For a long time, researchers have tried to modify metallographic structures. In low alloy steel structure, it is very important to lift the percentage of acicular ferrite (AF) in the weld as much as possible. Attempts to achieve a content of acicular ferrite above 55% in the weld metal deposit have not been successful in standard processes such as metal inert gas/metal active gas (MIG/MAG), Manual Metal Arc (MMA), submerged arc welding, and even in laser welding processes [

7,

8]. Acicular ferrite is a fine Widmanstätten constituent which is nucleated by an optimum intra-granular dispersion of oxide/sulfide/silicate/nitrite particles [

9,

10]. The role of non-metallic inclusions (mainly oxides and nitrides) during the austenite-acicular ferrite conversion was proven [

5,

9], where small inclusions (in the range of 0.3–0.6 µm) could be beneficial for the formation of acicular ferrite in welding conditions. Nevertheless, the presence of beneficial inclusions such as TiO, TiN, and MnAl

2O

4 with a lattice parameter similar to ferrite could not guarantee more than 55% of AF in the WMD [

5]. This microstructure is advantageous over other microstructures due to its chaotic ordering, which increases toughness [

6,

9,

10].

It has also been found that some oxide inclusions may modify the shape of the Charpy V impact curve as a function of temperature—especially the upper and lower toughness shelf [

11]. Particularly favorable is the influence of both TiO and MnAl

2O

4 inclusions on the impact strength [

9,

11]. The amount of oxygen in the weld metal deposit corresponded directly with the size and chemical composition of the inclusions. It is believed that the main deoxidizers (Si, Mn, Al, Ti, B) should be present in the WMD in a very precise domain where manganese should not exceed 1 wt %, silicon should not exceed 0.5 wt %, titanium should not exceed 0.003 wt %, aluminum should not exceed 0.03 wt %, and boron should not exceed 0.0003 wt % in the WMD [

12]. The influence of aluminum as an important deoxidizer is described in the Japanese Nippon Steel Corporation patent [

13], which reports that the low impact toughness of the WMD could be explained by too high an Al content (0.12 wt %). In contrast, the American patent of Incorporated Teledyne [

14] states that the amount of aluminum should be at a minimum level of 0.03 wt %. These results have been further confirmed by the results obtained by Evans [

12,

15,

16]. The increase in impact toughness can be achieved in many ways: titanium and boron are important in the formation of oxides and nitrides; aluminum has a higher affinity for oxygen; and titanium has a higher affinity for nitrogen [

17,

18]. Titanium and boron are more affected by the increase in strength rather than impact toughness, which may not be beneficial [

19]. The optimum titanium content of the welded electrode is dependent not only on the oxygen content of the weld, but also on the content of other elements—especially C, Al, B, and N. Masumoto [

20] concluded that the optimum titanium and boron content in the weld metal was 0.01–0.05 wt % Ti and 0.001–0.003 wt % B, respectively. Titanium can also get into the welded steel. The Teledyne Incorporation patent [

14] states that the optimum titanium content in the base electrode WMD should be present in the WMD at a level lower than 0.07 wt %. In the AWS E7018 electrode, the optimum titanium content was in the range of 0.002–0.07 wt %. The strength of the weld grew rapidly with an increase in titanium, but the best impact toughness of the weld metal deposit was reached with 0.03 wt % Ti. Titanium is often introduced into the WMD together with boron, though there is usually approximately 10 times more titanium than boron in the WMD [

9,

11]. According to the Nippon Steel Corporation GB20150337B patent, the most beneficial amount of those elements should be on the level of 0.03–0.05 wt % Ti and 0.005–0.007 wt % B, respectively. There is also a view that boron segregates to the austenite grains and hinders ferrite nucleation [

9,

21,

22].

Thewlis [

9,

11] also emphasized the importance of beneficial inclusions in the formation of acicular ferrite and stated that the alloy containing Al, Ti, and B formed the non-metallic inclusion MnAl

2O

4 (galaxite) instead of MnO·SiO

2. Galaxite has the exact same lattice parameters as ferrite. The average size of these inclusions ranges from 0.32–0.38 μm, which could be treated as optimal and corresponds to the amount of acicular ferrite in the WMD at a level of 50% (assuming that the average size of inclusions in the WMD is between 0.2–1 μm). Ahlbom [

23] concluded on the basis of a literature review that the high impact toughness of low alloy weld metal deposits was dependent on the amount of oxygen. Węgrzyn [

24] suggested that the division in the welding processes into oxygen and nitrogen content in metal was initiated by Ti. All-time research did not allow the acicular ferrite content to be raised in the weld metal deposit.

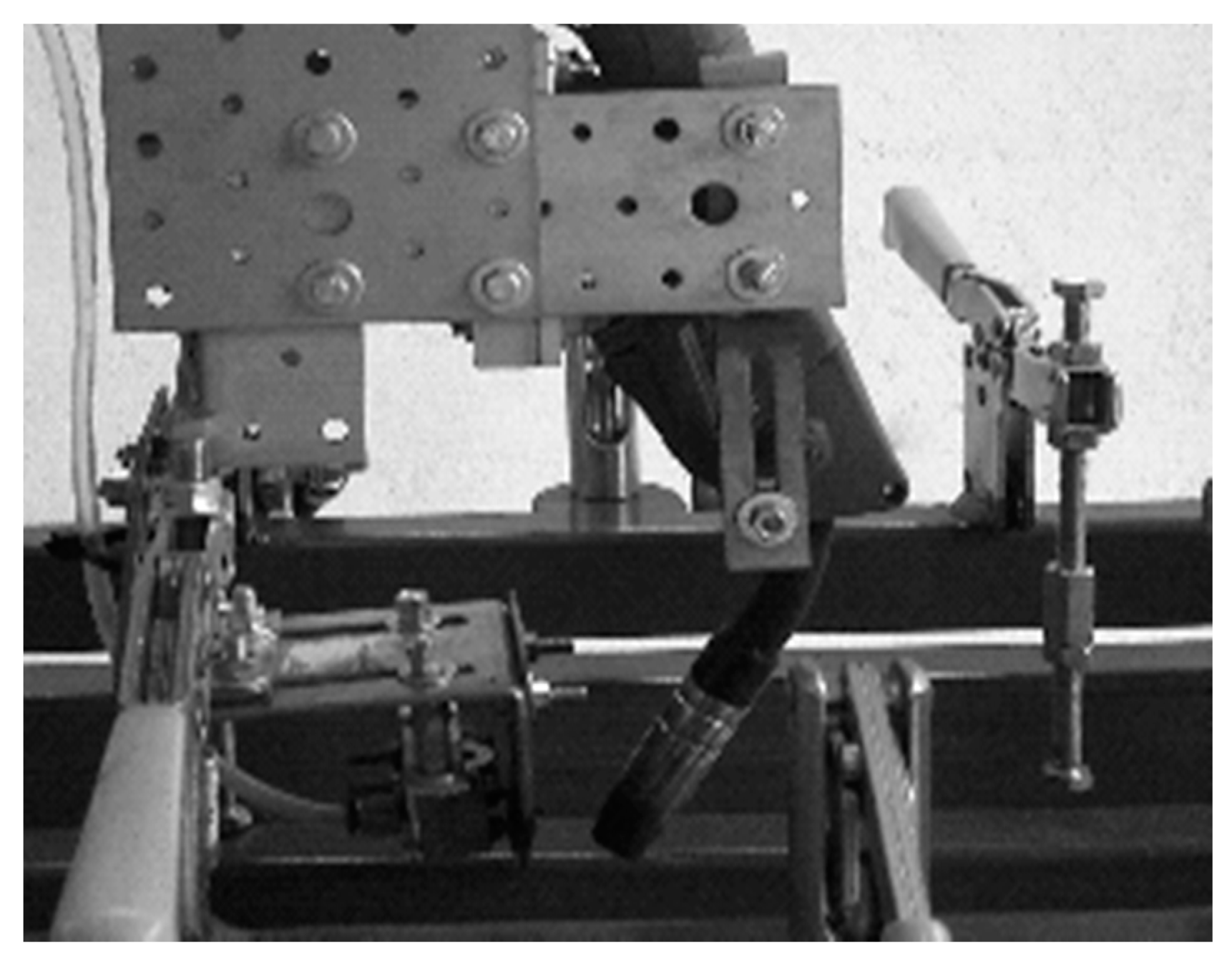

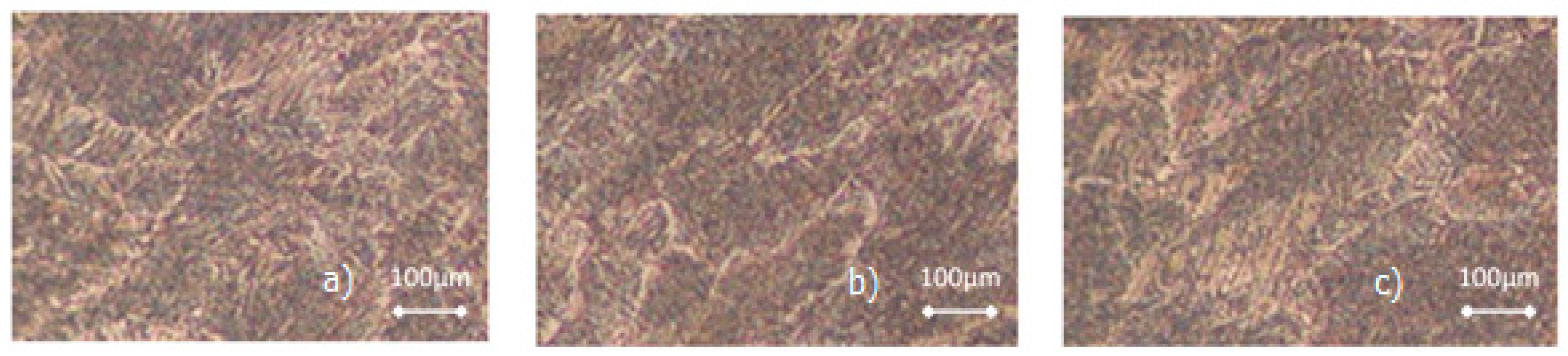

Recently, a micro-jet cooling application in steel welding and spray technologies has been invented as micro-jet cooling after the MAG welding process as a way of obtaining weld metal deposits with a higher amount of acicular ferrite (AF) in the weld metal deposit (WMD) that is not possible to achieve in standard metallurgical methods. Generally, the metallographic structure of WMD with elevated amounts of acicular ferrite corresponds to a much higher impact toughness. It is possible to obtain this phase in a weld due to precise and selective micro-jet cooling just after welding, where acicular ferrite can be achieved at a much higher percentage instead of grain boundary ferrite, which does not have time to grow [

25]. The main parameters of micro-jet cooling can be varied: (1) cooling stream diameter (between 40–60 µm), and (2) gas pressure (between 0.4–0.7 MPa). Micro-jet gases and its mixtures were treated as a main influencing factor on the formation of acicular ferrite (argon, helium, nitrogen, air). General assumptions of an innovative welding process with micro-jet cooling are presented in this paper. This investigation has proven that the new micro-jet technology still has the potential for growth, and might be a great achievement in welding technology to steer weld metal structure and the corresponding impact toughness. Micro-jet cooling also allows for a smaller deflection—especially in the long weld structures. Micro-jet cooling can also be treated as a very good direction in surface welding due to the excellent tribological properties of the welded layers [

26,

27]. The use of modern techniques is an attempt to optimize the production systems connected with welding and foundries. Micro-jet cooling was also tested in foundries, and can be used as the econometric model based on the methodology proposed by Szymszal et al. [

28].