Effects of ECAP and Annealing Treatment on the Microstructure and Mechanical Properties of Mg-1Y (wt. %) Binary Alloy

Abstract

:1. Introduction

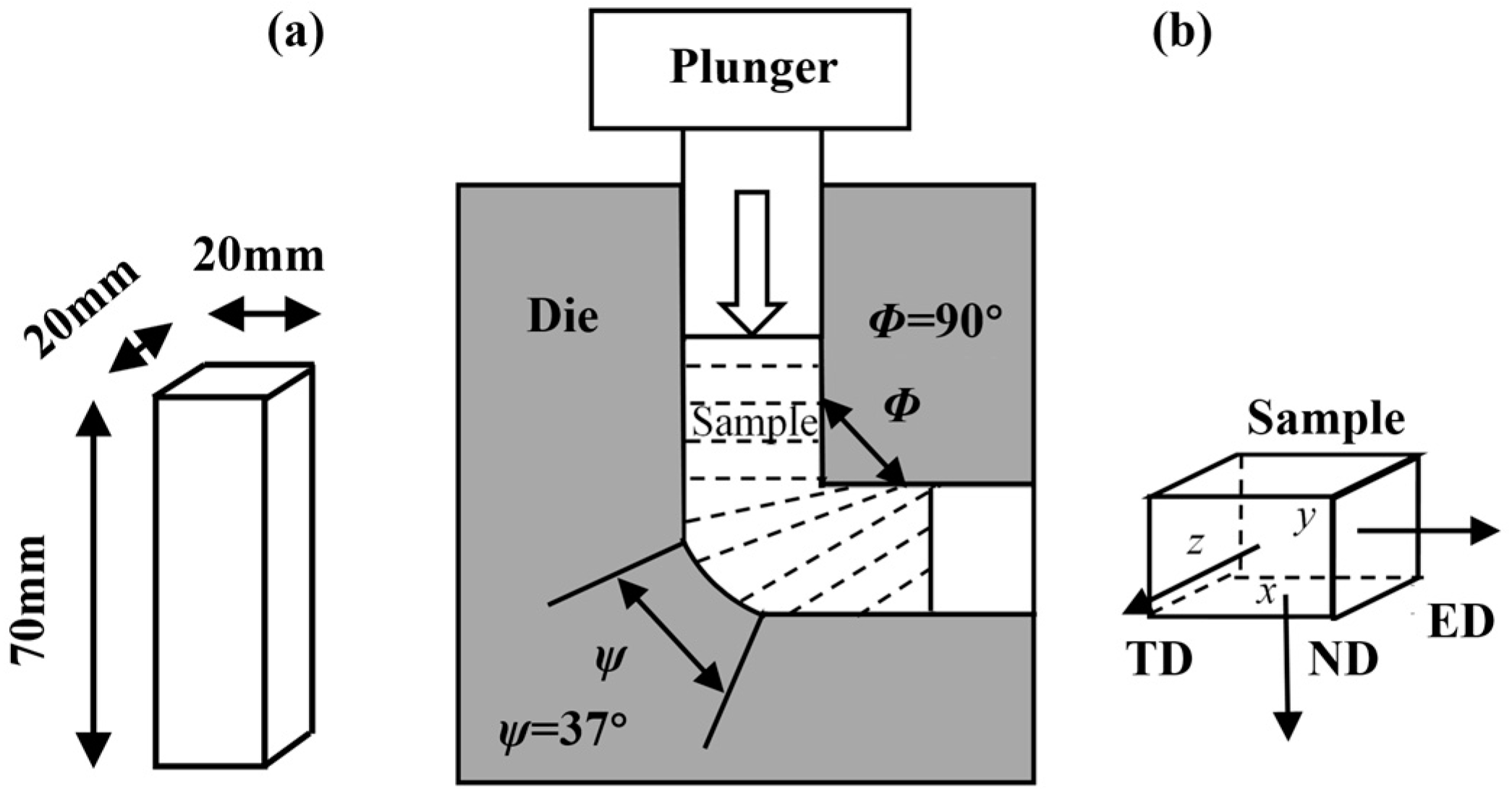

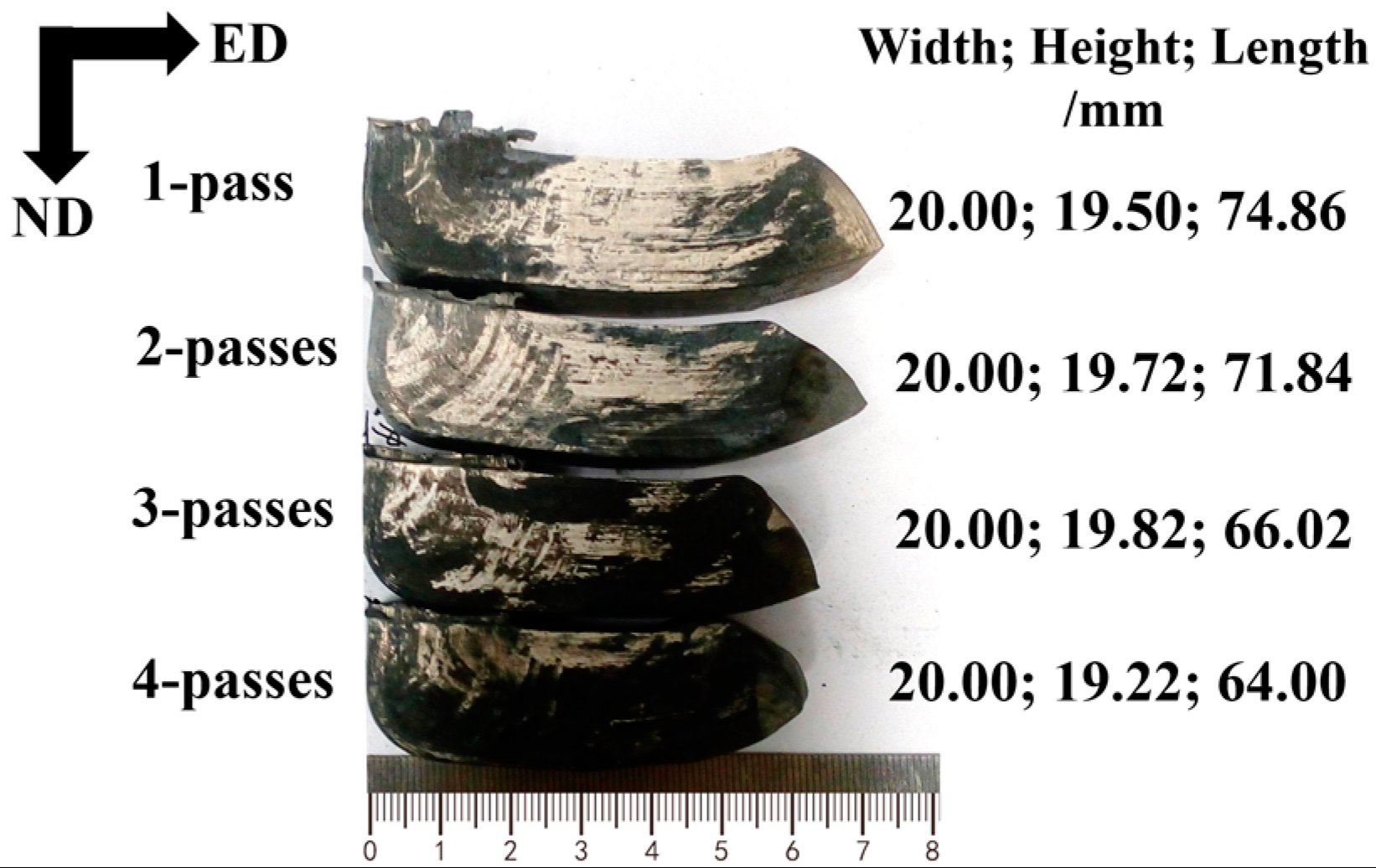

2. Materials and Methods

3. Results and Discussion

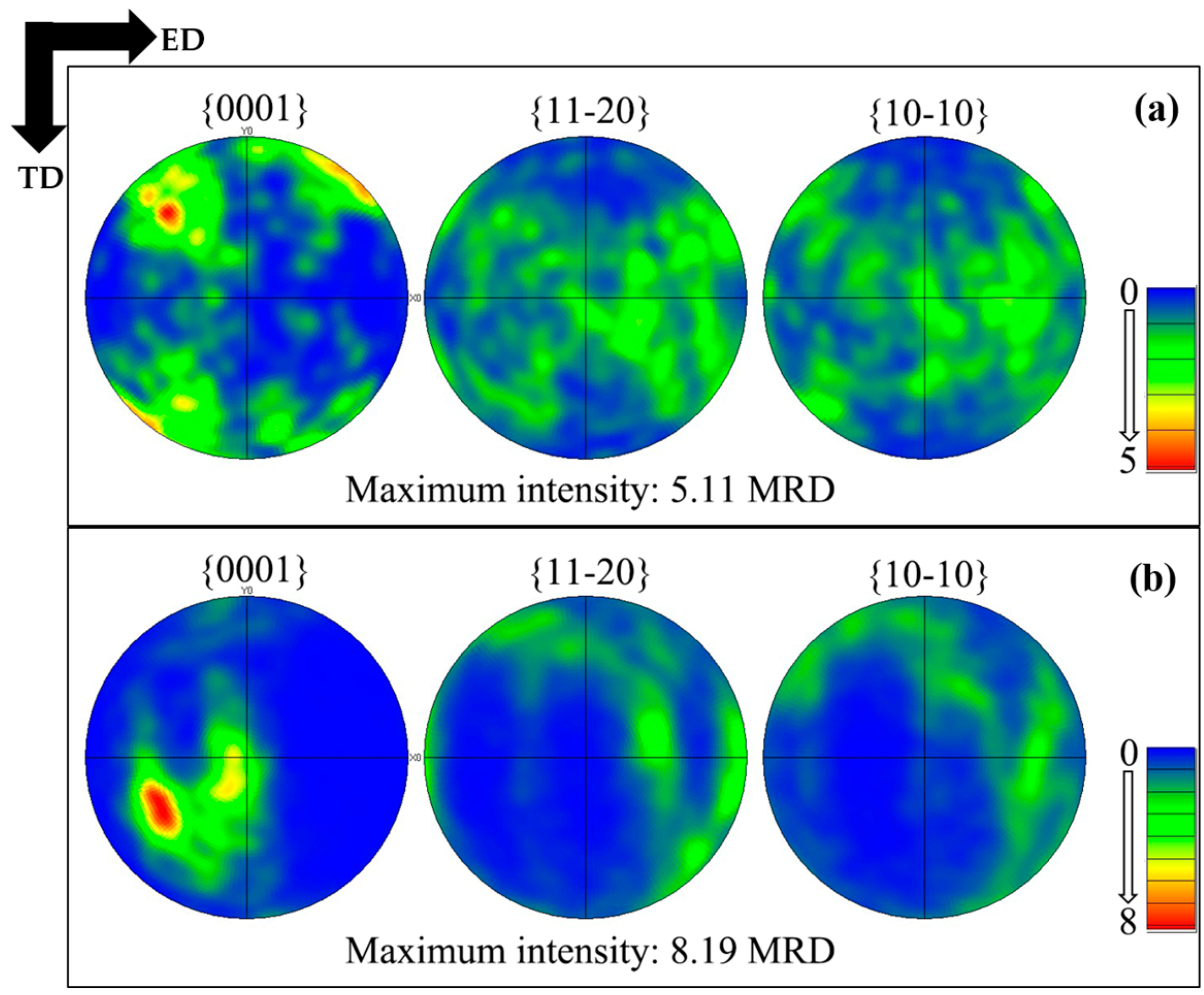

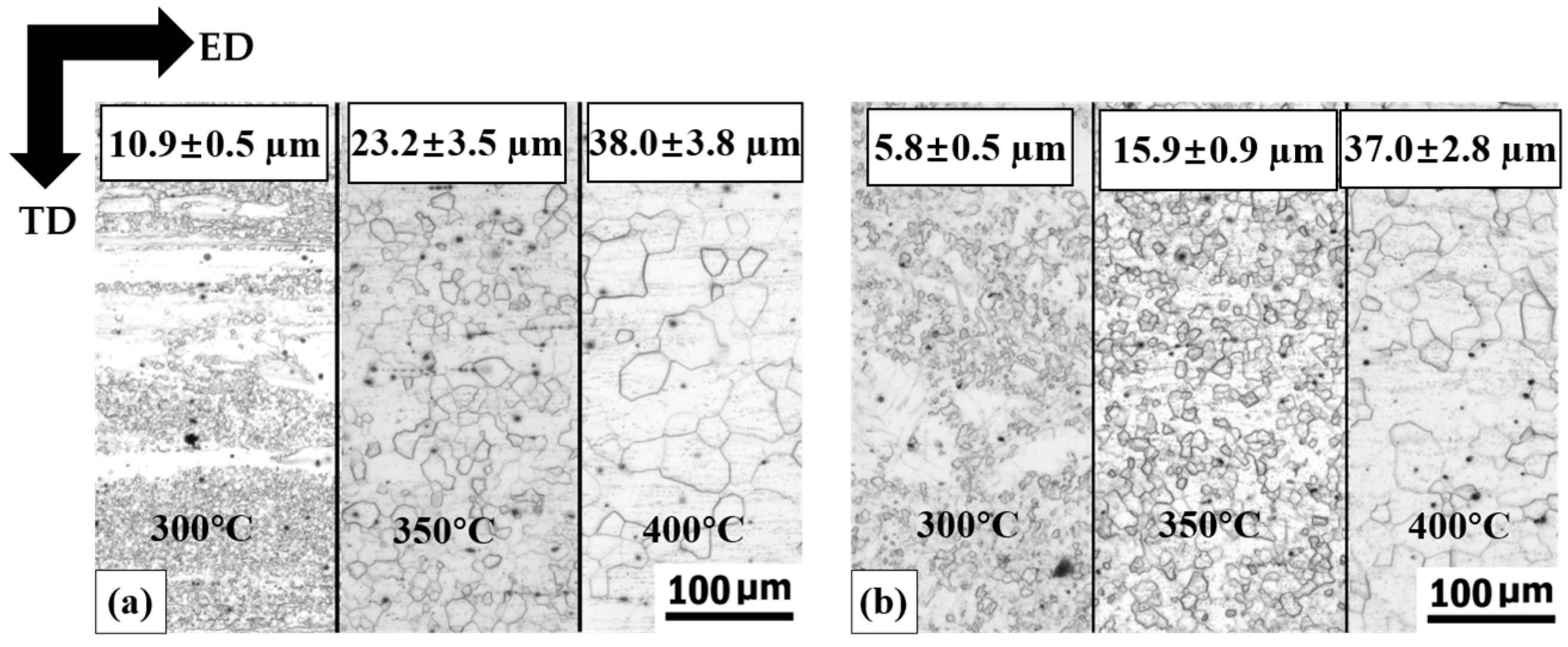

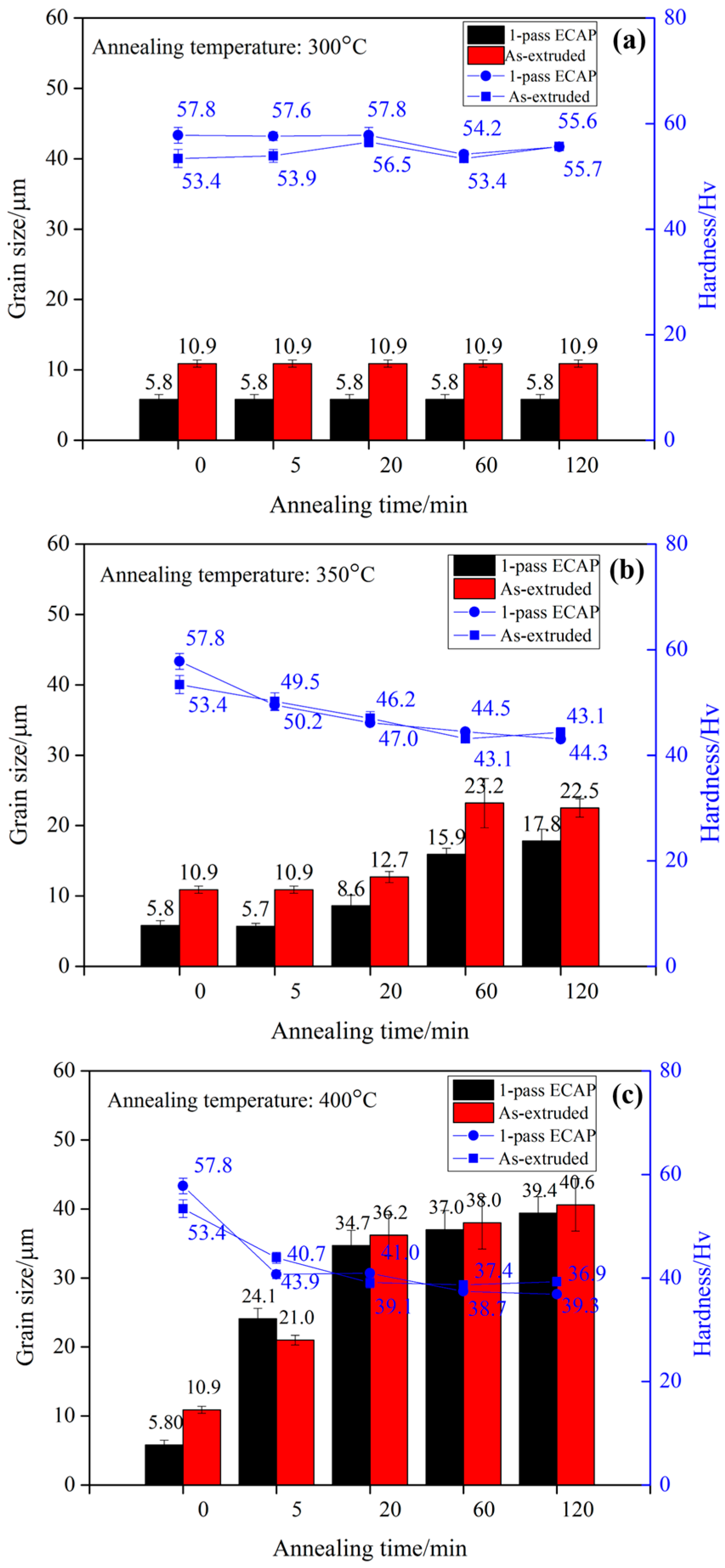

3.1. Microstructures

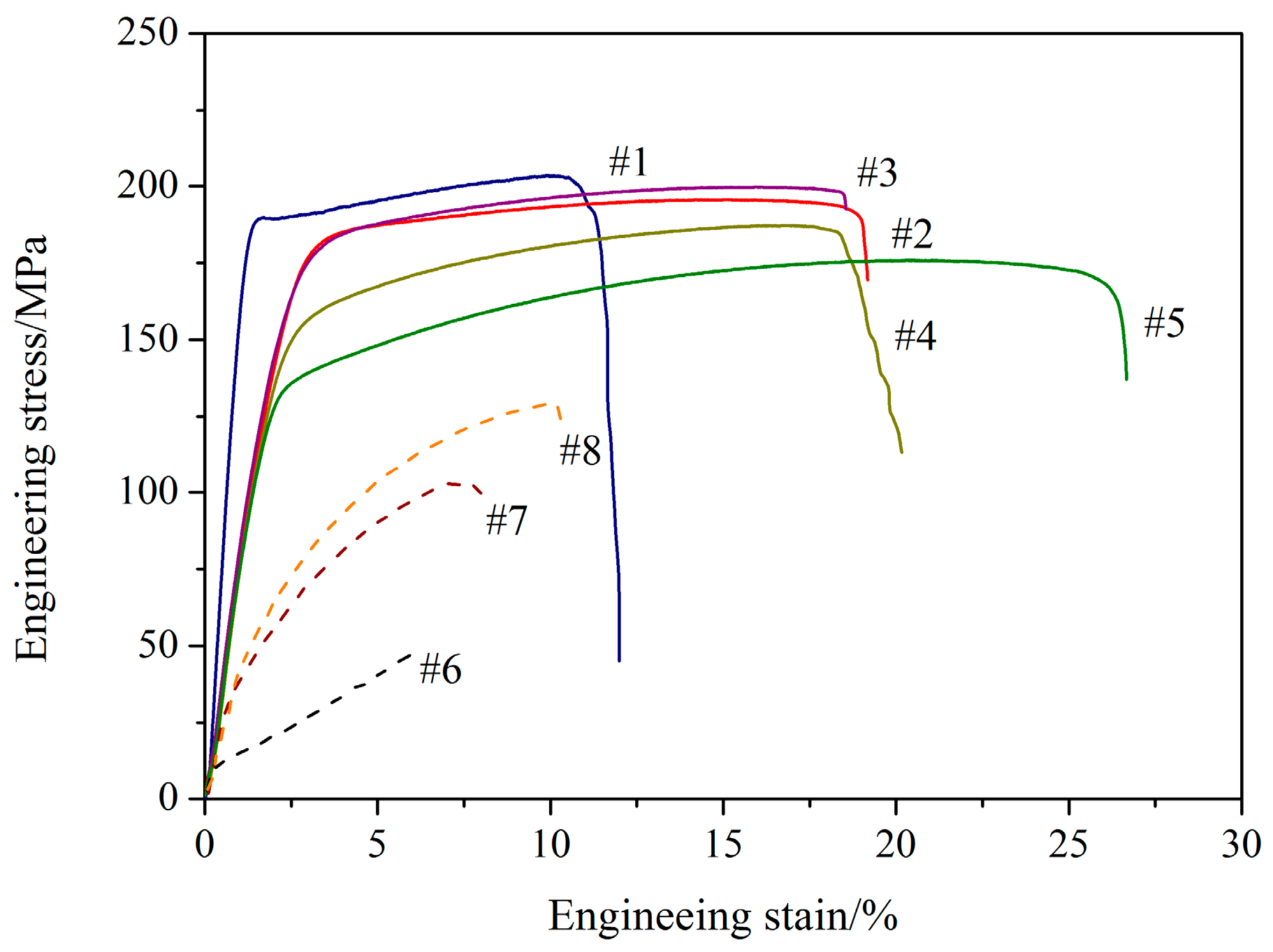

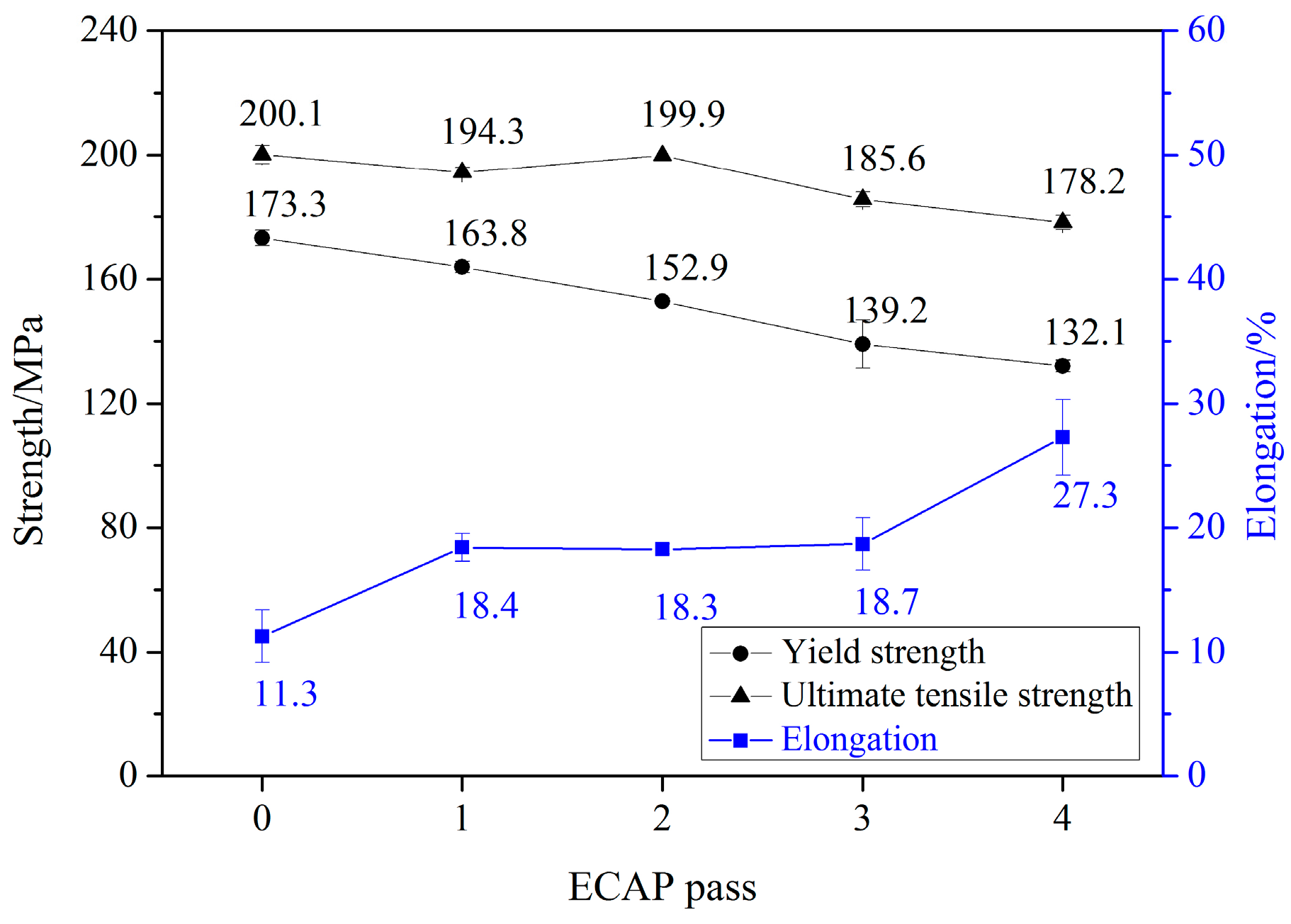

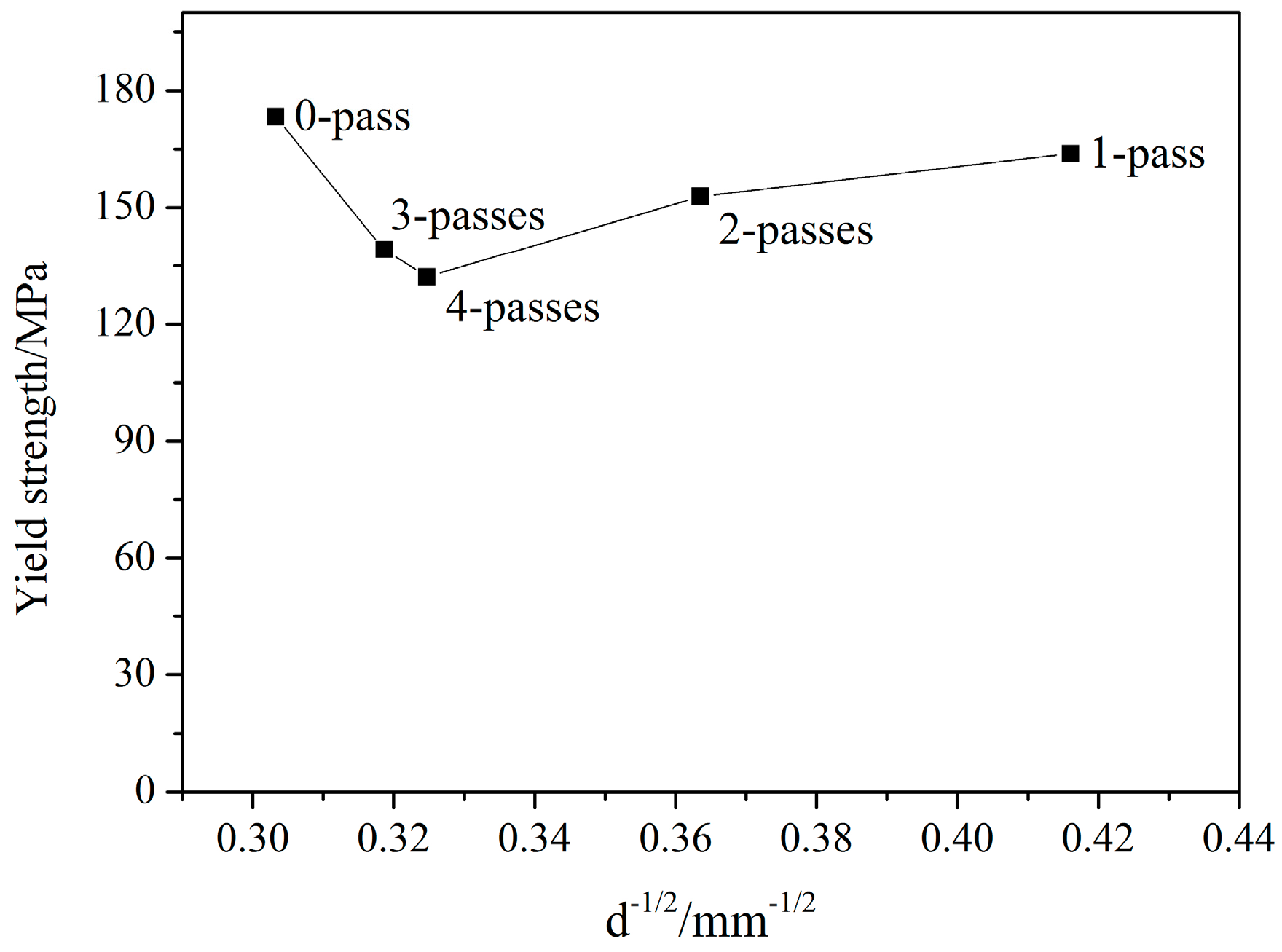

3.2. Mechanical Properties

3.3. Fractography

4. Conclusions

- The grain size of as-extruded materials (~10.9 μm) is refined significantly by 1-pass ECAP (~5.8 μm), and resulted in a remarkably enhanced elongation to failure (EL) (~+62%) with a slightly decreased strength (~−3%) comparing to the as-extruded condition (EL = ~11.3%, UTS = ~200 MPa). The EL is further increased to ~27.3% (~+142%) after 4-pass ECAP compared to the as-extruded condition, which is mainly due to the much more homogenized microstructure. The split basal poles with about 60° rotations to the extruded direction (ED) and the relatively coarsened grain size by SRX and post-DRX after 4-pass ECAP might be responsible for the decreased strength with increasing ECAP pass.

- With increasing ECAP pass, the proportions of cleavage planes decreasing and more highly developed tearing ridges, tiny dimples are observed indicating large plastic deformation occurred before fracture, which is consistent with the remarkable enhancement of the EL.

- Annealing treatments indicate that recovery dominantly occurs at 300 °C, SRX and grain growth emerge at 350 °C and 400 °C, respectively. Meanwhile, the grain growth and hardness decrease rapidly even within 5 min for 1-pass ECAPed alloy at annealing temperature 400 °C, implying a larger grain boundary mobility induced by higher deformation energy than the as-extruded ones.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Friedrich, H.; Schumann, S. Research for a “new age of magnesium” in the automotive industry. Mater. Process. Technol. 2001, 117, 276–281. [Google Scholar] [CrossRef]

- Avedusian, M.M.; Baker, H. Magnesium and Magnesium Alloys, ASM Specialty Handbook; ASM International: Materials Park, OH, USA, 1999. [Google Scholar]

- Rokhlin, L.L. Magnesium Alloys Containing Rare Earth Metals; CRC Press: London, UK, 2003. [Google Scholar]

- Tekumalla, S.; Seetharaman, S.; Almajid, A.; Gupta, M. Mechanical Properties of Magnesium-Rare Earth Alloy Systems: A Review. Metals 2014, 5, 1–39. [Google Scholar] [CrossRef]

- Somekawa, H.; Osawa, Y.; Singh, A.; Washio, K.; Kato, A.; Mukai, T. Effect of Micro-Alloying Elements on Deformation Behavior in Mg–Y Binary Alloys. Mater. Trans. 2014, 55, 182–187. [Google Scholar] [CrossRef]

- Gao, L.; Chen, R.S.; Han, E.H. Effects of rare-earth elements Gd and Y on the solid solution strengthening of Mg alloys. J. Alloy Compd. 2009, 481, 379–384. [Google Scholar] [CrossRef]

- Hantzsche, K.; Bohlen, J.; Wendt, J.; Kainer, K.U.; Yi, S.B.; Letzig, D. Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets. Scr. Mater. 2010, 63, 725–730. [Google Scholar] [CrossRef]

- Suzuki, M.; Sato, H.; Maruyama, K.; Oikawa, H. Creep behavior and deformation microstructures of Mg–Y alloys at 550 K. Mater. Sci. Eng. A 1998, 252, 248–255. [Google Scholar] [CrossRef]

- Sandlöbes, S.; Zaefferer, S.; Schestakow, I.; Yi, S.; Gonzalez-Martinez, R. On the role of non-basal deformation mechanisms for the ductility of Mg and Mg–Y alloys. Acta Mater. 2011, 59, 429–439. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Korznikov, A.V.; Mulyukov, R.R. Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater. Sci. Eng. A 1993, 168, 141–148. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Jin, Z.; Valiev, R.Z.; Zhu, Y.T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 2004, 52, 4589–4599. [Google Scholar] [CrossRef]

- Langdon, T.G. The principles of grain refinement in equal-channel angular pressing. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, Y.; Zhang, J.; Kang, Z. Microstructure and mechanical properties of equal channel angular pressed Mg–Y–RE–Zr alloy. Mater. Sci. Technol. 2016, 32, 969–975. [Google Scholar] [CrossRef]

- Alizadeh, R.; Mahmudi, R.; Ngan, A.H.W.; Pereira, P.H.R.; Huang, Y.; Langdon, T.G. Microstructure, Texture, and Superplasticity of a Fine-Grained Mg-Gd-Zr Alloy Processed by Equal-Channel Angular Pressing. Metall. Mater. Trans. A 2016, 47, 6056–6069. [Google Scholar] [CrossRef]

- Yamashita, A.; Horita, Z.; Langdon, T.G. Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. Mater. Sci. Eng. A 2001, 300, 142–147. [Google Scholar] [CrossRef]

- Agnew, S.R.; Horton, J.A.; Lillo, T.M.; Brown, D.W. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing. Scr. Mater. 2004, 50, 377–381. [Google Scholar] [CrossRef]

- Kim, W.J.; An, C.W.; Kim, Y.S.; Hong, S.I. Mechanical properties and microstructures of an AZ61 Mg Alloy produced by equal channel angular pressing. Scr. Mater. 2002, 47, 39–44. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Knauer, E.; Freudenberger, J.; Marr, T.; Kauffmann, A.; Schultz, L. Grain Refinement and Deformation Mechanisms in Room Temperature Severe Plastic Deformed Mg-AZ31. Metals 2013, 3, 283–297. [Google Scholar] [CrossRef]

- Cottam, R.; Robson, J.; Lorimer, G.; Davis, B. Dynamic recrystallization of Mg and Mg–Y alloys: Crystallographic texture development. Mater. Sci. Eng. A 2008, 485, 375–382. [Google Scholar] [CrossRef]

- Wang, L.; Min, G.H.; Gao, P.P.; Wang, X.Y.; Yu, H.S.; Cui, H.W. Effects of Annealing Treatment on the Microstructure and Mechanical Properties of Magnesium Alloy Sheets. Appl. Mech. Mater. 2013, 303–306, 2524–2527. [Google Scholar] [CrossRef]

- Lapovok, R.; Gao, X.; Nie, J.; Estrin, Y.; Mathaudhu, S.N. Enhancement of properties in cast Mg–Y–Zn rod processed by severe plastic deformation. Mater. Sci. Eng. A 2014, 615, 198–207. [Google Scholar] [CrossRef]

- Kim, W.J.; Hong, S.I.; Kim, Y.S.; Min, S.H.; Jeong, H.T.; Lee, J.D. Texture development and its effect on mechanical properties of an AZ61 Mg alloy fabricated by equal channel angular pressing. Acta Mater. 2003, 51, 3293–3307. [Google Scholar] [CrossRef]

- Stanford, N. Micro-alloying Mg with Y, Ce, Gd and La for texture modification—A comparative study. Mater. Sci. Eng. A 2010, 527, 2669–2677. [Google Scholar] [CrossRef]

- Sauvage, X.; Wilde, G.; Divinski, S.V.; Horita, Z.; Valiev, R.Z. Grain boundaries in ultrafine grained materials processed by severe plastic deformation and related phenomena. Mater. Sci. Eng. A 2012, 540, 1–12. [Google Scholar] [CrossRef]

- Bohlen, J.; Yi, S.B.; Swiostek, J.; Letzig, D.; Brokmeier, H.G.; Kainer, K.U. Microstructure and texture development during hydrostatic extrusion of magnesium alloy AZ31. Scr. Mater. 2005, 53, 259–264. [Google Scholar] [CrossRef]

- Lentz, M.; Klaus, M.; Beyerlein, I.J.; Zecevic, M.; Reimers, W.; Knezevic, M. In situ X-ray diffraction and crystal plasticity modeling of the deformation behavior of extruded Mg–Li–(Al) alloys: An uncommon tension–compression asymmetry. Acta Mater. 2015, 86, 254–268. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, S.; Huang, N. Effects of ECAE processing temperature on the microstructure, mechanical properties, and corrosion behavior of pure Mg. Int. J. Miner. Metall. Mater. 2015, 22, 639–647. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 219–224. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Huang, G.; Yin, D.; Li, K.; Wang, Q.; Zhou, H. Effects of ECAP and Annealing Treatment on the Microstructure and Mechanical Properties of Mg-1Y (wt. %) Binary Alloy. Metals 2017, 7, 119. https://doi.org/10.3390/met7040119

Wei J, Huang G, Yin D, Li K, Wang Q, Zhou H. Effects of ECAP and Annealing Treatment on the Microstructure and Mechanical Properties of Mg-1Y (wt. %) Binary Alloy. Metals. 2017; 7(4):119. https://doi.org/10.3390/met7040119

Chicago/Turabian StyleWei, Jie, Guanghao Huang, Dongdi Yin, Kangning Li, Qudong Wang, and Hao Zhou. 2017. "Effects of ECAP and Annealing Treatment on the Microstructure and Mechanical Properties of Mg-1Y (wt. %) Binary Alloy" Metals 7, no. 4: 119. https://doi.org/10.3390/met7040119

APA StyleWei, J., Huang, G., Yin, D., Li, K., Wang, Q., & Zhou, H. (2017). Effects of ECAP and Annealing Treatment on the Microstructure and Mechanical Properties of Mg-1Y (wt. %) Binary Alloy. Metals, 7(4), 119. https://doi.org/10.3390/met7040119