Dynamic Recovery and Superelasticity of Columnar-Grained Cu–Al–Mn Shape Memory Alloy

Abstract

:1. Introduction

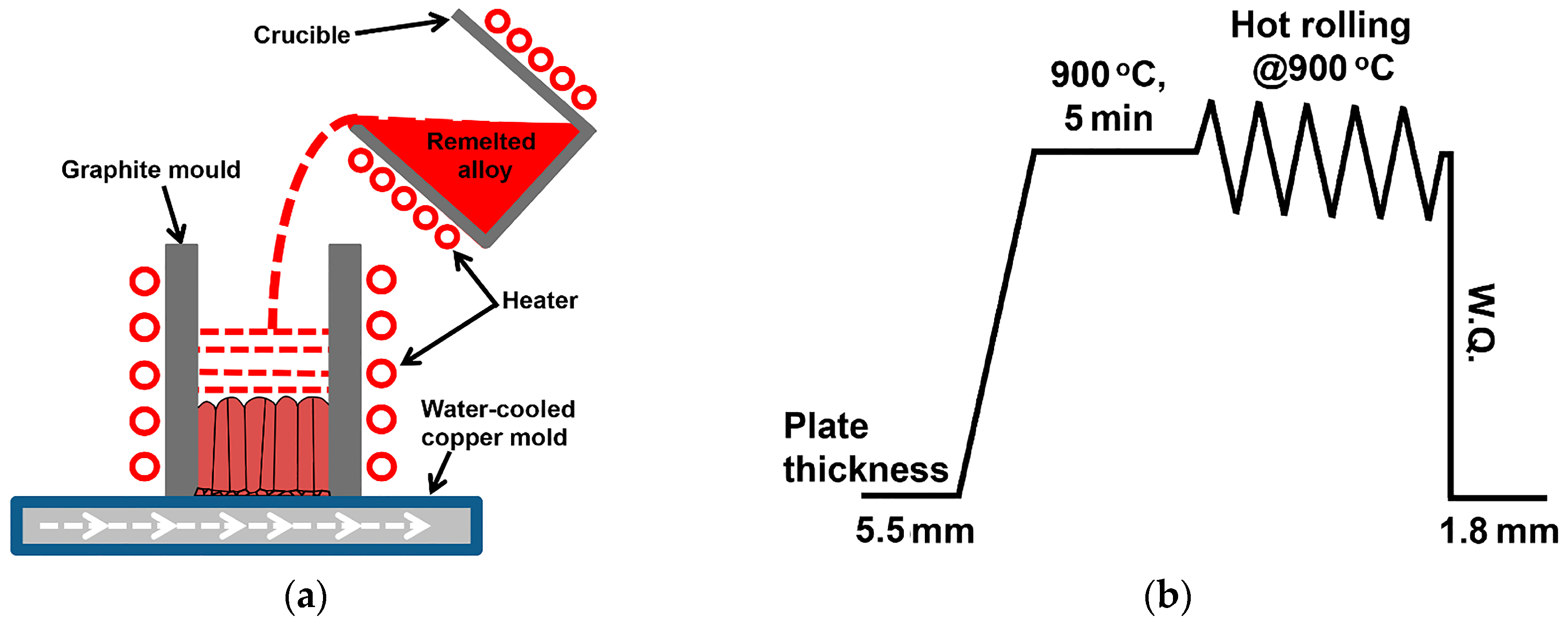

2. Materials and Methods

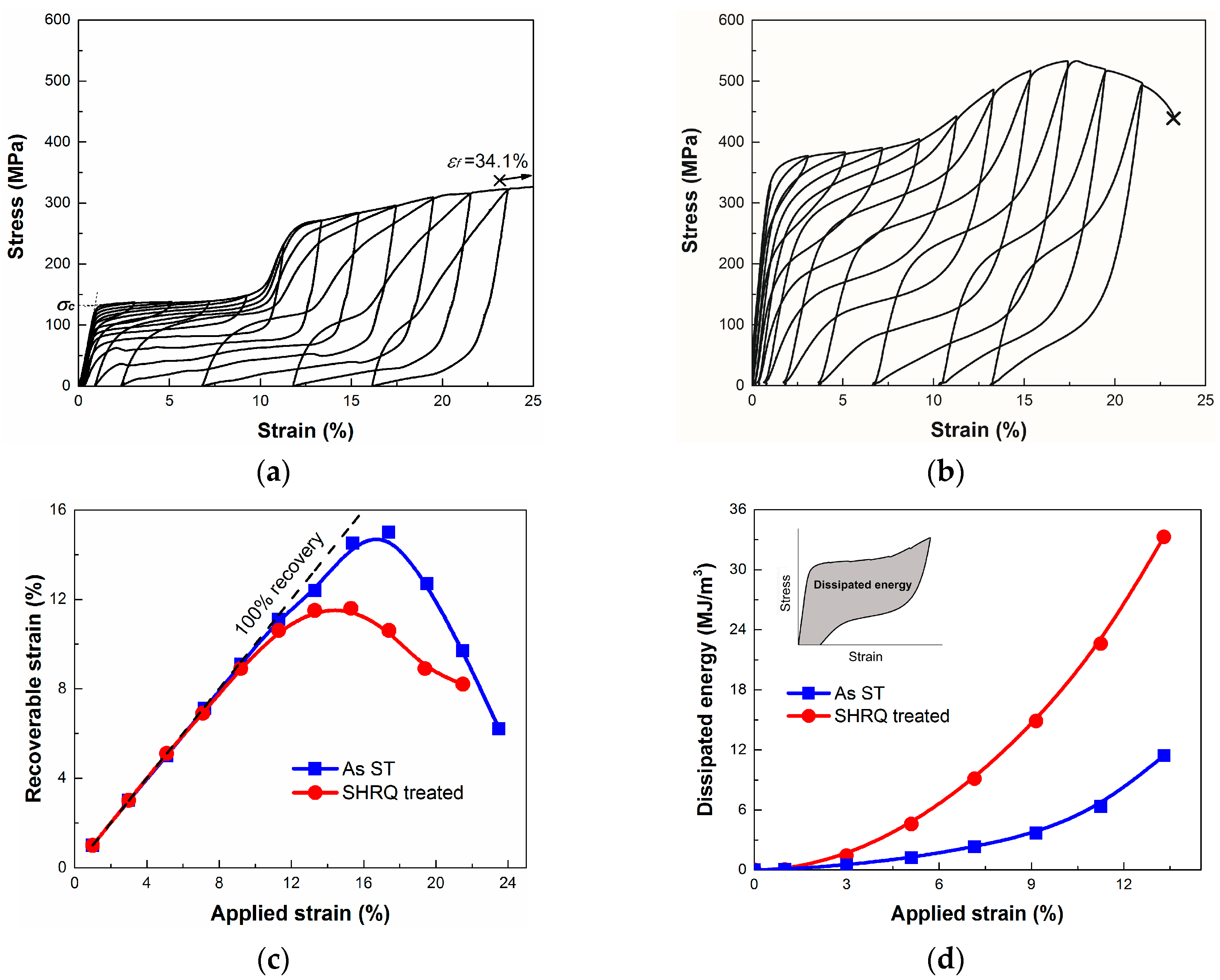

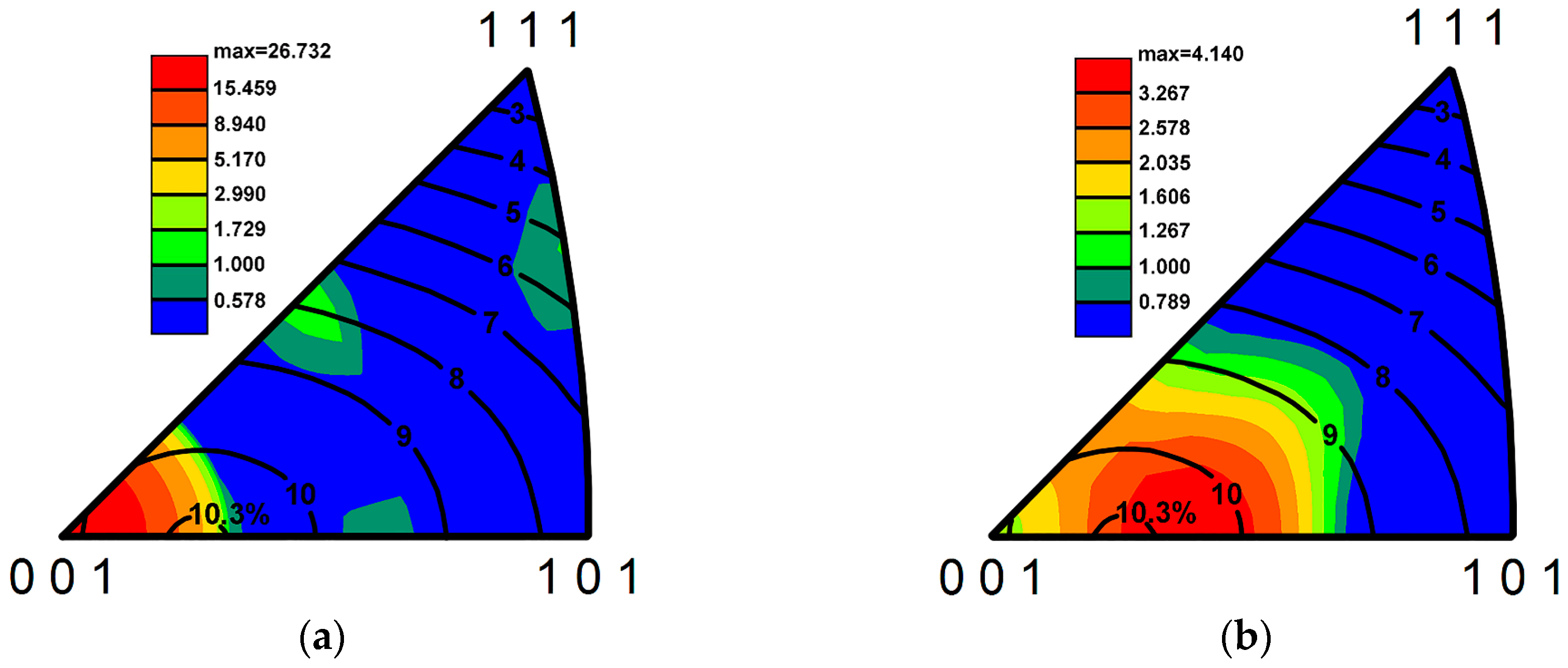

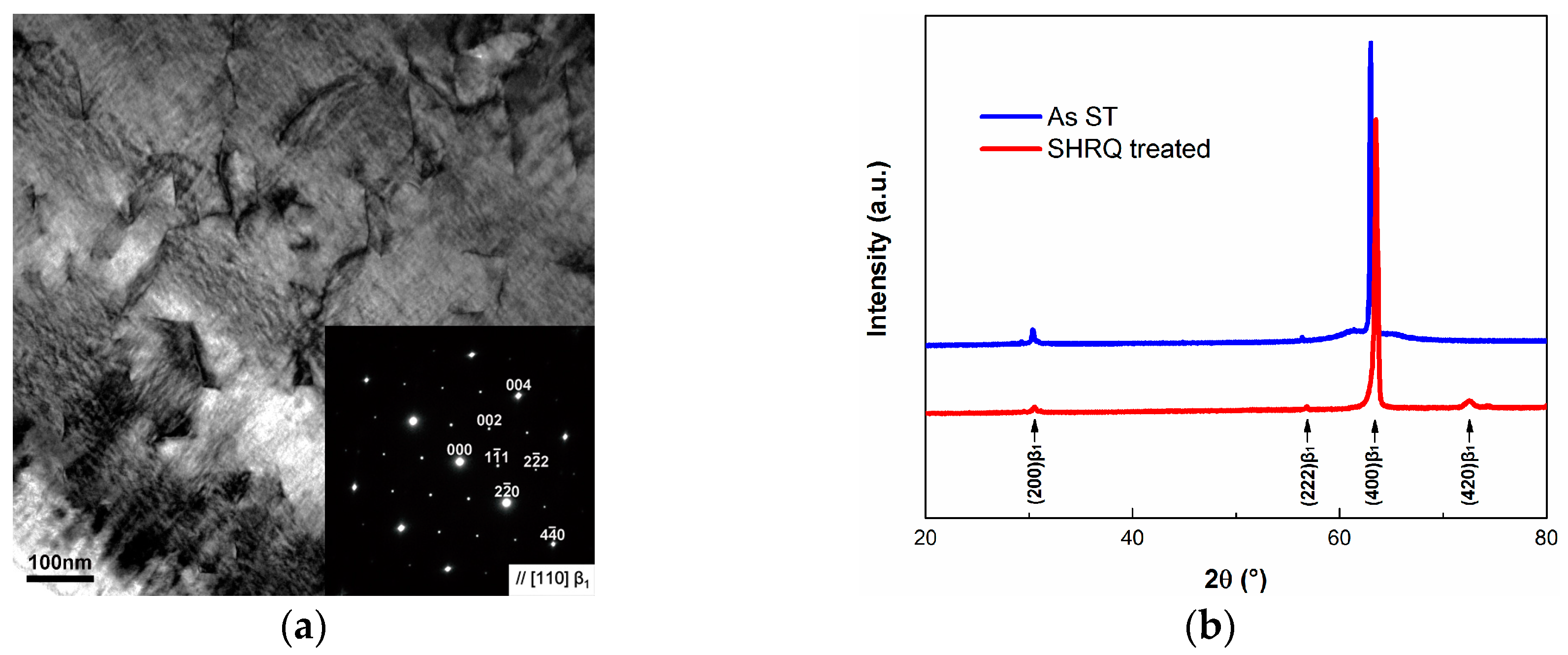

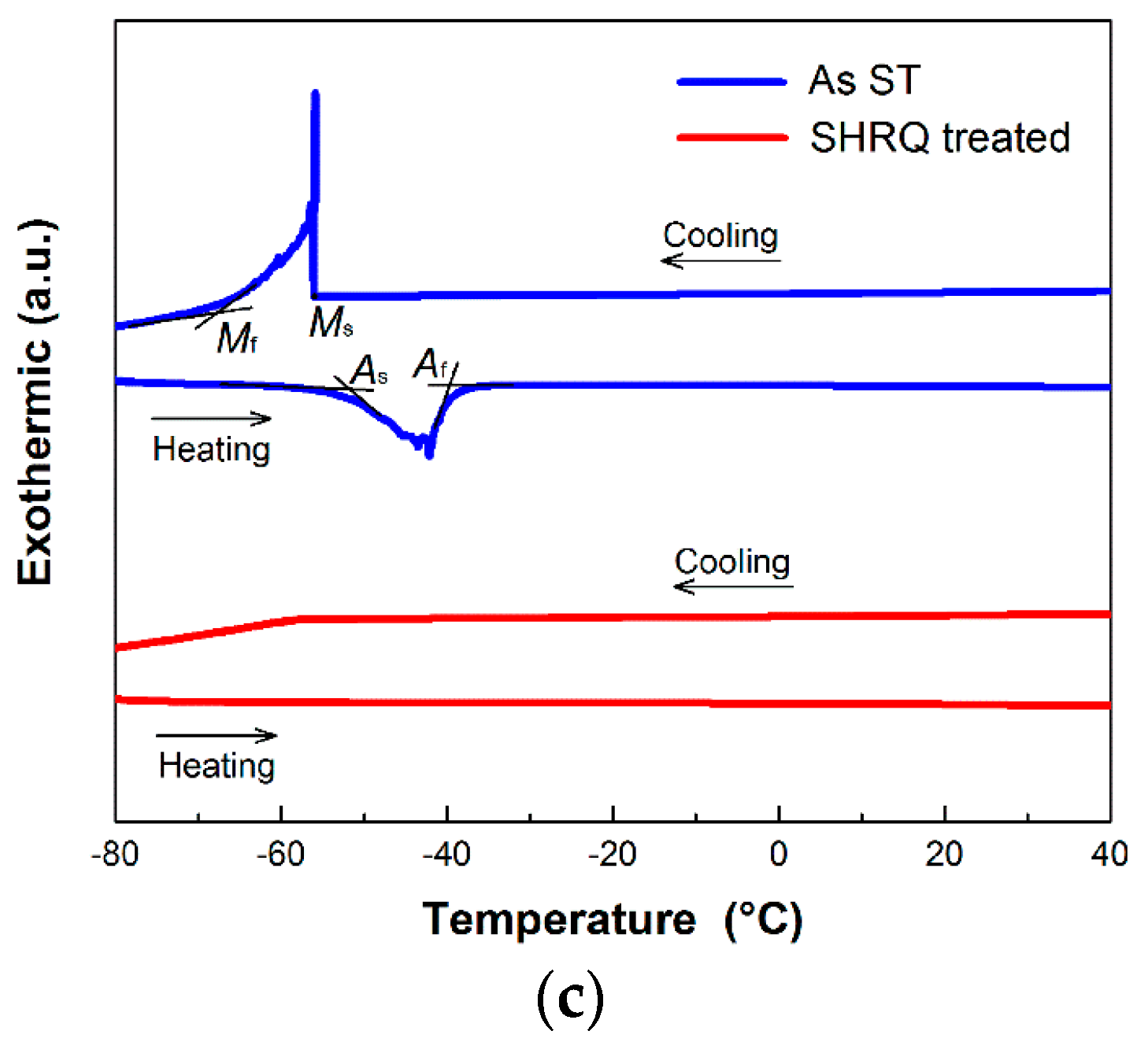

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Otsuka, O.; Wayman, C.M. Shape Memory Materials, 1st ed.; Cambridge University Press: Cambridge, UK, 1998; pp. 97–116. [Google Scholar]

- Juan, J.S.; Nó, M.L.; Schuh, C.A. Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nat. Nanotechnol. 2009, 4, 415–419. [Google Scholar] [CrossRef] [PubMed]

- Sutou, Y.; Omori, T.; Kainuma, R.; Ishida, K. Ductile Cu–Al–Mn shape memory alloys: General properties and applications. Mater. Sci. Technol. 2008, 24, 896–901. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Yamauchi, K.; Ono, N.; Kainuma, R.; Ishida, K. Effect of grain size and texture on pseudoelasticity in Cu–Al–Mn-based shape memory wire. Acta Mater. 2005, 53, 4121–4133. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Kainuma, R.; Ishida, K. Grain size dependence of pseudoelasticity in polycrystalline Cu–Al–Mn-based shape memory sheets. Acta Mater. 2013, 61, 3842–3850. [Google Scholar] [CrossRef]

- Liu, J.L.; Huang, H.Y.; Xie, J.X. The roles of grain orientation and grain boundary characteristics in the enhanced superelasticity of Cu71.8Al17.8Mn10.4 shape memory alloys. Mater. Des. 2014, 64, 427–433. [Google Scholar] [CrossRef]

- Liu, J.L.; Huang, H.Y.; Xie, J.X. Superelastic anisotropy characteristics of columnar-grained Cu–Al–Mn shape memory alloys and its potential applications. Mater. Des. 2015, 85, 211–220. [Google Scholar] [CrossRef]

- Fu, H.D.; Song, S.; Zhuo, L.; Zhang, Z.H.; Xie, J.X. Enhanced mechanical properties of polycrystalline Cu–Al–Ni alloy through grain boundary orientation and composition control. Mater. Sci. Eng. A 2016, 650, 218–224. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Kainuma, R.; Ono, N.; Ishida, K. Enhancement of superelasticity in Cu–Al–Mn-Ni shape-memory alloys by texture control. Metall. Mater. Trans. A 2002, 22, 2814–2824. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Oxford, UK, 2004; pp. 415–437. [Google Scholar]

- Yu, J.; Liu, X.; Xie, J. Study on dynamic recrystallization of a Cu-based alloy BFe10-1-1 with continuous columnar grains. Acta Metall. Sin. 2011, 47, 482–488. [Google Scholar]

- Liu, Y.K.; Huang, H.Y.; Xie, J.X. Effect of compression direction on the dynamic recrystallization behavior of continuous columnar-grained CuNi10Fe1Mn alloy. Int. J. Miner. Mater. Metall. 2015, 28, 851–859. [Google Scholar] [CrossRef]

- Ma, J.; Karaman, I. Expanding the repertoire of shape memory alloy. Science 2010, 327, 1468–1469. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, Y.; Himuro, Y.; Kainuma, R.; Sutou, Y.; Ishida, K. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 2010, 327, 1488–1490. [Google Scholar] [CrossRef] [PubMed]

- Wollants, P.; Bonte, M.D.; Roos, J.R. Thermodynamic analysis of the stress-induced martensitic transformation in a single crystal. Z. Metallk. 1979, 70, 113–117. [Google Scholar]

- Sutou, Y.; Koeda, N.; Omori, T.; Kainuma, R.; Ishida, K. Effect of aging on bainitic and thermally induced martensitic transformations in ductile Cu–Al–Mn-based shape memory alloys. Acta Mater. 2009, 57, 5748–5758. [Google Scholar] [CrossRef]

- Xu, S.; Huang, H.Y.; Xie, J.; Takekawa, S.; Xu, X.; Omori, T.; Kainuma, R. Giant elastocaloric effect covering wide temperature range in columnar-grained Cu71.5Al17.5Mn11 shape memory alloy. APL Mater. 2016, 4, 106106. [Google Scholar] [CrossRef]

- Kainuma, R.; Takahashi, S.; Ishida, K. Ductile shape memory alloys of the Cu–Al–Mn system. J. Phys. IV 1995, 5, 961–966. [Google Scholar] [CrossRef]

- Ortín, J.; Planes, A. Thermodynamic analysis of thermal measurements in thermoelastic martensitic transformations. Acta Metall. 1988, 36, 1873–1889. [Google Scholar] [CrossRef]

- Karaca, H.E.; Acar, E.; Basaran, B.; Noebe, R.D.; Chumlyakov, Y.I. Superelastic response and damping capacity of ultrahigh-strength [111]-oriented NiTiHfPd single crystals. Scri. Mater. 2012, 67, 447–450. [Google Scholar] [CrossRef]

- Romero, R.; Lovey, F.C.; Ahlers, M. The effect of β phase plastic deformation on martensitic transformation in Cu–Zn and Cu–Zn–Al single crystals. Scri. Metall. 1990, 24, 285–289. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Huang, H.; Xie, J.; Kimura, Y.; Xu, X.; Omori, T.; Kainuma, R. Dynamic Recovery and Superelasticity of Columnar-Grained Cu–Al–Mn Shape Memory Alloy. Metals 2017, 7, 141. https://doi.org/10.3390/met7040141

Xu S, Huang H, Xie J, Kimura Y, Xu X, Omori T, Kainuma R. Dynamic Recovery and Superelasticity of Columnar-Grained Cu–Al–Mn Shape Memory Alloy. Metals. 2017; 7(4):141. https://doi.org/10.3390/met7040141

Chicago/Turabian StyleXu, Sheng, Haiyou Huang, Jianxin Xie, Yuta Kimura, Xiao Xu, Toshihiro Omori, and Ryosuke Kainuma. 2017. "Dynamic Recovery and Superelasticity of Columnar-Grained Cu–Al–Mn Shape Memory Alloy" Metals 7, no. 4: 141. https://doi.org/10.3390/met7040141