Effect of Al-5Ti-0.62C-0.2Ce Master Alloy on the Microstructure and Tensile Properties of Commercial Pure Al and Hypoeutectic Al-8Si Alloy

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

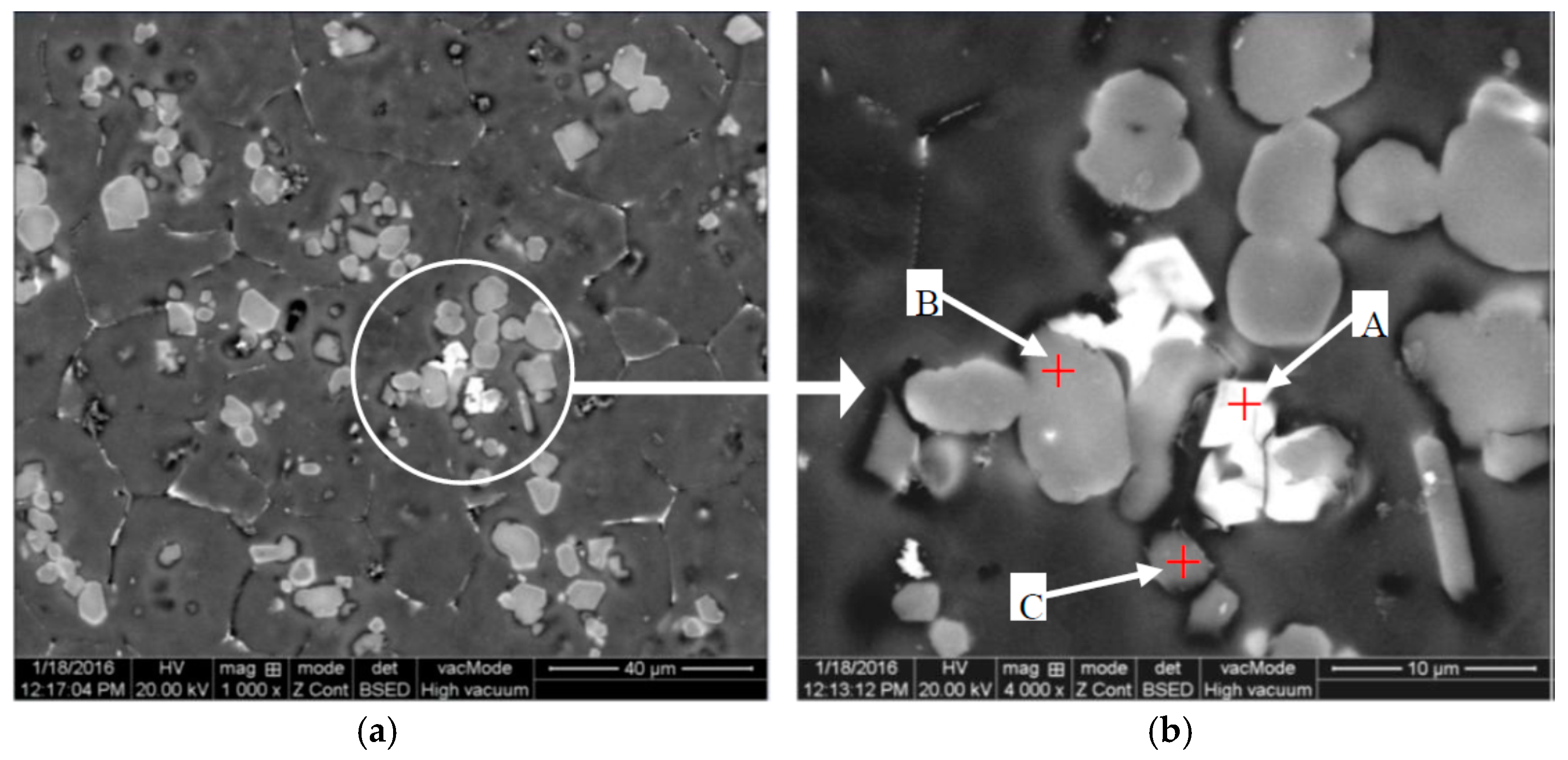

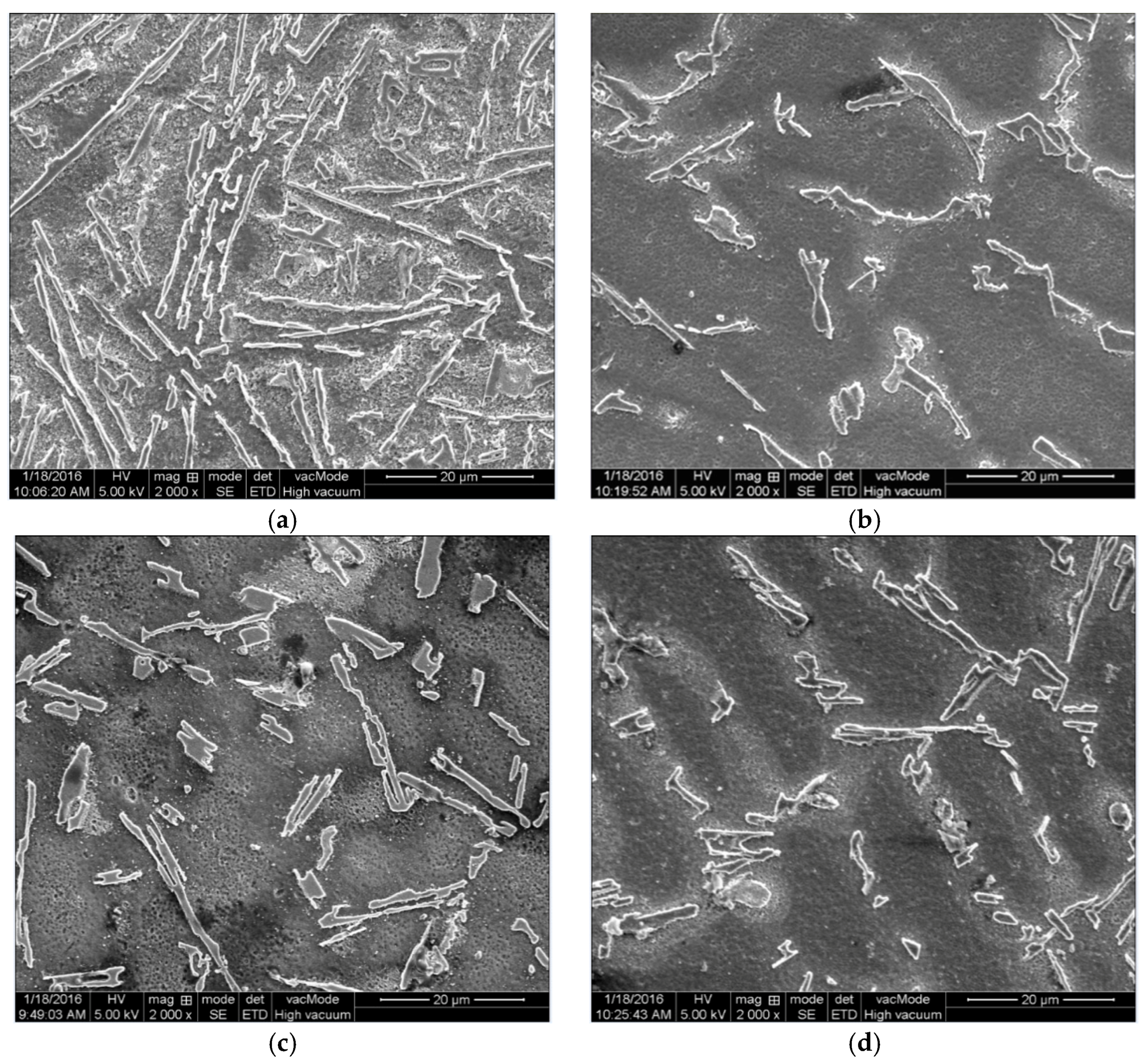

3.1. Microstructure of Al-5Ti-0.62C-0.2Ce Master Alloy

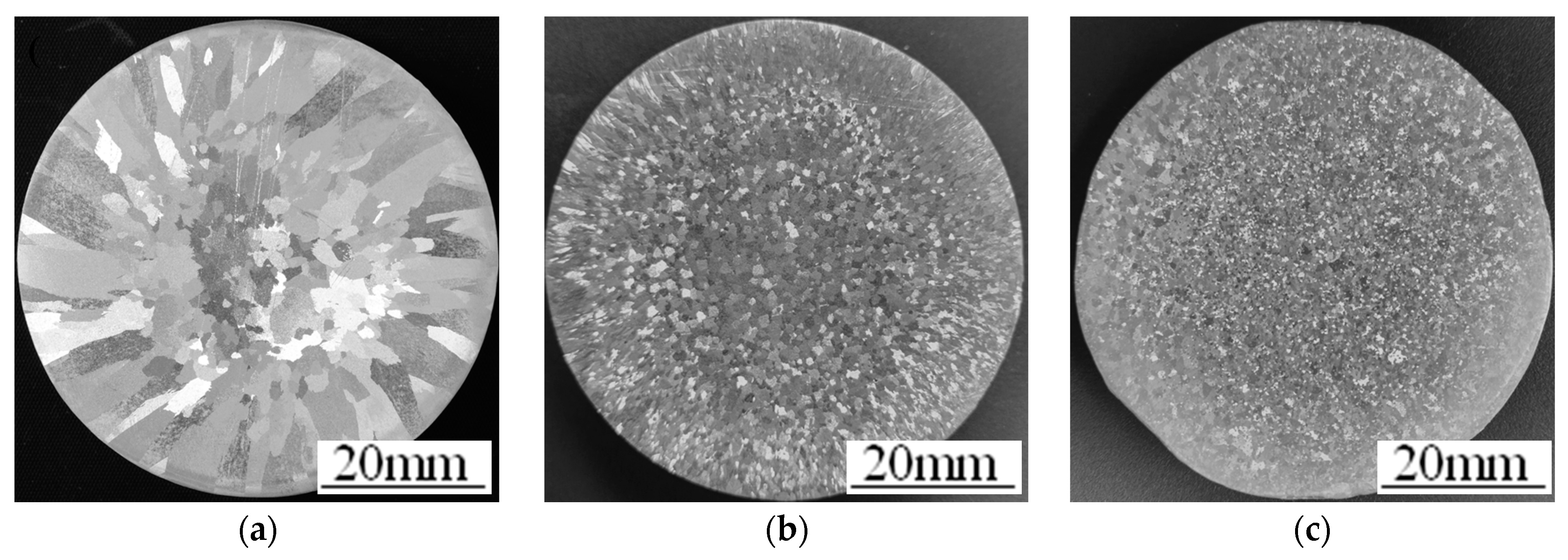

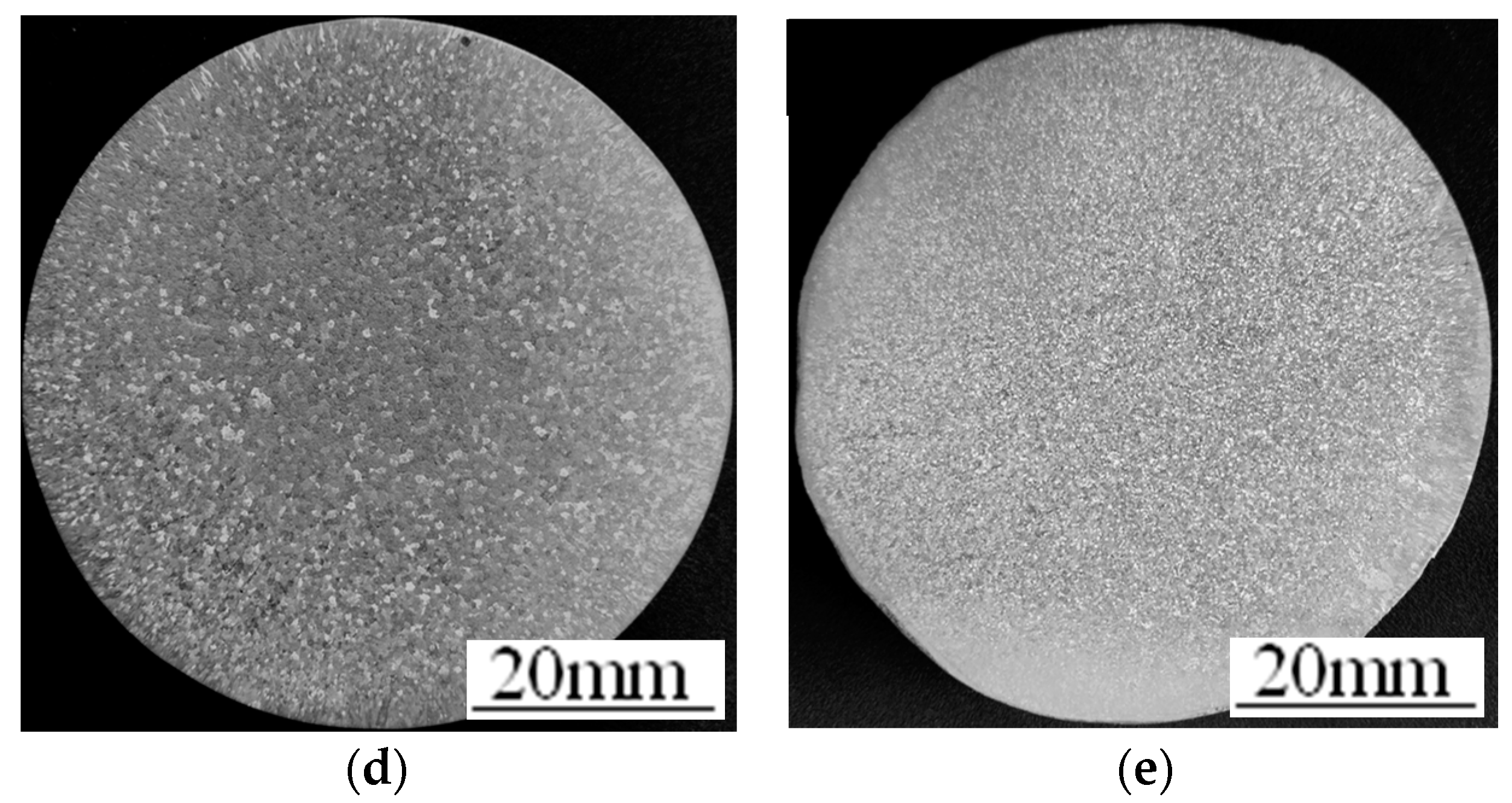

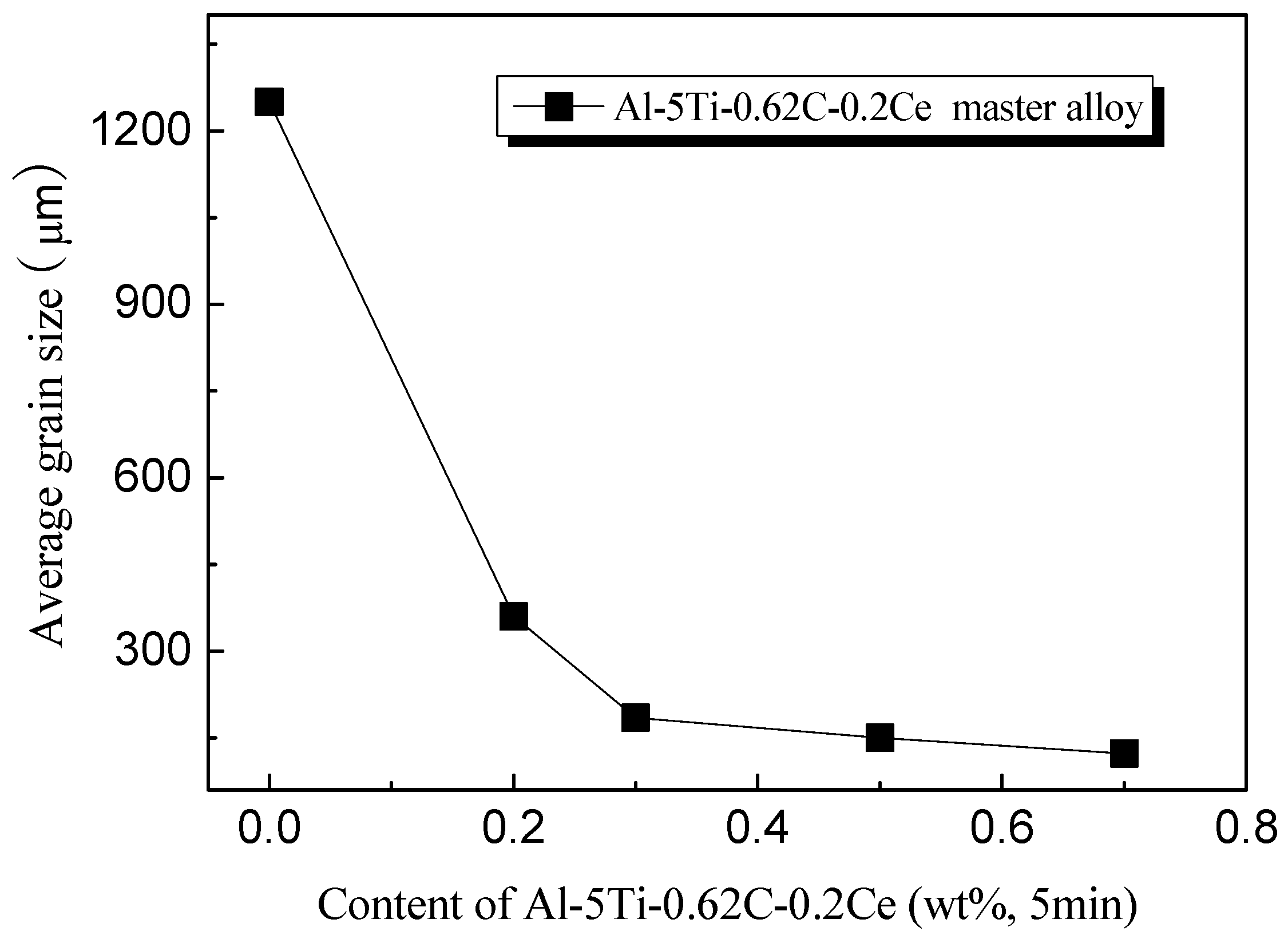

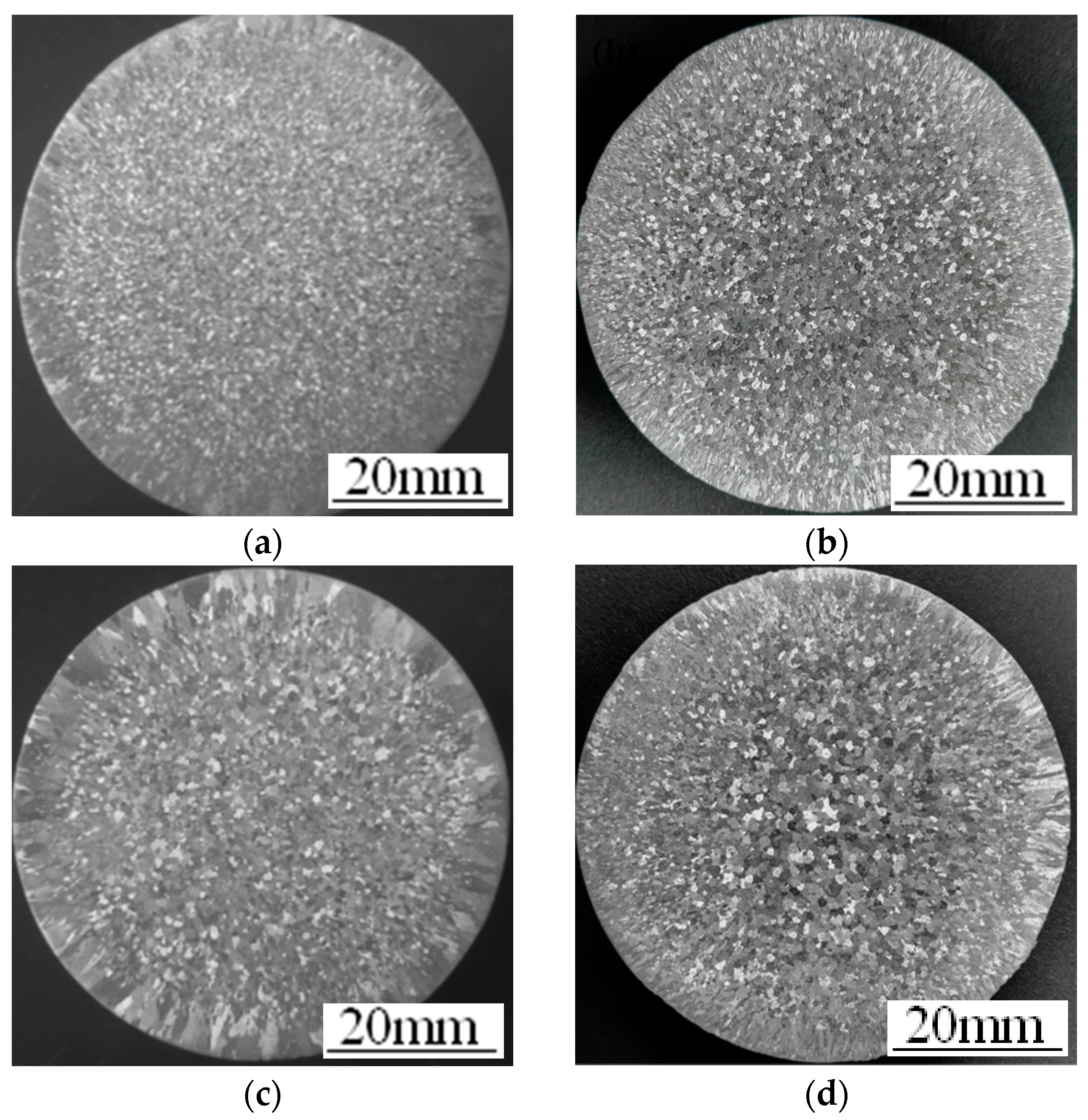

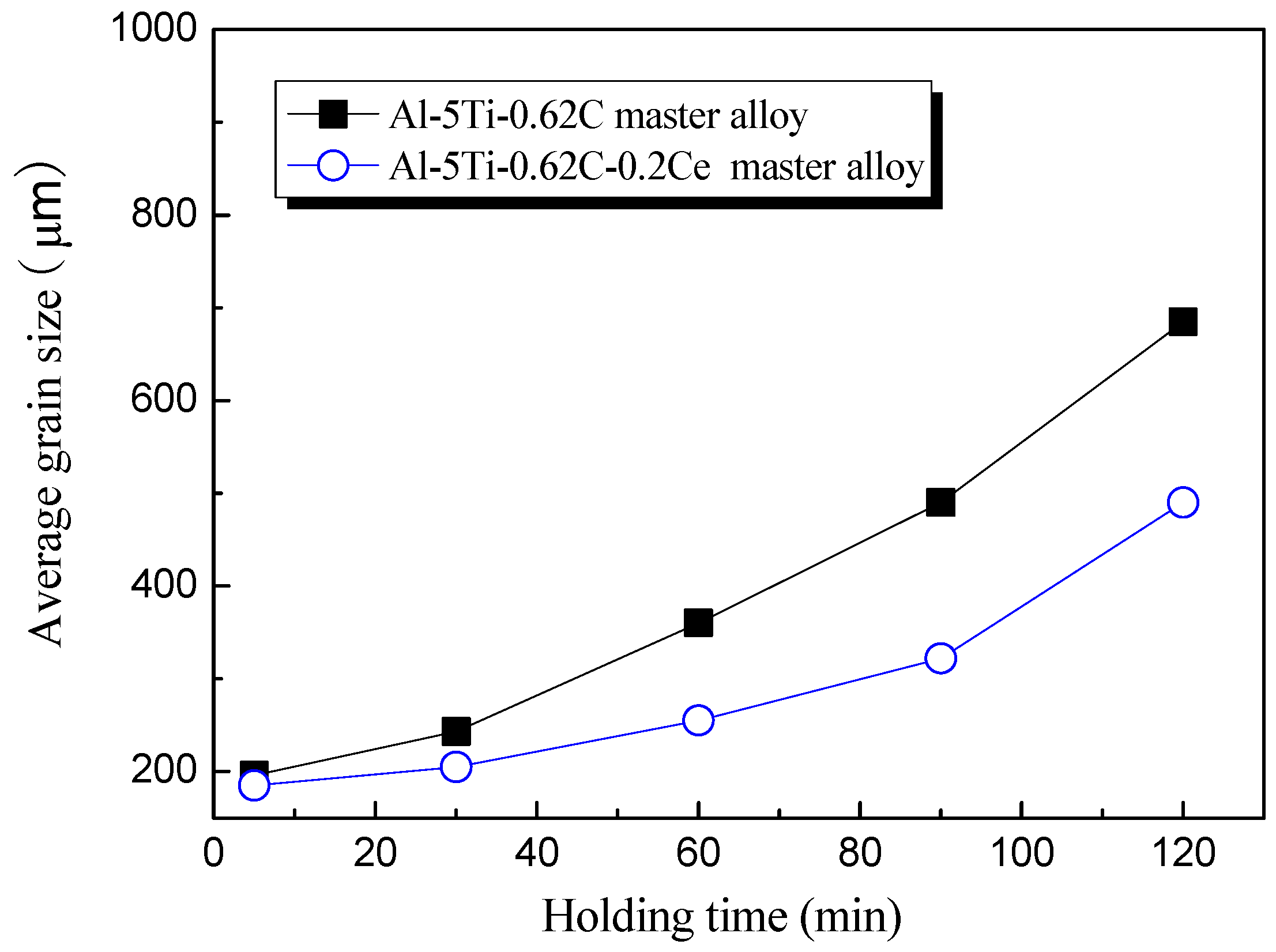

3.2. The Effect of Al-5Ti-0.62C-0.2Ce Master Alloy on Microstructure of Commercial Pure Al

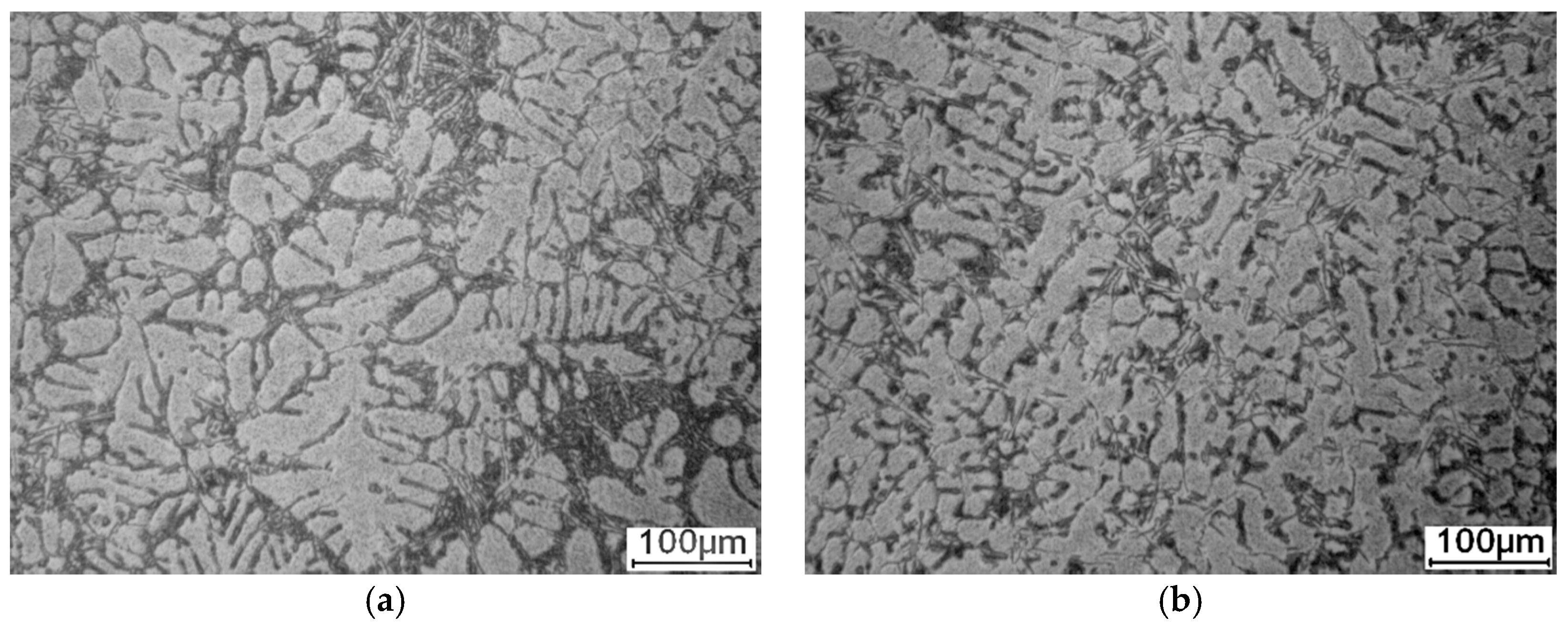

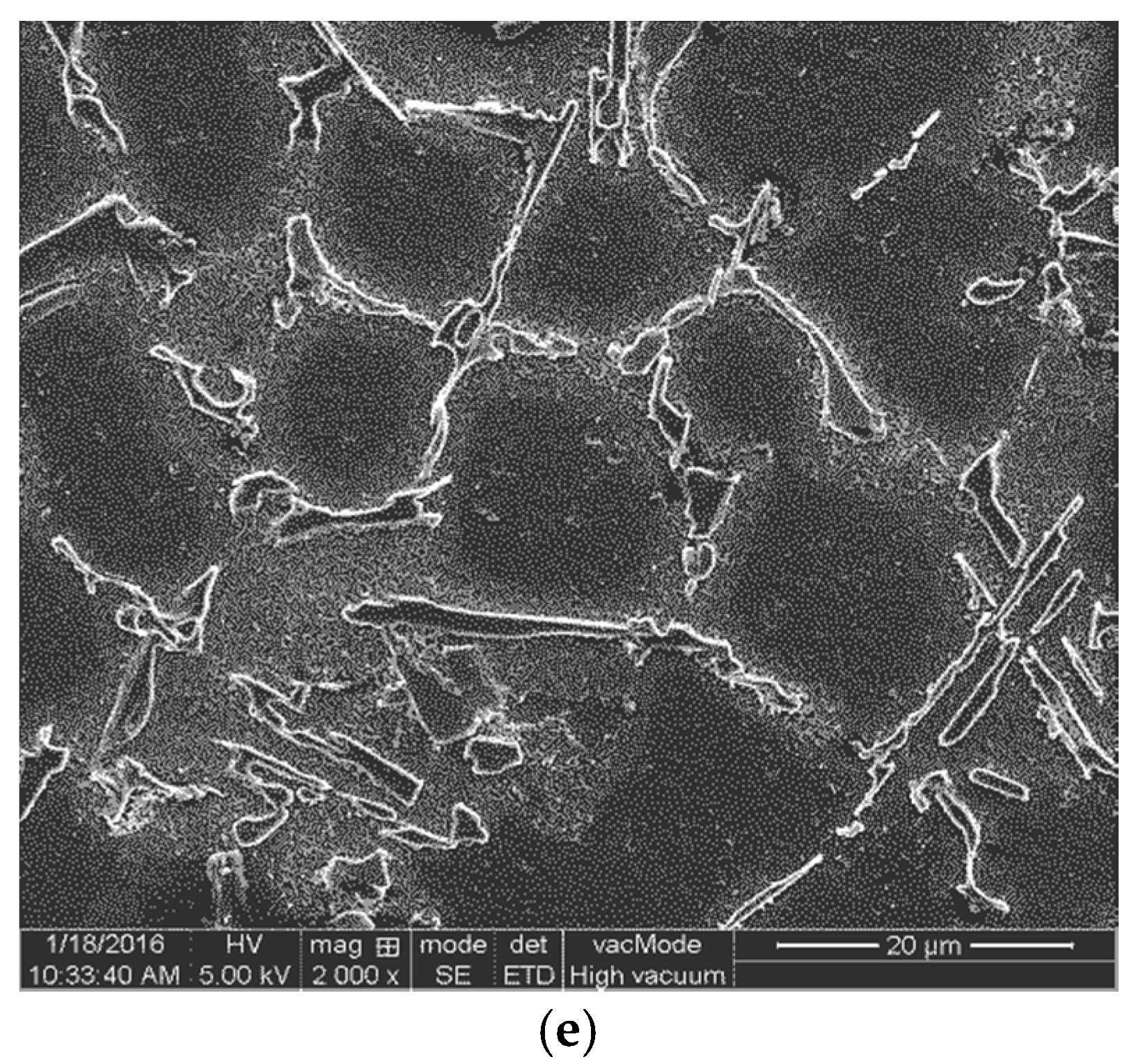

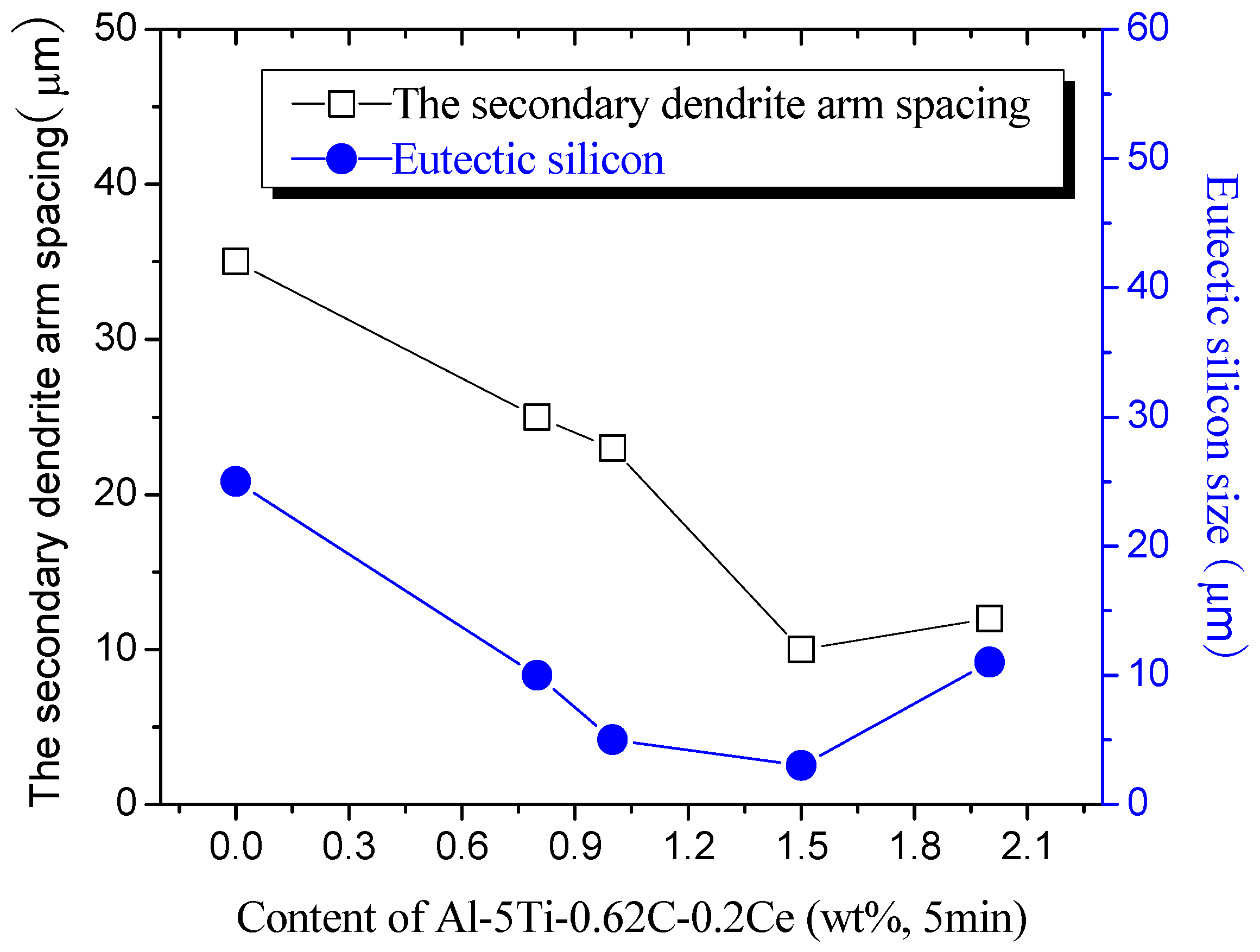

3.3. The Effect of Al-5Ti-0.62C-0.2Ce Master Alloy on Microstructure of Hypoeutectic Al-8Si Alloy

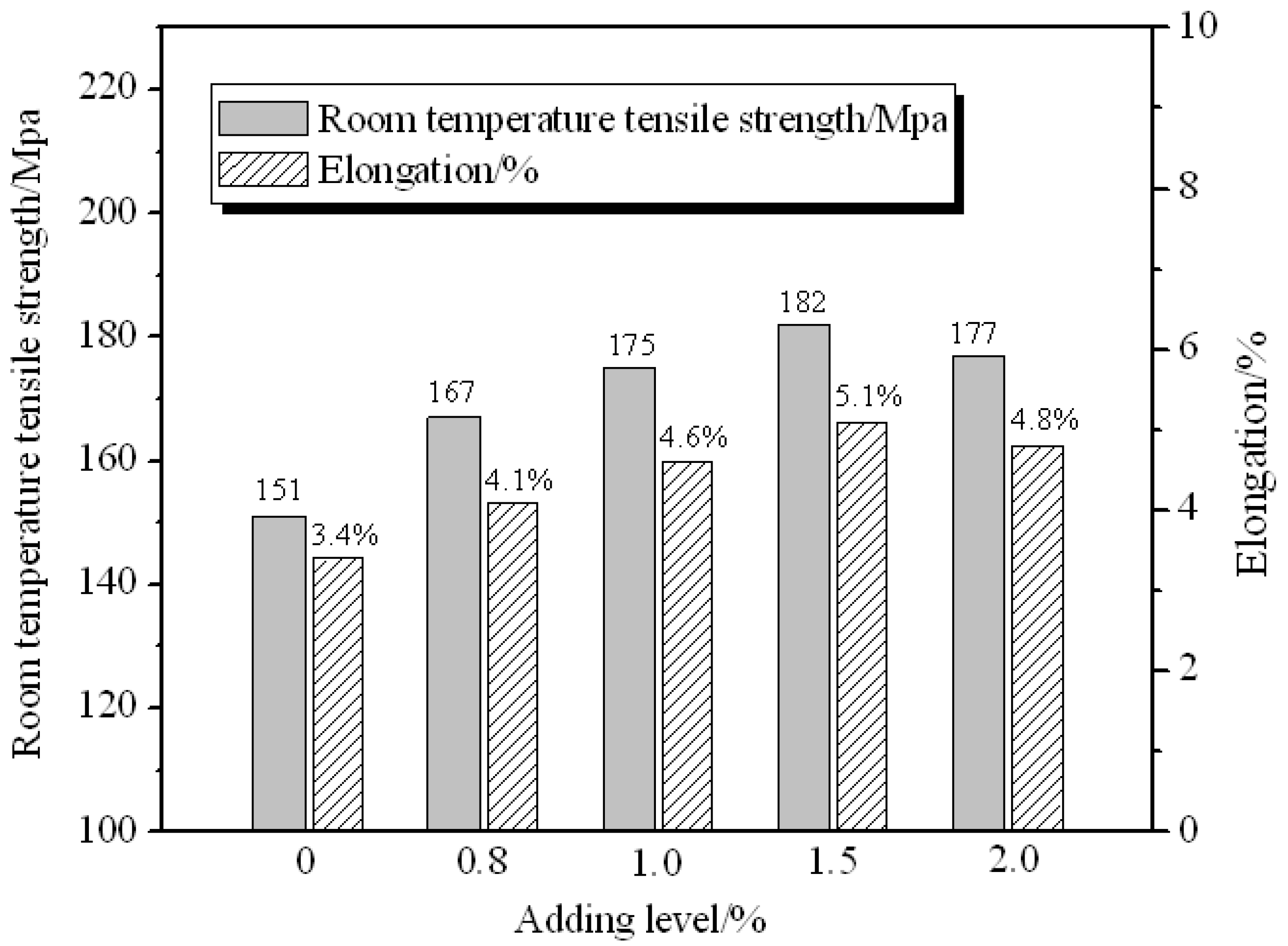

3.4. The Effects of Al-5Ti-0.62C-0.2Ce Master Alloy on Mechanical Properties of Commercial Pure Al and Hypoeutectic Al-8Si Alloy

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, T.M.; Chen, Z.N.; Fu, H.W. Grain refinement mechanism of pure aluminum by inoculation with Al-B master alloy. Mater. Sci. Eng. A 2012, 549, 136–143. [Google Scholar] [CrossRef]

- Xiong, Y.H.; Yang, A.M.; Guo, Y.P. Production of Al-Ti-C grain refiners with the addition of elemental carbon. Mater. Des. 2010, 31, S30–S35. [Google Scholar]

- Krajewski, W.K.; Greer, A.L. EBSD study of ZnAl25 alloy inoculated with ZnTi4 master alloy. Mater. Sci. Forum 2006, 508, 281–285. [Google Scholar] [CrossRef]

- Krajewski, W.K. Determination of Al site preference in L12TiZn3-base trialuminides. Mater. Sci. Forum 2006, 508, 615–620. [Google Scholar] [CrossRef]

- Krajewski, W.K.; Buraś, J.; Krajewski, P.K.; Greer, A.L.; Faerber, K.; Schumacher, P. New developments of Al-Zn cast alloys. Mater. Today 2015, 2, 4978–4983. [Google Scholar] [CrossRef]

- Xu, C.H.; Liang, L.P.; Lu, B.F.; Zhang, J.S.; Liang, W. Effect of La on microstructure and grain-refining performance of Al-Ti-C grain refiner. J. Rare Earth 2006, 24, 596–601. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Wang, M.X.; Weng, Y.G.; Song, T.F.; Huo, Y.P.; Xie, J.P. Effect of silicon on grain refinement of aluminum produced by electrolysis. Mater. Trans. 2003, 44, 2157–2162. [Google Scholar] [CrossRef]

- Kumar, G.S.; Murty, B.S.; Chakraborty, M. Development of Al-Ti-C grain refiners and study of their grain refining efficiency on Al and Al-7Si alloy. J. Alloys Compd. 2005, 396, 143–150. [Google Scholar] [CrossRef]

- Yucel, B. Grain refining efficiency of Al-Ti-C alloys. J. Alloys Compd. 2006, 422, 128–131. [Google Scholar]

- Kumar, G.S.; Murty, B.S.; Chakraborty, M. Grain refinement response of LM25 alloy towards Al-Ti-C and Al-Ti-B grain refiners. J. Alloys Compd. 2009, 472, 112–120. [Google Scholar] [CrossRef]

- Li, Y.L.; Feng, H.K.; Cao, F.R.; Chen, Y.B.; Gong, L.Y. Effect of high density ultrasonic on the microstructure and refining property of Al-5Ti-0.25C grain refiner alloy. Mater. Sci. Eng. A 2008, 487, 518–523. [Google Scholar] [CrossRef]

- Zhao, H.L.; Song, Y.; Li, M.; Guan, S.K. Grain refining efficiency and microstructure of Al-Ti-C-RE master alloy. J. Alloys Compd. 2010, 508, 206–211. [Google Scholar] [CrossRef]

- Ding, W.W.; Zhang, X.Y.; Zhao, W.J.; Xia, T.D. Microstructure of Al-5Ti-0.6C-1Ce master alloy and its grain-refining performance. Int. J. Mater. Res. 2015, 106, 1240–1243. [Google Scholar] [CrossRef]

- Liu, X.F.; Wang, Z.Q.; Zhang, Z.G.; Bian, X.F. The relationship between microstructures and refining performances of Al-Ti-C master alloys. Mater. Sci. Eng. A 2002, 332, 70–74. [Google Scholar]

- Liu, Y.M.; Xu, B.F.; Cai, X.; Li, L.H.; Chen, Q.L. The preparation of in situ TiC/Al composite by additive CeO2. J. Shanghai Jiaotong Univ. 2004, 38, 1122–1125. [Google Scholar]

- Wu, Q.L.; Sun, Y.S.; Xue, F.; Zhuo, J. Effect of CeO2 addition on microstructure and properties of in-situ TiC strengthened steel. J. Chin. Rare Earth Soc. 2008, 26, 92–96. [Google Scholar]

- Wang, L.D.; Zhu, D.Y.; Wei, Z.L.; Huang, L.A.; Song, W.; Yang, S.Q.; He, X.; Gu, H.L.; Chen, Y. Effect of adding Ce2O3 on fabrication of Al-Ti-C refiner. J. Chin. Rare Earth Soc. 2010, 28, 90–96. [Google Scholar]

- Wang, L.D.; Wei, Z.L.; Yang, X.B.; Zhu, D.Y.; Chen, H.X.; Chen, Y.L.; Hong, L.H.; Li, Q.J. Thermodynamics analysis of Al-Ti-C-RE prepared by rare earth oxide Ce2O3. Trans. Nonferr. Met. Soc. China 2013, 23, 2928–2935. [Google Scholar]

- Ding, W.W.; Zhang, X.Y.; Zhao, W.J. Microstructure evolution and grain refining performance of new green kind of Al-5Ti-C master alloy. Int. J. Cast. Met. Res. 2015, 28, 89–96. [Google Scholar] [CrossRef]

- Ding, W.W.; Zhao, W.J.; Xia, T.D. Grain refining action of Al-5Ti-C and Al-TiC master alloys with Al-5Ti master alloy addition for commercial purity aluminum. Int. J. Cast. Met. Res. 2014, 27, 187–192. [Google Scholar] [CrossRef]

- Banerji, A.; Reif, W. Development of Al-Ti-C grain refiners containing TiC. Metall. Trans. A 1986, 17, 2127–2137. [Google Scholar] [CrossRef]

- Wang, S.H.; Wang, Z.F.; Fan, X.Y.; Jia, X.F.; Zhao, Y.; Zhang, L. Effect of different RE Ce master alloy on microstructure of A356 alloy. China Foundry Mach. Technol. 2010, 4, 7–11. [Google Scholar]

- Shaha, S.K.; Cerwinski, F.; Kasprzak, W.; Friedman, J.; Chen, D.L. Effect of solidification rate and loading mode on deformation behavior of cast Al-Si-Cu-Mg alloy with additions of transition metals. Mater. Sci. Eng. A 2015, 636, 361–372. [Google Scholar] [CrossRef]

- Ding, W.W.; Xia, T.D.; Zhao, W.J.; Xu, Y.T. Effect of Al-5Ti-C master alloy on the microstructure and mechanical properties of hypereutectic Al-20%Si alloy. Materials 2014, 7, 1188–1200. [Google Scholar] [CrossRef]

- Chang, J.Y.; Moon, I.G.; Choi, C.S. Refinement of cast microstructure of hypereutectic Al-Si alloys through the addition of rare earth metals. J. Mater. Sci. 1998, 33, 5015–5023. [Google Scholar] [CrossRef]

- Yang, Y.F.; Xu, C.L.; Wang, H.Y.; Liu, C.; Jiang, Q.C. Effect of Y2O3 on microstructure and mechanical properties of hypereutectic Al-20%Si alloy. Trans. Nonferr. Met. Soc. China 2006, 16, 1332–1335. [Google Scholar]

| Materials | Supplier | Grain Size/μm | Purity/% |

|---|---|---|---|

| Al powder | The Northwest Aluminum Company | 61–74 | 99.6 |

| Ti powder | Shangxi Baoji state Construction Pioneer Metals Corporation | 38–44 | 99.3 |

| C powder | Qingdao Huatai Lubricate Pressurize Science & Technology | 11–30 | 99.8 |

| CeO2 powder | Tianjin Guanfu Fine Chemical Research Institute | 1–2 | 99.5 |

| Commercially pure Al | The Northwest Aluminum Company | - | 99.7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, W.; Xu, C.; Zhang, H.; Zhao, W.; Guo, T.; Xia, T. Effect of Al-5Ti-0.62C-0.2Ce Master Alloy on the Microstructure and Tensile Properties of Commercial Pure Al and Hypoeutectic Al-8Si Alloy. Metals 2017, 7, 227. https://doi.org/10.3390/met7060227

Ding W, Xu C, Zhang H, Zhao W, Guo T, Xia T. Effect of Al-5Ti-0.62C-0.2Ce Master Alloy on the Microstructure and Tensile Properties of Commercial Pure Al and Hypoeutectic Al-8Si Alloy. Metals. 2017; 7(6):227. https://doi.org/10.3390/met7060227

Chicago/Turabian StyleDing, Wanwu, Chen Xu, Haixia Zhang, Wenjun Zhao, Tingbiao Guo, and Tiandong Xia. 2017. "Effect of Al-5Ti-0.62C-0.2Ce Master Alloy on the Microstructure and Tensile Properties of Commercial Pure Al and Hypoeutectic Al-8Si Alloy" Metals 7, no. 6: 227. https://doi.org/10.3390/met7060227

APA StyleDing, W., Xu, C., Zhang, H., Zhao, W., Guo, T., & Xia, T. (2017). Effect of Al-5Ti-0.62C-0.2Ce Master Alloy on the Microstructure and Tensile Properties of Commercial Pure Al and Hypoeutectic Al-8Si Alloy. Metals, 7(6), 227. https://doi.org/10.3390/met7060227