Effect of Austempering Time on the Microstructure and Carbon Partitioning of Ultrahigh Strength Steel 56NiCrMoV7

Abstract

:1. Introduction

2. Experimental

3. Results

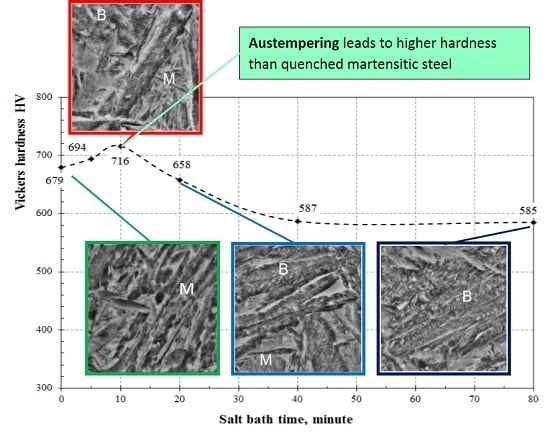

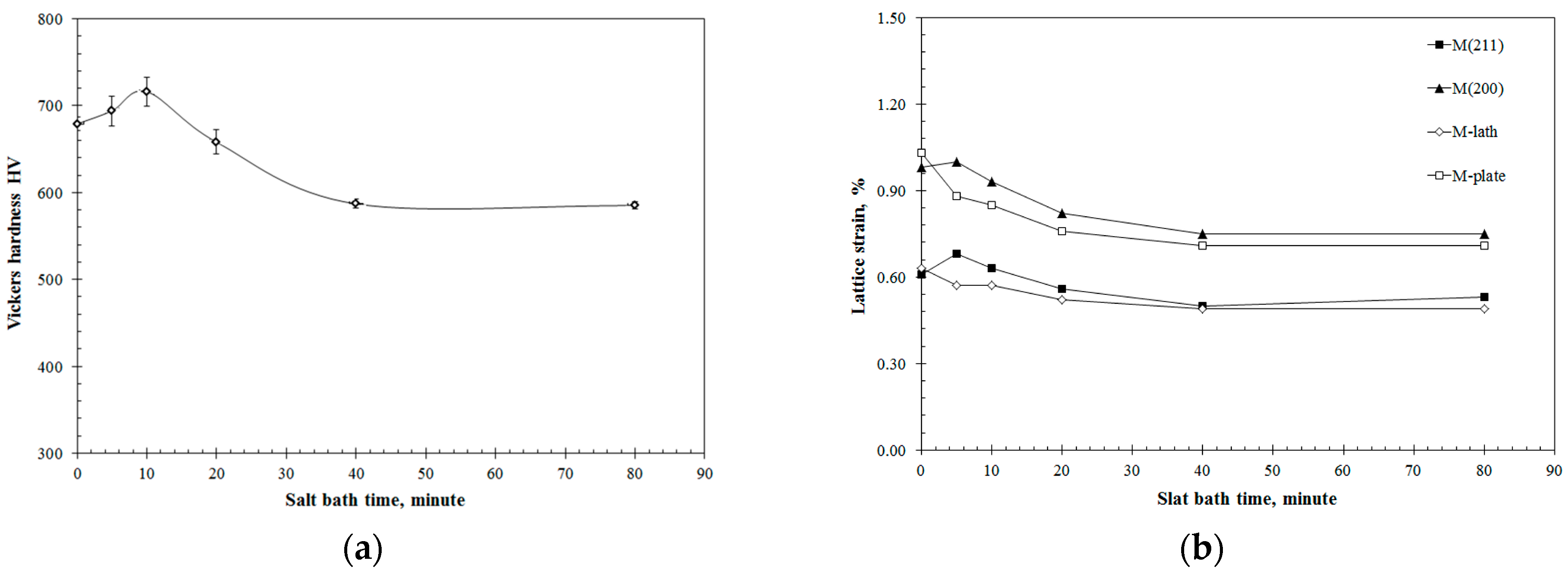

3.1. Hardness Property of Austempered Samples

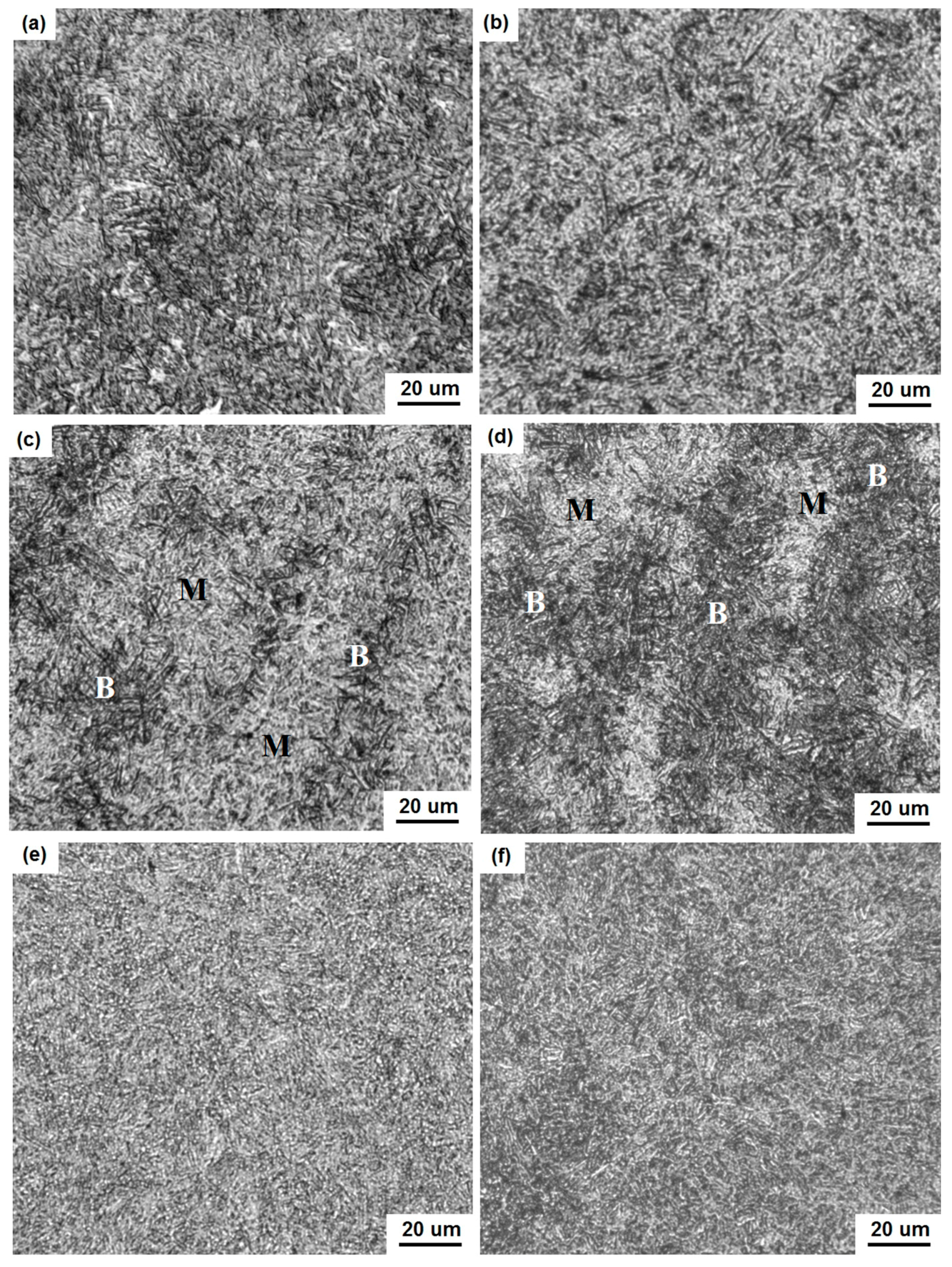

3.2. Microstructure Observed in Optical Microscopy

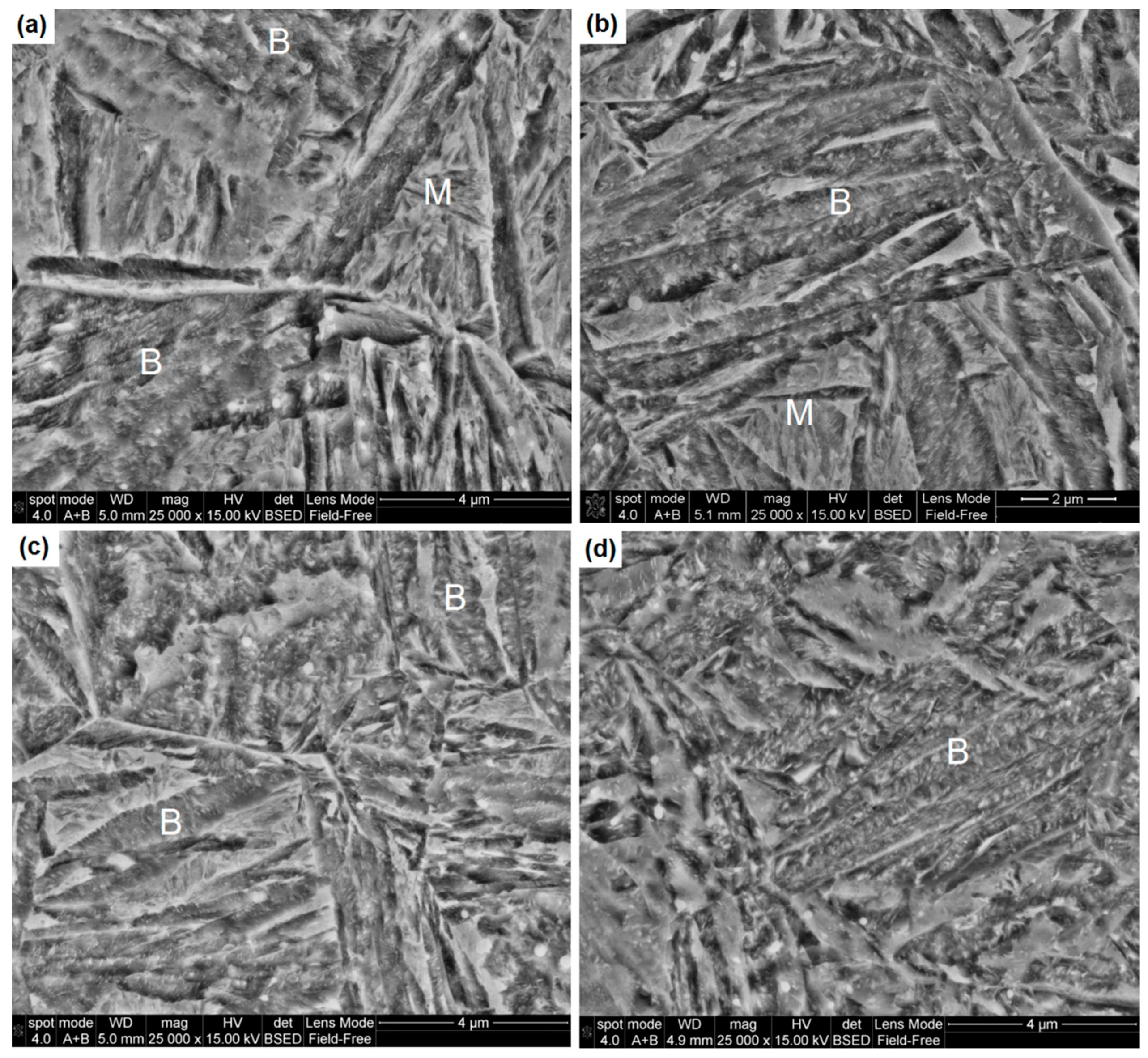

3.3. Microstructure Observed in Scanning Electron Microscopy

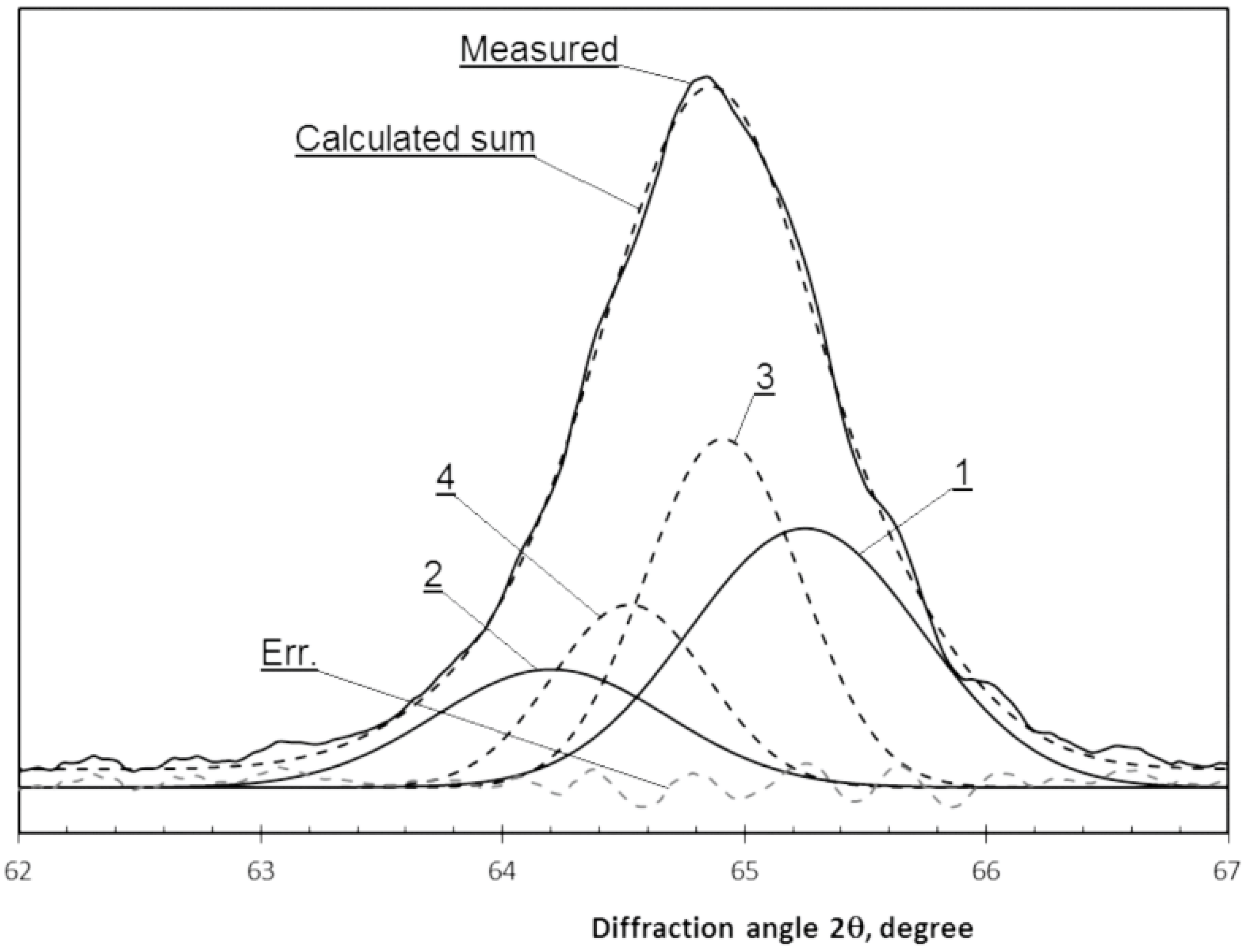

3.4. Results of X-ray Diffraction Analyses

4. Discussion

4.1. Hardening Mechanism in Austempering Treatment

4.2. Effect of Austempering Time on the Resultant Microstructure

5. Conclusions

- (1)

- Soaking super-cooled austenite at a temperature above its Ms temperature favours the refining of the transformed ferritic microstructure, which may be related to short-range spinodal decomposition of carbon in the incubation period;

- (2)

- The best hardening state is obtained prior to remarkable carbide precipitation, i.e., when most carbon atoms remain supersaturated in the bct-structured ferrite;

- (3)

- Following longer austempering time, the bainitic ferrite becomes increasingly decarbonised through continuous carbon clustering and carbide precipitation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, Z.; He, Z.Q.; Jin, J.J.; Zhong, P. Development of Aeronautical Ultra-High Strength Steels; National Defence Industry Press: Beijing, China, 2012. [Google Scholar]

- Krauss, G. Deformation and fracture in martensitic carbon steels tempered at low temperatures. Metall. Mater. Trans. B 2001, 32, 205–221. [Google Scholar] [CrossRef]

- Tomita, Y. Development of fracture toughness of ultrahigh strength, medium carbon, low alloy steels for aerospace applications. Int. Mater. Rev. 2000, 45, 27–37. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawell, K.J.A.; Jones, G.D.; Brown, P. Design of novel high strength bainitic steels. Mater. Sci. Technol. 2001, 17, 512–522. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawell, K.J.A.; Jones, D.G.; Brown, P. Very strong low temperature bainite. Mater. Sci. Technol. 2002, 18, 279–284. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Very strong bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 251–257. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G. Ultra high strength bainitic steels. ISIJ Int. 2005, 45, 1736–1740. [Google Scholar] [CrossRef]

- Kang, M.K.; Zhu, M.; Zhang, M.X. Mechanism of bainite nucleation in steel, iron and copper alloys. J. Mater. Sci. Technol. 2005, 21, 437–444. [Google Scholar]

- Kang, M.K.; Zhu, M. Stabilization of austenite in quenched alloy steels. Acta Metall. Sin. 2005, 41, 673–679. [Google Scholar]

- Wang, T.S.; Li, X.Y.; Zhang, F.C.; Zheng, Y.Z. Microstructures and mechanical properties of 60Si2CrVA steel by isothermal transformation at low temperature. Mater. Sci. Eng. 2006, 438–440, 1124–1127. [Google Scholar] [CrossRef]

- Malakondaiah, G.; Srinivas, M.; Rao, P.R. Ultrahigh-strength low-alloy steels with enhanced fracture toughness. Prog. Mater. Sci. 1997, 42, 209–242. [Google Scholar] [CrossRef]

- Rao, T.V.L.N.; Dikshit, S.N.; Malakondaiah, G.; Rap, P.R. On mixed upper bainite-martensite in an AISI 4330 steel exhibiting an uncommonly improved strength-toughness combination. Scr. Metall. Mater. 1990, 24, 1323–1328. [Google Scholar] [CrossRef]

- Park, K.T.; Kwon, H.J. Interpretation of the strengthening of steel with lower bainite and martensite mixed microstructure. Met. Mater. Int. 2001, 7, 95–99. [Google Scholar] [CrossRef]

- Abbaszadeh, K.; Kheirandish, S.; Saghafian, H. The effect of lower bainite volume fraction on tensile and impact properties of D6AC medium carbon low alloy ultrahigh strength steel. Iran. J. Mater. Sci. Eng. 2010, 7, 31–38. [Google Scholar]

- Sharma, S.; Sangal, S.; Mondal, K. Development of new high-strength carbide-free bainitic steels. Metall. Mater. Trans. A 2011, 42, 3921–3923. [Google Scholar] [CrossRef]

- Safi, S.M.; Givi, M.K.B. A new step heat treatment for steel AISI 4340. Met. Sci. Heat Treat. 2014, 56, 79–81. [Google Scholar] [CrossRef]

- Lan, H.F.; Du, L.X.; Zhou, N.; Liu, X.H. Effect of austempering route on microstructural characterization of nanobainitic steel. Acta Metall. Sin. 2014, 27, 19–26. [Google Scholar] [CrossRef]

- Young, C.H.; Bhadeshia, H.K.D.H. Strength of mixtures of bainite and martensite. Mater. Sci. Technol. 1994, 10, 209–214. [Google Scholar] [CrossRef]

- Kang, M.K.; Ai, Y.L.; Zhang, M.X.; Yang, Y.Q.; Zhu, M.; Chen, Y. Carbon content of bainite ferrite in 40CrMnSiMoV steel. Mater. Chem. Phys. 2009, 118, 438–441. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Jimenez, J.A.; Yen, H.W.; Miller, M.K.; Morales-Rivas, L.; Kuntz, M.; Ringer, S.P.; Yang, J.R.; Caballero, F.G. Low temperature bainitic ferrite: Evidence of carbon super-saturation and tetragonality. Acta Mater. 2015, 91, 162–173. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Miller, M.K.; Jimenez, J.A. On measurement of carbon content in retained austenite in a nanostructured bainitic steel. J. Mater. Sci. 2012, 57, 1004–1010. [Google Scholar] [CrossRef]

- Speer, J.G.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Edmonds, D.V.; He, K.; Rizzo, F.C.; De Cooman, B.C.; Matlock, D.K.; Speer, J.G. Quenching and partitioning martensite—A novel steel heat treatment. Mater. Sci. Eng. A 2006, 438–440, 25–34. [Google Scholar] [CrossRef]

- Rong, Y. Advanced Q–P–T steels with ultrahigh strength-high ductility. Acta Metall. Sin. 2011, 47, 1483–1489. [Google Scholar]

- Li, H.Y.; Lu, X.W.; Li, W.J.; Jin, X.J. Microstructure and mechanical properties of an ultrahigh-strength 40SiMnNiCr steel during the on-step quenching and partitioning process. Metall. Mater. Trans. A 2010, 41, 1284–1300. [Google Scholar] [CrossRef]

- Hsu, T.Y. Carbon diffusion and kinetics during the lath martensite formation. J. Phys. IV Fr. 1995, 5, C8-351–C8-354. [Google Scholar]

- Luo, Q.; Kitchen, M.; Patel, V.; Magowan, S. Carbon partitioning and structure evolution in the hardening treatments of high strength steel. In Proceedings of the 20th Congress of International Federation for Heat Treatment and Surface Engineering, Beijing, China, 23–25 October 2012; pp. 111–117. [Google Scholar]

- Luo, Q.; Kitchen, M.; Patel, V.; Filleul, M.; Owens, D. Partial-isothermally-treated low alloy ultrahigh strength steel with martensitic/bainitic microstructure. In HSLA Steels 2015, Microalloying 2015 & Offshore Engineering Steels 2015; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 433–438. [Google Scholar]

- Garg, A.; McNelley, T.R. Estimation of martensite carbon content in as-quenched AISI 52100 steel by X-ray diffraction. Mater. Lett. 1986, 4, 214–218. [Google Scholar] [CrossRef]

- Abbaschian, R.; Abbeschian, L. Physical Metallurgy Principles, Reed-Hill RE, 4th ed.; Cengage Learning: Stanford, CA, USA, 1994. [Google Scholar]

- Luo, Q. A new XRD method to quantify plate and lath martensites of hardened medium-carbon steel. J. Mater. Eng. Perform. 2016, 25, 2170–2179. [Google Scholar] [CrossRef]

- Kang, M.K.; Yang, Y.Q.; Wei, Q.M.; Yang, Q.M.; Meng, X.K. On the prebainitic phenomenon in some alloys. Metall. Mater. Trans. A 1994, 25, 1941–1946. [Google Scholar] [CrossRef]

- Wu, X.L.; Zhang, X.Y.; Meng, X.K.; Kang, M.K.; Yang, Y.Q. Formation of carbon-poor regions during pre-bainitic transformation. Mater. Lett. 1995, 22, 141–144. [Google Scholar] [CrossRef]

- Khan, S.A.; Bhadeshia, H.K.D.H. The bainite transformation in chemically heterogeneous 300M high-strength steel. Metall. Trans. A 1990, 21, 859–875. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Kang, M.K.; Wu, X.L.; Chen, D.M.; Han, D. Study on several carbide variants in the low bainite of 65Si2MnWA steel by TEM. Chin. Sci. Bull. 1994, 39, 1583–1584. [Google Scholar]

- Luo, C.P.; Liu, J. Crystallography of lath martensite and lower bainite in alloy steels. Mater. Sci. Eng. A 2006, 438–440, 149–152. [Google Scholar] [CrossRef]

- Yang, F.B.; Bai, B.Z.; Liu, D.Y.; Chang, K.D.; Wei, D.Y.; Fang, H.S. Microstructure and properties of a carbide-free bainite/martensite ultrahigh strength steel. Acta Metall. Sin. 2004, 40, 296–300. [Google Scholar]

- Kang, M.K.; Yang, Y.Q.; Zhang, X.Y.; Sun, J.L.; Jia, F.S.; Wu, X.L. Bainitic transformation in silicon-containing steels. Acta Metall. Sin. 1996, 32, 897–903. [Google Scholar]

- Kang, M.K.; Zhang, M.X.; Zhu, M. In-situ observation of bainite growth during isothermal holding. Acta Mater. 2006, 54, 2121–2129. [Google Scholar] [CrossRef]

- Hsu, T.Y.; Li, X.M. Diffusion of carbon during the formation of low-carbon martensite. Scr. Metall. 1983, 17, 1285–1288. [Google Scholar] [CrossRef]

- Lawrynowicz, Z. Carbon partitioning during bainite transformation in low alloy steels. Mater. Sci. Technol. 2002, 18, 1322–1324. [Google Scholar] [CrossRef]

- Caballero, F.G.; Miller, M.K.; Clarke, A.J.; Garcia-Mateo, C. Examination of carbon partitioning into austenite during tempering of bainite. Scr. Mater. 2010, 63, 442–445. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Beladi, H.; Xiong, X.Y.; Adachi, Y.; Hodgson, P.D. Nanoscale microstructure characterization of a nanobainitic steel. Acta Mater. 2011, 59, 5511–5522. [Google Scholar] [CrossRef]

- Fielding, L.C.D. The bainite controversy. Mater. Sci. Technol. 2013, 29, 383–399. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Shanina, B.D.; Berns, H. On the correlation between electron structure and short range atomic order in iron-based alloys. Acta Mater. 2000, 48, 3879–3893. [Google Scholar] [CrossRef]

- Shanint, B.D.; Gavriljuk, V.G.; Konchits, A.A.; Kolesnik, S.P. The influence of substitutional atoms upon the electron structure of the iron-based transition metal alloys. J. Phys. 1998, 10, 1825–1838. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Q.; Kitchen, M.; Abubakri, S. Effect of Austempering Time on the Microstructure and Carbon Partitioning of Ultrahigh Strength Steel 56NiCrMoV7. Metals 2017, 7, 258. https://doi.org/10.3390/met7070258

Luo Q, Kitchen M, Abubakri S. Effect of Austempering Time on the Microstructure and Carbon Partitioning of Ultrahigh Strength Steel 56NiCrMoV7. Metals. 2017; 7(7):258. https://doi.org/10.3390/met7070258

Chicago/Turabian StyleLuo, Quanshun, Matthew Kitchen, and Shahriar Abubakri. 2017. "Effect of Austempering Time on the Microstructure and Carbon Partitioning of Ultrahigh Strength Steel 56NiCrMoV7" Metals 7, no. 7: 258. https://doi.org/10.3390/met7070258