3.1. Monotonic and Low Cycle Fatigue Properties

Figure 4 shows the tensile test of Alloy 617, with a strain rate of 5.85 × 10

−4/s at 950 °C that was first done as a reference data for better understanding and explanation of fracture behavior. It is notable that the yield strength (YS) and the ultimate tensile strength (UTS) values were determined from the area in which the plastic deformation occurred (non-uniform) along the engineering stress–strain relationship, as well as with the highest stress magnitude during deformation behavior, respectively. The elastic modulus was calculated according to the slope in the elastic region, which is in good agreement with that reported in the literature [

5]. The tensile elongation and reduction of area (as a definition of material ductility) are also in accordance with the literature.

LCF testing of Alloy 617 was completed in air at 950 °C regarding the different applied total strain ranges to provide a baseline data for the fatigue behavior.

Table 2 reports the LCF test total strain condition, cycles to failure, cycles to initiation, plastic strain range, and stress range at half-life cycle. The results of fatigue tests consistently showed an appropriate decrease of fatigue life as a number of cycles according to the increase in the total strain range. We could find relatively higher plastic strain magnitude results in large plastic deformation which probably induced early crack nucleation. Most of fatigue life is spent in micro crack nucleation. These results could suggest that at higher total strain ranges, the reduction in fatigue life can be taken as being superior to cyclic plastic deformation. However, the stress response behavior was decreased when the total strain range was elevated, which is a definition of the cyclic softening mechanism. This point of view will be explained in the next section according to the cyclic damage mechanism at the very high temperature process.

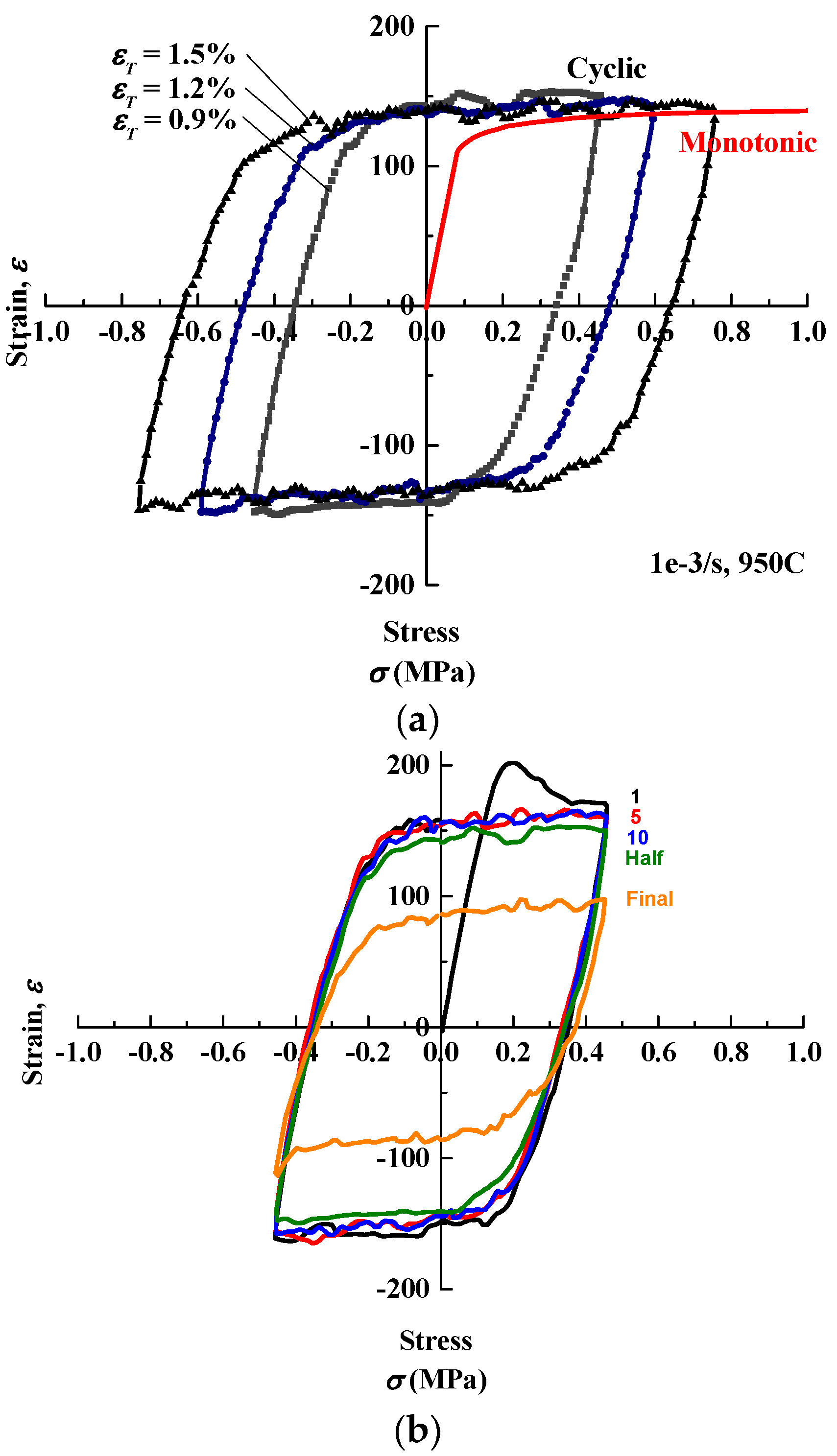

Figure 5a shows the hysteresis loops that represented a reduction in the peak stress response with the increasing total strain range. However, the plastic strain also becomes significantly higher as the shape of the hysteresis loops is wider.

Figure 5b shows the interval cycles in the hysteresis loops as a stress–strain response of Alloy 617 tested at 0.9% total strain range. In this phenomenon, a cyclic softening mechanism was observed as the stress response was decreased with the increasing of the number of cycles. The stable cycle phase was reached generally above 10 cycles, therefore, the half-life value is appropriate as the stable behavior during LCF loadings.

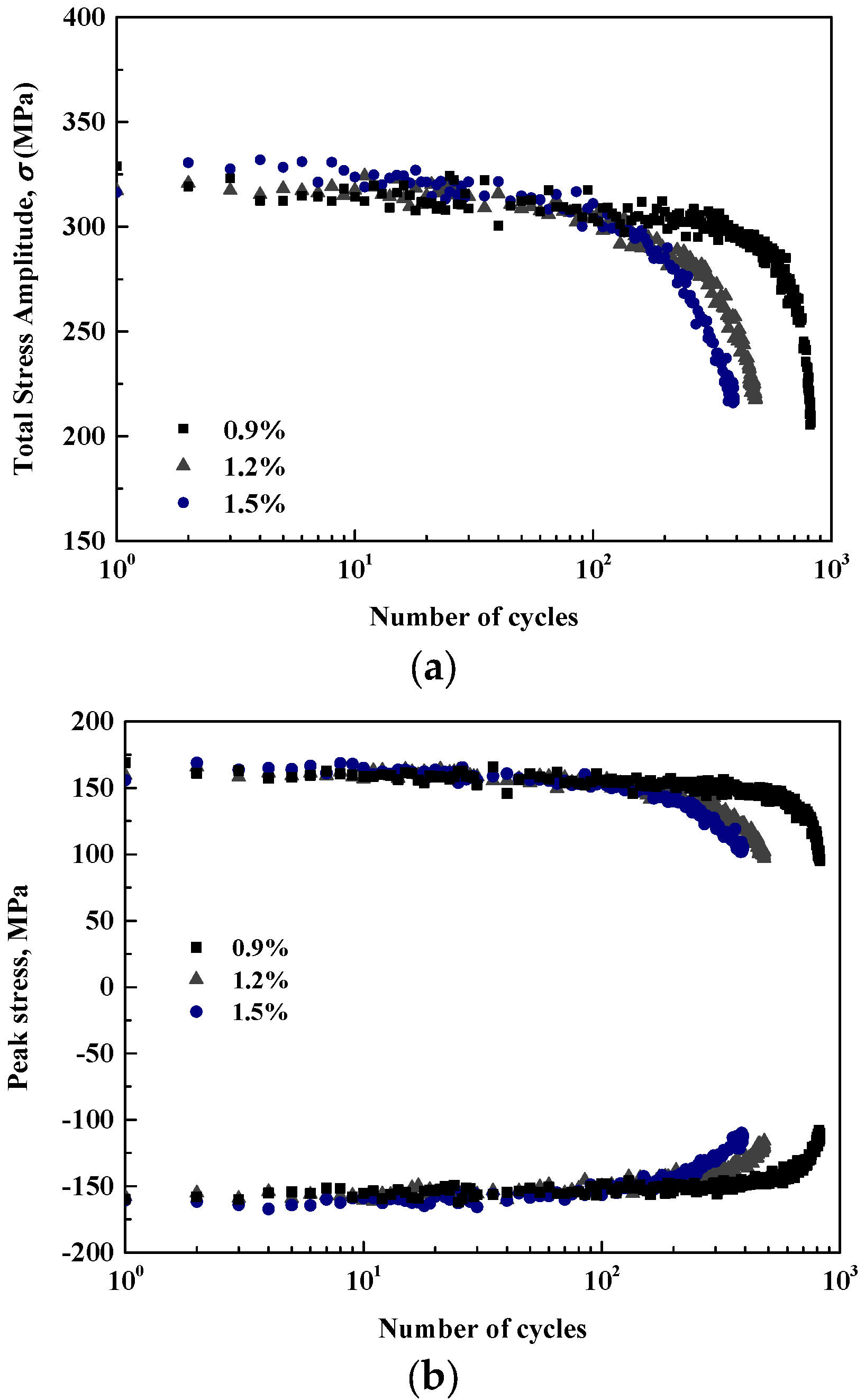

Figure 6 shows the cyclic stress response behavior of Alloy 617 at different applied total strain ranges. Almost all of the stress amplitude paths of Alloy 617 at 950 °C exhibit a cyclic softening region for the major portion of the life, as shown in

Figure 6a. At the end of the test, the stress amplitude was decreased rapidly as a formation of macro-crack initiation or just prior to failure. Under the lowest total strain range, i.e., 0.9%, a short saturation phase was also observed with a longer fatigue resistance.

Figure 6b shows that the peak tensile and compressive stress response under different applied total strain ranges were of the same magnitude. At all the testing conditions, the peak tensile and compressive stresses as a function of cycle (

Figure 6b) reached a stable value within less than 30 cycles. Also, it is noted that the cyclic stress response behavior is consistent with the shape of the cyclic stress–strain hysteresis loops shown in

Figure 5.

In this section, the LCF data are systematically analyzed to describe the material properties. The total strain can be determined as plastic and elastic strain elements through the cyclic stress–strain relationship, as described in Equation (1):

where Δε

T/2 is the total strain amplitude, Δε

e/2 is the elastic strain amplitude, Δε

p/2 is the plastic strain amplitude, Δσ is the stress magnitude,

E is the elastic modulus,

K′ and

n′ are the cyclic strength coefficient and cyclic strain hardening exponent, respectively.

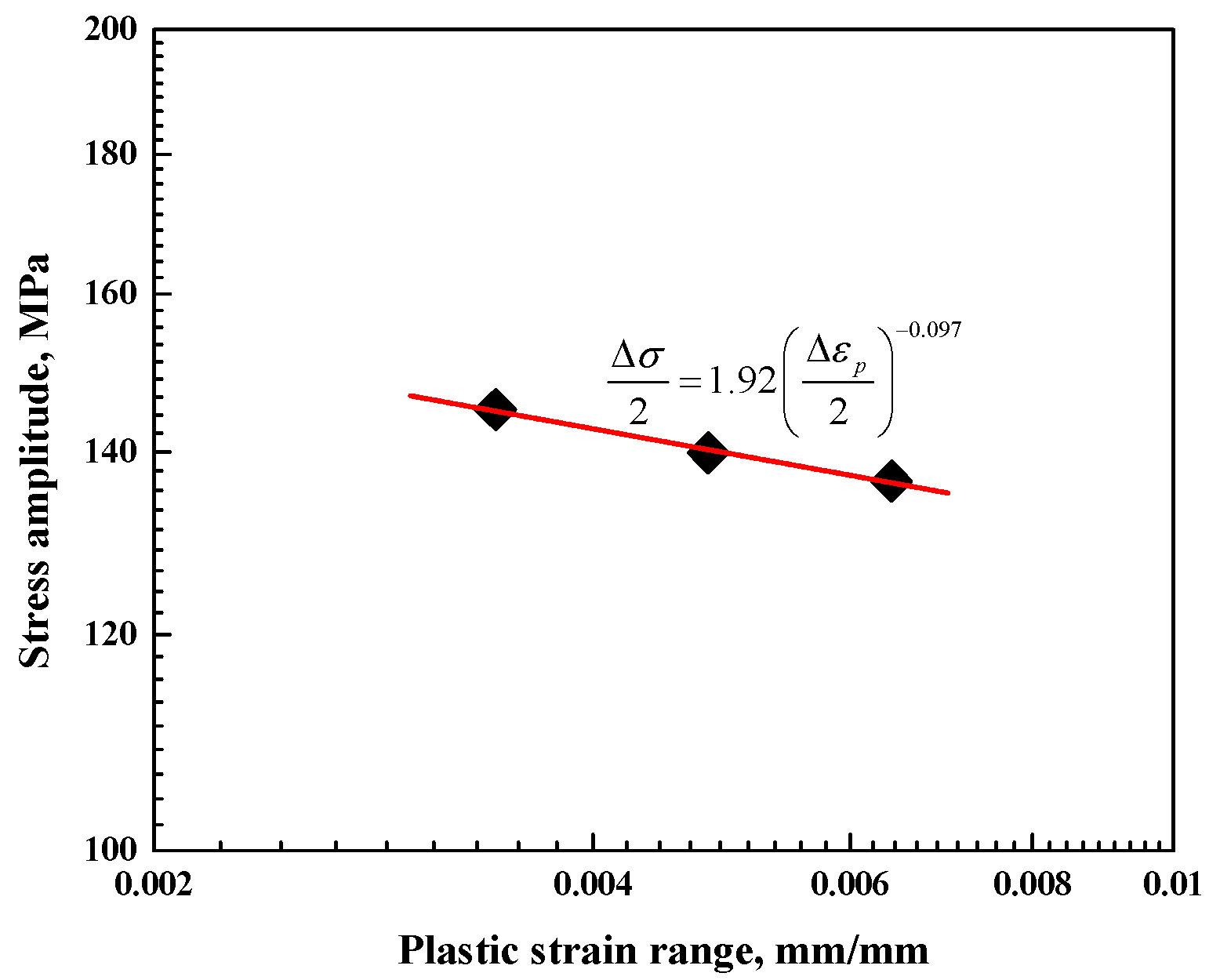

The above equation can be simplified between the stress magnitude and plastic strain components for describing the material response behavior. Using the well-known Ramberg–Osgood relationship, the linear regression can be taken and is provided as a measure to cyclic straining as follows:

Figure 7 shows the cyclic stress response versus plastic strain amplitude at half-life. The material constants of the Ramberg–Osgood relationship,

K′ and

n′, can be reasonably obtained through the cyclic stress–strain curves by linear regression of log–log scale. The

K′ value was obtained with about 83.2 (MPa), and

n′ value was −0.097. The negative sign in the slope means that the stress flow was decreasing continuously with an increase in plastic flow. This cyclic behavior of Alloy 617 indicates the cyclic softening mechanism as a function of the total strain range. This finding is in good agreement with that of the empirical rule (σ

uts/σ

ys < 1.2), in which metallic materials will cyclically soften; in this study, we found that (σ

uts/σ

ys = 1.134). According to Wright et al. [

6], they confirmed that a decrease in peak flow stress followed by an increase in the strain range is characteristic of a solute drag creep deformation mechanism. Also, it has been reported in previous work that a consequence of the solute drag creep mechanism operating during LCF of Alloy 617 at high temperature ranges of 900–950 °C [

6,

7] was due to the amount of solute atoms motion, which reduces the flow stress.

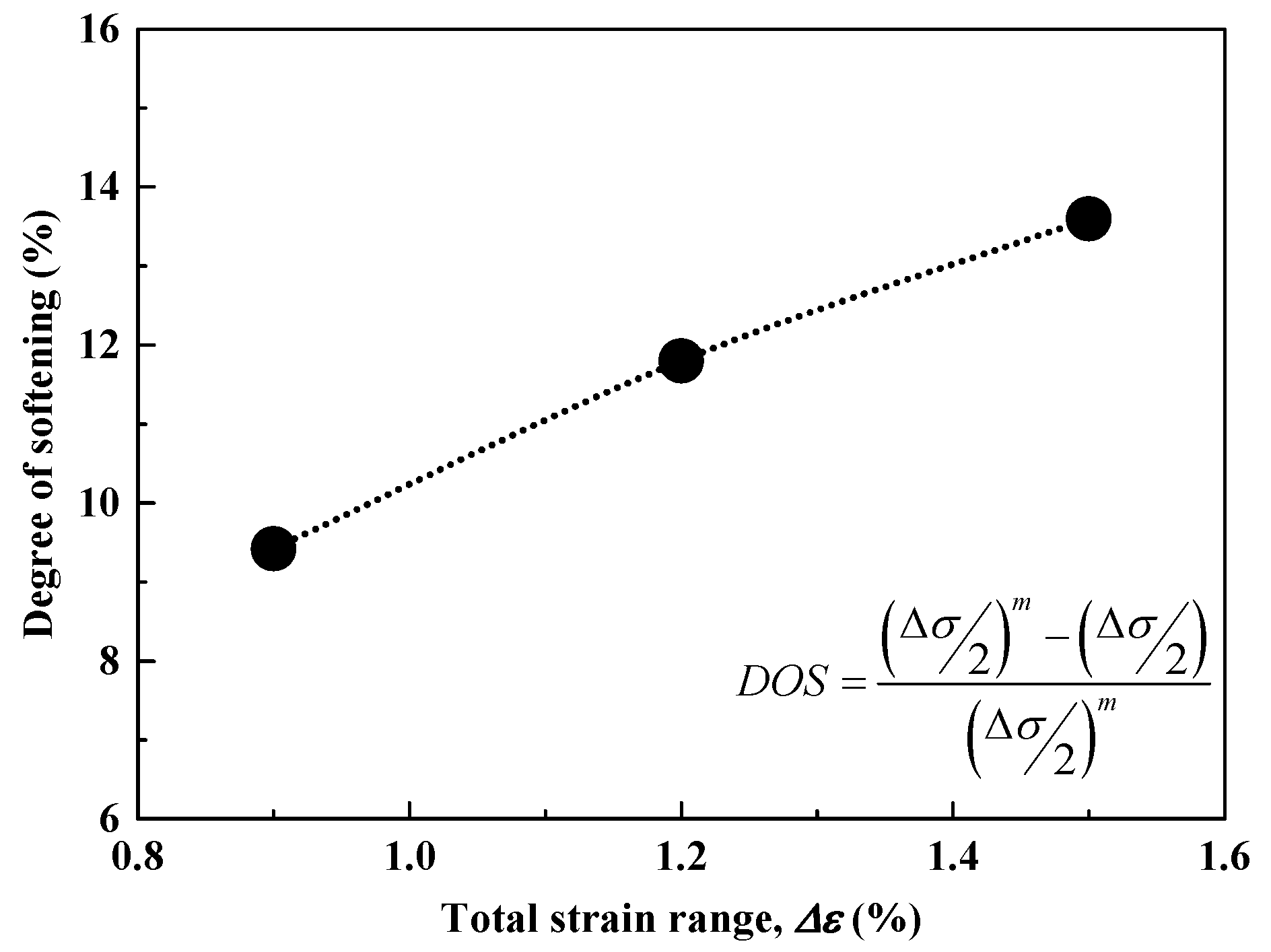

Branco et al. [

10] reported that evaluation of the variation of the cyclic softening with the total strain range during cyclic loading can be done through the characterization of the degree of softening (DOS), as given in Equation (3):

where Δσ/2

max and Δσ/2 represent the maximum stress amplitude and the stress amplitude at the half-life, respectively.

Figure 8 shows the degree of softening calculated as the total strain range dependency. According to the result, a continuous increase in the softening rate acts as a function of total strain ranges. This mechanism occurred as a decrease in flow stress to enforce the total strain range in the high temperature regime, and thus an increase in the magnitude of the softening rate.

3.2. Low Cycle Fatigue Damage Evaluation

The axial strain control cycling test provides the important information on the strain–life relationship. Therefore, the Alloy 617 may represent a typical Coffin–Manson life dependence on the total strain range. The well-known Coffin–Manson fatigue design method, or strain–life relationship, correlates the number of cycles, Nf, with the strain profile during LCF loadings. This model can be used to model the LCF problem, when the plastic strain range, Δεp, is the same or even larger than the elastic strain range, Δεe. The Coffin–Manson method can be worked out with the stress–strain (log scale) relationship to describe the hysteresis loop and considers the cyclic softening or hardening of the material.

The Coffin–Manson relationship consists of elastic and plastic strain elements. The first approach is the relation between stress amplitude and fatigue life, which in turn determines the elastic strain definition. Equation (4) is proposed:

where σ

f′ is the fatigue strength coefficient,

b is the fatigue strength exponent, and

2Nf is the number of reversals to failure. From Equation (4), the material constants can be determined through the linear relationship in a log–log scale using a least square fit method based on experimental data.

The strain based as a dependence parameter can be separated into the plastic and elastic strain ranges. In the LCF regime, the correlation between the plastic strain amplitude and the fatigue life is expressed by:

where ε

f′ is the fatigue ductility coefficient and

c is the fatigue ductility exponent. The material constants can be determined through the least square fit method as well. Alloy 617 resistance to the total strain ranges can be defined by the summation of its elastic and plastic deformation, which are expressed by Coffin–Manson relationships. Equation (6) graphically represents the Coffin–Manson curves of strain amplitude and the number of reversals to failure, as shown in

Figure 9. All material constants are listed in

Table 3. The

c slope value was determined as about −0.80. This value is comparable to the literature review [

6], where they found the

c slope of ≈−1 at 950 °C. At all total strain ranges, it could be seen that the plastic regime controlled the fatigue deformation. The domain is in the intersection between the plastic and elastic strain line, called by the transition of the fatigue life, (

Nt = 3789 cycles). When

2Nf is lower than

Nt, a plastic strain is dominant and the ductility governs the fatigue resistance. Otherwise, when

2Nf is higher than

Nt, the elastic strain is dominant and the strength governs the fatigue resistance. Furthermore, an excellent correlation between predicted life and experimental data through the Coffin–Manson relationship can be observed of Alloy 617 under the isothermal condition with a value of 5.11% error variance.

One of the proposed models that seems to be more complex, is the so-called strain energy density based model. The fatigue of materials is a specific energy consuming process with an absorption of the cyclic deformation, and the fatigue life can be characterized by this absorbed mechanical energy [

11]. The fatigue life analysis procedure based on total strain energy density has been used to separate the effect of microstructures on the fatigue life. The total dissipated energy is the sum of the plastic energy and the elastic energy in (MJ/m

3). This parameter model has been found to play an important role in the LCF damage process [

10,

11,

12,

13].

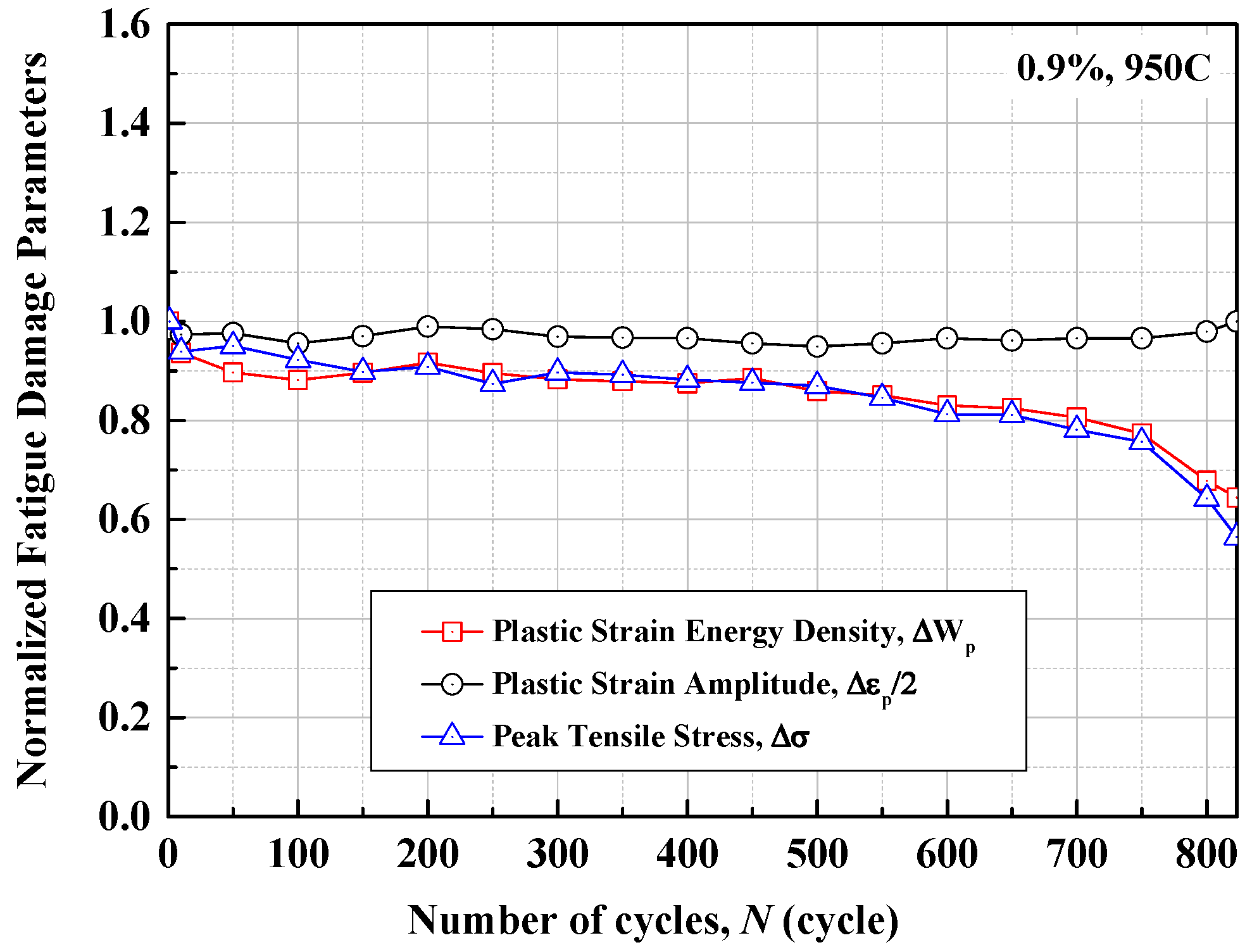

Figure 10 represents the evolutions of several fatigue damage parameters with the number of cycles on Alloy 617 where each parameter is normalized by its maximum value. As is seen, the peak stress amplitude and plastic strain energy density experienced variation at the ultimate phase. On the other hand, the plastic strain is more homogeneous during cycles at high temperature. In this case, the magnitude of stress and plastic strain are related to the active slip movement and its resistance, respectively.

The plastic strain energy density is characterized by the inside area of the hysteresis loop. Hence, the plastic strain energy density is related to the absorption of plastic deformation during cyclic loading. The inside area can be integrally evaluated through the empirical equation or based on the previous material constants obtained in the strain–life relationship. Therefore, the plastic strain energy, ΔWp, and number of reversals can be satisfied using the following Equation:

To consider the effect of mean stress, especially during the tensile portion, S. Hyuk et al. [

13] adopted the tensile mean stress effect, i.e., a tensile elastic strain energy density, Δ

We. In the case of longer fatigue life, the plastic deformation is difficult to measure. The summation of this can be used to our advantage for parameter determination. The elastic strain energy is related to the material properties such as the elastic modulus and the stress of material during LCF. Thus, the relation can be determined through the following Equation:

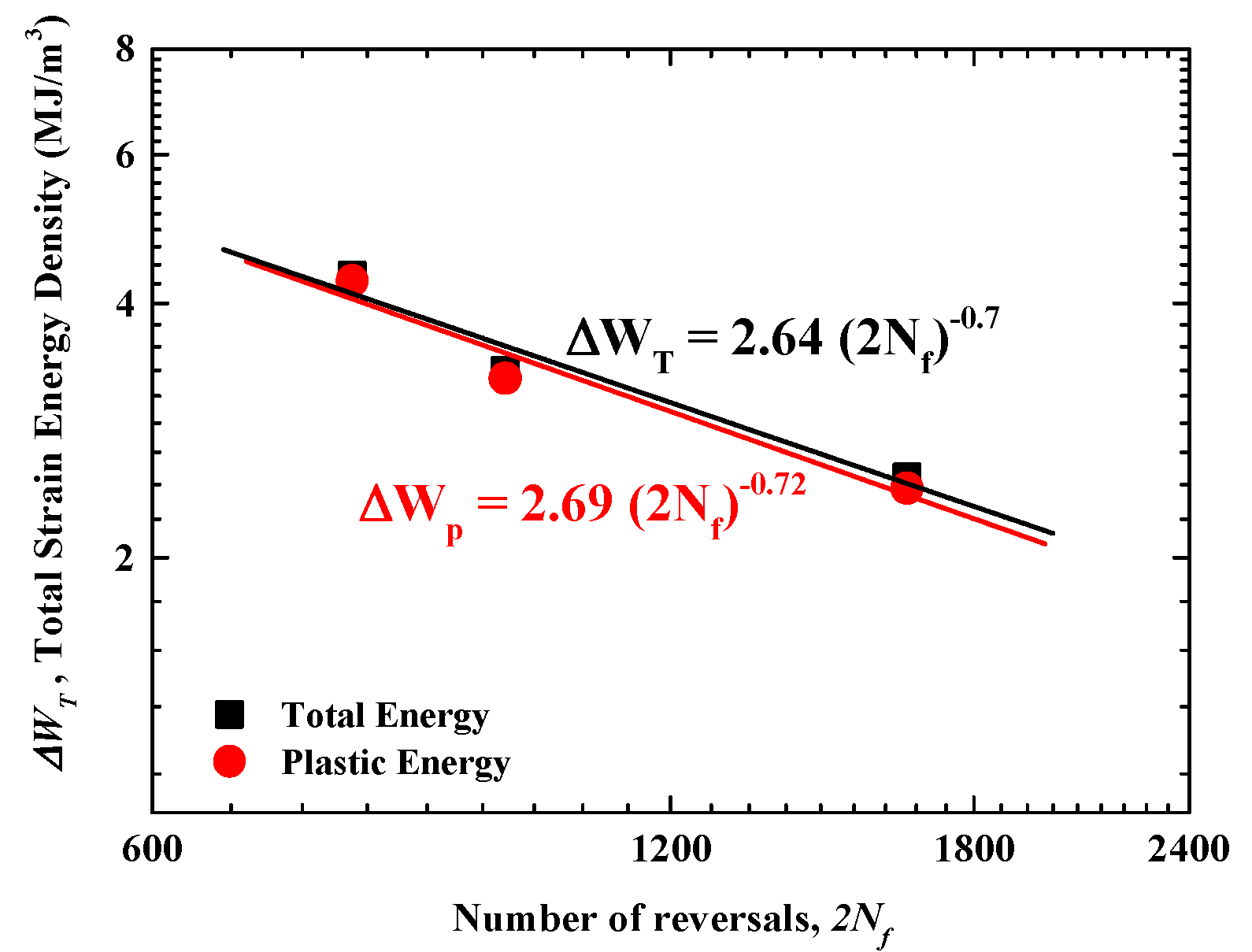

As mentioned above, the total strain energy density, Δ

WT, is the summation of the plastic strain energy and the elastic strain energy density (Δ

WT = Δ

Wp + Δ

We). This formulation is more suitable for fully reversed tests. From this point of view, the strain energy density is related to the number of cycles (or number of reversals) through power law, and can be estimated by the following equation:

where the material constants

A and α are the material energy absorption capacity and the fatigue exponent, respectively. These material constants can be determined from the universal slope based on the experimental data.

Figure 11 shows the fatigue life curves based on the total and plastic strain energy dissipated per cycle. There was no significant difference of the related constants, and both the curves exhibit good linearity and can be satisfied through the linear regression. From that, the existing energy absorbed during the mean strain is very small, thus the effect of the mean strain is noticed to be the minor influence. Specifying the total strain energy per cycle is used for the fatigue life studied at hand. The

A value was obtained with about 436.5, and the α value was −0.7 from the best fit to the experimental data. The prediction of service lifetime based on the total strain energy density-based model is very close to the proposed function with a scattering value of 6.61%. Using a similar approach and universal slope, the prediction of service lifetime can be derived in a particular operation.