The Effect of Initial Structure on Phase Transformation in Continuous Heating of a TA15 Titanium Alloy

Abstract

:1. Introduction

2. Material and Procedures

2.1. Material

2.2. Metallographic Examination

2.3. Differential Scanning Calorimetry

2.4. Dilatometry

3. Results and Discussion

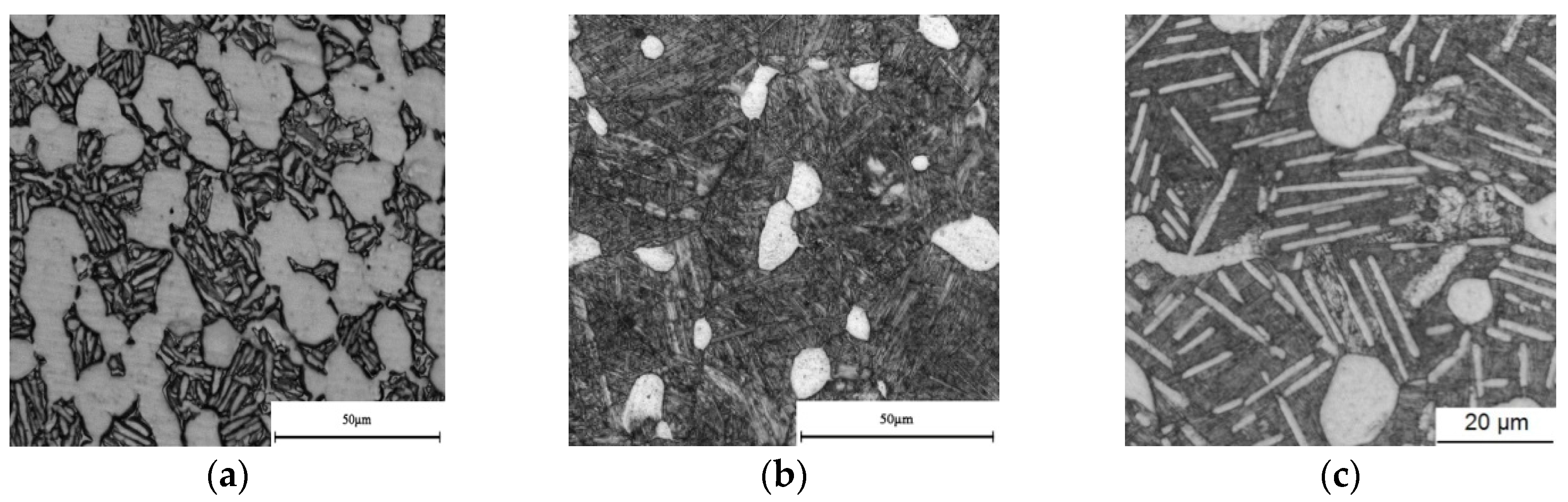

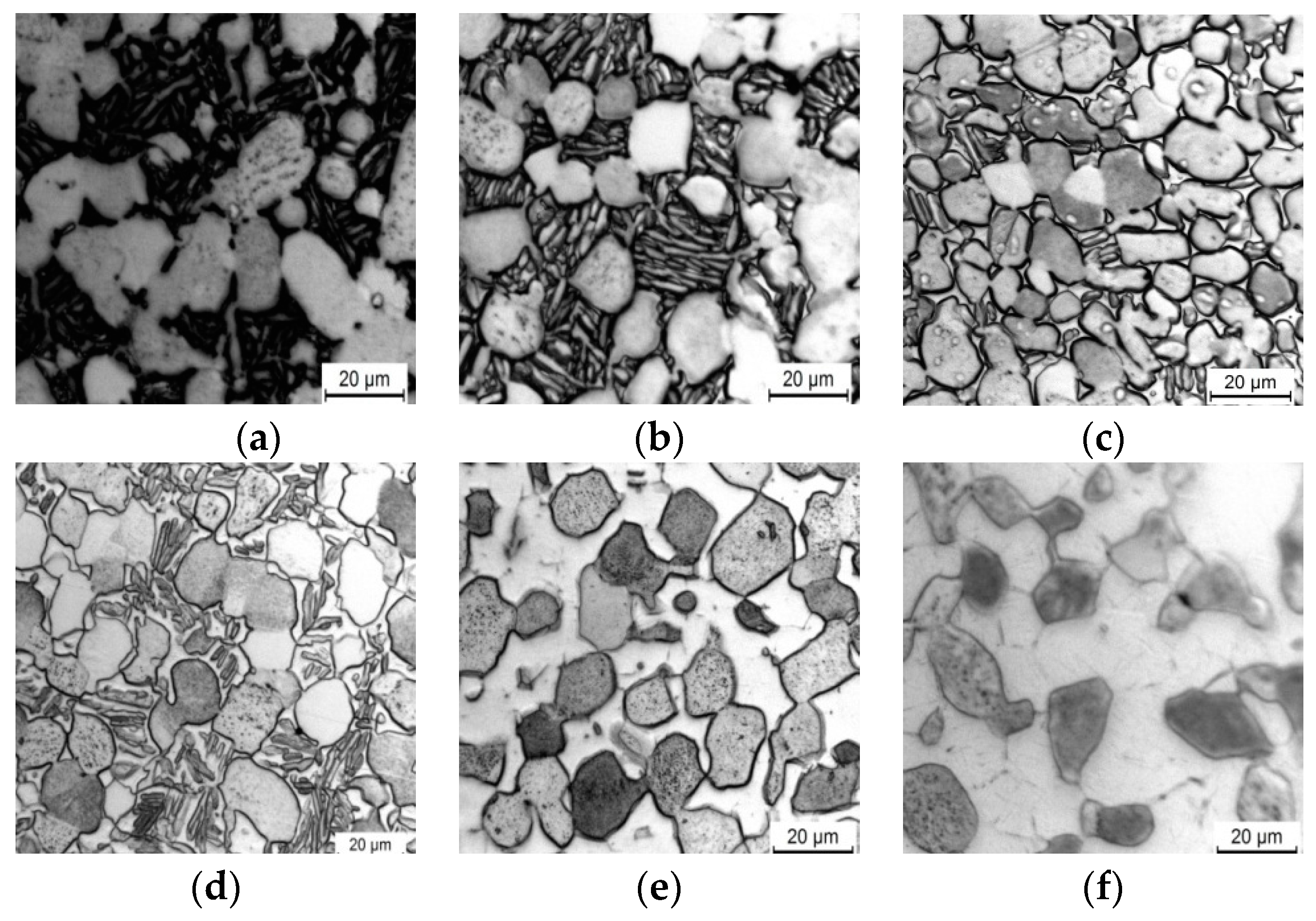

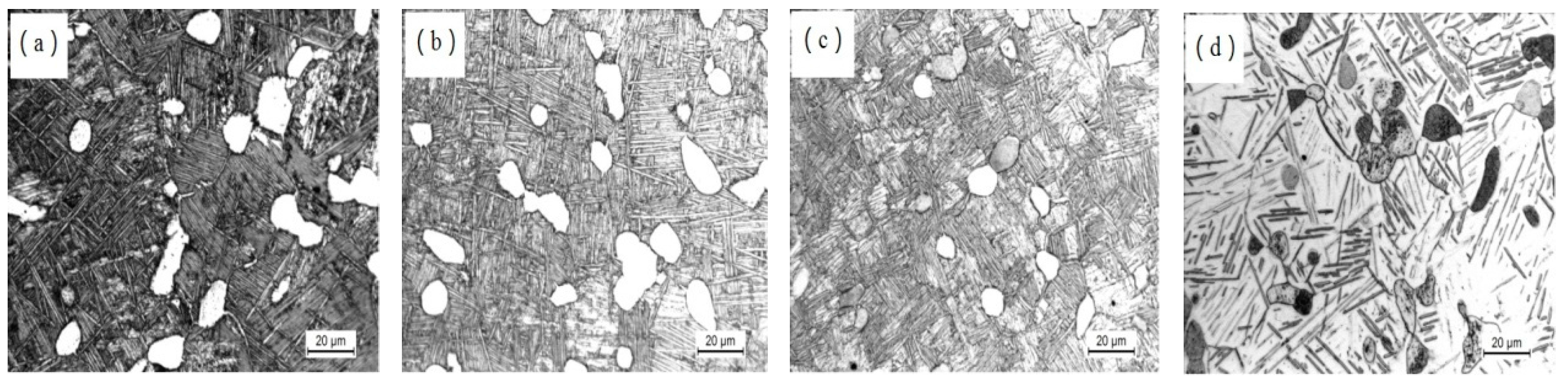

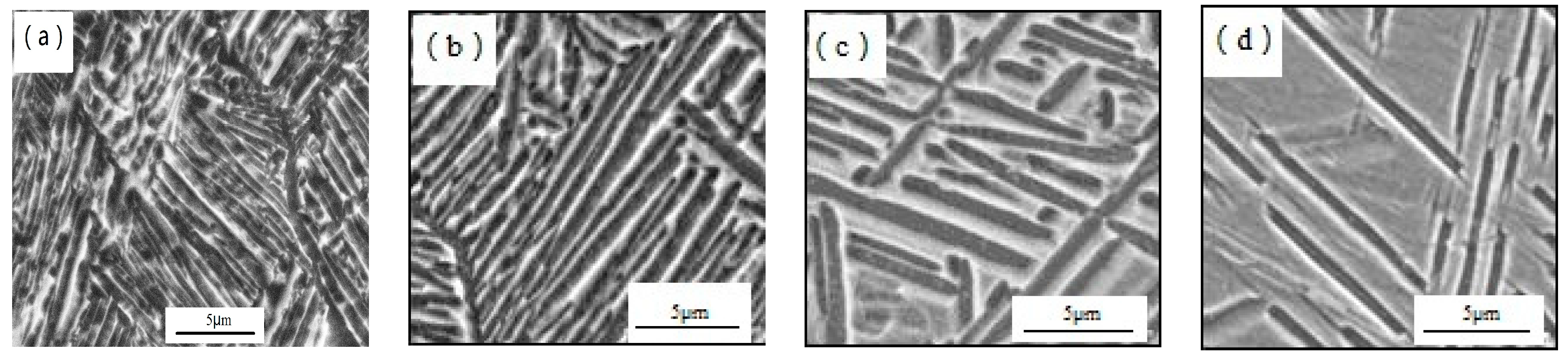

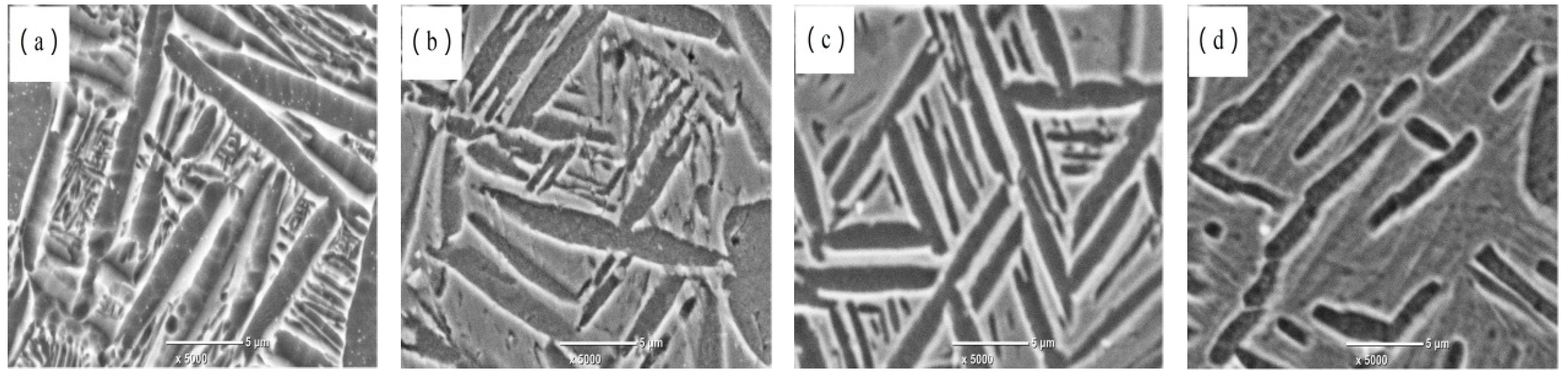

3.1. Microstructure Observations

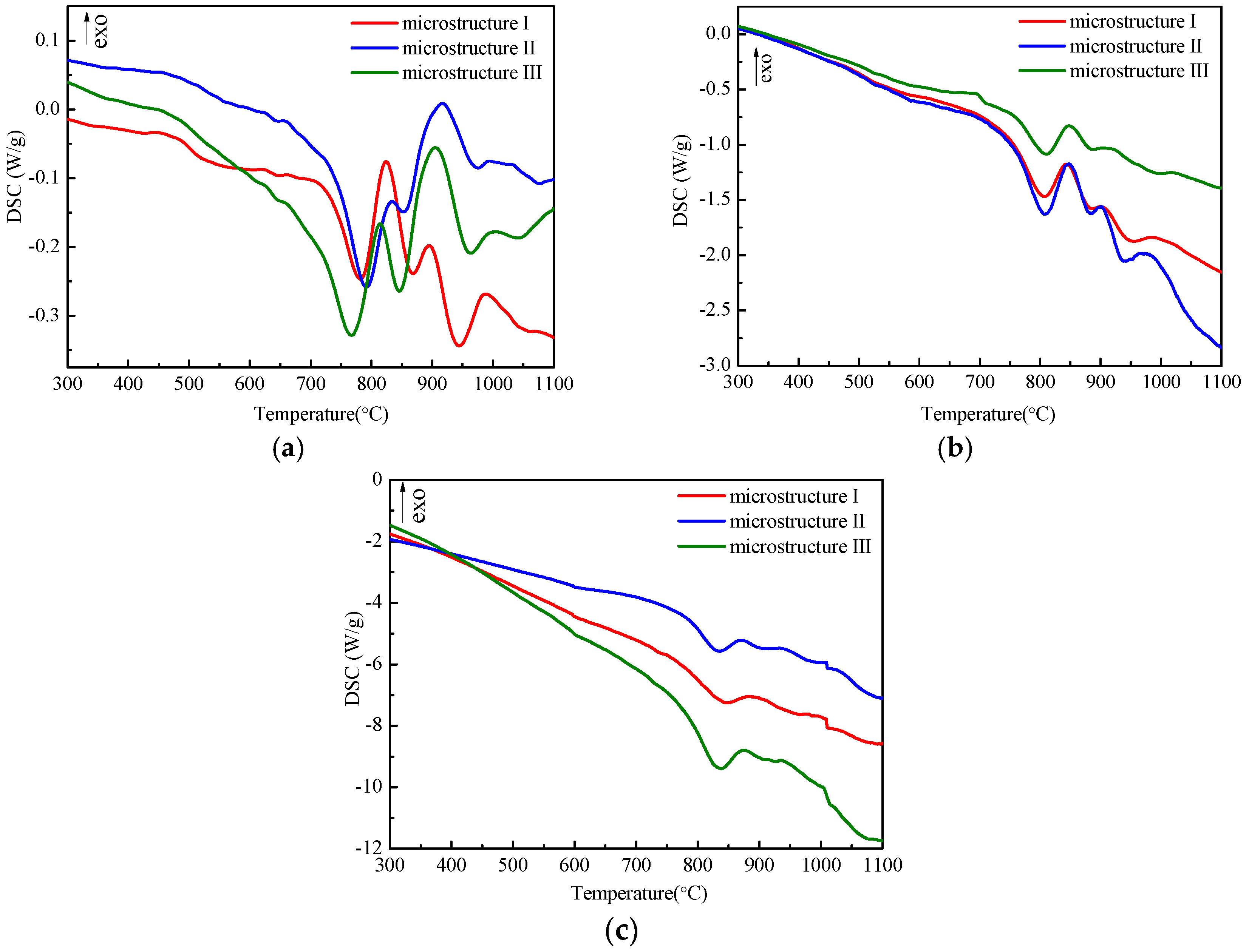

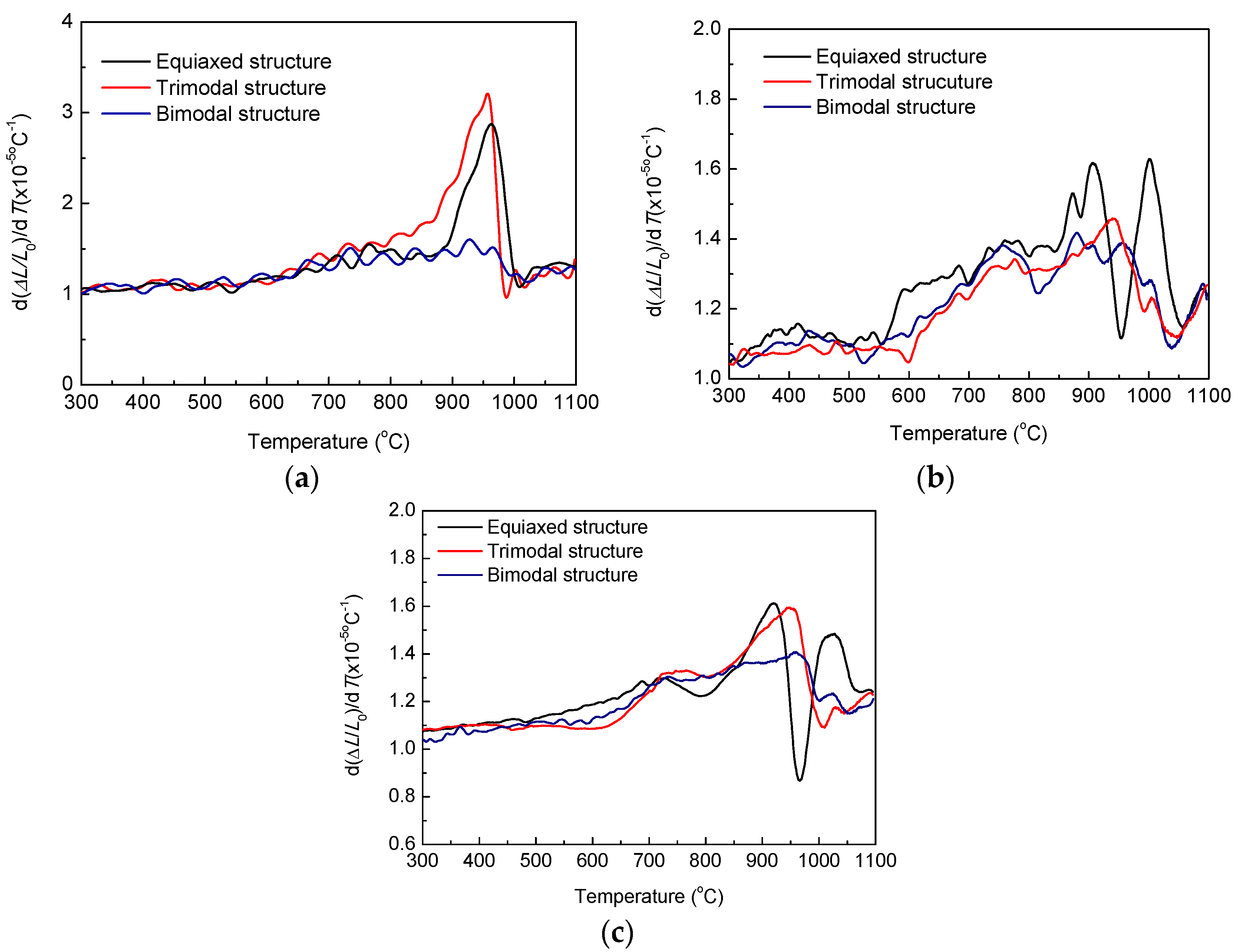

3.2. Analysis of Differential Scanning Calorimetry and Dilatometry

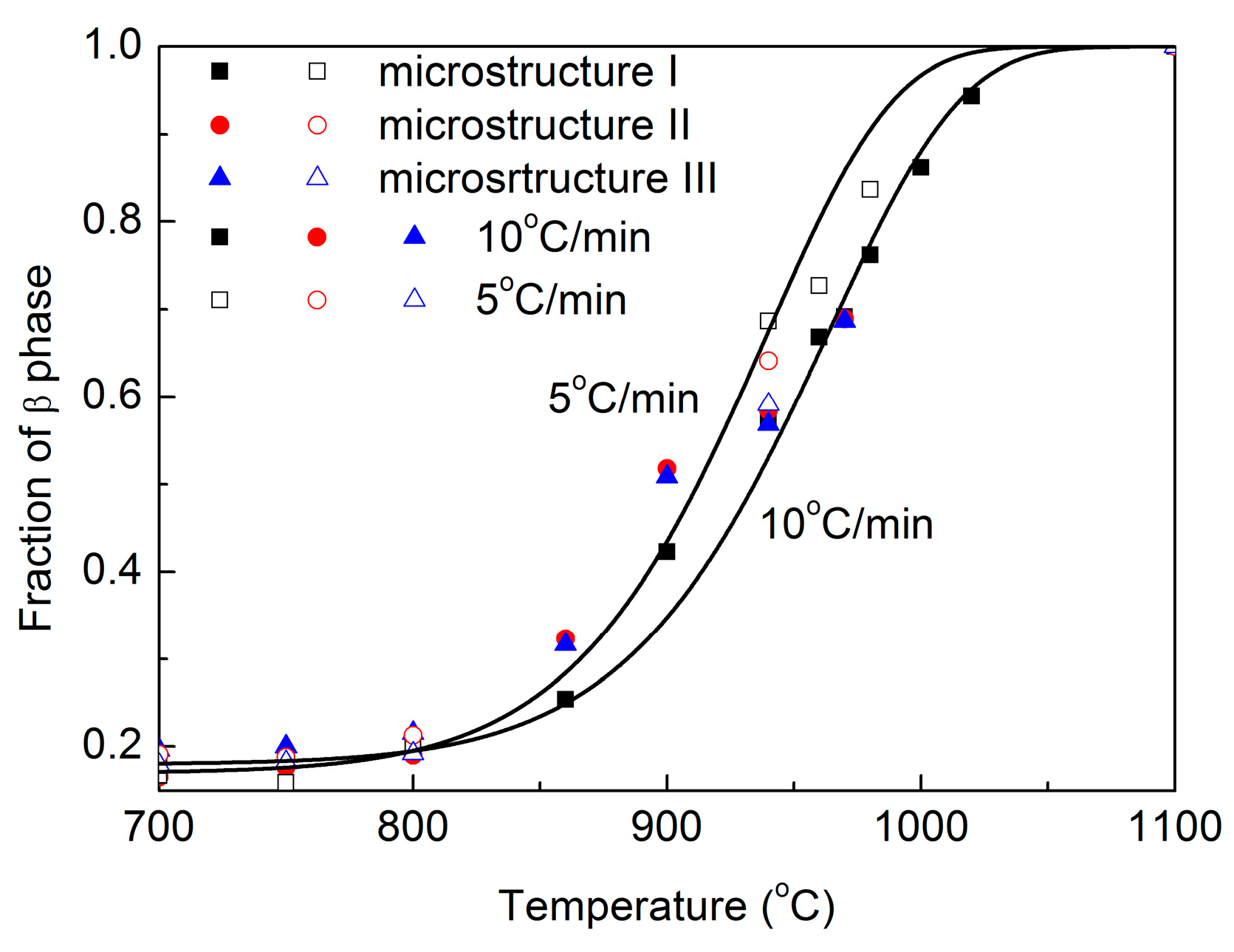

3.3. Transformation Kinetics

4. Conclusions

- (1)

- A four stage phase transformation occurs during continuous heating of the TA15 titanium alloy for microstructure I and III: the decomposition of residual β phase, the transformation of tiny α laths, the transformation of coarse α laths and the transformation of equiaxed α. The secondary and third stages overlap for microstructure II. The four stages of phase transformation overlap with increasing heating rate.

- (2)

- The α-to-β transformation is accompanied by the coarsening of secondary α laths for microstructure II, resulting in significant changes in the size and volume fraction of α laths.

- (3)

- The phase transformation kinetics is not affected by the initial structure when the transformation of equiaxed α becomes dominant. In the presence of lamellar α, the specimen with initially microstructure I has the highest transformed fraction under slow heating but the lowest transformed fraction under rapid heating.

- (4)

- The transformed fraction increases with temperature in a sigmoidal way which can be fitted by the JMA model. The determined JMA exponent is close to 1, suggesting phase transformation is controlled by the growth of existing large β phase.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lütjering, G.; Williams, J.C. Titanium; Springer: Berlin, Germany, 2007. [Google Scholar]

- Beranoagirre, A.; Lacalle, L.N.L. Grinding of gamma TiAl intermetallic alloys. Procedia Eng. 2013, 63, 489–498. [Google Scholar] [CrossRef]

- Beranoagirre, A.; Olvera, D.; Lacalle, L.N.L. Milling of gamma titanium–aluminum alloys. Int. J. Adv. Manuf. Technol. 2012, 62, 83–88. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Zeng, W.D.; Yu, H.Q. An investigation of a new near-beta forging process for titanium alloys and its application in aviation components. Mater. Sci. Eng. A 2005, 393, 204–212. [Google Scholar] [CrossRef]

- Tang, B.; Kou, H.; Zhang, X.; Gao, P.; Li, J. Study on the formation mechanism of α lamellae in a near β titanium alloy. Prog. Nat. Sci. Mater. Int. 2016, 26, 385–390. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, S.; Yang, H. Nucleation and growth mechanism of α-lamellae of Ti alloy TA15 cooling from an α + β phase field. Acta Mater. 2013, 61, 2057–2064. [Google Scholar] [CrossRef]

- He, D.; Zhu, J.C.; Zaefferer, S.; Raabe, D.; Liu, Y.; Lai, Z.L.; Yang, X.W. Influences of deformation strain, strain rate and cooling rate on the Burgers orientation relationship and variants morphology during β → α phase transformation in a near α titanium alloy. Mater. Sci. Eng. A 2012, 549, 20–29. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Wang, Q.J.; Hu, Q.M.; Liu, J.R.; Yu, B.B.; Yang, R. Effect of β (110) texture intensity on α-variant selection and microstructure morphology during β/α phase transformation in near α titanium alloy. Acta Mater. 2017, 126, 372–382. [Google Scholar] [CrossRef]

- Kherrouba, N.; Bouabdallah, M.; Badji, R.; Carron, D.; Amir, M. β to α transformation kinetics and microstructure of Ti-6Al-4V alloy during continuous cooling. Mater. Chem. Phys. 2016, 181, 462–469. [Google Scholar] [CrossRef]

- Liu, H.H.; Niinomi, M.; Nakai, M.; Cho, K.; Fujii, H. Deformation-induced omega-phase transformation in a beta-type titanium alloy during tensile deformation. Scr. Mater. 2017, 130, 27–31. [Google Scholar] [CrossRef]

- Jonas, J.J.; Aranas, C.; Fall, A.; Jahazi, M. Transformation softening in three titanium alloys. Mater. Des. 2017, 113, 305–310. [Google Scholar] [CrossRef]

- Wang, Y.H.; Kou, H.C.; Chang, H.; Zhu, Z.; Su, X.; Li, J.; Zhou, L. Phase transformation in TC21 alloy during continuous heating. J. Alloys Compd. 2009, 472, 252–256. [Google Scholar] [CrossRef]

- Sha, W.; Guo, Z.L. Phase evolution of Ti–6Al–4V during continuous heating. J. Alloys Compd. 1999, 290, L3–L7. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Requena, G.; Buslaps, T.; Alfeld, M.; Boesenberg, U. Role of element partitioning on the α–β phase transformation kinetics of a bi-modal Ti–6Al–6V–2Sn alloy during continuous heating. J. Alloys Compd. 2015, 626, 330–339. [Google Scholar] [CrossRef]

- Elmer, J.W.; Palmer, T.A.; Babu, S.S.; Zhang, W.; DebRoy, T. Phase transformation dynamics during welding of Ti–6Al–4V. J. Appl. Phys. 2004, 95, 8327–8339. [Google Scholar] [CrossRef]

- Guo, L.G.; Zhu, S.; Yang, H.; Fan, X.G.; Chen, F.L. Quantitative analysis of microstructure evolution induced by temperature rise during (α + β) deformation of TA15 titanium alloy. Rare Met. 2016, 35, 223–229. [Google Scholar] [CrossRef]

- Chen, F.; Xu, G.; Zhang, X.; Zhou, K. Exploring the phase transformation in β-quenched Ti-55531 alloy during continuous heating via, dilatometric measurement, microstructure characterization, and diffusion analysis. Metall. Mater. Trans. A 2016, 47, 5383–5394. [Google Scholar] [CrossRef]

- Malinov, S.; Guo, Z.; Sha, W.; Wilson, A. Differential scanning calorimetry study and computer modeling of β ⇒ α phase transformation in a Ti-6Al-4V alloy. Metall. Mater. Trans. A 2001, 32, 879–887. [Google Scholar] [CrossRef]

- Motyka, M.; Kubiak, K.; Sieniawski, J.; Ziaja, W. Phase transformations and characterization of α + β titanium alloys. In Comprehensive Materials Processing; Hashmi, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 2, pp. 7–36. [Google Scholar]

- Elmer, J.W.; Palmer, T.A.; Babu, S.S.; Specht, E.D. In situ observations of lattice expansion and transformation rates of α and β phases in Ti–6Al–4V. Mater. Sci. Eng. A 2005, 391, 104–113. [Google Scholar] [CrossRef]

- Guo, Z.; Keong, K.G.; Sha, W. Crystallisation and phase transformation behaviour of electroless nickel phosphorus platings during continuous heating. J. Alloys Compd. 2003, 358, 112–119. [Google Scholar] [CrossRef]

- Liu, Y.C.; Sommer, F.; Mittemeijer, E.J. Abnormal austenite–ferrite transformation behavior in substitutional Fe-based alloys. Acta Mater. 2003, 51, 507–519. [Google Scholar] [CrossRef]

- Meng, M.; Yang, H.; Fan, X.G.; Yan, S.L.; Zhao, A.M.; Zhu, S. On the modeling of diffusion-controlled growth of primary α in heat treatment of two-phase Ti-alloys. J. Alloys Compd. 2016, 691, 67–80. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Lehner, T.M.; Miller, J.D.; Doherty, R.D.; Fueere, D.U. α/β heat treatment of a titanium alloy with a nonuniform microstructure. Metall. Mater. Trans. A 2007, 38, 910–921. [Google Scholar] [CrossRef]

| Microstructure | Yield Strength | Elongation | Fracture Toughness | Creep Strength | HCF Strength | LCF Strength |

|---|---|---|---|---|---|---|

| Bimodal | ++ | −/o | + | + | +/o | + |

| Trimodal | + | −/o | + | + | + | ++ |

| Microstructure | Phase Transition |

|---|---|

| I | residual β-secondary α, secondary α-β, lamellar α-β, equaixed α-β |

| II | residual β-secondary α, secondary α/lamellar α-β, equaixed α-β |

| III | residual β-secondary α, secondary α-β, lamellar α-β, equaixed α-β |

| ln (k0) | n | Q (kJ/mol) |

|---|---|---|

| 26.9 | 0.75 | 333 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, X.; Li, Q.; Zhao, A.; Shi, Y.; Mei, W. The Effect of Initial Structure on Phase Transformation in Continuous Heating of a TA15 Titanium Alloy. Metals 2017, 7, 200. https://doi.org/10.3390/met7060200

Fan X, Li Q, Zhao A, Shi Y, Mei W. The Effect of Initial Structure on Phase Transformation in Continuous Heating of a TA15 Titanium Alloy. Metals. 2017; 7(6):200. https://doi.org/10.3390/met7060200

Chicago/Turabian StyleFan, Xiaoguang, Qi Li, Anming Zhao, Yuguo Shi, and Wenjia Mei. 2017. "The Effect of Initial Structure on Phase Transformation in Continuous Heating of a TA15 Titanium Alloy" Metals 7, no. 6: 200. https://doi.org/10.3390/met7060200