Experimental Investigation on the Fatigue Life of Ti-6Al-4V Treated by Vibratory Stress Relief

Abstract

:1. Introduction

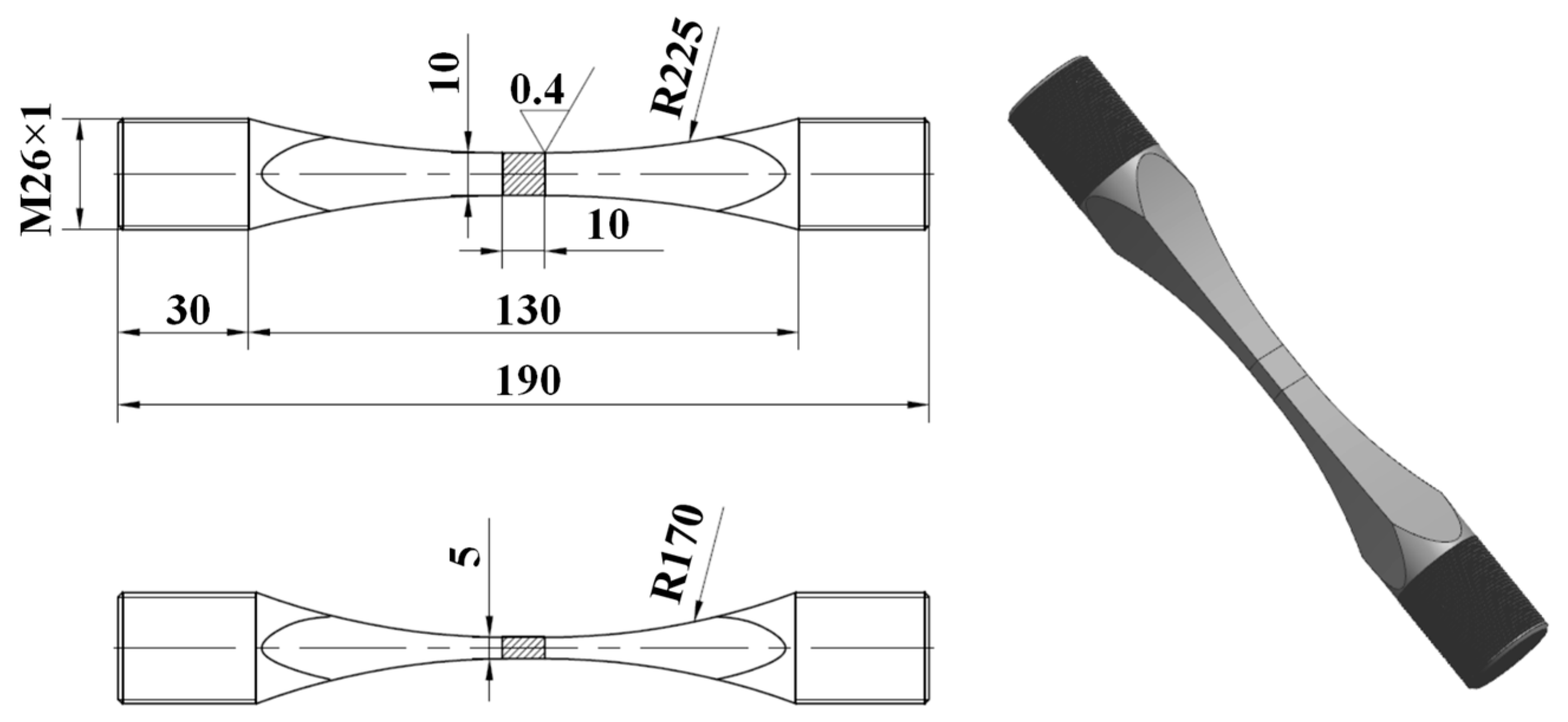

2. Experiments

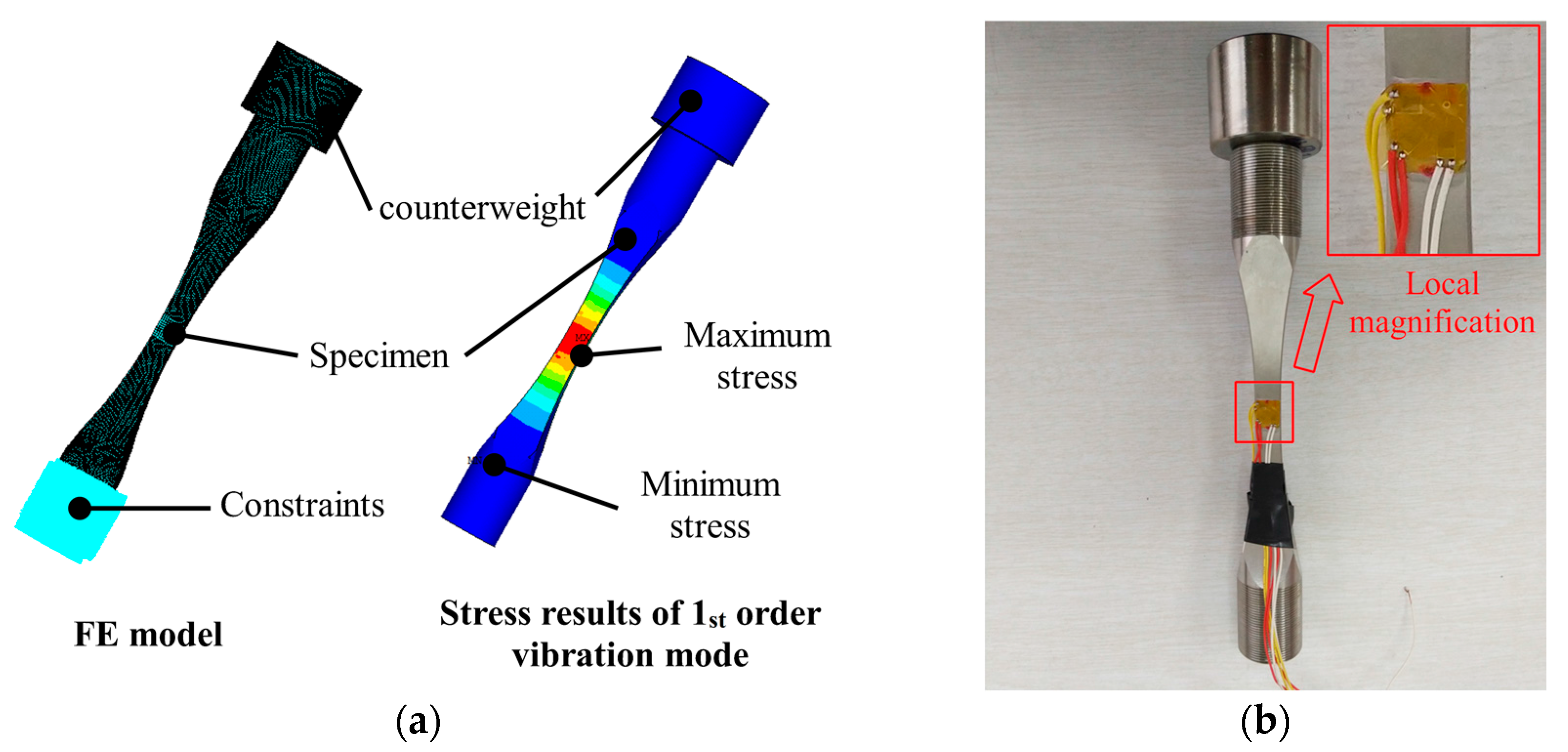

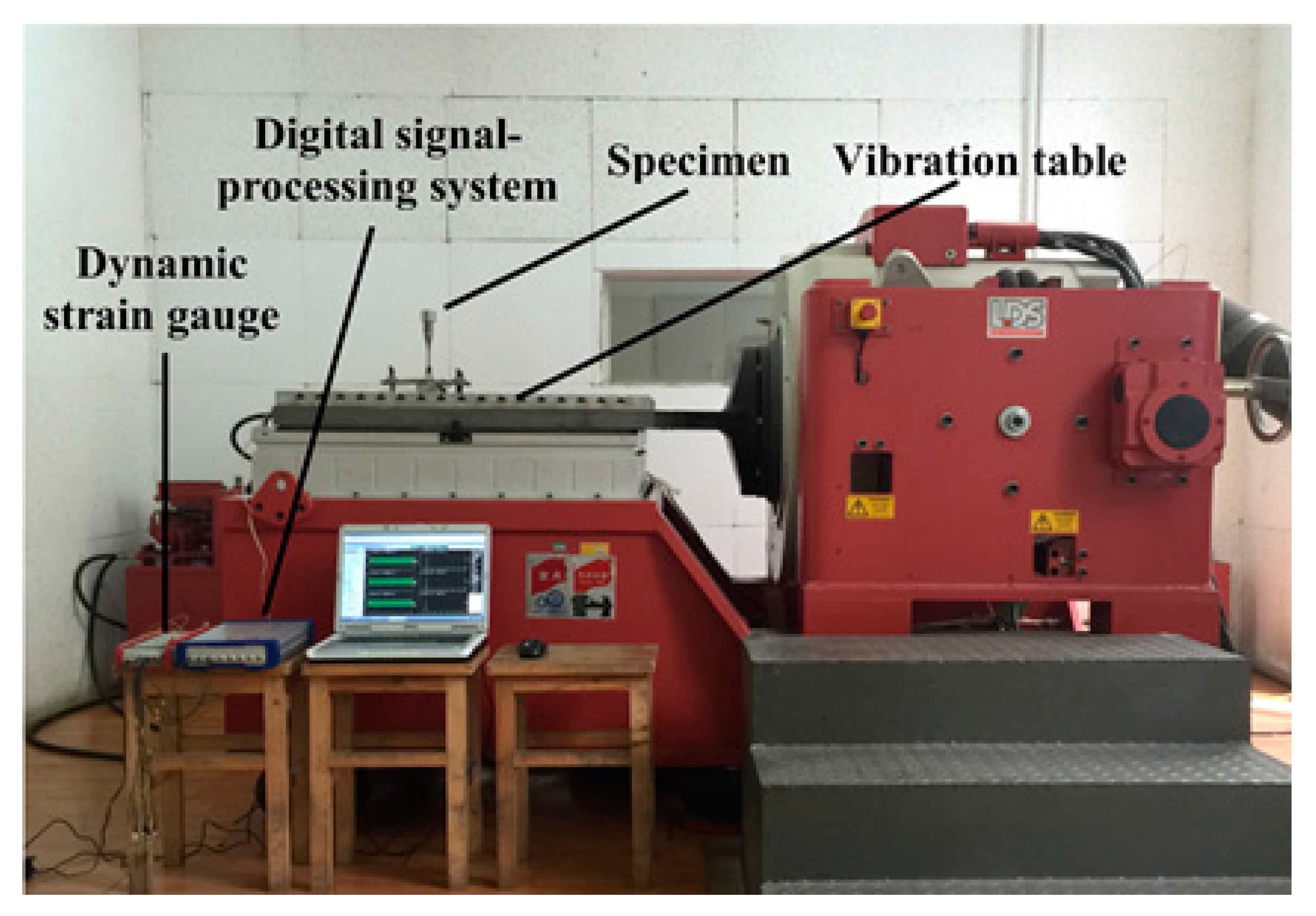

2.1. Dynamic Stress Measurement Tests

2.2. VSR Tests

2.3. Residual Stress Measurement Tests

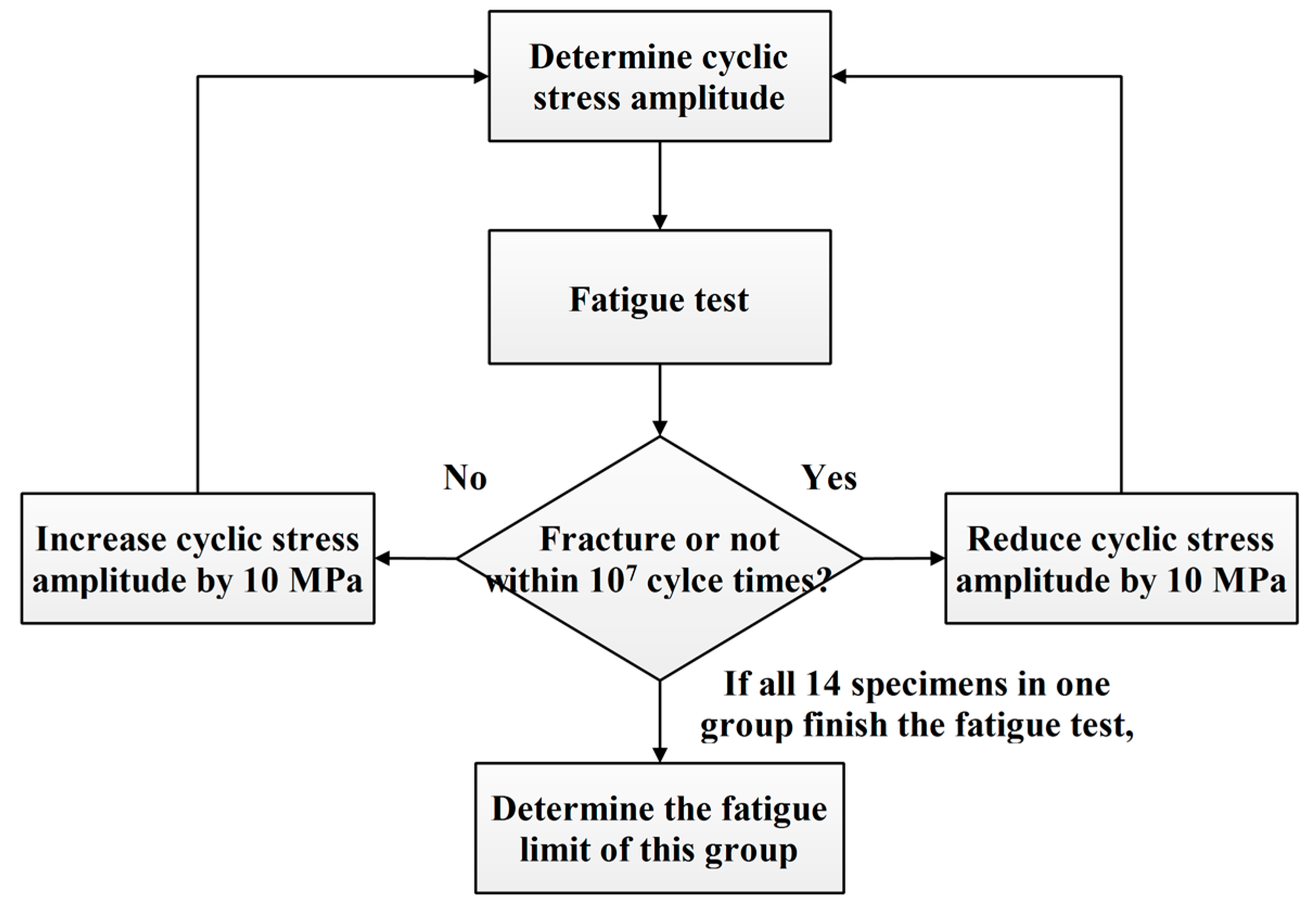

2.4. Uniaxial Tension-Compression Fatigue Experiments

3. Results and Discussion

3.1. Dynamic Stress Measurement Tests

3.2. Residual Stress Measurement Tests

3.3. Uniaxial Tension-Compression Fatigue Experiments

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Barsoum, Z.; Barsoum, I. Residual stress effects on fatigue life of welded structures using LEFM. Eng. Fail. Anal. 2009, 16, 449–467. [Google Scholar] [CrossRef]

- Schajer, G.S. Relaxation Methods for Measuring Residual Stresses: Techniques and Opportunities. Exp. Mech. 2010, 50, 1117–1127. [Google Scholar] [CrossRef]

- Yeom, H.; Choi, B.; Seol, T.; Lee, M.; Jeon, Y. Very High Cycle Fatigue of Butt-Welded High-Strength Steel Plate. Metals 2017, 7, 103. [Google Scholar] [CrossRef]

- Wu, Q.; Li, D.; Zhang, Y. Detecting Milling Deformation in 7075 Aluminum Alloy Aeronautical Monolithic Components Using the Quasi-Symmetric Machining Method. Metals 2016, 6, 80. [Google Scholar] [CrossRef]

- Webster, G.A.; Ezeilo, A.N. Residual stress distributions and their influence on fatigue lifetimes. Int. J. Fatigue 2001, 23, 375–383. [Google Scholar] [CrossRef]

- Cheng, X.; Fisher, J.W.; Prask, H.J.; Gnäupel-Herold, T.; Yen, B.T.; Roy, S. Residual stress modification by post-weld treatment and its beneficial effect on fatigue strength of welded structures. Int. J. Fatigue 2003, 25, 1259–1269. [Google Scholar] [CrossRef]

- James, M.N.; Hughes, D.J.; Chen, Z.; Lombard, H.; Hattingh, D.G.; Asquith, D.; Yates, J.R.; Webster, P.J. Residual stresses and fatigue performance. Eng. Fail. Anal. 2007, 14, 384–395. [Google Scholar] [CrossRef]

- Sasahara, H. The effect on fatigue life of residual stress and surface hardness resulting from different cutting conditions of 0.45%C steel. Int. J. Mach. Tools Manuf. 2005, 45, 131–136. [Google Scholar] [CrossRef]

- LaRue, J.E.; Daniewicz, S.R. Predicting the effect of residual stress on fatigue crack growth. Int. J. Fatigue 2007, 29, 508–515. [Google Scholar] [CrossRef]

- Pouget, G.; Reynolds, A.P. Residual stress and microstructure effects on fatigue crack growth in AA2050 friction stir welds. Int. J. Fatigue 2008, 30, 463–472. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Scardi, P.; Ricardo, C.L.A.; Bandini, M. Reverse bending fatigue of shot peened 7075-T651 aluminium alloy: The role of residual stress relaxation. Int. J. Fatigue 2009, 31, 1225–1236. [Google Scholar] [CrossRef]

- Nikitin, I.; Scholtes, B.; Maier, H.J.; Altenberger, I. High temperature fatigue behavior and residual stress stability of laser-shock peened and deep rolled austenitic steel AISI 304. Scr. Mater. 2004, 50, 1345–1350. [Google Scholar] [CrossRef]

- Bagherifard, S.; Slawik, S.; Fernández-Pariente, I.; Pauly, C.; Mücklich, F.; Guaglianoa, M. Nanoscale surface modification of AISI 316L stainless steel by severe shot peening. Mater. Des. 2016, 102, 68–77. [Google Scholar] [CrossRef]

- Fernández-Pariente, I.; Bagherifard, S.; Guagliano, M.; Ghelichi, R. Fatigue behavior of nitrided and shot peened steel with artificial small surface defects. Eng. Fract. Mech. 2013, 103, 2–9. [Google Scholar] [CrossRef]

- Zabeen, S.; Preuss, M.; Withers, P.J. Evolution of a laser shock peened residual stress field locally with foreign object damage and subsequent fatigue crack growth. Acta Mater. 2015, 83, 216–226. [Google Scholar] [CrossRef]

- Yoichi, Y.; Yusuke, U.; Hiroshi, K.; Shinozaki, M. Fatigue life prediction of small notched Ti-6Al-4V specimens using critical distance. Eng. Fract. Mech. 2010, 77, 1439–1453. [Google Scholar]

- Bourassa, P.L.; Yue, S.; Bobyn, J.D. The effect of heat treatment on the fatigue strength of microknurled Ti-6Al-4V. J. Biomed. Mater. Res. A 1997, 37, 291–300. [Google Scholar] [CrossRef]

- Golden, P.J.; John, R.; Porter, W.J. Variability in Room Temperature Fatigue Life of Alpha + Beta Processed Ti-6Al-4V (Preprint). Int. J. Fatigue 2009, 31, 1764–1770. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Shi, C.-B.; Qi, Y.-F.; Zhu, Q.-T. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Nitrogen-Alloyed High-Mn Austenitic Hot Work Die Steel. Metals 2017, 7, 94. [Google Scholar] [CrossRef]

- Dawson, R.; Moffat, D.G. Vibratory Stress Relief: A Fundamental Study of Its Effectiveness. J. Eng. Mater. Technol. 1980, 102, 169–176. [Google Scholar] [CrossRef]

- Walker, C.A.; Waddell, A.J.; Johnston, D.J. Vibratory stress relief—An investigation of the underlying processes. Proc. Inst. Mech. Eng. E-J. Process Mech. Eng. 1995, 209, 51–58. [Google Scholar] [CrossRef]

- Sun, M.C.; Sun, Y.H.; Wang, R.K. The vibratory stress relief of a marine shafting of 35# bar steel. Mater. Lett. 2004, 58, 299–303. [Google Scholar]

- Sun, M.C.; Sun, Y.H.; Wang, R.K. Vibratory stress relieving of welded sheet steels of low alloy high strength steel. Mater. Lett. 2004, 58, 1396–1399. [Google Scholar] [CrossRef]

- Wang, J.S.; Hsieh, C.C.; Lin, C.M.; Kuo, C.W.; Wu, W. Texture evolution and residual stress relaxation in a cold-rolled Al-Mg-Si-Cu alloy using vibratory stress relief technique. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44, 806–818. [Google Scholar] [CrossRef]

- Wang, J.S.; Hsieh, C.C.; Lai, H.H.; Kuo, C.W.; Wu, P.T.Y.; Wu, W. The relationships between residual stress relaxation and texture development in AZ31 Mg alloys via the vibratory stress relief technique. Mater. Charact. 2015, 99, 248–253. [Google Scholar] [CrossRef]

- Rao, D.; Wang, D.; Chen, L.; Ni, C. The effectiveness evaluation of 314L stainless steel vibratory stress relief by dynamic stress. Int. J. Fatigue 2007, 29, 192–196. [Google Scholar] [CrossRef]

- Kwofie, S. Plasticity model for simulation, description and evaluation of vibratory stress relief. Mater. Sci. Eng. A 2009, 516, 154–161. [Google Scholar] [CrossRef]

- Lv, T.; Zhang, Y. A combined method of thermal and vibratory stress relief. J. Vibroeng. 2015, 17, 2837–2845. [Google Scholar]

- Vardanjani, M.J.; Ghayour, M.; Homami, R.M. Analysis of the Vibrational Stress Relief for Reducing the Residual Stresses Caused by Machining. Exp. Tech. 2016, 40, 705–713. [Google Scholar] [CrossRef]

- Djuric, D.; Vallant, R.; Kerschbaumer, K.; Enzinger, N. Vibration stress relief treatment of welded high-strength martensitic steel. Weld. World 2011, 55, 86–93. [Google Scholar] [CrossRef]

- Wozney, G.P.; Crawmer, G.R. An investigation of vibrational stress relief in steel. Weld. Res. Suppl. 1968, 23, 411–419. [Google Scholar]

- Munsi, S.M.Y.; Waddell, J.; Walker, C. The Influence of Vibratory Treatment on the Fatigue Life of Welds: A Comparison with Thermal Stress Relief. Strain 2001, 37, 141–149. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Y. Effect of vibratory stress relief on fatigue life of aluminum alloy 7075-T651. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, Y.; Zhang, H. Dynamic characteristic analysis and experiment for integral impeller based on cyclic symmetry analysis method. Chin. J. Aeronaut. 2012, 25, 804–810. [Google Scholar] [CrossRef]

- Baumeister, J.; Monno, M.; Goletti, M.; Mussi, V.; Weise, J. Dynamic Behavior of Hybrid APM (Advanced Pore Morphology Foam) and Aluminum Foam Filled Structures. Metals 2012, 2, 211–218. [Google Scholar] [CrossRef]

- Gere, J.M.; Goodno, B.J. Mechanics of materials. In Mechanics of Materials; Van Nostrand Reinhold Co.: New York, NY, USA, 1972; pp. 211–291. [Google Scholar]

- Fan, D. Heat treatment technology data manual. In Heat Treatment Technology Data Manual; China Machine Press: Beijing, China, 2000; pp. 497–499. (In Chinese) [Google Scholar]

- Gao, Z.; Jiang, X.; Xiong, J.; Guo, G.; Gan, W.; Xia, Y.; Wang, S.; Zeng, B. Fatigue performance test design and data processing. In Fatigue Performance Test Design and Data Processing; Beihang University Press: Beijing, China, 1995. (In Chinese) [Google Scholar]

- Chauvenet, W. A Manual of Spherical and Practical Astronomy. In A Manual of Spherical and Practical Astronomy; J. B. Lippincott & Co.: Philadelphia, PA, USA, 1960. [Google Scholar]

- Fu, W.E.; Cohen, P.H.; Ruud, C.O. Experimental investigation of the machining induced residual stress tensor under mechanical loading. J. Manuf. Process. 2009, 11, 88–96. [Google Scholar] [CrossRef]

- Lia, B.; Jiang, X.; Yang, J.; Liang, Y.S. Effects of depth of cut on the redistribution of residual stress and distortion during the milling of thin-walled part. Thin-Walled Struct. 2015, 216, 223–233. [Google Scholar] [CrossRef]

- Yildiz, K.; Eken, S.; Kaya, M.O. Simulation of vibration stress relief after welding based on FEM. Acta Metall. Sin. (Engl. Lett.) 2008, 21, 289–294. [Google Scholar]

| Density/kg·m3 | Elastic Modulus/GPa | Poisson’s Ratio | Yield Strength/MPa |

|---|---|---|---|

| 4440 | 110 | 0.33 | 980 |

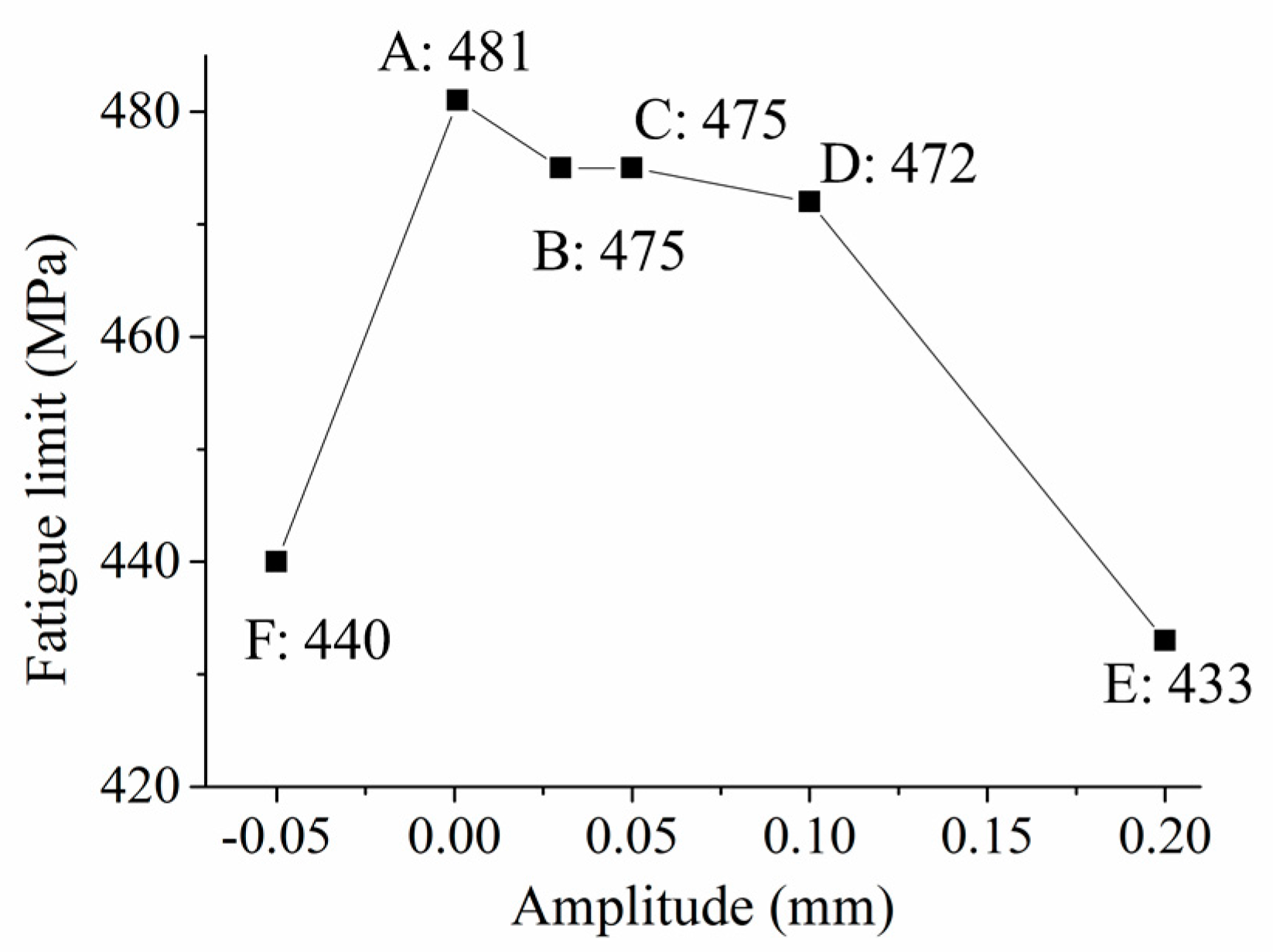

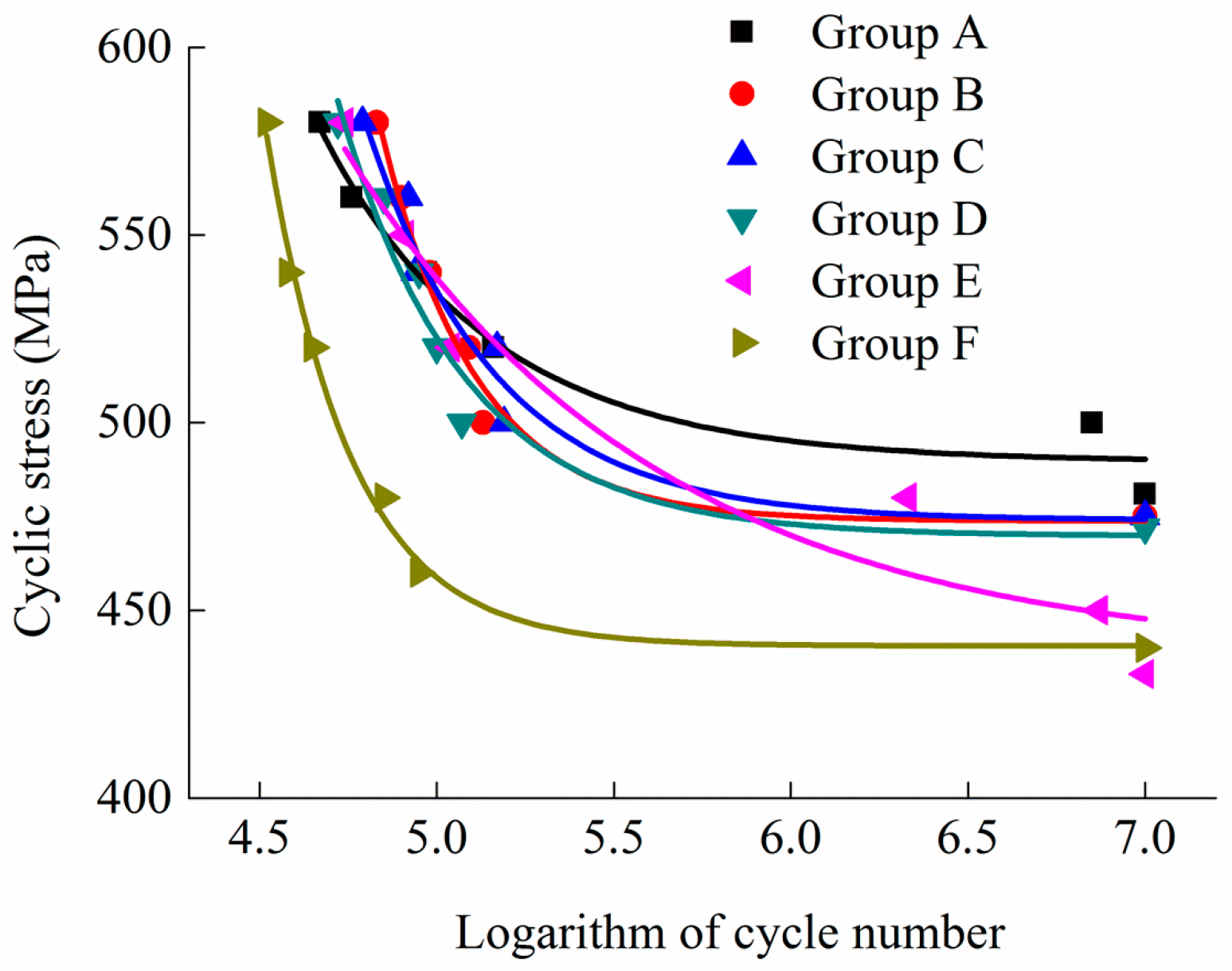

| Results | Group A | Group B | Group C | Group D | Group E | Group F |

|---|---|---|---|---|---|---|

| Fatigue limit (MPa) | 481 | 475 | 475 | 472 | 430 | 440 |

| Percentage change | / | −1.25% | −1.25% | −1.87% | −10.60% | −8.52% |

| Surface stress(MPa) | 217 | 86.7 | 108 | 34.1 | 21.3 | 5.91 |

| Percentage change | / | −60.05% | −50.23% | −84.29% | −90.18% | −97.28% |

| Average stress (MPa) | 13.55 | 1.22 | 4.47 | 3.43 | 4.24 | 8.15 |

| Percentage change | / | −90.99% | −67.02% | −74.68% | −68.68% | −39.87% |

| Dynamic stress (MPa) | / | 8.68 | 14.43 | 28.76 | 57.22 | / |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.-J.; Zhang, Y.-D.; Wu, Q.; Song, J. Experimental Investigation on the Fatigue Life of Ti-6Al-4V Treated by Vibratory Stress Relief. Metals 2017, 7, 158. https://doi.org/10.3390/met7050158

Gao H-J, Zhang Y-D, Wu Q, Song J. Experimental Investigation on the Fatigue Life of Ti-6Al-4V Treated by Vibratory Stress Relief. Metals. 2017; 7(5):158. https://doi.org/10.3390/met7050158

Chicago/Turabian StyleGao, Han-Jun, Yi-Du Zhang, Qiong Wu, and Jing Song. 2017. "Experimental Investigation on the Fatigue Life of Ti-6Al-4V Treated by Vibratory Stress Relief" Metals 7, no. 5: 158. https://doi.org/10.3390/met7050158