow effect on the microstructure, fluid flow was induced by three pairs of coils located close to the sample that can yield a rotating magnetic field (RMF) up to 6 mT at a frequency of 50 Hz. Applied stirring with induction

B = 6 mT induced first azimuthal flow and additional secondary flows in radial and axial directions [

14,

15,

16] still by laminar flow and produced characteristic microstructure features including enrichment of eutectics or intermetallics in the specimen center. Such structures were previously observed in AlSiMg [

17], AlSiCu, [

18], AlSiFe [

14,

19,

20,

21], Pb-Sn [

22], Sn-Cd [

23] alloys, where segregation of alloying elements, particular location of phases or modification of dendritic structure might be observed.

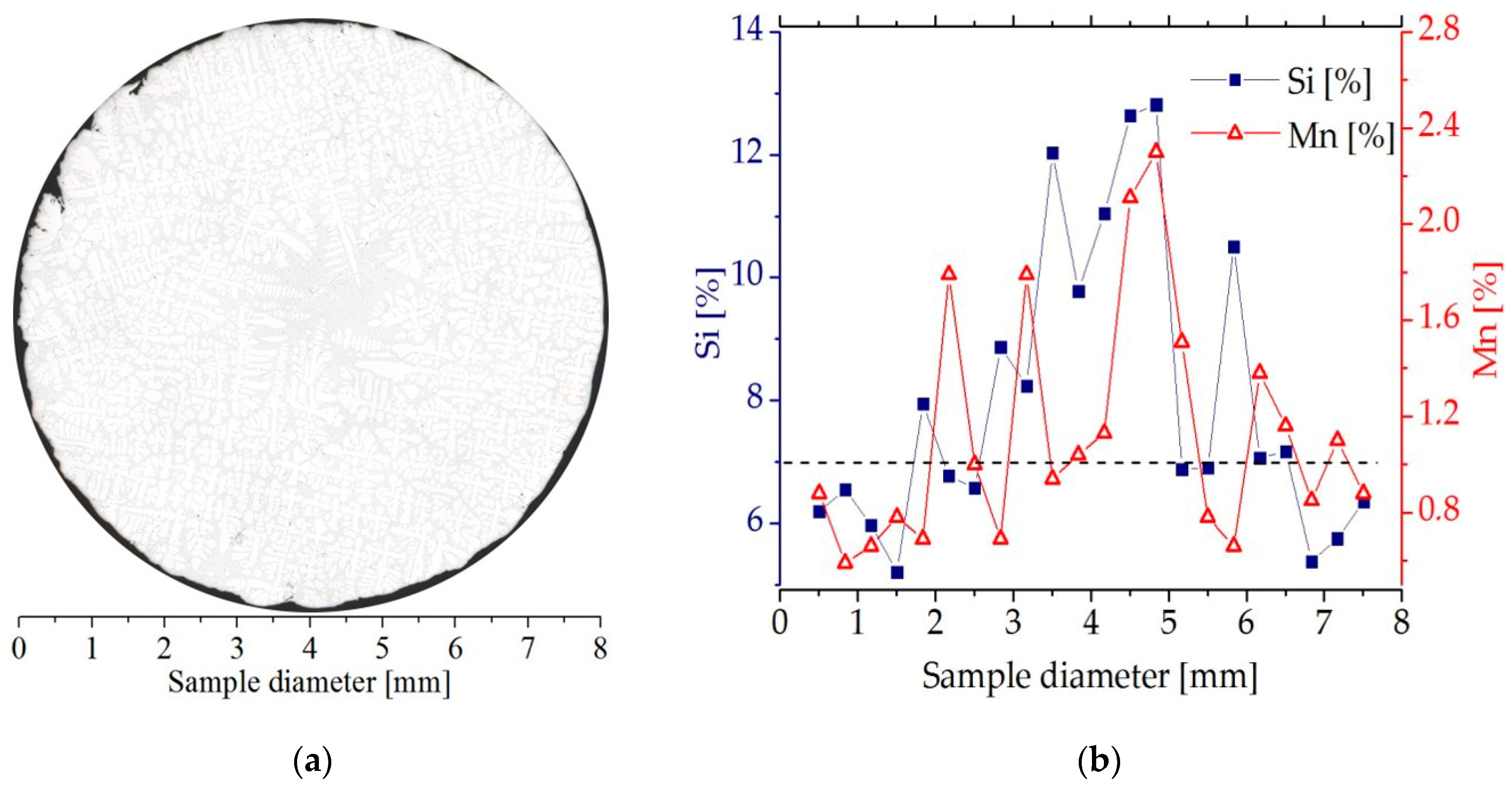

The solidified samples were cut (Isocut 4000, Buehler) at a height of 45 mm from the bottom heater. The coordinate 0 mm on the longitudinal specimen section (

Figure 3a) corresponds to this cut, that is, a solidification distance of 45 mm. The composition across each specimen was investigated on a transverse cross-section using EDS (Princeton Gamma-Tech Instruments Inc., Princeton, NJ, USA) in Vega Tescan SEM (Tescan, Brno, Czech Republic). Each scan consisted of 22 points, spaced 0.363 mm apart, as shown in

Figure 3b. The samples showed some segregation of the Si and Mn toward the center. This compositional variation is also visible in

Figure 3a as an increase in eutectic fraction in the center of the sample.

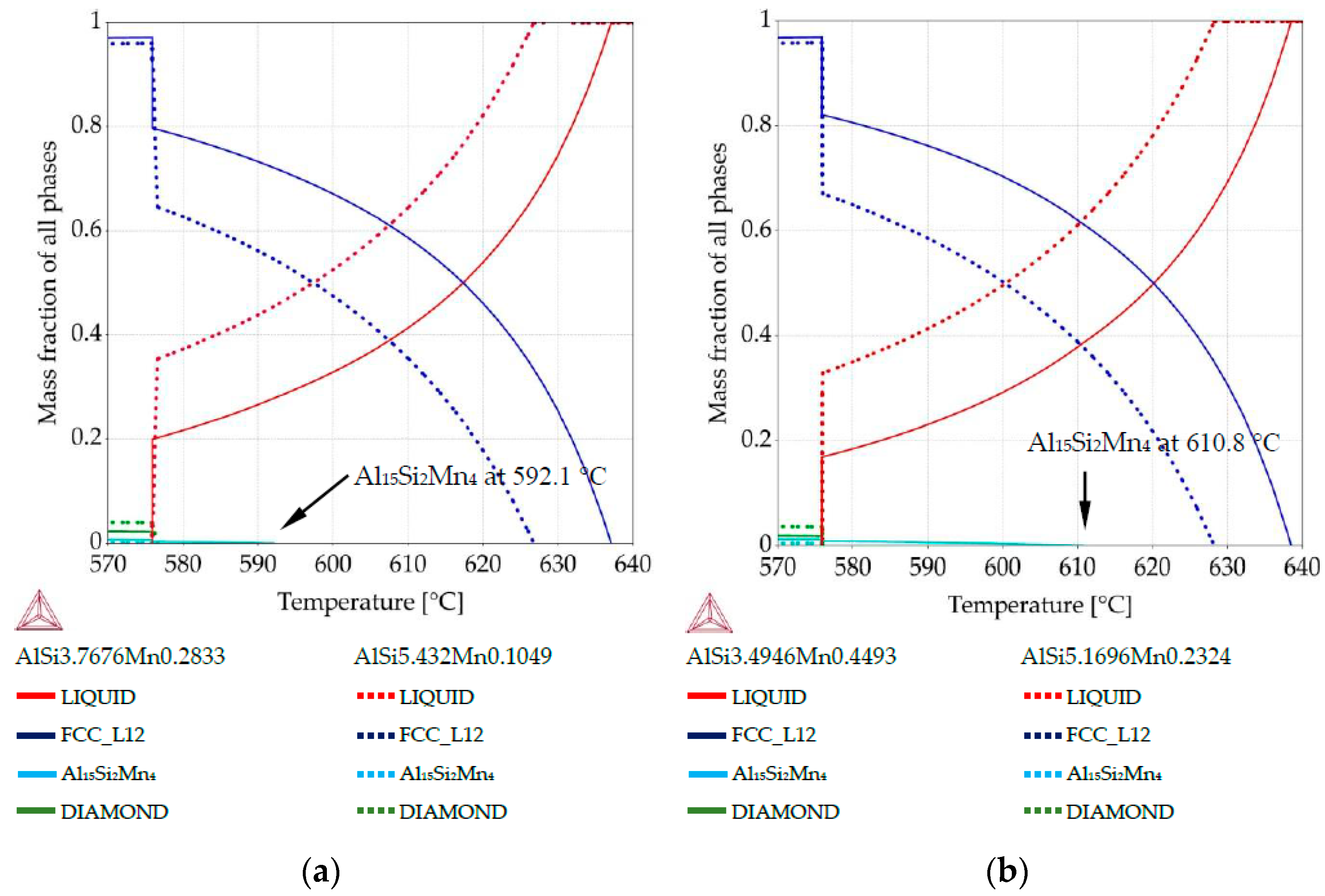

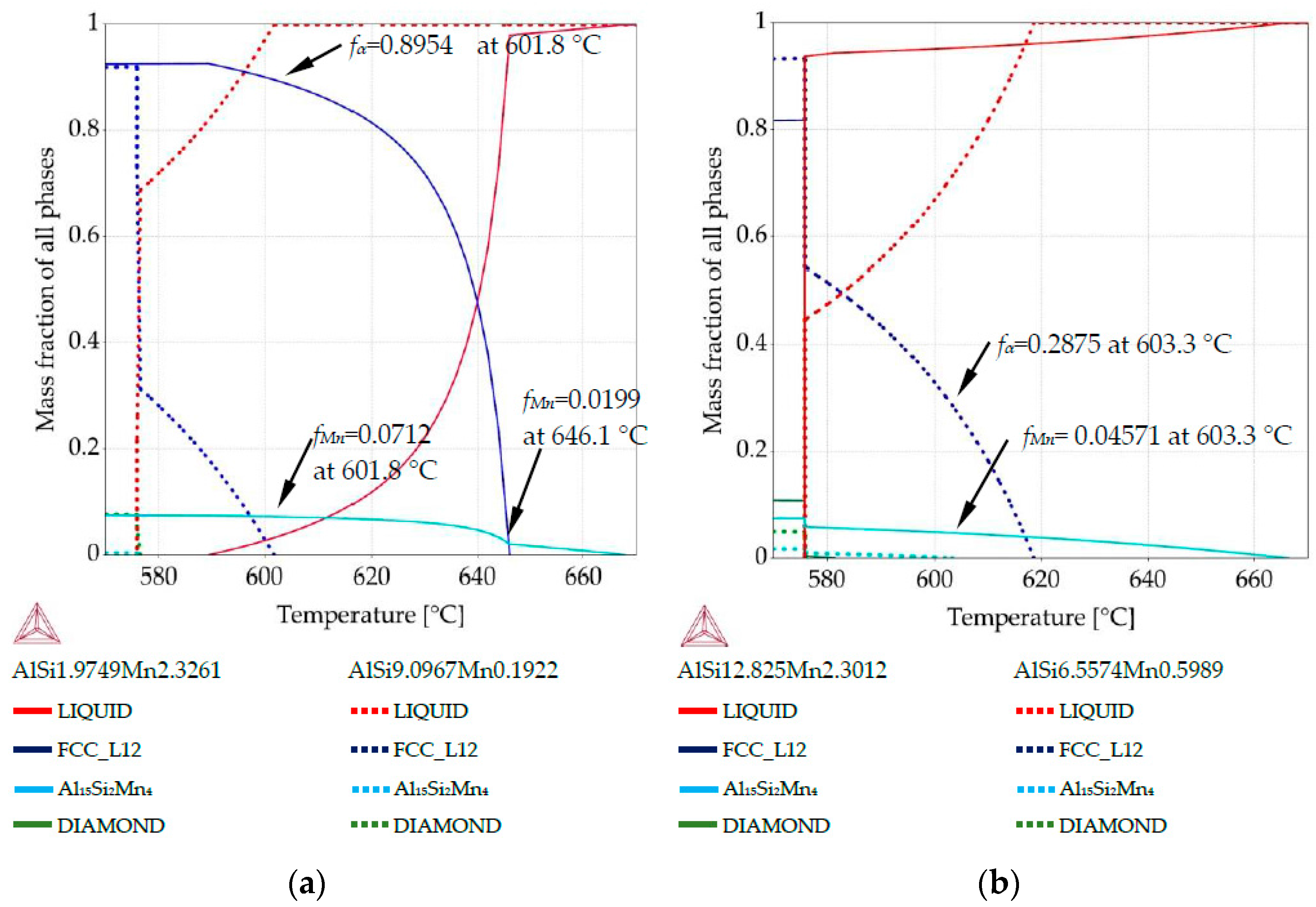

In the current study, we made use of five specimens with compositions AlSi5Mn0.2, AlSi5Mn0.4 AlSi5Mn1.0, AlSi7Mn1.0 and AlSi9Mn1.0, all solidified with induced flow (with RMF). The chemical compositions measured on various cross-sections were located on the Al-Si-Mn phase diagram and treated as potentially solidifying alloys within the specimens. For selected compositions, the solidification paths were calculated in Thermo-Calc using the assumption of Scheil-Gulliver solidification. Application of the Scheil equation, which assumes no diffusion in the solid and complete mixing in the liquid, is common in directional solidification, and the additional mixing of the liquid due to the RMF makes it particularly appropriate for these samples. The solidification paths calculated in Thermo-Calc allow us to identify possible solidification outcomes (that is, the precipitation order of predicted phases and their compositions) for various positions within each sample. For example, for the AlSi5Mn0.4 specimen shown in

Figure 3b, the compositions AlSi3.49Mn0.44 (at position 0.5 mm) and AlSi5.15Mn0.23 (at position 4.1 mm) were analyzed. The compositions were chosen to present the most extreme differences in solidification behavior.

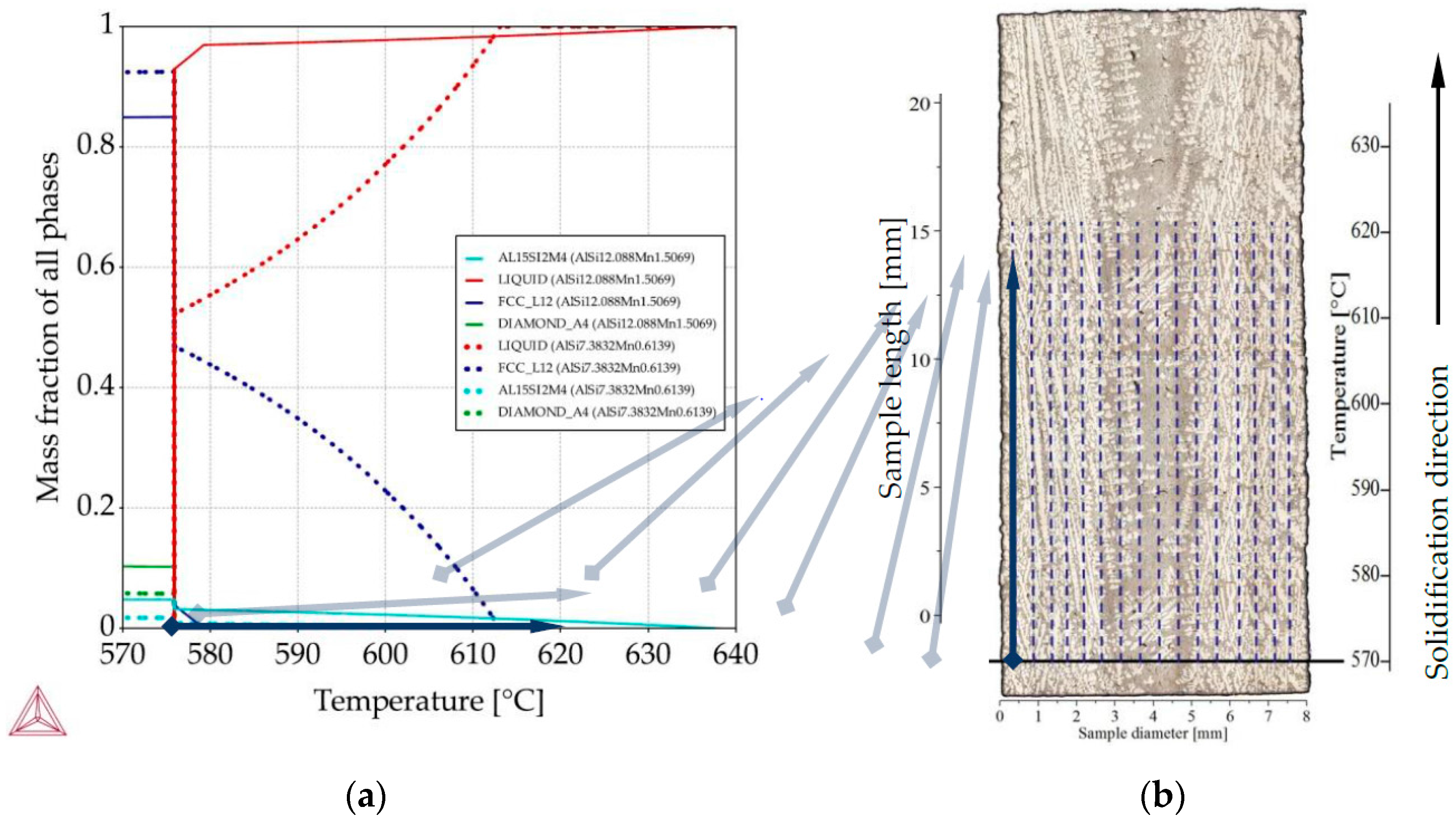

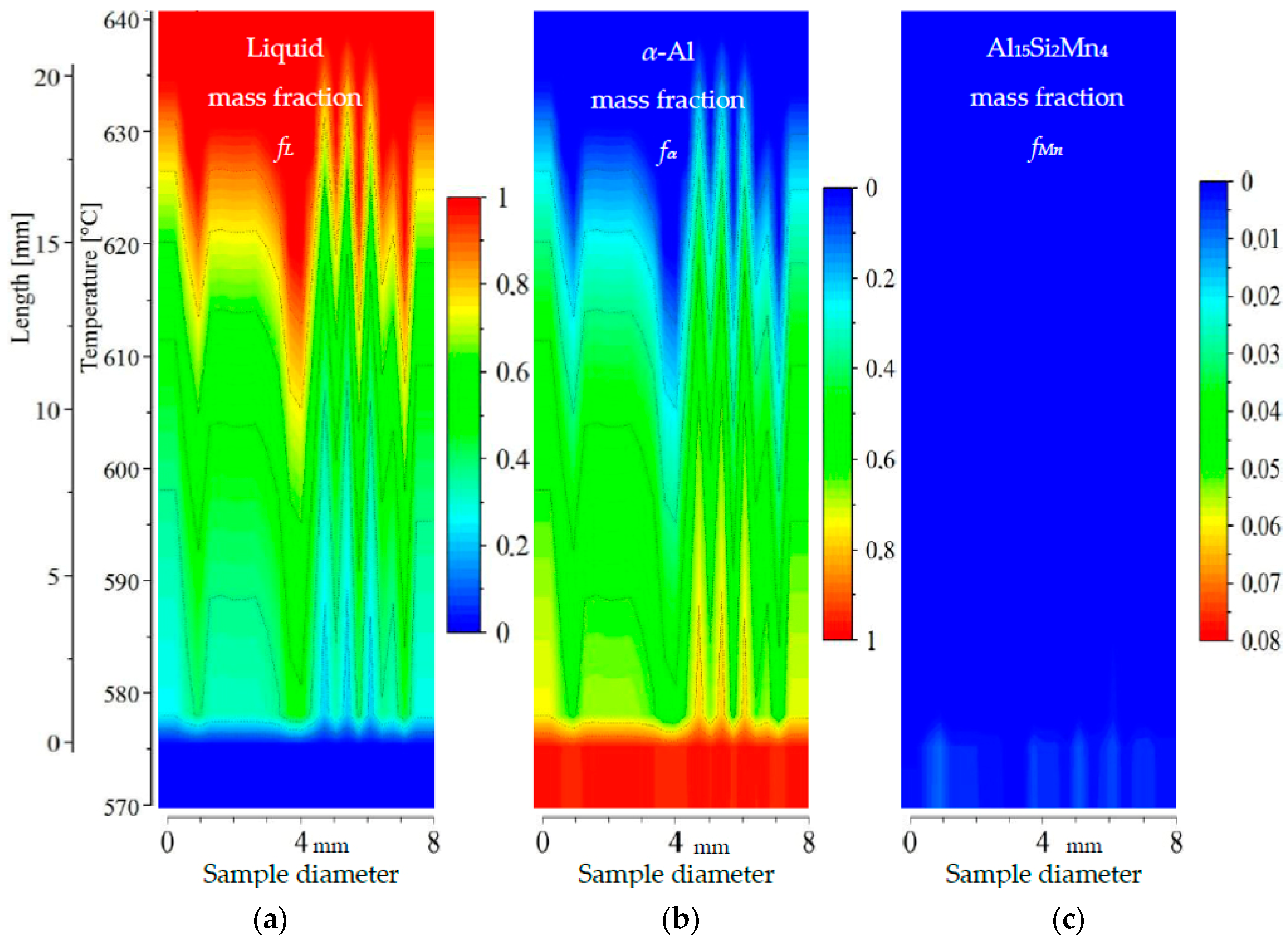

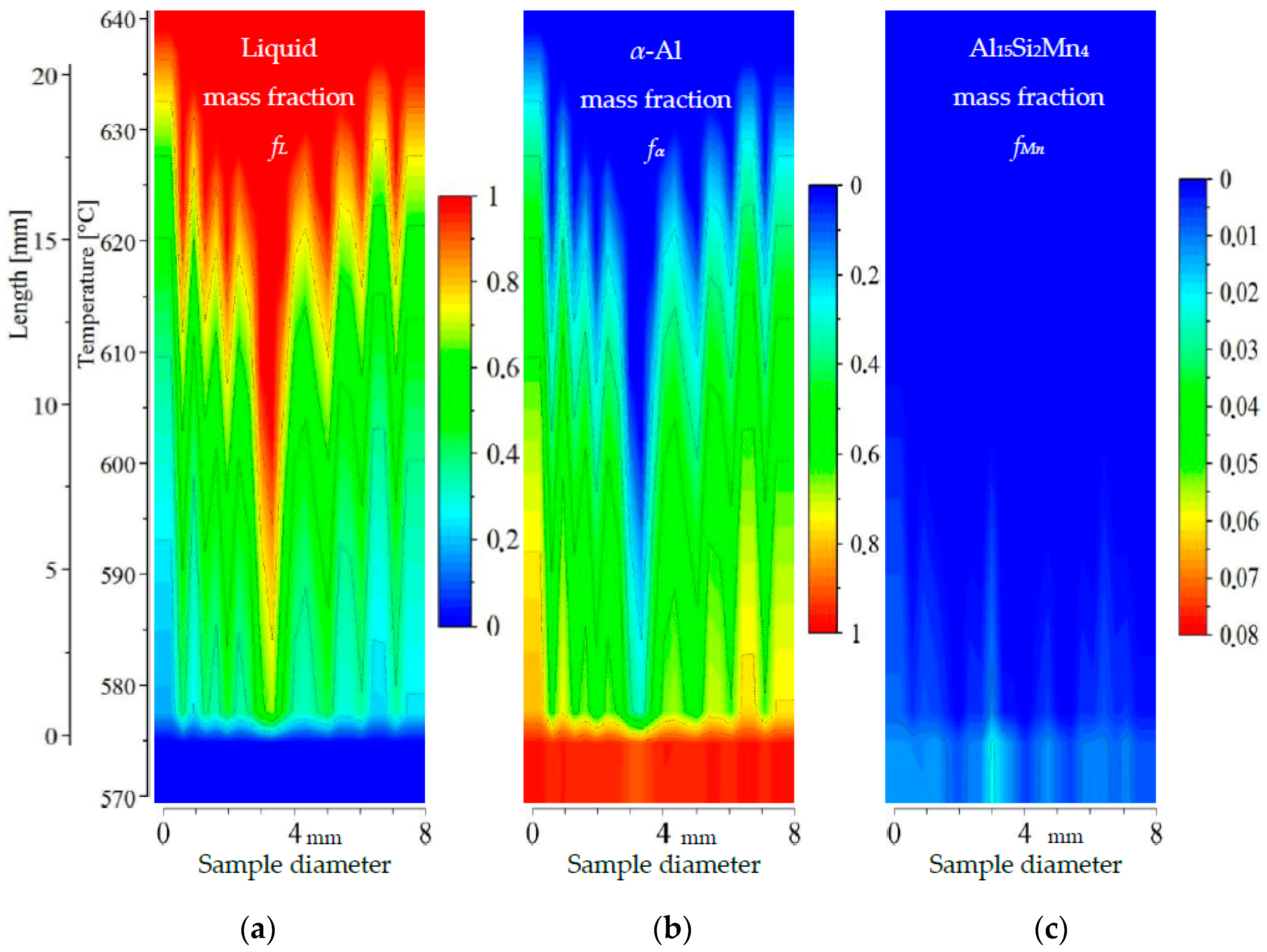

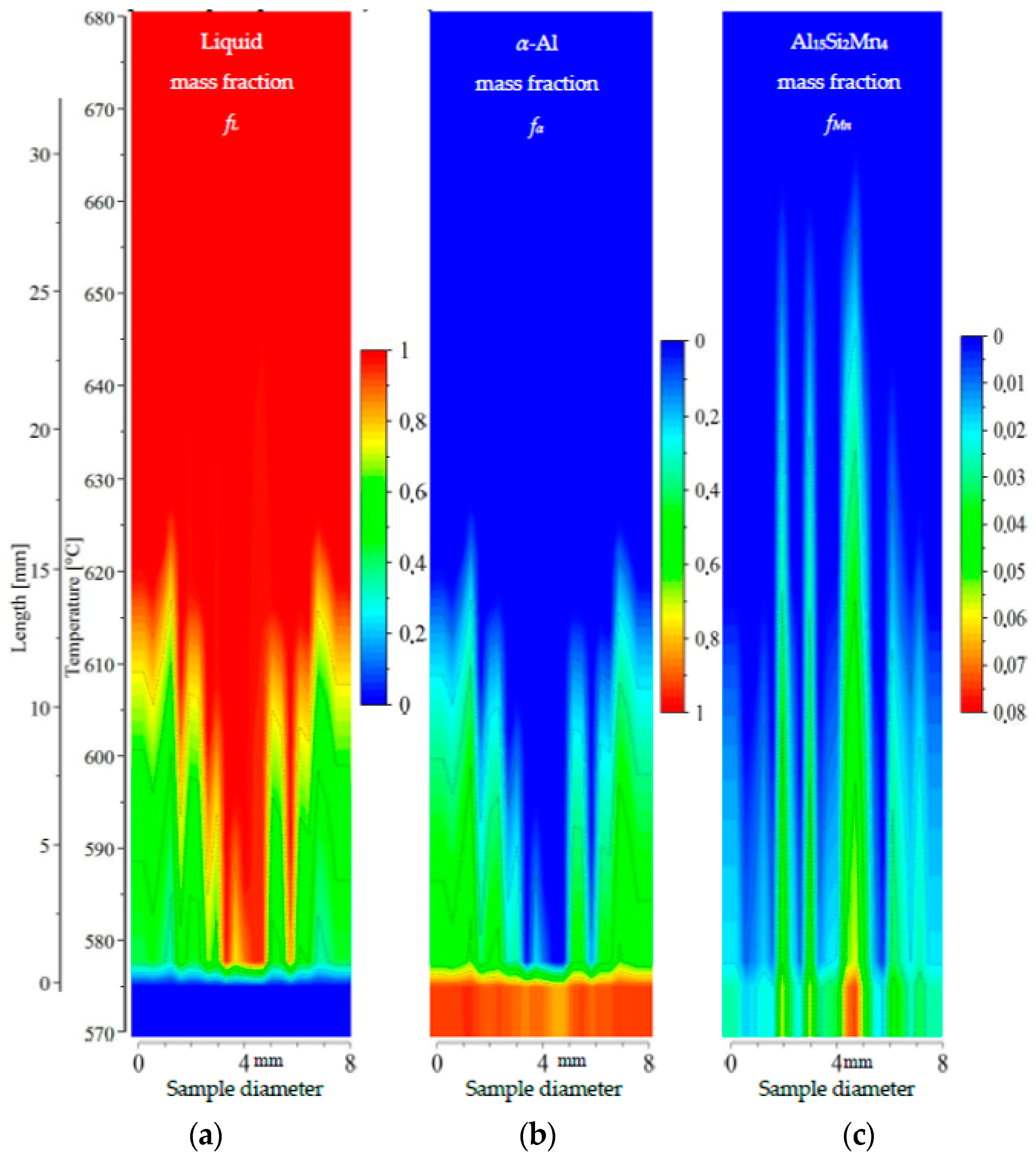

For all twenty-two measured compositions on all five specimens, Thermo-Calc “property diagrams” were calculated, which provide the precipitation sequence and mass fraction of phases as a function of decreasing temperature. Taking each of the twenty-two points as if it were an independent alloy, the calculated property diagrams were assigned a position (along the diameter) on the longitudinal section, as showed by “flying” light blue arrows on

Figure 4. Because the EDS measurements enclosed the rectangle areas with dimensions about 0.36 mm, by distances between them 0.36 too, it seemed applicable to assign data from property diagrams into suitable 0.36 m wide areas. The data from the “property diagram” for chosen composition (an independent alloy) were transformed using graphical software, from charts into 0.36 wide belts and placed with spacing (0.36 mm) equal measuring interval. Transformation from temperature into length was based on linear temperature field supported by slow solidification velocity 0.04 mm/s. It would, of course, also be possible to apply a nonlinear temperature field, gained e.g., from thermal macro-scale modeling, and produce the same type of plots. For each specimen, the property diagrams were used to prepare 2D maps showing the mass fraction (of liquid, α-Al dendrites, Al

15Si

2Mn

4) as a function of location on the longitudinal section and temperature (or length) of phase precipitation (

Figure 4). The controlled solidification conditions (consistent, known temperature gradient and velocity) in Artemis-3 allowed for rescaling the temperature axis into a length axis, showing in this way 2D maps of the mushy zone as function of position within the sample, both across the diameter and along the solidification direction.

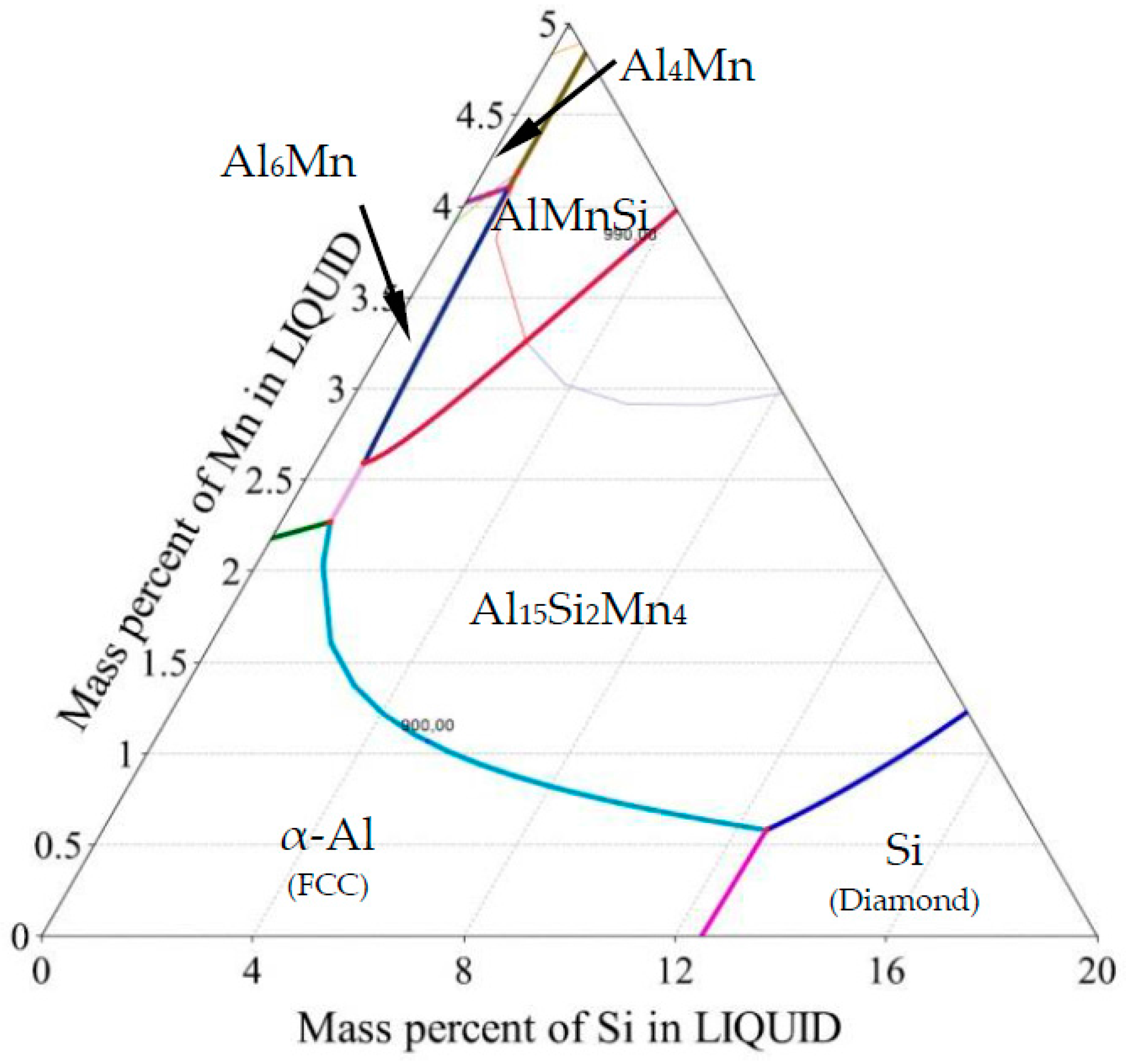

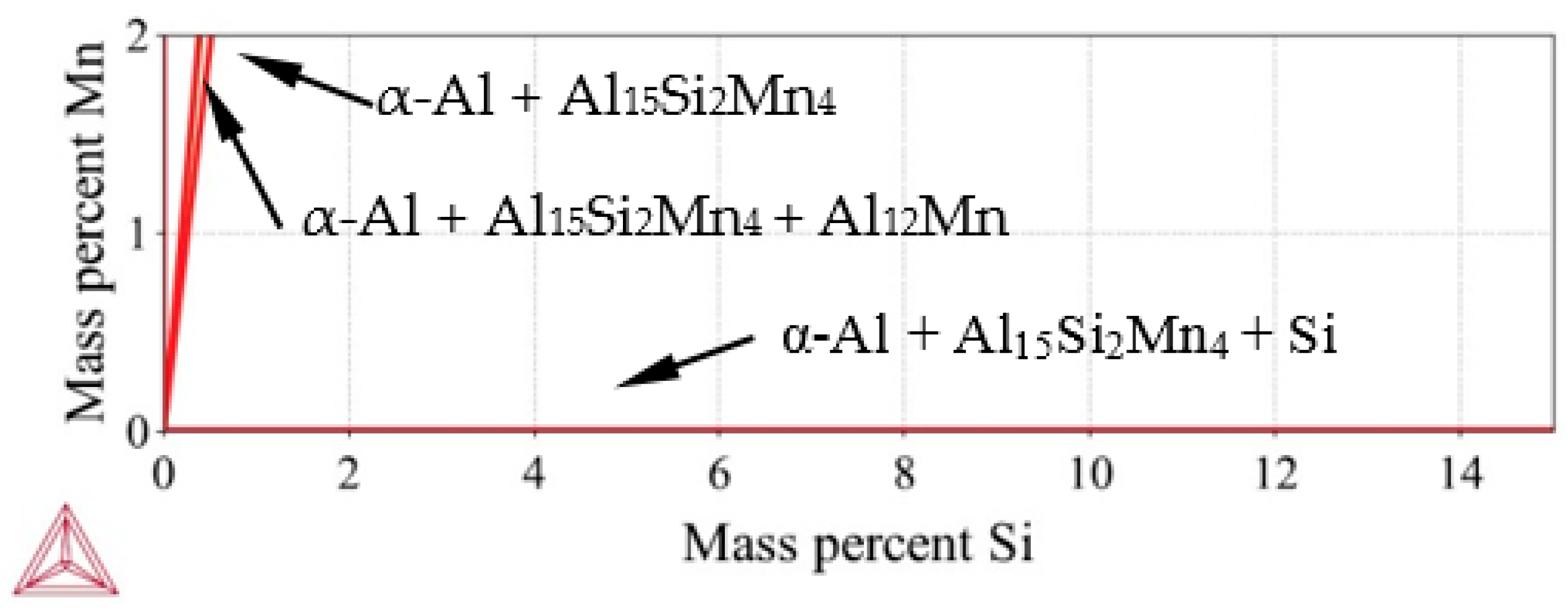

The ternary phase diagram shown in

Figure 5 is a liquidus projection generated in Thermo-Calc with temperature range 550–900 °C and interval 2 °C. Scheil solidification was calculated with temperature interval 1 °C and mass fraction interval 0.005. Property diagrams (Figures 6–13) were generated by temperature interval 2 °C and mass fraction interval 0.017–0.059 for liquid and α-Al, and 0.00017–0.00148 for Al

15Si

2Mn

4.

4. Discussion

The combination of phase diagrams, Scheil-Gulliver solidification, and property diagrams has been used broadly in materials science to better understand the complex relationships between composition, microstructure and processing conditions. However, the application of property diagrams described in the current study for mushy zone prediction is unique.

On the 2D maps (

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13), the most reliable values are those of mass fraction for the solidified area at temperatures below 575 °C. The measurement of chemical composition was conducted by 20 °C and seems to agree with that in the specimen at 575 °C. The plot of mass fractions above 575 °C (of discussed phases) is the projection resulting from chemical composition mostly frozen at 575 °C, but the real mushy zone is determined by Si and Mn release and intensive stirring (RMF) and may differ from

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13.

Due to the use of aerogels [

11,

24]—a transparent material (90% transmission in the range 500–2000 nm wavelength) with low thermal conductivity (5–20 mW/m·K)—it was possible to measure the intensity of radiation from surface of solidifying sample. Recorded radiation intensity was used for precise determination of solidification velocity using the peak-effect by solidus temperature. Based on the radiation intensity, developed by Steinbach and Ratke [

24], the method for mass fraction calculation is suitable for planar front present in Artemis-3 facility by solidification without electromagnetic stirring. In the current study by melt flow (not planar front) and very small amount of Mn-rich intermetallics (by 0.2 to 1 wt % Mn), it was impossible to validate directly the mass fraction of occurring phases, except through reference to simulation results [

16].

The study of simulated directional solidification for AlSi7 (

G = 4 K/mm,

B = 3 mT) by Hainke [

16] took into consideration, among other things, rejection of solute and fluid flow. The melt flow calculations present velocity isolines (not velocity values) that descend 4 mm in the specimen center in comparison to the edges of the sample. The simulation results [

16] show the liquid mass fraction isoline

fL = 0.0 also reaching 4 mm deep into the mushy zone in the central part of the specimen, and mass fraction isoline

fL = 0.325 reaching 7.15 mm. Results similar to those of Hainke were found in the experimental study [

25] but clearly show deeper liquid channels, to a depth of 12–15 mm for specimen AlSi7Fe1.0 and 9–13 mm for AlSi7Fe0.5, with high liquid mass fraction and low α-Al mass fraction, and the presence of β phases. This study, like the current work, used a temperature gradient of 3 K/mm, while the calculations of liquid channel depth by Hainke [

16] were done using a temperature gradient of 4 K/mm. This means that the mushy zone in [

16] might be estimated to be about 32% longer than when simulating with 3 K/mm. The current study presents comparable results to [

16,

25]; for the same Si content (specimen AlSi7Mn1.0), we see a 13 mm long mushy zone based on α-Al area (575–615 °C). This sample also has a 28 mm long area (575–660 °C) for Al

15Si

2Mn

4, indicating Mn-phases growing in the liquid channel and above the dendrites. Similar observations indicating formation of the liquid channel apply to specimens AlSi5Mn0.4, AlSi5Mn1.0 and AlSi9Mn1.0.

The 2D maps showed precipitation of Mn-rich phases after α-Al at every point across the diameter of specimens AlSi5Mn0.2 and AlSi5Mn0.4, including the liquid channel (

Figure 9c and

Figure 10c). For the specimen AlSi5Mn0.2 (

Figure 9c), the liquid channel is completely empty of Al

15Si

2Mn

4, which doesn’t appear until essentially the final ternary eutectic reaction. For AlSi5Mn0.4, the Mn phase begins to form earlier, but still at a temperature just after the α-Al dendrites appear, meaning the liquid channel is also empty of Al

15Si

2Mn

4. With 5 wt % Si, the dendritic structure is dense and seems not to allow Mn-intermetallics to flow into liquid area above dendrite tips, although it might be possible in the liquid channel in the specimen center, where only dendrite tips or AlSi eutectic exists as the first Mn phases form.

According to the maps, manganese rich-phases precipitate first across considerable regions of the specimens AlSi5Mn1.0 and AlSi7Mn1.0, especially in the central liquid channel. According to the composition measurements, the starting point for Al

15Si

2Mn

4 growth at some points is far above dendrite tips, at the beginning of the mushy zone. In the AlSi9Mn1.0, Mn phases may precipitate first across nearly all of the specimens. Only very near the edges of the sample is the composition such that the Mn phases start to form close to final eutectic temperature 575.9 °C. By 9 wt % Si, the dendritic structure is thinner and the flow of Mn-intermetallics between dendrite arms seems possible. Such a possibility depends strongly on the dimension and morphology of intermetallics. According to [

26], we may distinguish Mn phases with different morphologies: cube, colony of cubes, tree shaped, platelet shaped, and rib shaped phases. In addition, the formation of other phases caused by the presence of additional alloy components (e.g., Mg) might decrease the fluidity of the solidifying melt [

27].

In previous studies of AlSiFe specimens produced using the same experimental technique [

25], with decreasing mushy zone length, the width of the liquid channel increased and the amount of β-Al

5FeSi in it decreased. Fe-rich phases formed first only in the liquid channel. Basing on the 2D maps, in current specimens, with decreasing mushy zone length, the number (mass fraction) of precipitating Mn-phases increased. On the Al-Si-Mn phase diagram (

Figure 1 and

Figure 5 and

Figure 6), the eutectic groove for intermetallic formation (L → α-Al + Al

15Si

2Mn

4 + L) goes from the point with concentration Al-12.55 wt % Si-0.45 wt % Mn to point Al-1.1 wt % Si-2.23 wt % Mn. However, in the Fe-containing alloys, the eutectic groove (L → α-Al + β-Al

5FeSi + L) goes from Al-12.56 wt % Si-0.90 wt % Fe to Al-4.2 wt % Si-2.05 wt % Fe. This means that, for the Al-Si-Fe system, an alloy solidifying along the eutectic groove (L → α-Al + β-Al

5FeSi) has higher amounts of Fe in comparison to the equivalent eutectic groove in the Al-Si-Mn system (L → α-Al + Al

15Si

2Mn

4), indicating that Mn maintains an important role in determining solidification path even at lower compositions such as those in these sample (0.2%, 0.4% and 1.0% Mn). By comparing these two Al-Si systems, comparing the phase diagrams and samples with similar compositions and varied amounts of the third element shows that the flow effect on the morphology may differ from alloy to alloy.

For the samples studied here, the mushy zone length varies from 20 mm (AlSi5Mn0.2) to 32 mm (AlSi5Mn1.0), while, for Fe containing alloys [

25], it varied from 10 mm (AlSi9Fe0.2) to 20 mm (AlSi5Fe1.0). This may be the next cause for differences in Mn and Fe segregation. In [

16], stirring was weaker, caused by a rotating electromagnetic field of 3 mT, while, in [

25], and, in the current study, the RMF was 6 mT. According to [

28], the flow in the axial direction may constrain the mushy zone length to 12 mm in a temperature gradient of 4 K/mm and with electromagnetic field strength 3 mT. However, that is much less than the observed lengths of the mushy zones reported in [

25] and current study (

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13). The simulated flow velocities [

28] in the axial direction are 2.5 mm/s for strength 3 mT and 10.5 mm/s for 6 mT. There is no information that increased flow velocities due to increased field strength may point on the longer area with included flow.

All the computations and discussions were developed considering fixed composition along sample length without composition change during solidification. However, during solidification, the composition may change due to fluid flow evolution or due to the segregation in the remaining liquid. The earlier EDS measurements [

29] for AlSi7Fe1.0 alloy on similar specimens (with 8 mm diameter and 120 mm long), showed almost constant Si and Fe concentration along samples solidified without melt stirring. However, for solidification with high rotating magnetic field (HRMF) of 150 mT and temperature gradient 7 K/mm, segregation was found to occur both along and across sample. The concentration increased almost linearly from the sample beginning (2.5 wt % Si and 0.6 wt % Fe, coordinate 1 mm), to the sample end (12.8 wt % Si and 1.7 wt % Fe, coordinate 100 mm). Considering a similar linear increase, given the length of our predicted dendrite area (about 20 mm), between solidus isoline and dendrite tips, the concentration might increase about 1.2 wt % Si. Such an increase would shift the points on the Al-Si-Mn phase diagram (

Figure 5) to the right, decreasing the liquidus about 7 °C and causing the mushy zone to be about 2.3 mm shorter. Such a composition shift would also result in a slightly wider liquid channel. Considering that the segregation measurements [

29] by HRMF were made with 150 mT and current studies by RMF only 6 mT, it can be safely estimated that any change to the values presented here resulting from segregation along the sample length would be much less than a 10% reduction in mushy zone length and similarly scaled change to the liquid channel width.

The formation of the liquid channel in the specimen center is compatible with current and previous studies [

25]. The main cause for the channel is segregation of Si, causing a shift to the right on the phase diagram toward the direction of the final ternary eutectic reaction. The segregation of Mn is not so uniform as was observed for Fe in [

25], where the specimen center was clearly enriched in iron. Specimens with manganese show some enrichment in the center (e.g., AlSi9Mn1.0), but also some enrichment outside the center (e.g., AlSi5Mn1.0). This seems to result from different morphologies between platelet shaped β-Al

5FeSi and complicated shaped Mn-rich phases [

26].

The 2D maps revealed a mushy zone 20 mm long for AlSi5Mn0.2, 21 mm for AlSi5Mn0.4, 33 mm for AlSi5Mn1.0, 28 mm for AlSi7Mn1.0 and 21 mm for AlSi9Mn1.0. The changes in Si concentration mean different fractions of AlSi eutectic and α-Al dendrites, and variation in the permeability of the dendritic skeleton. For AlSi5Mn0.2 and AlSi5Mn0.4, the 2D maps present a liquid channel empty of Mn phase regions, while the maps for AlSi5Mn1.0, AlSi7Mn1.0 and AlSi9Mn1.0 show channels filled with Al15Si2Mn4, which also appeared and presumably flowed above the dendrite tips. These factors strongly determine permeability of mushy zone near the sample edges and in the specimen center, at the top and bottom of the mushy zone. The fluid flow generated by the magnetic field should be analyzed carefully for each specimen. In the AlSi5Mn0.2 and AlSi5Mn0.4 specimens, the fluid flow may be damped more strongly by longer and denser dendritic structures and Mn-phases located deep within the dendrite mesh. However, in AlSi5Mn1.0, AlSi7Mn1.0 and AlSi9Mn1.0, the stirring of the alloy may be stronger because of differences in the dendritic area (shorter and thinner α-Al regions) but with many more Mn intermetallics between and above dendrites.