Effects of Micro-Sized Ferrite and Austenite Grains on the Pitting Corrosion Behavior of Lean Duplex Stainless Steel 2101

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

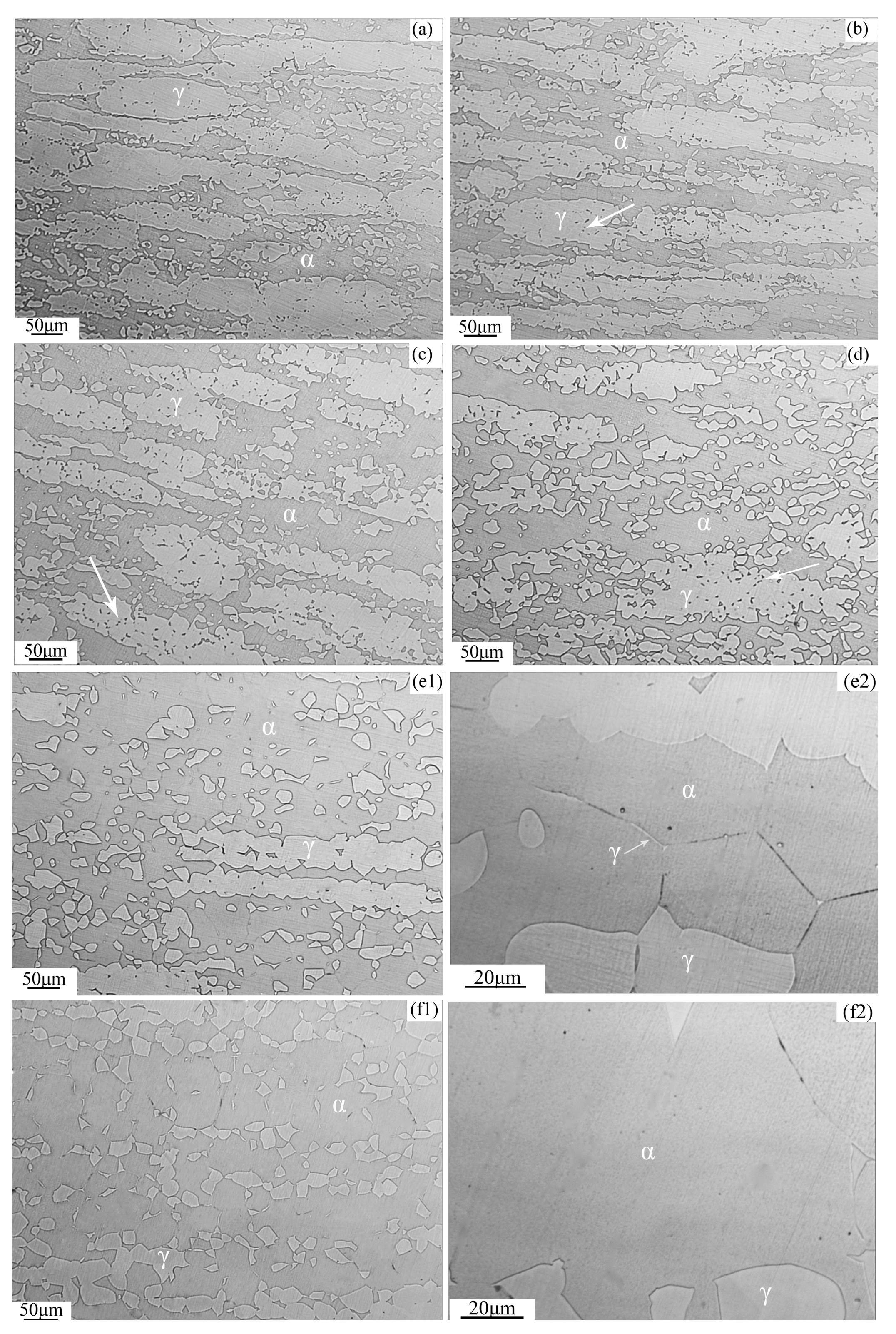

3.1. Microstructure Evolution during Annealing Treatment

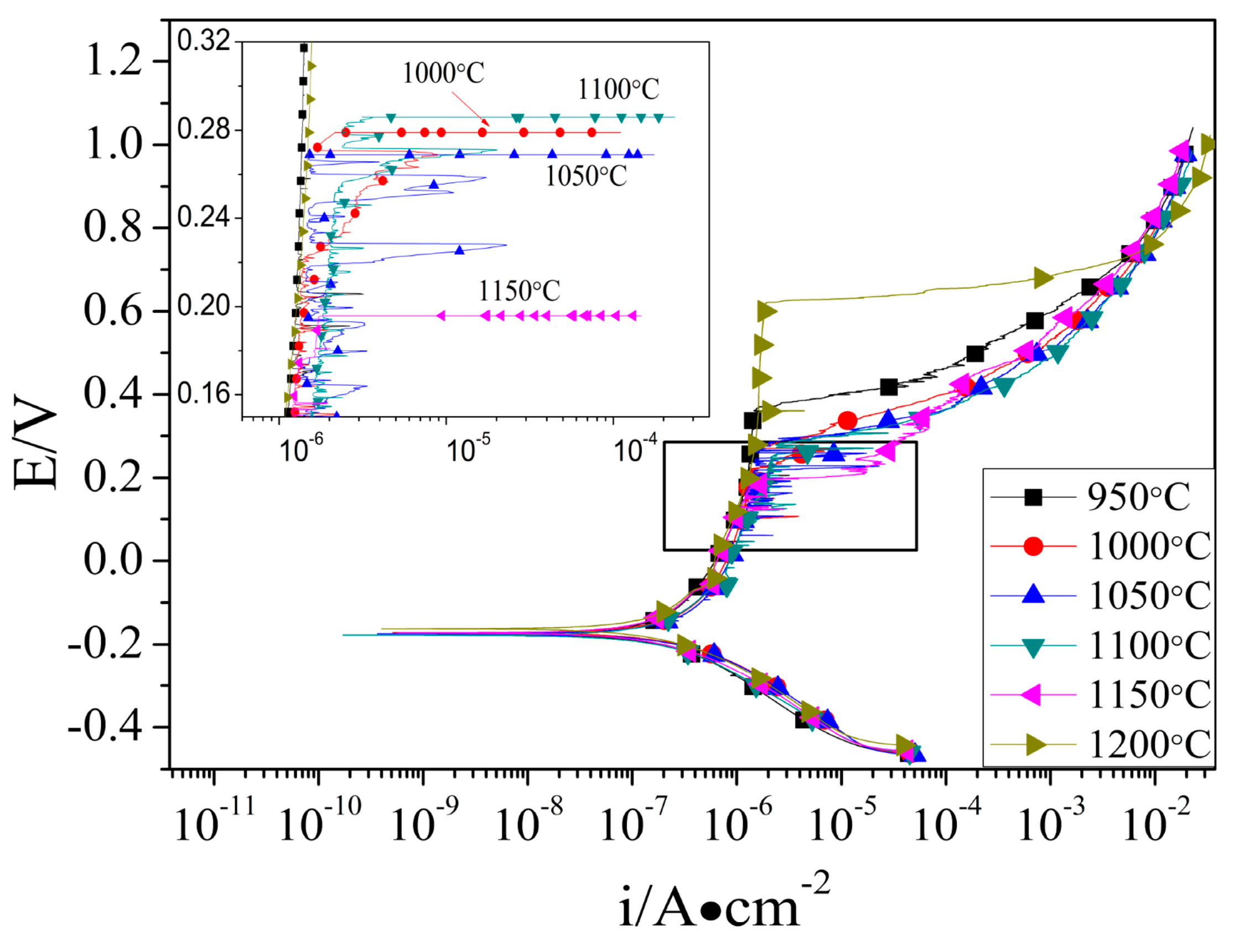

3.2. Influence of Annealing Temperature on Electrochemical Corrosion

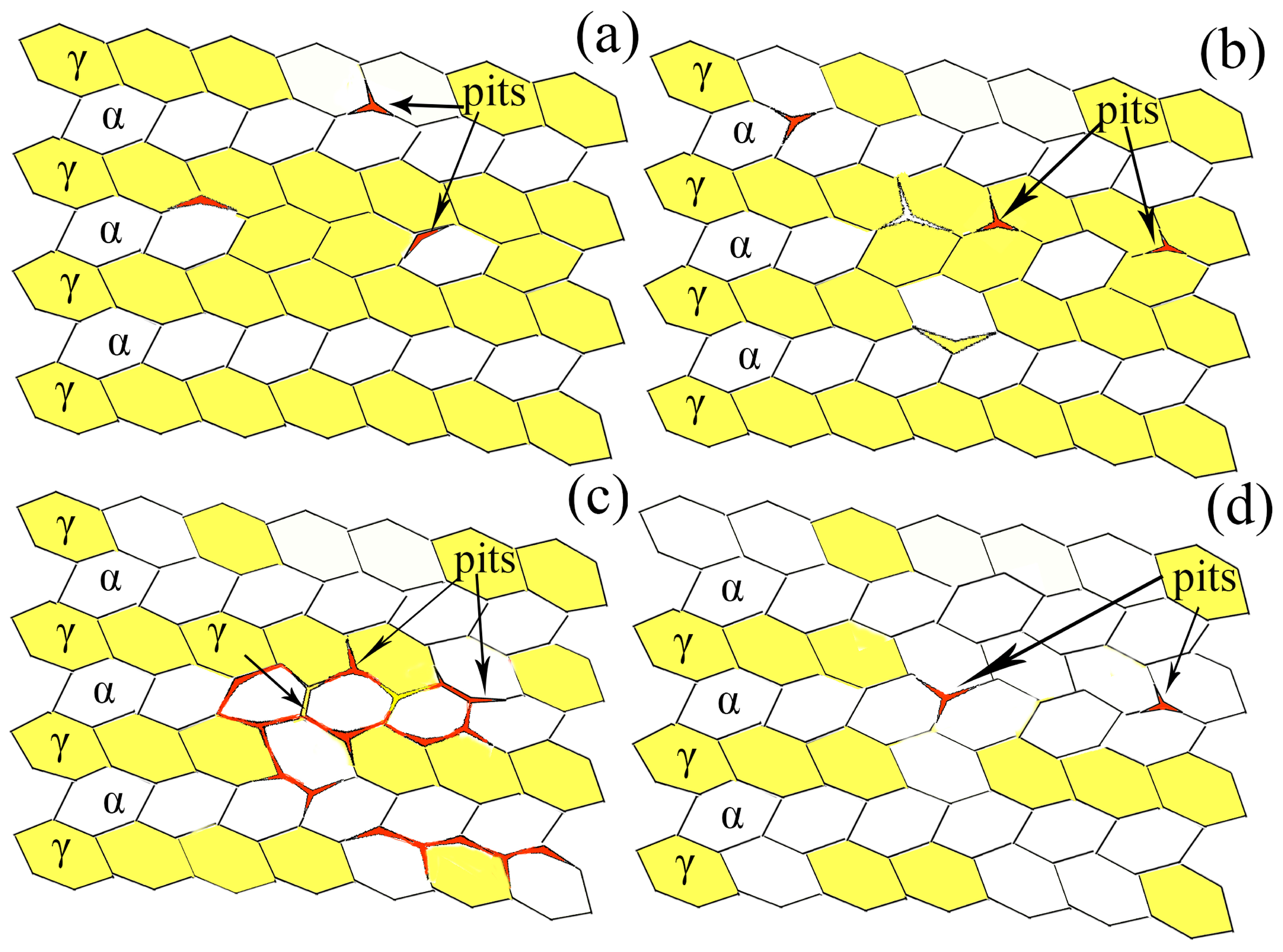

3.3. Pitting Corrosion Evolution as a Function of Annealing Temperature

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Charles, J. Duplex stainless steels—A review after DSS ‘07 held in Grado. Steel Res. Int. 2008, 105, 455–465. [Google Scholar] [CrossRef]

- Rosso, M.; Peter, I. About heat treatment and properties of duplex stainless steels. J. Achiev. Mater. Manuf. Eng. 2013, 59, 26–36. [Google Scholar]

- Toor, I.-H.; Hyun, P.J. Development of high Mn-N duplex stainless steel for automobile structural components. Corros. Sci. 2008, 50, 404–410. [Google Scholar] [CrossRef]

- Ezuber, H.; El-Houd, M.A. Effects of sigma phase precipitation on seawater pitting of duplex stainless steel. Desalination 2007, 207, 268–275. [Google Scholar] [CrossRef]

- Ravindranath, K.; Malhotra, S.N. The influence of aging on the intergranular corrosion of 22 chromium-5 nickel duplex stainless steel. Corros. Sci. 1995, 37, 121–132. [Google Scholar] [CrossRef]

- Moura, V.S.; Lima, L.D. Influence of microstructure on the corrosion resistance of the duplex stainless steel UNS S31803. Mater. Charact. 2008, 59, 1127–1132. [Google Scholar] [CrossRef]

- Pohl, M.; Storz, O. Sigma phase in duplex-stainless steels. Z. Metallkd. 2004, 95, 631–638. [Google Scholar] [CrossRef]

- Sathirachinda, N.; Pettersson, R. Depletion effects at phase boundaries in 2205 duplex stainless steel characterized with SKPFM and TEM/EDS. Corros. Sci. 2009, 51, 1850–1860. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, L.Z. Study of precipitation in 2101 duplex stainless steel. Mater. Sci. Technol. 2010, 26, 515–521. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y. Effect of aging on the corrosion resistance of 2101 lean duplex stainless steel. Mater. Charact. 2009, 60, 1522–1528. [Google Scholar] [CrossRef]

- Cervo, R.; Ferro, P. Annealing temperature effects on super duplex stainless steel UNS S32750 welded joints. II: Pitting corrosion resistance evaluation. J. Mater. Sci. 2010, 45, 4378–4389. [Google Scholar] [CrossRef]

- Deng, B.; Jiang, Y.M. Effect of annealing treatment on microstructure evolution and the associated corrosion behaviour of a super-duplex stainless steel. J. Alloys Compd. 2010, 493, 461–464. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, W. Influence of annealing treatment on the corrosion resistance of lean duplex stainless steel 2101. Electrochim. Acta 2009, 54, 5387–5392. [Google Scholar] [CrossRef]

- Westin, E.M.; Brolund, B. Weldability aspects of a newly developed duplex stainless steel LDX 2101. Steel Res. Int. 2008, 79, 473–481. [Google Scholar] [CrossRef]

- Wang, K.Y.; Lo, K.H. The influences of martensitic transformations on cavitation-erosion damage initiation and pitting resistance of a lean austenitic stainless steel. Mater. Res. 2016, 19, 1366–1371. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Pardal, J.M. Martensitic transformation induced by cold deformation of lean duplex stainless steel UNS S32304. Mater. Res. 2014, 17, 381–385. [Google Scholar] [CrossRef]

- Ha, H.Y.; Jang, M.H. Interpretation of the relation between ferrite fraction and pitting corrosion resistance of commercial 2205 duplex stainless steel. Corros. Sci. 2014, 89, 154–162. [Google Scholar] [CrossRef]

- Lacerda, J.C.D.; Cândido, L.C. Effect of volume fraction of phases and precipitates on the mechanical behavior of UNS S31803 duplex stainless steel. Int. J. Fatigue 2015, 74, 81–87. [Google Scholar] [CrossRef]

- Nie, H.; Xiong, J. Effects of multi-scale microstructure on pitting corrosion and mechanical properties of high-Mn-N low-Ni superduplex stainless steel. Rare Met. Mater. Eng. 2012, 41, 575–580. [Google Scholar]

- Tan, H.; Jiang, Y. Effect of annealing temperature on the pitting corrosion resistance of super duplex stainless steel UNS S32750. Mater. Charact. 2009, 60, 1049–1054. [Google Scholar] [CrossRef]

- Moayed, M.H.; Newman, R.C. Evolution of current transients and morphology of metastable and stable pitting on stainless steel near the critical pitting temperature. Corros. Sci. 2006, 48, 1004–1018. [Google Scholar] [CrossRef]

- Lai, J.K.L.; Wong, K.W. Effect of solution treatment on the transformation behavior of cold-rolled duplex stainless steels. Mater. Sci. Eng. A 1995, 203, 356–364. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | P | S | Cr | Ni | Mo | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (wt. %) | 0.02 | 0.50 | 5.46 | 0.03 | 0.0017 | 21.76 | 1.50 | 0.16 | 0.14 | Bal. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Li, Y.; He, Y.; Wang, J.; Liu, X.; Zhang, Y.; Han, P. Effects of Micro-Sized Ferrite and Austenite Grains on the Pitting Corrosion Behavior of Lean Duplex Stainless Steel 2101. Metals 2017, 7, 168. https://doi.org/10.3390/met7050168

Hu Y, Li Y, He Y, Wang J, Liu X, Zhang Y, Han P. Effects of Micro-Sized Ferrite and Austenite Grains on the Pitting Corrosion Behavior of Lean Duplex Stainless Steel 2101. Metals. 2017; 7(5):168. https://doi.org/10.3390/met7050168

Chicago/Turabian StyleHu, Yadi, Yuping Li, Yan He, Jian Wang, Xinglong Liu, Yong Zhang, and Peide Han. 2017. "Effects of Micro-Sized Ferrite and Austenite Grains on the Pitting Corrosion Behavior of Lean Duplex Stainless Steel 2101" Metals 7, no. 5: 168. https://doi.org/10.3390/met7050168

APA StyleHu, Y., Li, Y., He, Y., Wang, J., Liu, X., Zhang, Y., & Han, P. (2017). Effects of Micro-Sized Ferrite and Austenite Grains on the Pitting Corrosion Behavior of Lean Duplex Stainless Steel 2101. Metals, 7(5), 168. https://doi.org/10.3390/met7050168