Microstructure and Properties of the Interface Area in the Laser Cladded Ni Based Coatings on the 1Cr10Mo1NiWVNbN Steel

Abstract

:1. Introduction

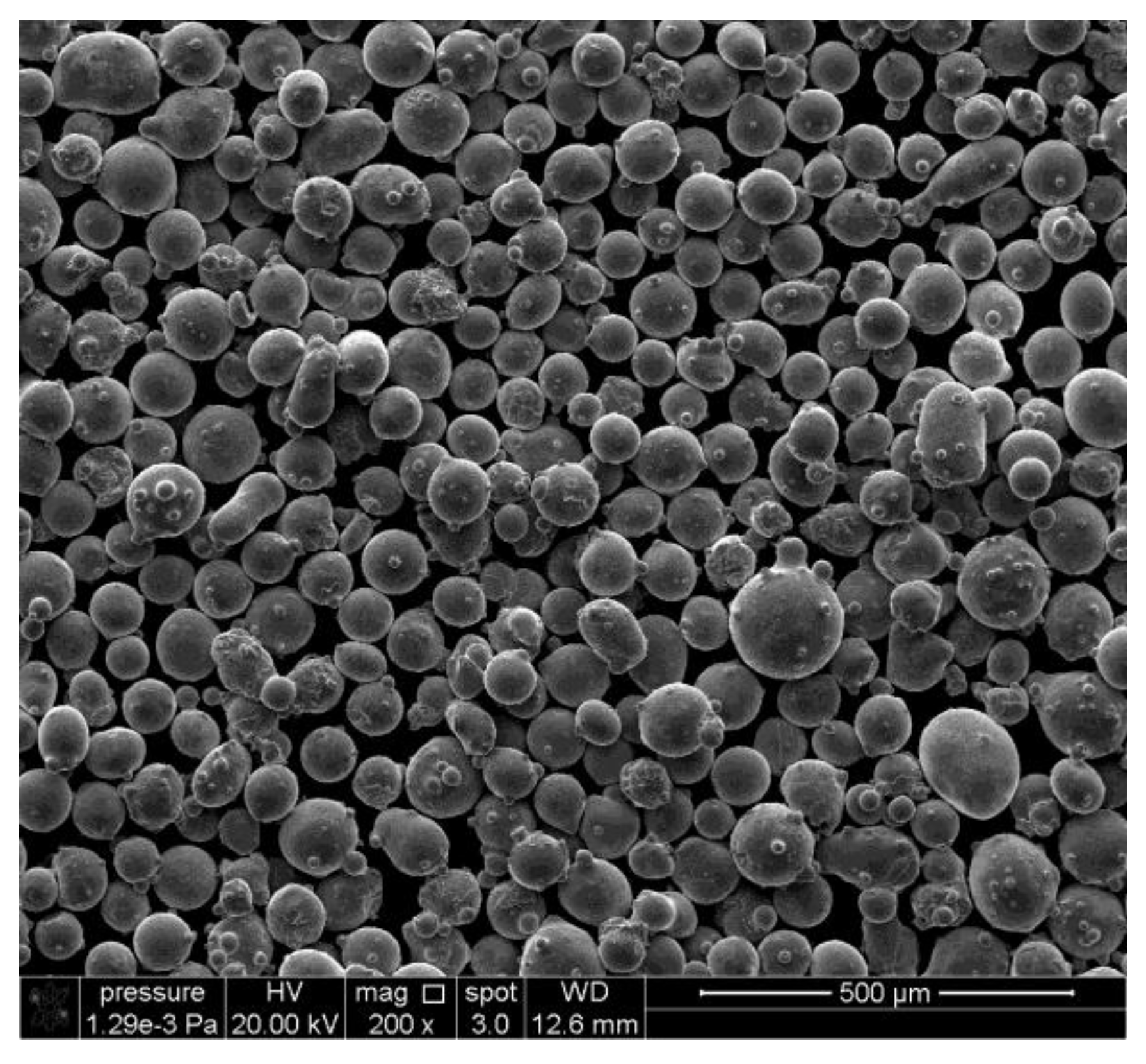

2. Materials and Experimental Procedures

3. Results and Discussion

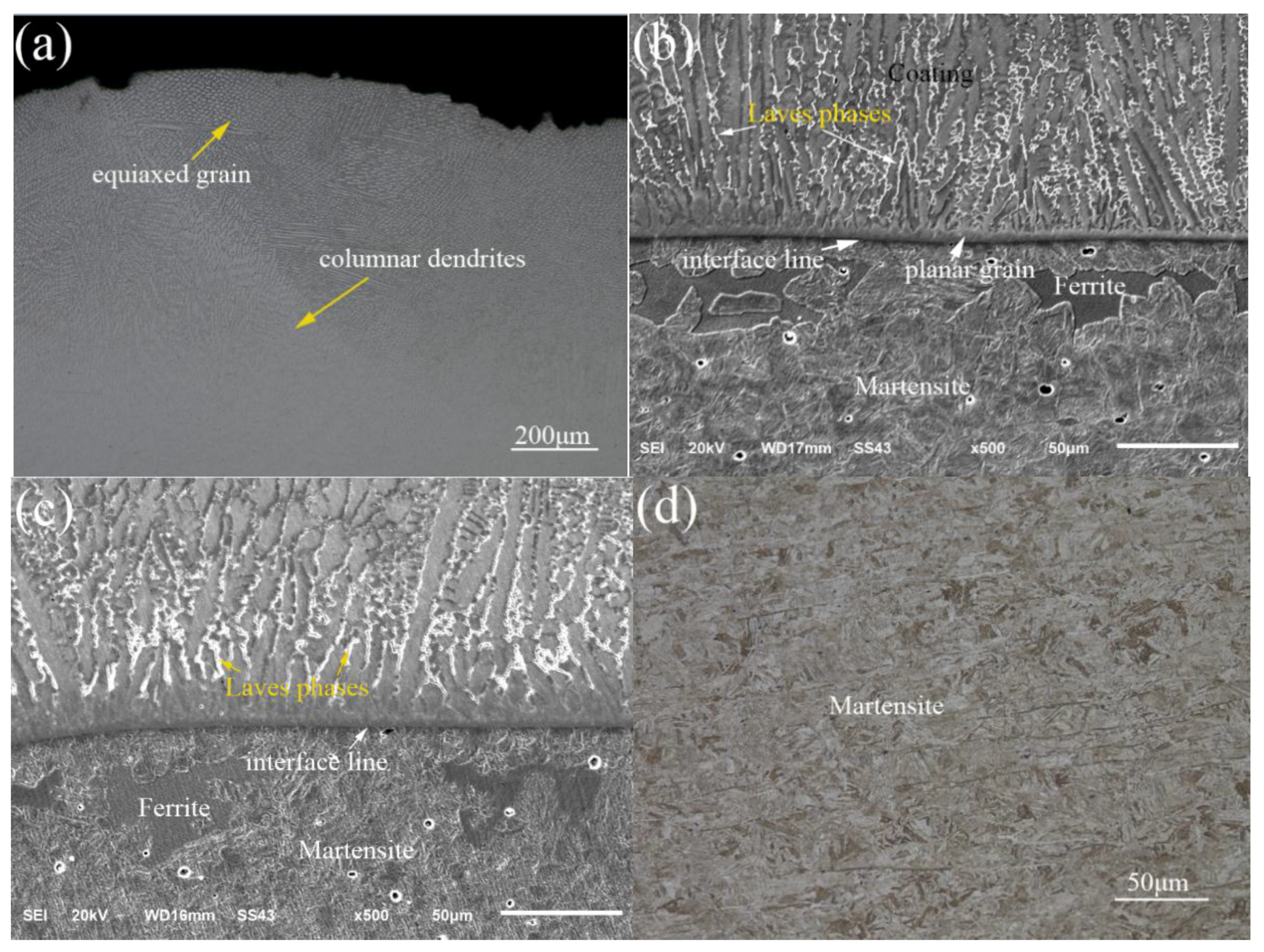

3.1. Solidification Microstructure

3.2. The Microstructure in the Coatings

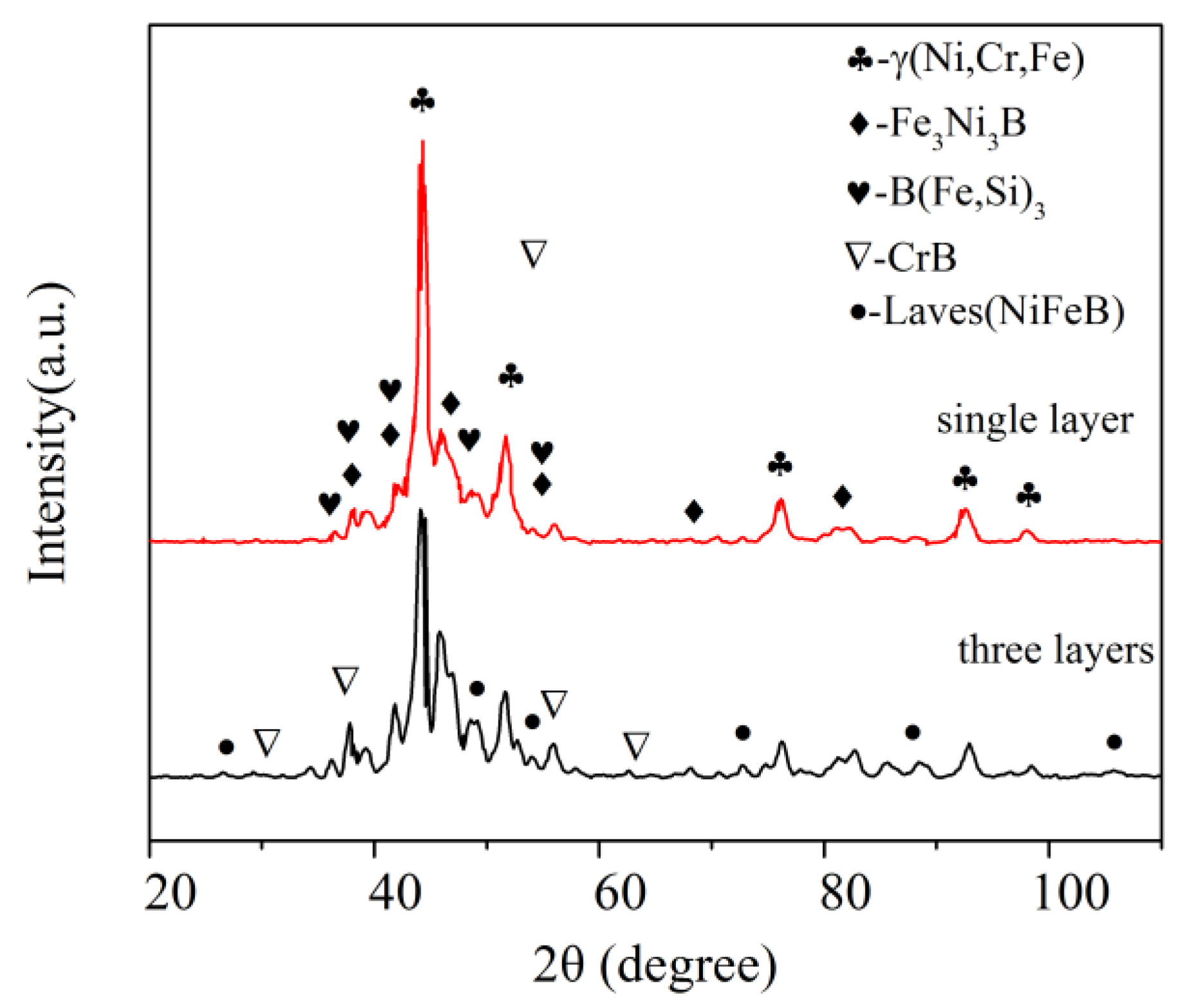

3.3. XRD Analysis

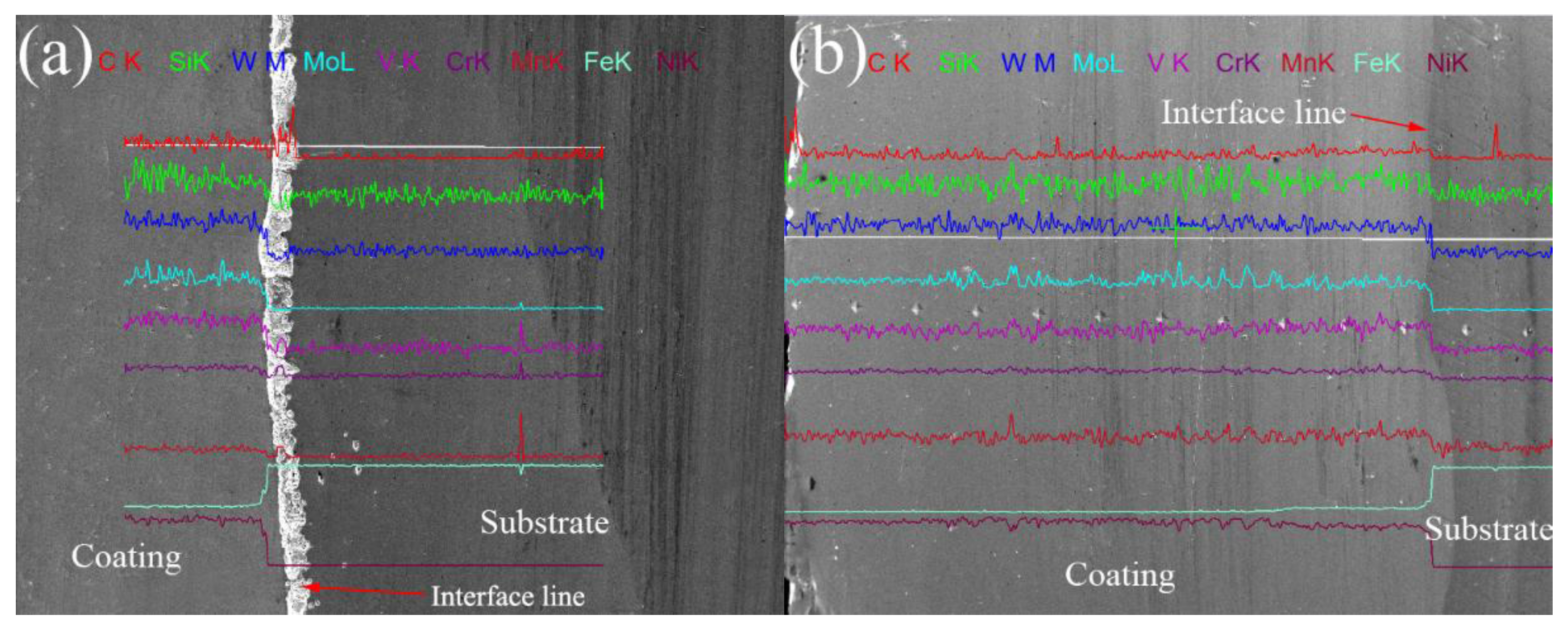

3.4. The Chemical Composition Distribution

3.5. Microhardness

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shen, Y.; Shang, Z.; Xu, Z.; Liu, W.; Huang, X.; Liu, H. The nature of nano-sized precipitates in ferritic/martensitic steel P92 produced by thermomechanical treatment. Mater. Charact. 2016, 119, 13–23. [Google Scholar] [CrossRef]

- Lu, F.; Liu, P.; Ji, H.; Ding, Y.; Xu, X.; Gao, Y. Dramatically enhanced impact toughness in welded 10% Cr rotor steel by high temperature post-weld heat treatment. Mater. Charact. 2014, 92, 149–158. [Google Scholar] [CrossRef]

- Caballero, F.G.; Allain, S.; Cornide, J.; Puerta Velásquez, J.D.; Garcia-Mateo, C.; Miller, M.K. Design of cold rolled and continuous annealed carbide-free bainitic steels for automotive application. Mater. Des. 2013, 49, 667–680. [Google Scholar] [CrossRef]

- Mani, A.A.; Kumar, T.S.; Chandrasekar, M. Mechanical and metallurgical properties of dissimilar welded components (AISI 430 ferritic–AISI 304 austenitic stainless steels) by CO2 laser beam welding (LBW). J. Chem. Pharm. Sci. 2015, 974, 2115. [Google Scholar]

- Bettahar, K.; Bouabdallah, M.; Badji, R.; Gaceb, M.; Kahloun, C.; Bacroix, B. Microstructure and mechanical behavior in dissimilar 13Cr/2205 stainless steel welded pipes. Mater. Des. 2015, 85, 221–229. [Google Scholar] [CrossRef]

- Mourad, A.H.I.; Khourshid, A.; Sharef, T. Gas tungsten arc and laser beam welding processes effects on duplex stainless steel 2205 properties. Mater. Sci. Eng. A 2012, 549, 105–113. [Google Scholar] [CrossRef]

- Yang, G.; Wang, L.; Ceng, S. Influences of Chemical Composition and Heat Treatment Process on Mechanical Properties of 1Cr10Mo1NiWVNbN Rotor Steel. Mater. Mech. Eng. 2009, 8, 17–21. [Google Scholar]

- Ding, Z.; Hu, Q.; Zeng, L.; Li, J. Hot deformation characteristics of as-cast high-Cr ultra-super-critical rotor steel with columnar grains. Int. J. Miner. Metall. Mater. 2016, 23, 1275–1285. [Google Scholar] [CrossRef]

- Wang, L.; Tai, Q.; Yang, G. Effect of the Cooling Speed on the Impact Toughness and Microstructure of 0Cr11Ni2MoVNb Steel. Mater. Mech. Eng. 2006, 30, 31–33. [Google Scholar]

- Taban, E.; Deleu, E.; Dhooge, A. Laser welding of modified 12% Cr stainless steel: Strength, fatigue, toughness, microstructure and corrosion properties. Mater. Des. 2009, 30, 1193–1200. [Google Scholar] [CrossRef]

- Hope, A.T.; Lippold, J.C. Development and testing of a high-chromium, Ni-based filler metal resistant to ductility dip cracking and solidification cracking. Weld. World 2017, 61, 325–332. [Google Scholar] [CrossRef]

- Abe, T.; Sasahara, H. Dissimilar metal deposition with a stainless steel and nickel-based alloy using wire and arc-based additive manufacturing. Precis. Eng. 2016, 45, 387–395. [Google Scholar] [CrossRef]

- Xu, G.; Kutsuna, M.; Liu, Z. Characteristics of Ni-based coating layer formed by laser and plasma cladding processes. Mater. Sci. Eng. A 2006, 417, 63–72. [Google Scholar] [CrossRef]

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of dissimilar materials. CIRP Ann Manuf. Technol. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Zhao, X.; Dang, Y.; Yin, H.; Yuan, Y.; Lu, J.; Yang, Z.; Gu, Y. Evolution of the microstructure and microhardness of a new wrought Ni–Fe based superalloy during high temperature aging. J. Alloy. Compd. 2015, 644, 66–70. [Google Scholar] [CrossRef]

- Sexton, L.; Lavin, S.; Byrne, G. Laser cladding of aerospace materials. J. Mater. Process. Technol. 2002, 122, 63–68. [Google Scholar] [CrossRef]

- Wen, S.; Li, S.; Wei, Q.; Yan, C.; Zhang, S.; Shi, Y. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 2014, 214, 2660–2667. [Google Scholar]

- Kurz, W.; Fisher, D. Fundamentals of Solidification; Higher Education Press: Beijing, China, 2010; pp. 71–92. [Google Scholar]

- Ye, X.; Hua, X.; Wang, M.; Lou, S. Controlling hot cracking in Ni-based Inconel-718 superalloy cast sheets during tungsten inert gas welding. J. Mater. Process. Technol. 2015, 222, 381–390. [Google Scholar] [CrossRef]

- Zhang, L.; Danilova, E.V.; Steinbach, I.; Medvedev, D.; Galenko, P.K. Diffuse-interface modeling of solute trapping in rapid solidification: Predictions of the hyperbolic phase-field model and parabolic model with finite interface dissipation. Acta Mater. 2013, 61, 4155–4168. [Google Scholar] [CrossRef]

- Jendrzejewski, R.; Conde, A.; de Damborenea, J.; Sliwinski, G. Characterisation of the laser-clad stellite layers for protective coatings. Mater. Des. 2002, 23, 83–88. [Google Scholar] [CrossRef]

- Korsunsky, A.M.; McGurk, M.R.; Bull, S.J.; Page, T.F. On the hardness of coated systems. Surf. Coat Technol. 1998, 99, 171–183. [Google Scholar] [CrossRef]

- Maruyama, K.; Sawada, K.; Koike, J. Strengthening mechanisms of creep resistant tempered martensitic steel. ISIJ Int. 2001, 41, 641–653. [Google Scholar] [CrossRef]

- Krauss, G. Martensite in steel: Strength and structure. Mater. Sci. Eng. A 1999, 273, 40–57. [Google Scholar] [CrossRef]

- Ram, G.D.J.; Reddy, A.V.; Rao, K.P. Control of Laves phase in Inconel 718 GTA welds with current pulsing. Sci. Technol. Weld. Join. 2004, 9, 390–398. [Google Scholar]

| Materials | Element | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Cr | B | Fe | Ni | Mn | Mo | Nb | W | V | P | S | |

| Powder | 0.80 | 3.5 | 16 | 3.6 | 4.2 | Bal. | - | - | - | - | - | - | - |

| Substrate | 0.14 | 0.22 | 11 | - | Bal. | - | 0.58 | 1.2 | 0.05 | 0.3 | 0.2 | 0.02 | 0.02 |

| Scheme | Laser Power (kW) | Scanning Velocity (mm/s) | Spot Diameter (mm) | Layers Number |

|---|---|---|---|---|

| 1 | 3.6 | 7 | 4 | 1 |

| 2 | 3.6 | 7 | 4 | 3 |

| Laser Power (kW) | Number of Layers | Thickness (mm) | Width (mm) | Dilution Rate (%) |

|---|---|---|---|---|

| 3.6 | 1 | 0.9 | 5.7 | 7.8 |

| 3.6 | 3 | 2.6 | 8.3 | 3.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Guo, Y.; Lu, B.; Xu, M.; Xu, J. Microstructure and Properties of the Interface Area in the Laser Cladded Ni Based Coatings on the 1Cr10Mo1NiWVNbN Steel. Metals 2017, 7, 175. https://doi.org/10.3390/met7050175

Chen Y, Guo Y, Lu B, Xu M, Xu J. Microstructure and Properties of the Interface Area in the Laser Cladded Ni Based Coatings on the 1Cr10Mo1NiWVNbN Steel. Metals. 2017; 7(5):175. https://doi.org/10.3390/met7050175

Chicago/Turabian StyleChen, Yunxia, Yanbing Guo, Binfeng Lu, Mengjia Xu, and Jianhui Xu. 2017. "Microstructure and Properties of the Interface Area in the Laser Cladded Ni Based Coatings on the 1Cr10Mo1NiWVNbN Steel" Metals 7, no. 5: 175. https://doi.org/10.3390/met7050175

APA StyleChen, Y., Guo, Y., Lu, B., Xu, M., & Xu, J. (2017). Microstructure and Properties of the Interface Area in the Laser Cladded Ni Based Coatings on the 1Cr10Mo1NiWVNbN Steel. Metals, 7(5), 175. https://doi.org/10.3390/met7050175