Mechanical Characterization of Composite Coatings Formed by Reactive Detonation Spraying of Titanium

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

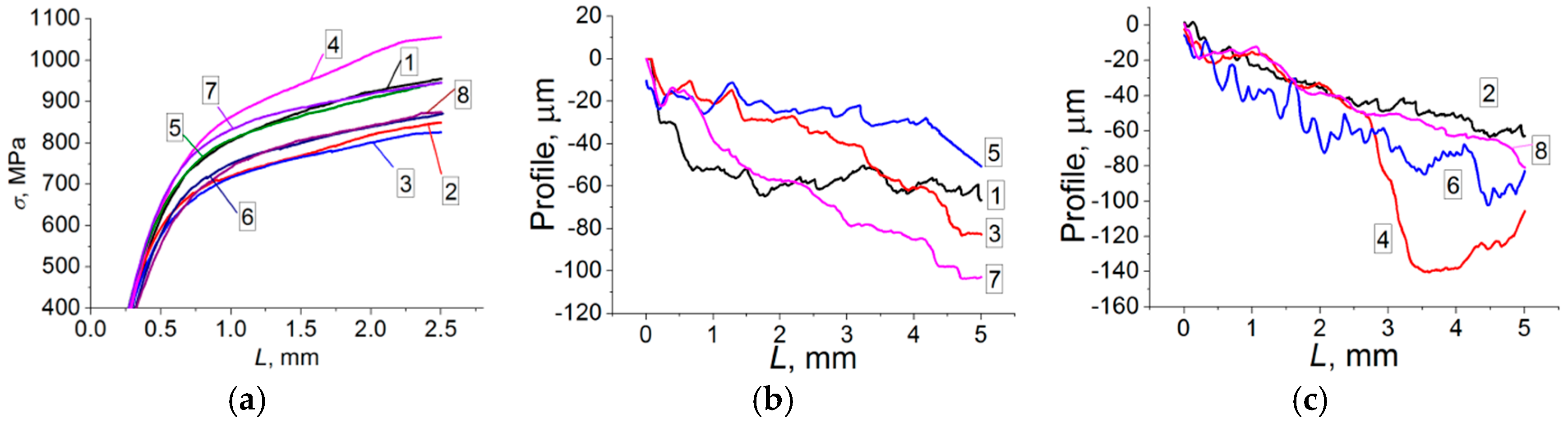

3.1. Three-Point Bending Test

3.2. Scratch Tests

3.2.1. Spraying Regime 1

3.2.2. Spraying Regime 2

3.2.3. Spraying Regime 3

3.2.4. Spraying Regime 4

3.2.5. Spraying Regime 5

3.2.6. Spraying Regime 6

3.2.7. Spraying Regime 7

3.2.8. Spraying Regime 8

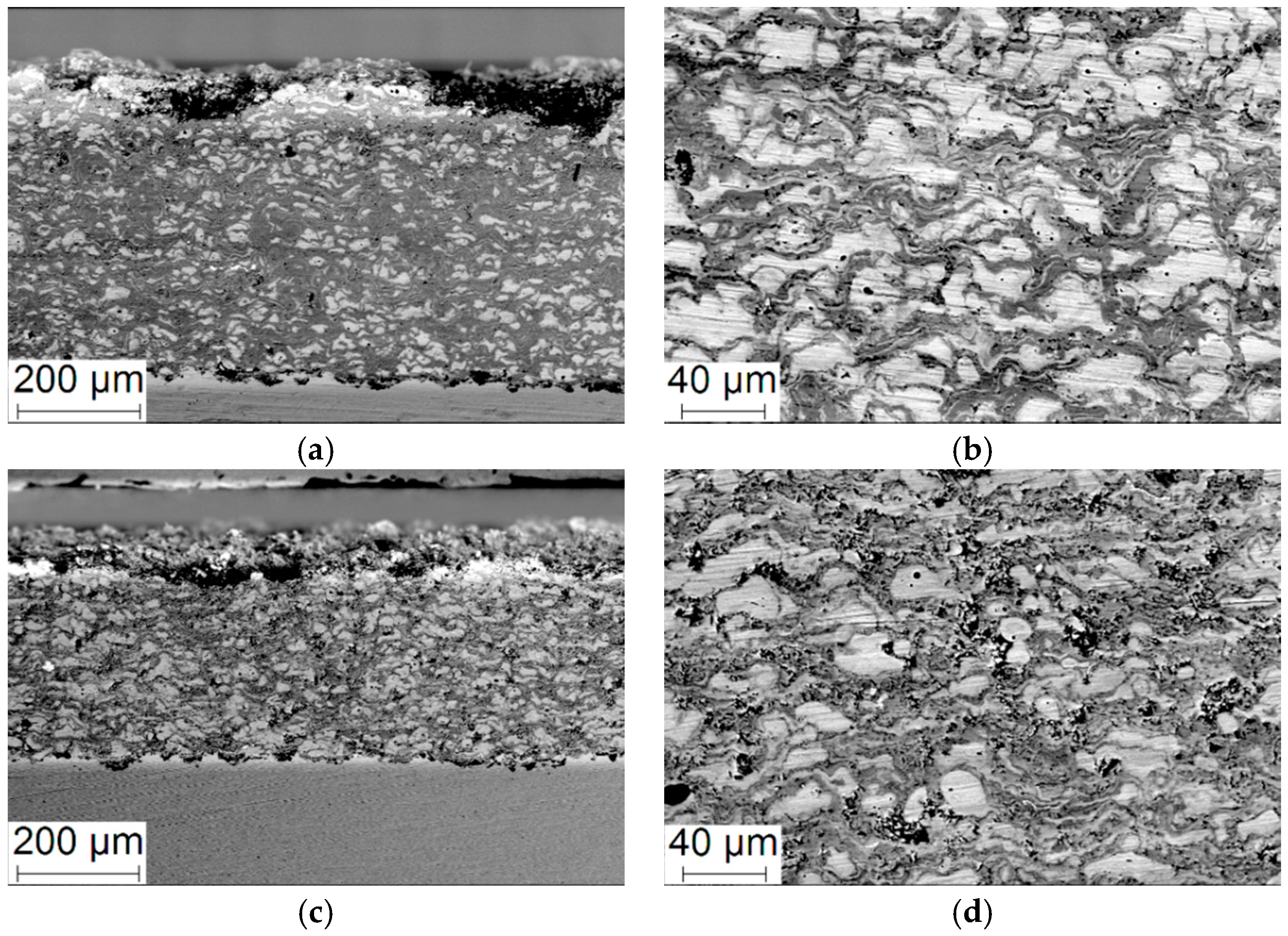

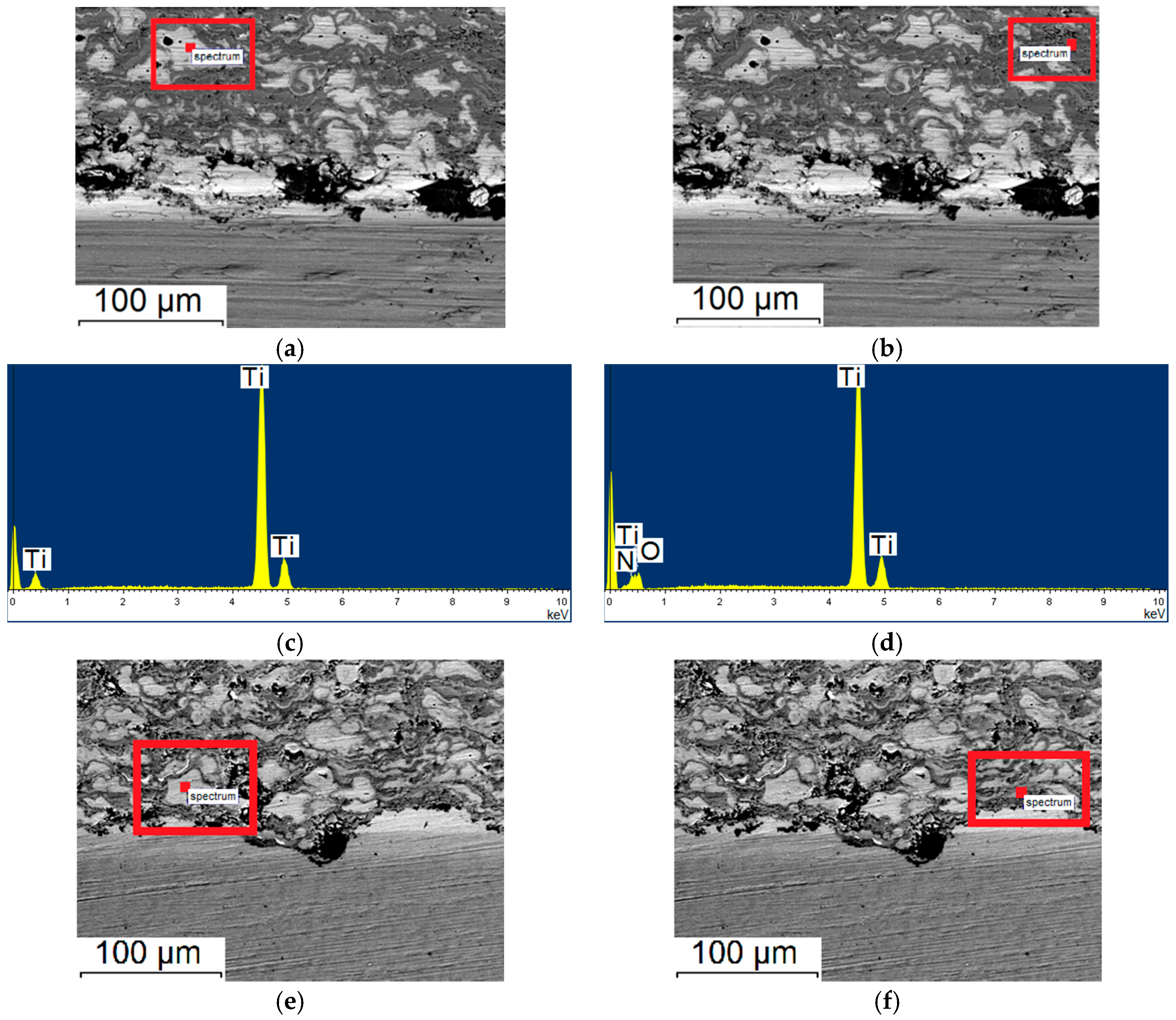

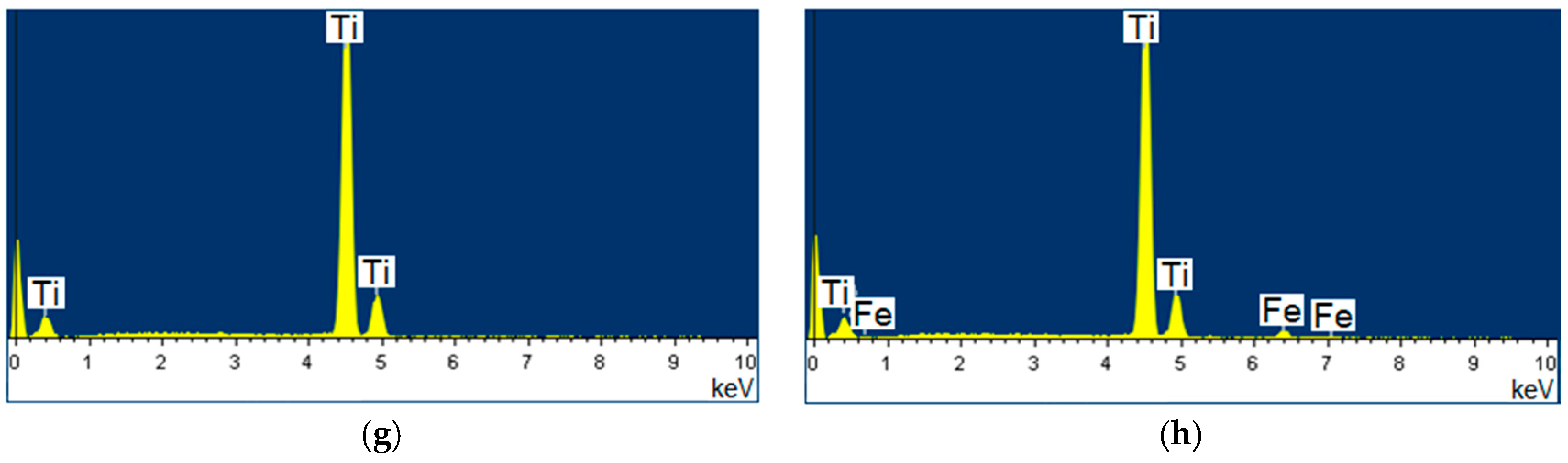

3.3. Coating Structure

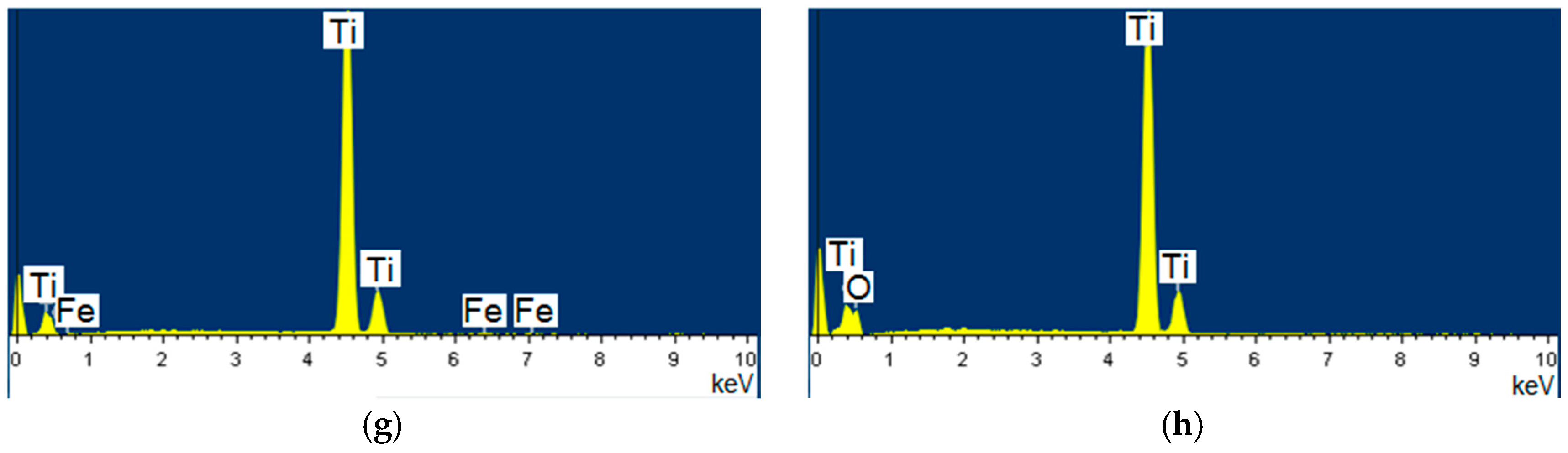

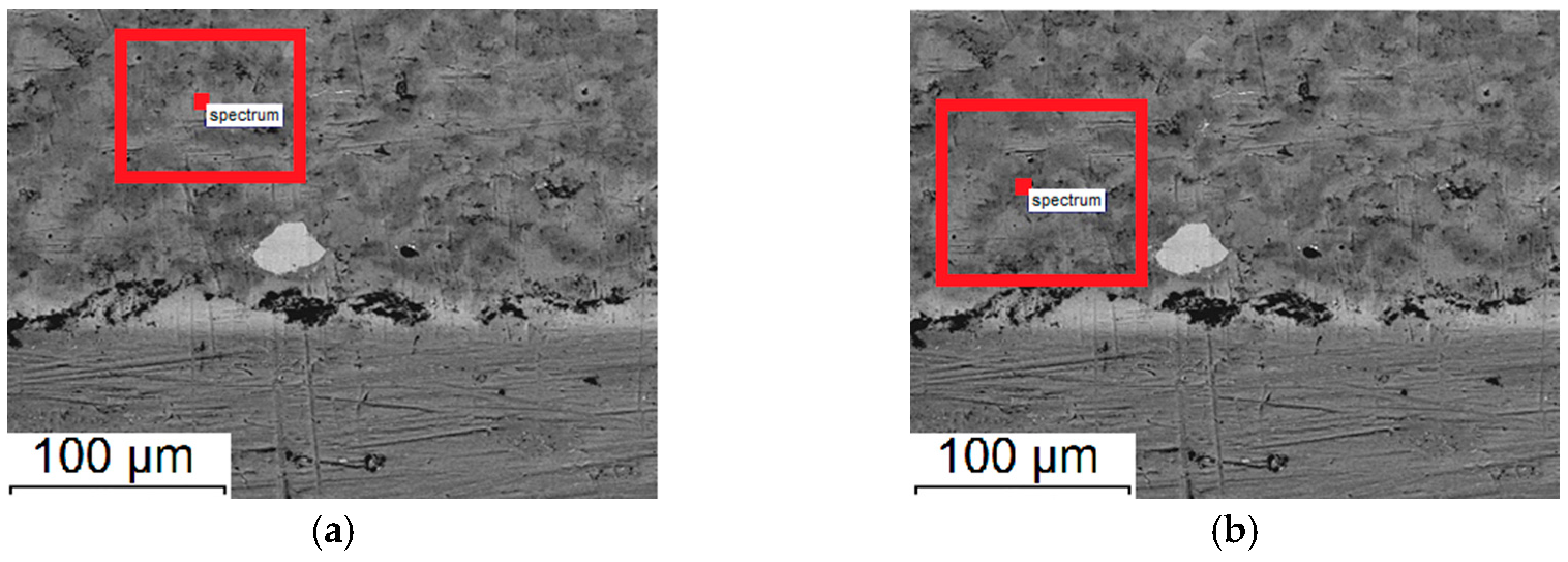

3.3.1. Spraying Regimes No. 1 and No. 2.

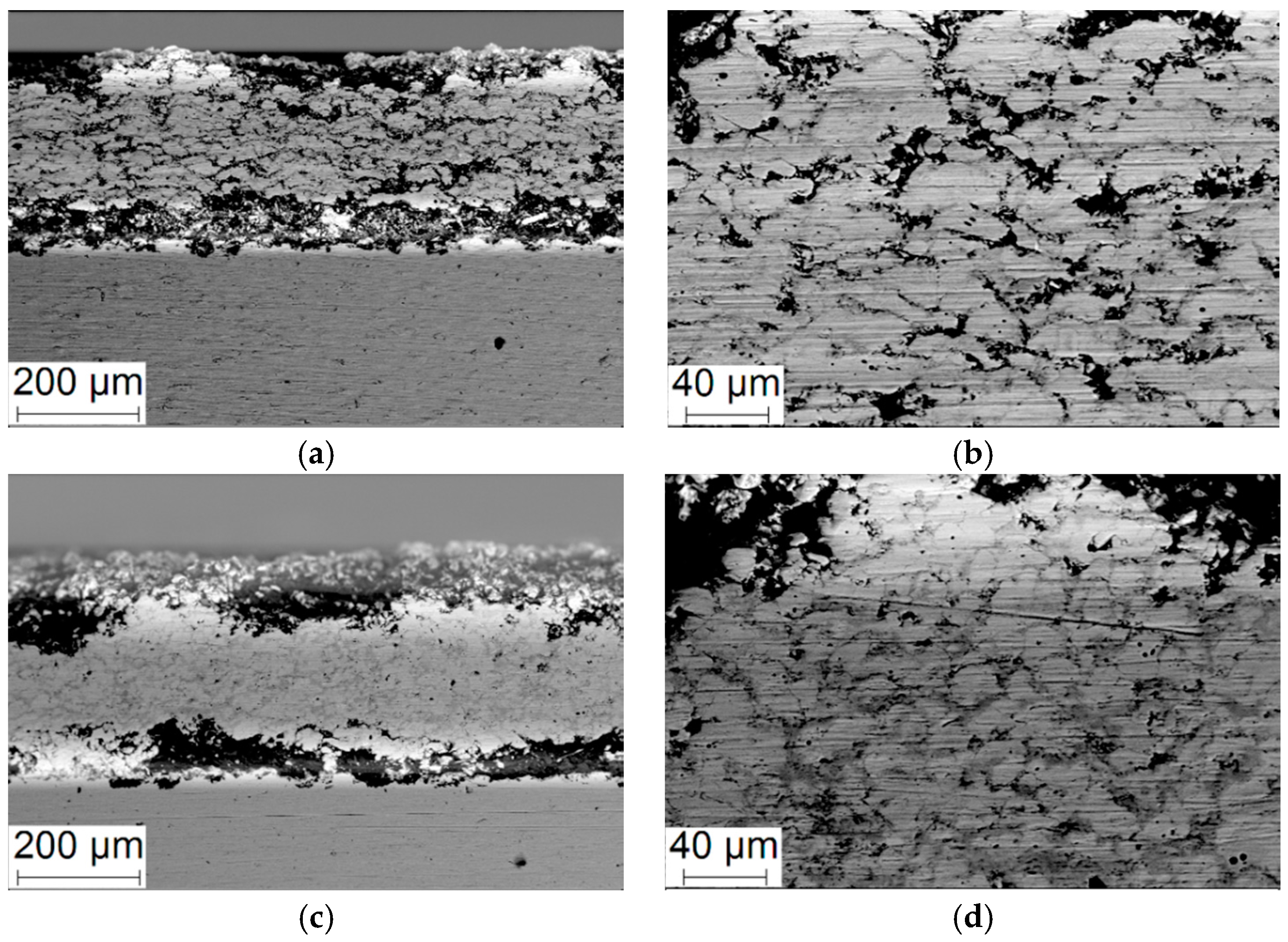

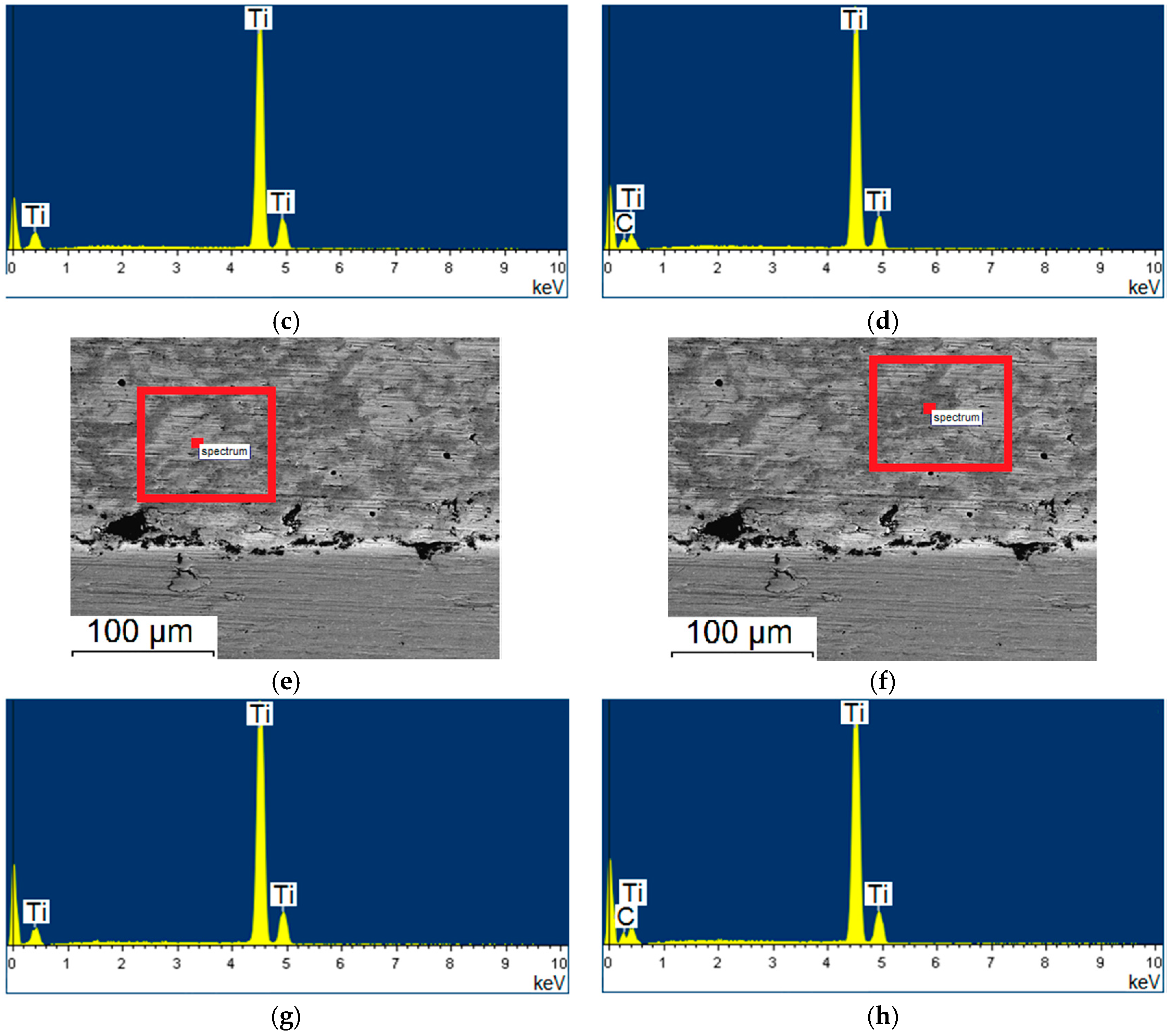

3.3.2. Spraying Regimes No. 3 and No. 4

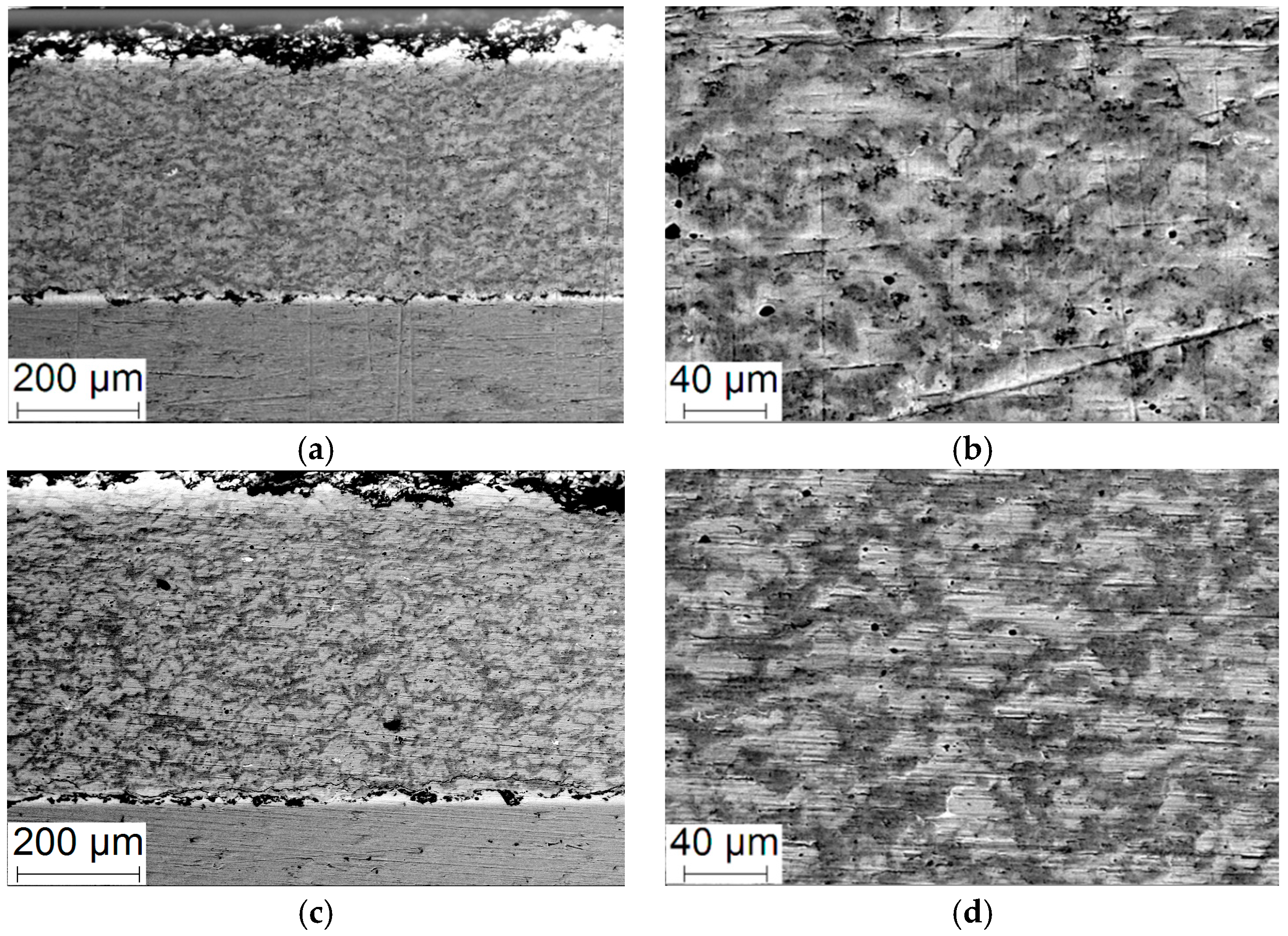

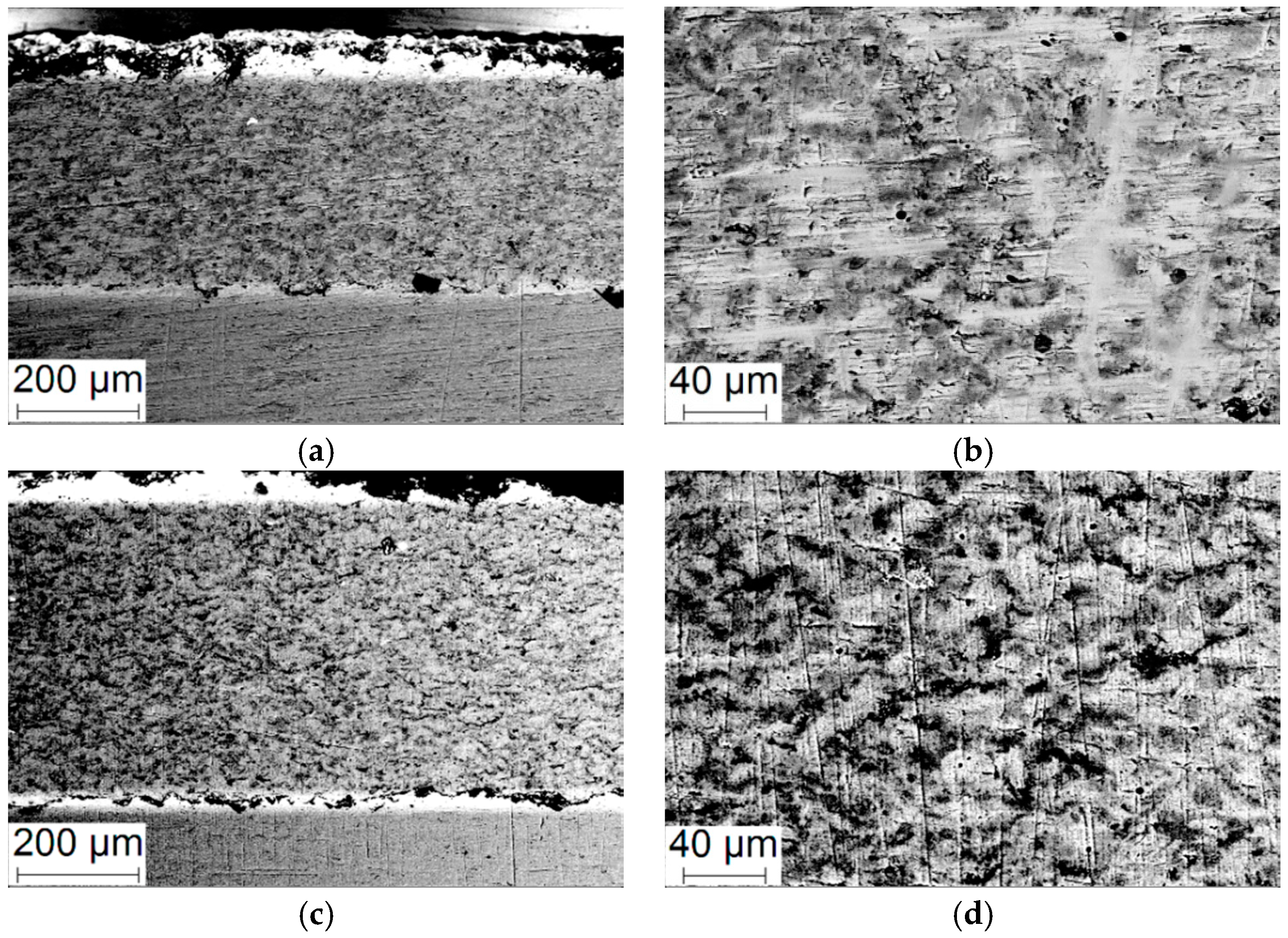

3.3.3. Spraying Regimes No. 5 and No. 6

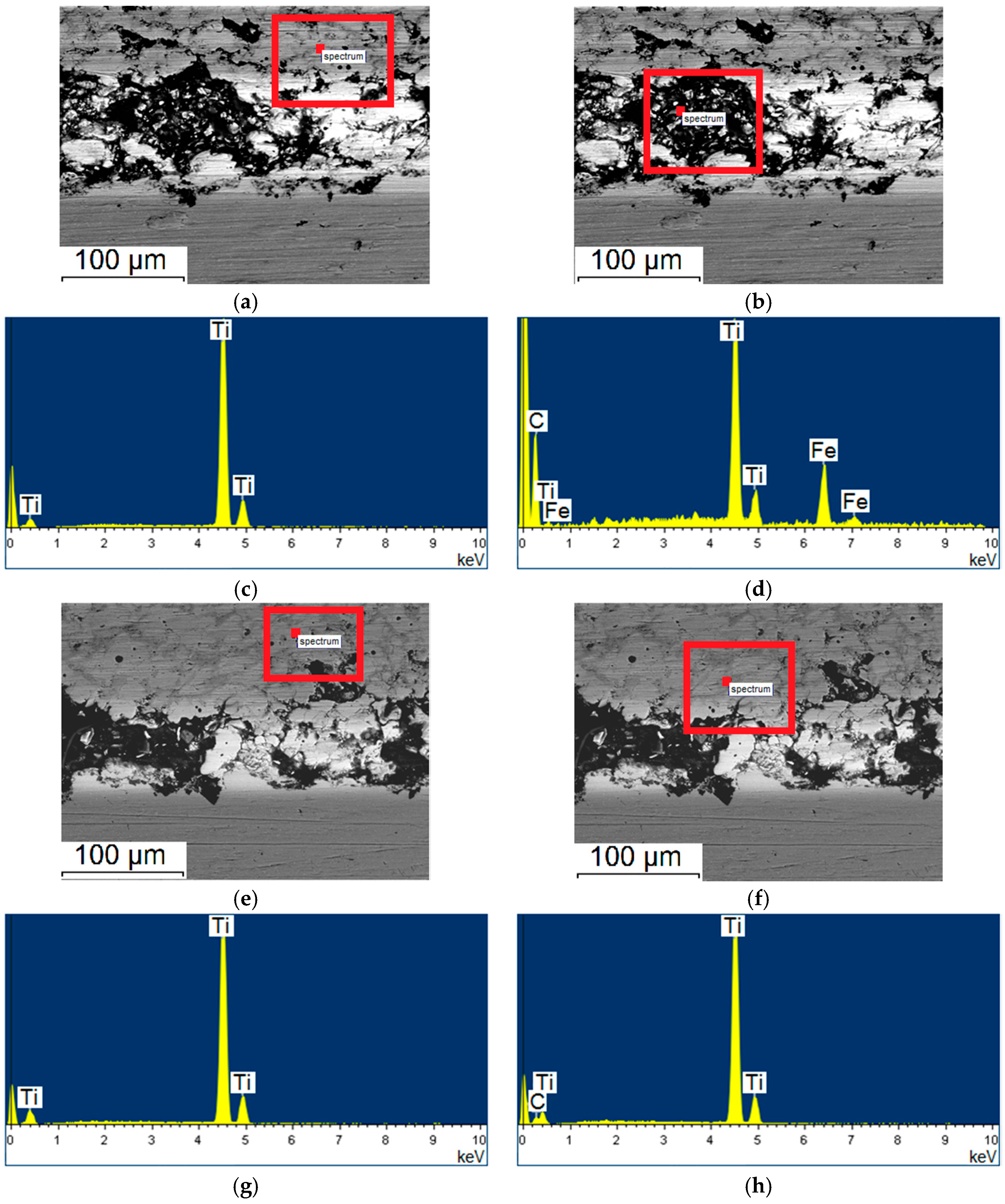

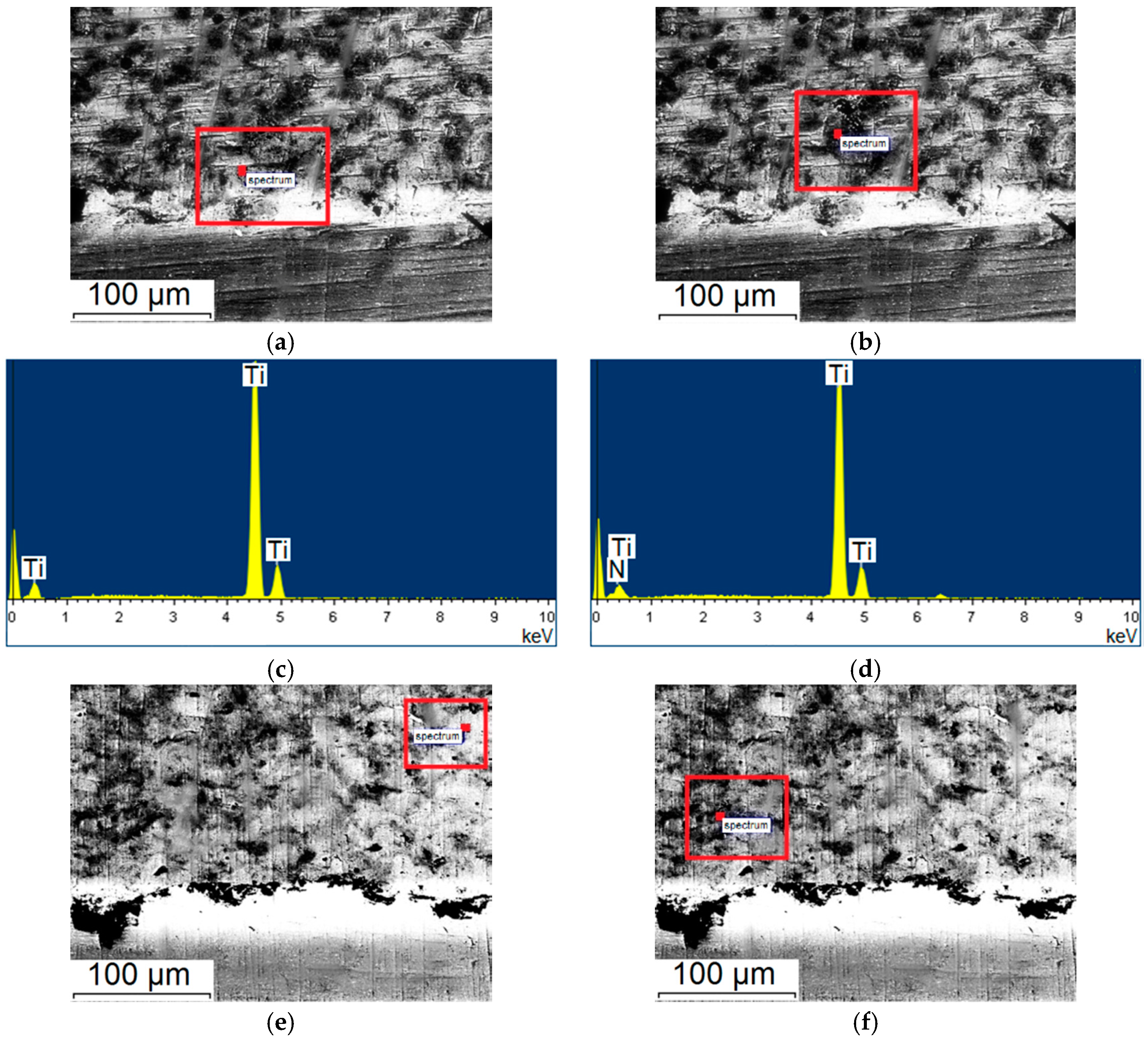

3.3.4. Spraying Regimes No. 7 and No. 8

4. Conclusions

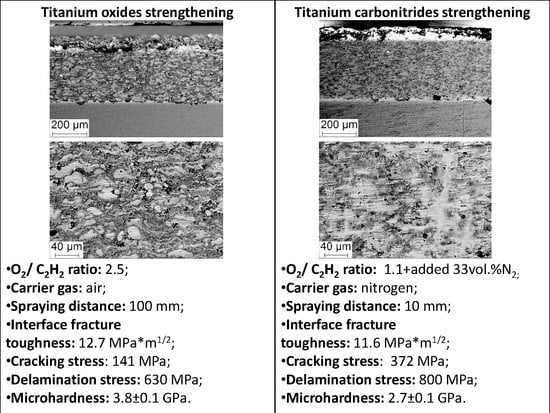

- In case of the spraying with air as a carrier gas, no nitrogen added into the explosive mixture, an increase in the O2/C2H2 from 1.1 and 2.5 leads to an increase in the cracking resistance and coating delamination stress under three-point bending, as well as the interface fracture toughness under the scratch test due to formation of a hierarchically organized coating structure with clearly exhibited phase boundaries. Deposition of titanium at O2/C2H2 = 2.5 allows obtaining coatings with a high fracture toughness, a high adhesion strength, a high microhardness and a low friction coefficient.

- In the event of spraying with nitrogen as a carrier gas, no nitrogen added into the explosive mixture, a short spraying distance (10 mm) and a low oxygen content in the explosive mixture (O2/C2H2 = 0.7) makes it possible to form a heterogeneous structure of the coating. This ensures mechanical properties comparable to those of the coatings, in which the oxide phases were predominantly formed. The coatings show a moderate crack resistance, a moderate adhesion strength, a high microhardness (H100 = 2.72 GPa) and a high friction coefficient (µ0 ~0.58).

- In case of the spraying with nitrogen as a carrier gas and nitrogen added to the explosive mixture, the formation of a complex heterogeneous structure makes it possible to achieve a high crack resistance under three-point bending, a high interface fracture toughness under the scratch test and a high microhardness (H100 = 2.74 GPa). The friction coefficient of the coating was µ0 ~0.68.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Deevi, S.C.; Sikka, V.K.; Swindeman, C.J.; Seals, R.D. Application of reaction synthesis principles to thermal spray coatings. J. Mater. Sci. 1997, 32, 3315–3325. [Google Scholar] [CrossRef]

- Fauchais, P.; Montavon, G.; Lima, R.S.; Marple, B.R. Engineering a new class of thermal spray nano-based microstructures from agglomerated nanostructured particles, suspensions and solutions: An invited review. J. Phys. D Appl. Phys. 2011, 44, 093001. [Google Scholar] [CrossRef] [Green Version]

- Kovaleva, M.; Tyurin, Y.; Kolisnichenko, O.; Prozorova, M.; Arseenko, M. Properties of detonation nanostructured titanium-based coatings. J. Therm. Spray Technol. 2013, 22, 518–524. [Google Scholar] [CrossRef]

- Zhao, L.; Lugscheider, E. Reactive plasma spraying of TiAl6V4 alloy. Wear 2002, 253, 1214–1218. [Google Scholar] [CrossRef]

- Fauchais, P.; Montavon, G.; Bertrand, G. From powders to thermally sprayed coatings. J. Therm. Spray Technol. 2010, 19, 56–80. [Google Scholar] [CrossRef]

- Valente, T.; Galliano, F.P. Corrosion resistance properties of reactive plasma-sprayed titanium composite coatings. Surf. Coat. Technol. 2000, 127, 86–92. [Google Scholar] [CrossRef]

- Ulianitsky, V.Y.; Dudina, D.V.; Batraev, I.S.; Kovalenko, A.I.; Bulina, N.V.; Bokhonov, B.B. Detonation spraying of titanium and formation of coatings with spraying atmosphere-dependent phase composition. Surf. Coat. Technol. 2015, 261, 174–180. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Z.; Zhou, Z.; Jiang, S.; Shao, J. Study on reactive atmospheric plasma-sprayed in situ titanium compound composite coating. J. Therm. Spray Technol. 2013, 22, 509–517. [Google Scholar] [CrossRef]

- Peat, T.; Galloway, A.; Toumpis, A.; McNutt, P.; Iqbal, N. The erosion performance of cold spray deposited metal matrix composite coatings with subsequent friction stir processing. Appl. Surf. Sci. 2017, 396, 1635–1648. [Google Scholar] [CrossRef]

- Klinkov, S.V.; Kosarev, V.F.; Sova, A.A.; Smurov, I. Deposition of multicomponent coatings by Cold Spray. Surf. Coat. Technol. 2008, 202, 5858–5862. [Google Scholar] [CrossRef]

- Sova, A.; Pervushin, D.; Smurov, I. Development of multimaterial coatings by cold spray and gas detonation spraying. Surf. Coat. Technol. 2010, 205, 1108–1114. [Google Scholar] [CrossRef]

- Panin, V.; Gromov, V.; Romanov, D.; Budovskikh, E.; Panin, S. The Physical Basics of Structure Formation in Electroexplosive Coatings. Dokl. Phys. 2017, 472, 650–653. [Google Scholar] [CrossRef]

- Dongmo, E.; Wenzelburger, M.; Gadow, R. Analysis and optimization of the HVOF process by combined experimental and numerical approaches. Surf. Coat. Technol. 2008, 202, 4470–4478. [Google Scholar] [CrossRef]

- Smurov, I.; Ulianitsky, V. Technology vision. Surf. Eng. 2011, 27, 557–559. [Google Scholar] [CrossRef]

- Senderowski, C.; Chodala, M.; Bojar, Z. Corrosion behavior of detonation gun sprayed Fe-Al type intermetallic coating. Materials 2015, 8, 1108–1123. [Google Scholar] [CrossRef] [PubMed]

- Saladi, S.; Menghani, J.; Prakash, S. Effect of CeO2 on cyclic hot-corrosion behavior of detonation-gun sprayed Cr3C2-NiCr coatings on Ni-based superalloy. J. Mater. Eng. Perform. 2015, 24, 1379–1389. [Google Scholar] [CrossRef]

- Senderowski, C. Nanocomposite Fe-Al Intermetallic coating obtained by gas detonation spraying of milled self-decomposing powder. J. Therm. Spray Technol. 2014, 23, 1124–1134. [Google Scholar] [CrossRef]

- Ibrahim, A.; Berndt, C.C. Fatigue and deformation of HVOF sprayed WC-Co coatings and hard chrome plating. Mater. Sci. Eng. A 2007, 456, 114–119. [Google Scholar] [CrossRef]

- Rajasekaran, B.; Raman, S.G.S.; Joshi, S.V.; Sundararajan, G. Performance of plasma sprayed and detonation gun sprayed Cu-Ni-In coatings on Ti-6Al-4V under plain fatigue and fretting fatigue loading. Mater. Sci. Eng. A 2008, 479, 83–92. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; de Lacalle, L.N.L.; Polvorosa, R. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Proc. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- de Lacalle, L.N.L.; Lamikiz, A.; Fernandes, M.H.; Gutiérrez, A.; Sánchez, J.A. Turning of thick thermal spray coatings. J. Therm. Spray Technol. 2001, 10, 249–254. [Google Scholar] [CrossRef]

- Toma, F.L.; Bertrand, G.; Chwa, S.O.; Klein, D.; Liao, H.; Meunier, C.; Coddet, C. Microstructure and photocatalytic properties of nanostructured TiO2 and TiO2-Al coatings elaborated by HVOF spraying for the nitrogen oxides removal. Mater. Sci. Eng. A. 2006, 417, 56–62. [Google Scholar] [CrossRef]

- Ulianitsky, V.; Shtertser, A.; Zlobin, S.; Smurov, I. Computer-controlled detonation spraying: From process fundamentals toward advanced applications. J. Therm. Spray. Technol. 2011, 20, 791–801. [Google Scholar] [CrossRef]

- Isakov, M.; Matikainen, V.; Koivuluoto, H.; May, M. Systematic analysis of coating-substrate interactions in the presence of flow localization. Surf. Coat. Technol. 2017, 324, 264–280. [Google Scholar] [CrossRef]

- Gere, J.; Goodno, B. Mechanics of Materials, 7th ed.; Cengage Learning: Toronto, ON, Canada, 2008; pp. 352–454. [Google Scholar]

- Zhou, Y.C.; Tonomori, T.; Yoshida, A.; Liu, L.; Bignall, G.; Hashida, T. Fracture characteristics of thermal barrier coatings after tensile and bending tests. Surf. Coat. Technol. 2002, 157, 118–127. [Google Scholar] [CrossRef]

| Spraying Regime | O2/C2H2 | Spraying Distance, mm | Explosive Charge, % | Carrier Gas | Coating Thickness (hcoat), μm |

|---|---|---|---|---|---|

| 1 | 1.1 | 100 | 30 | air | 270 |

| 2 | 2.5 | 100 | 30 | air | 275 |

| 3 | 1.1 | 10 | 40 | nitrogen | 160 |

| 4 | 0.7 | 10 | 40 | nitrogen | 291 |

| 5 | 0.7 | 10 | 50 | nitrogen | 190 |

| 6 | 0.7 | 100 | 50 | nitrogen | 750 |

| 7 | 1.1 + added 33 vol % N2 | 10 | 60 | nitrogen | 235 |

| 8 | 1.1 + added 33 vol % N2 | 100 | 60 | nitrogen | 285 |

| No. | σ2.5, MPa | σcr, MPa | σdelam, MPa | Kc, MPa·m1/2 | τ, MPa | Hμ, GPa | Friction Coefficient, μ0 | Maximum Depth of the Scratch, μm |

|---|---|---|---|---|---|---|---|---|

| 1 | 955 | 98.4 | 540 | 10.4 | 237.3 | 3.70 ± 0.03 | 0.406 | 66.6 |

| 2 | 850 | 140.5 | 630 | 12.7 | 295.3 | 3.84 ± 0.07 | 0.412 | 63.4 |

| 3 | 825 | 87.9 | 620 | 4.8 | 73.1 | 2.68 ± 0.07 | 0.637 | 83.3 |

| 4 | 1055 | 44.9 | 70 | 0.9 | 10.9 | 2.45 ± 0.11 | 0.661 | 140.5 |

| 5 | 945 | 94.2 | 730 | 7.6 | 132.9 | 2.72 ± 0.09 | 0.580 | 50.7 |

| 6 | 870 | 10 | 650 | - | - | 2.02 ± 0.01 | 0.594 | 102.2 |

| 7 | 945 | 372.1 | 800 | 11.6 | 228.7 | 2.74 ± 0.09 | 0.675 | 103.5 |

| 8 | 875 | 33.5 | 560 | 6.8 | 93.1 | 2.29 ± 0.02 | 0.585 | 80.9 |

| Regime No. | Characteristic Regions on the Cross-Section | Chemical Composition Determined by EDS, at. % | Phases Detected by the XRD | Crystallite Size, nm | Nanohard-Ness, GPa |

|---|---|---|---|---|---|

| 1 | Bright areas | Ti ~99%, O ~1% | - | - | 2.7 ± 1 |

| Dark areas | Ti ~65%, O ~35% | TiNxOy | 20 | 16.3 ± 3 | |

| TiO | 25 | ||||

| Ti2O3 | 30 | ||||

| 2 | Bright areas | Ti ~92%, O ~8% | - | - | 7.8 ± 2 |

| Dark areas | Ti ~55%, O ~45% | TiO | - | 9.7 ± 2 | |

| Ti2O3 | |||||

| Ti3O5 | |||||

| TiO2 | |||||

| 3 | Bright areas | Ti ~94%, O ~6% | - | - | 3.9 ± 0.6 |

| Dark areas | Ti ~50%, O ~15%, C ~35% | TiN | 20 | 7.7 ± 1.4 | |

| TiN0.3 | 20 | ||||

| 4 | Bright areas | Ti ~94%, O ~6% | - | - | 1.8 ± 0.8 |

| Dark areas | Ti ~70%, O ~5%, C ~25% | TiNvCw | 20 | 3.6 ± 1.5 | |

| 5 | Bright areas | Ti ~93%, O ~7% | - | - | 4.6 ± 0.8 |

| Dark areas | Ti ~70%, O ~10%, C ~20% | TiNvCw | 20 | 7.6 ± 1.7 | |

| 6 | Bright areas | Ti ~97%, O ~3% | - | - | 1.8 ± 0.6 |

| Dark areas | Ti ~60%, O ~15%, C ~25% | TiNvCw | 30 | 6.8 ± 1.6 | |

| TiC | 80 | ||||

| TiN | 25 | ||||

| TiN0.3 | 10 | ||||

| 7 | Bright areas | Ti ~95%, O ~5% | - | - | 2.5 ± 0.4 |

| Dark areas | Ti ~64%, O ~30%, C ~6% | TiN | 35 | 4.5 ± 1 | |

| TiN0.3 | 25 | ||||

| 8 | Bright areas | Ti ~95%, O ~5% | - | - | 4.6 ± 0.5 |

| Dark areas | Ti ~77%, O ~15%, C ~8% | TiN | - | 6.8 ± 1.8 | |

| TiN0.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panin, S.; Vlasov, I.; Dudina, D.; Ulianitsky, V.; Stankevich, R.; Batraev, I.; Berto, F. Mechanical Characterization of Composite Coatings Formed by Reactive Detonation Spraying of Titanium. Metals 2017, 7, 355. https://doi.org/10.3390/met7090355

Panin S, Vlasov I, Dudina D, Ulianitsky V, Stankevich R, Batraev I, Berto F. Mechanical Characterization of Composite Coatings Formed by Reactive Detonation Spraying of Titanium. Metals. 2017; 7(9):355. https://doi.org/10.3390/met7090355

Chicago/Turabian StylePanin, Sergey, Ilya Vlasov, Dina Dudina, Vladimir Ulianitsky, Roman Stankevich, Igor Batraev, and Filippo Berto. 2017. "Mechanical Characterization of Composite Coatings Formed by Reactive Detonation Spraying of Titanium" Metals 7, no. 9: 355. https://doi.org/10.3390/met7090355

APA StylePanin, S., Vlasov, I., Dudina, D., Ulianitsky, V., Stankevich, R., Batraev, I., & Berto, F. (2017). Mechanical Characterization of Composite Coatings Formed by Reactive Detonation Spraying of Titanium. Metals, 7(9), 355. https://doi.org/10.3390/met7090355