XPS and AFM Investigations of Ti-Al-N Coatings Fabricated Using DC Magnetron Sputtering at Various Nitrogen Flow Rates and Deposition Temperatures

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

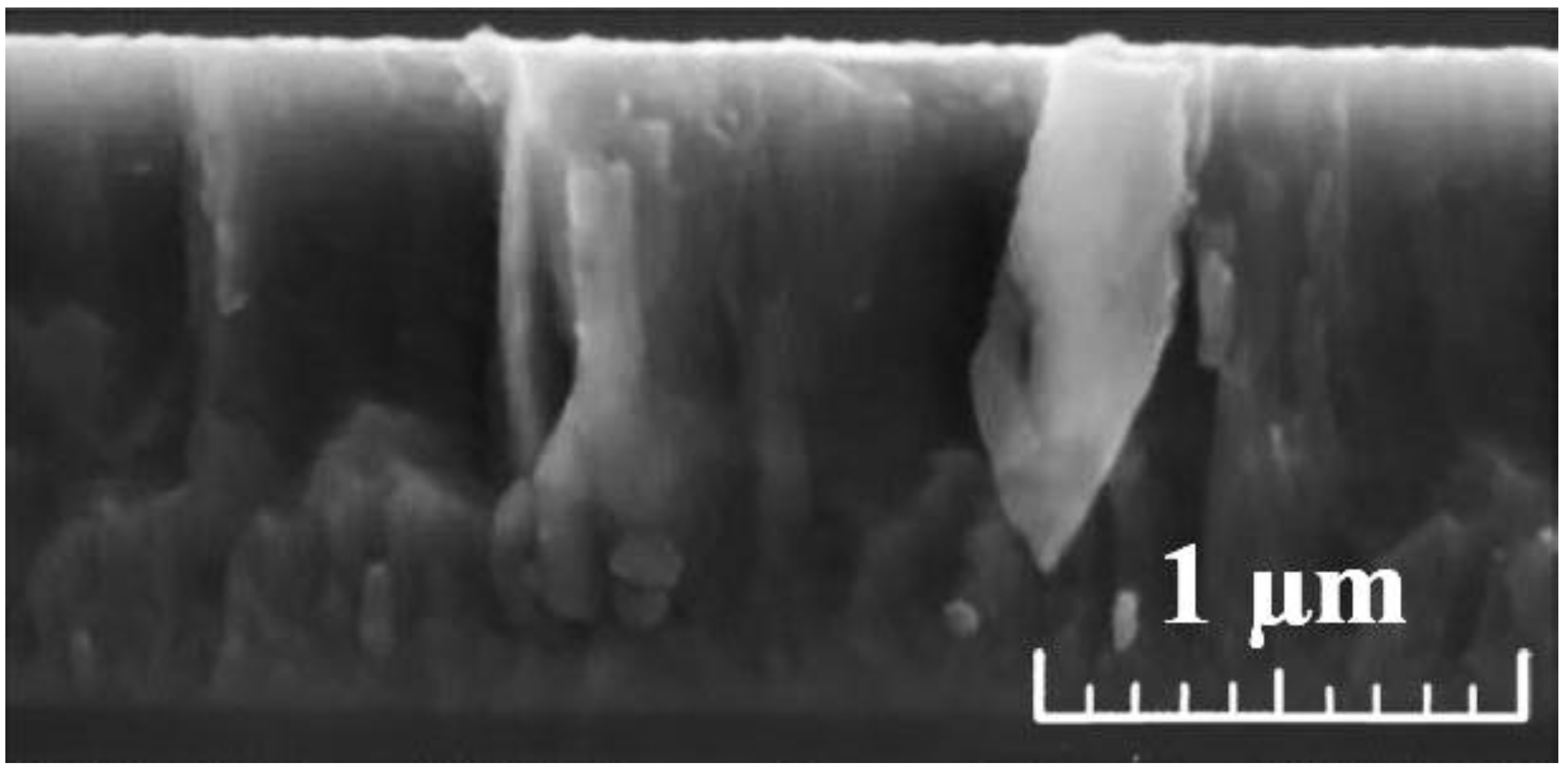

3.1. SEM and AFM

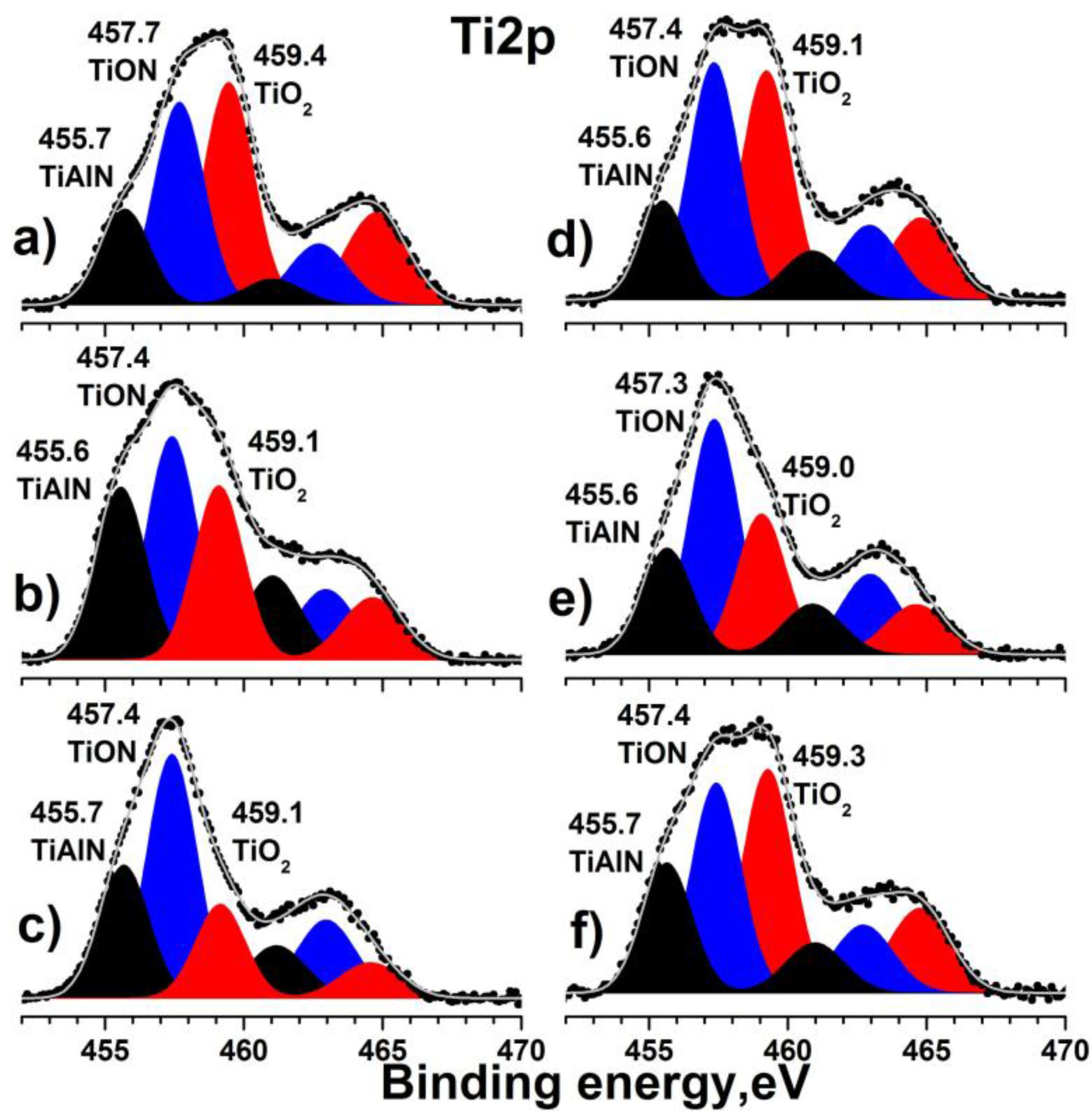

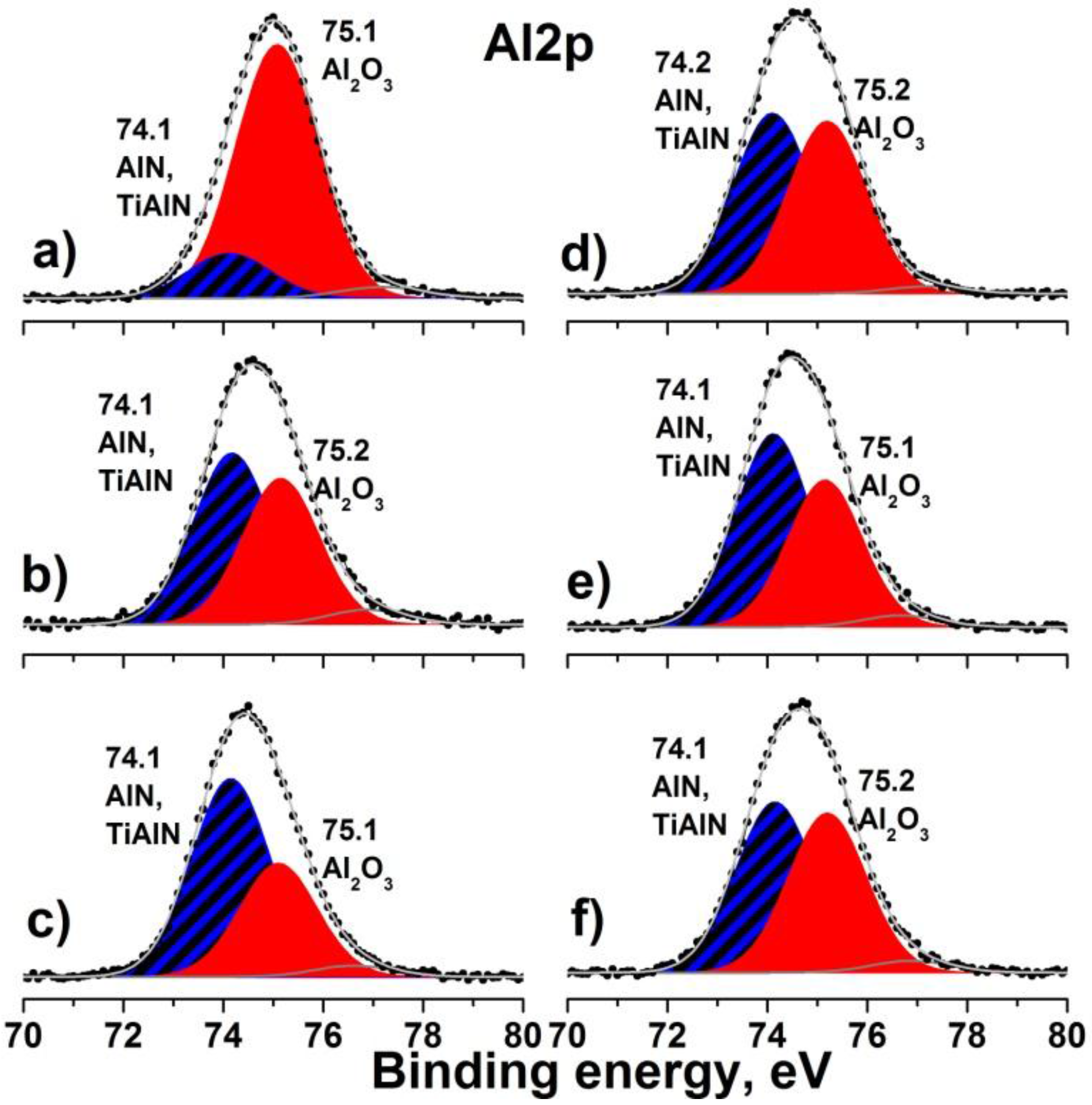

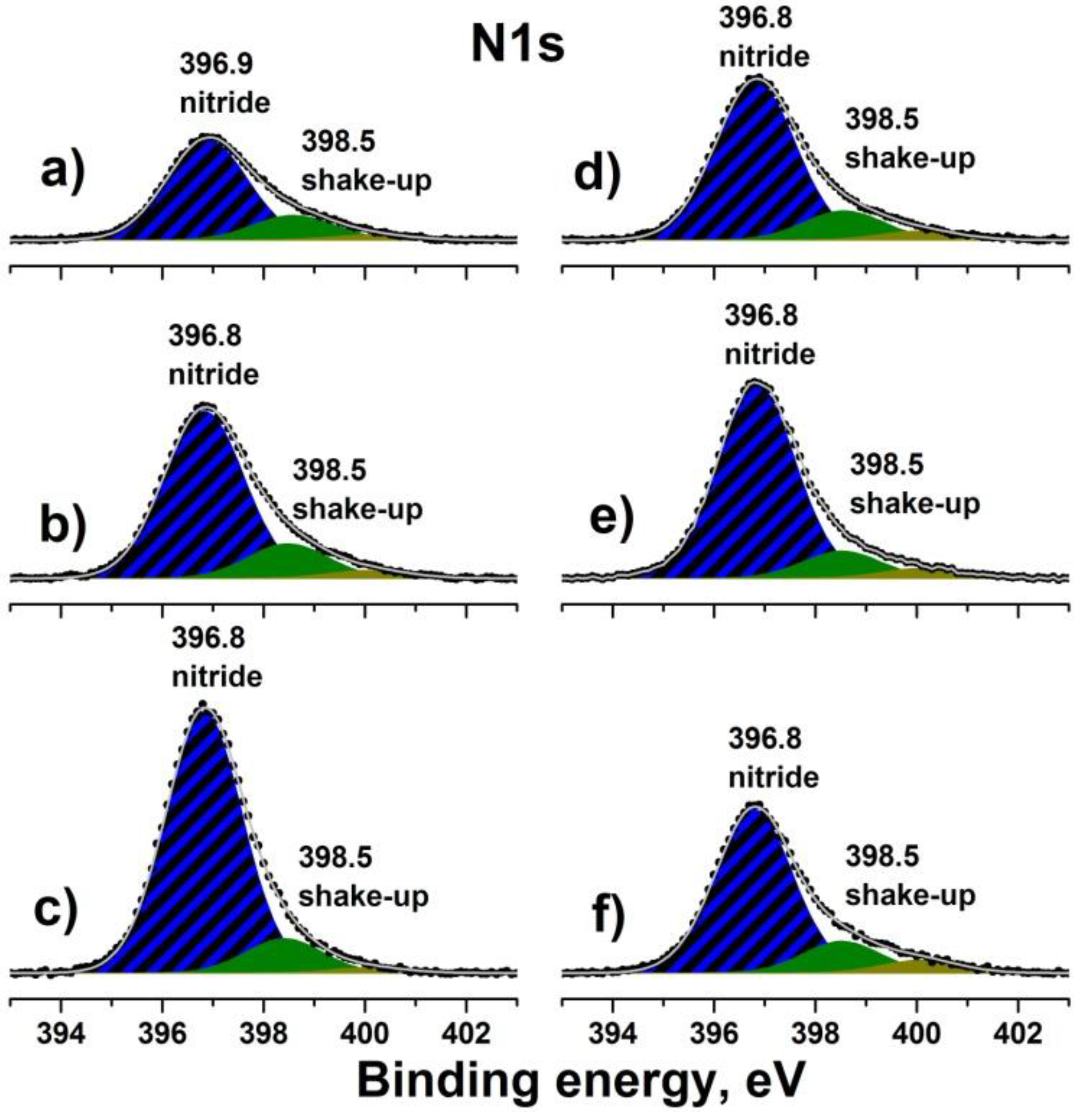

3.2. XPS

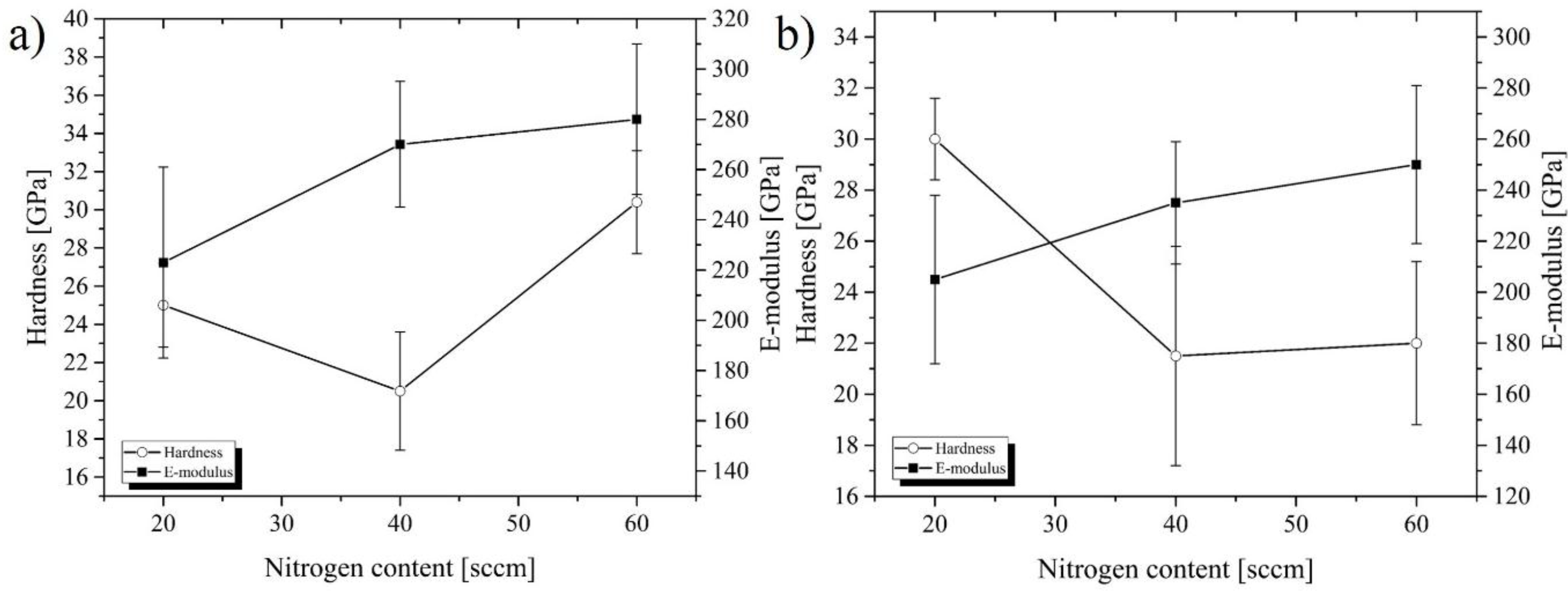

3.3. Nanoindentation

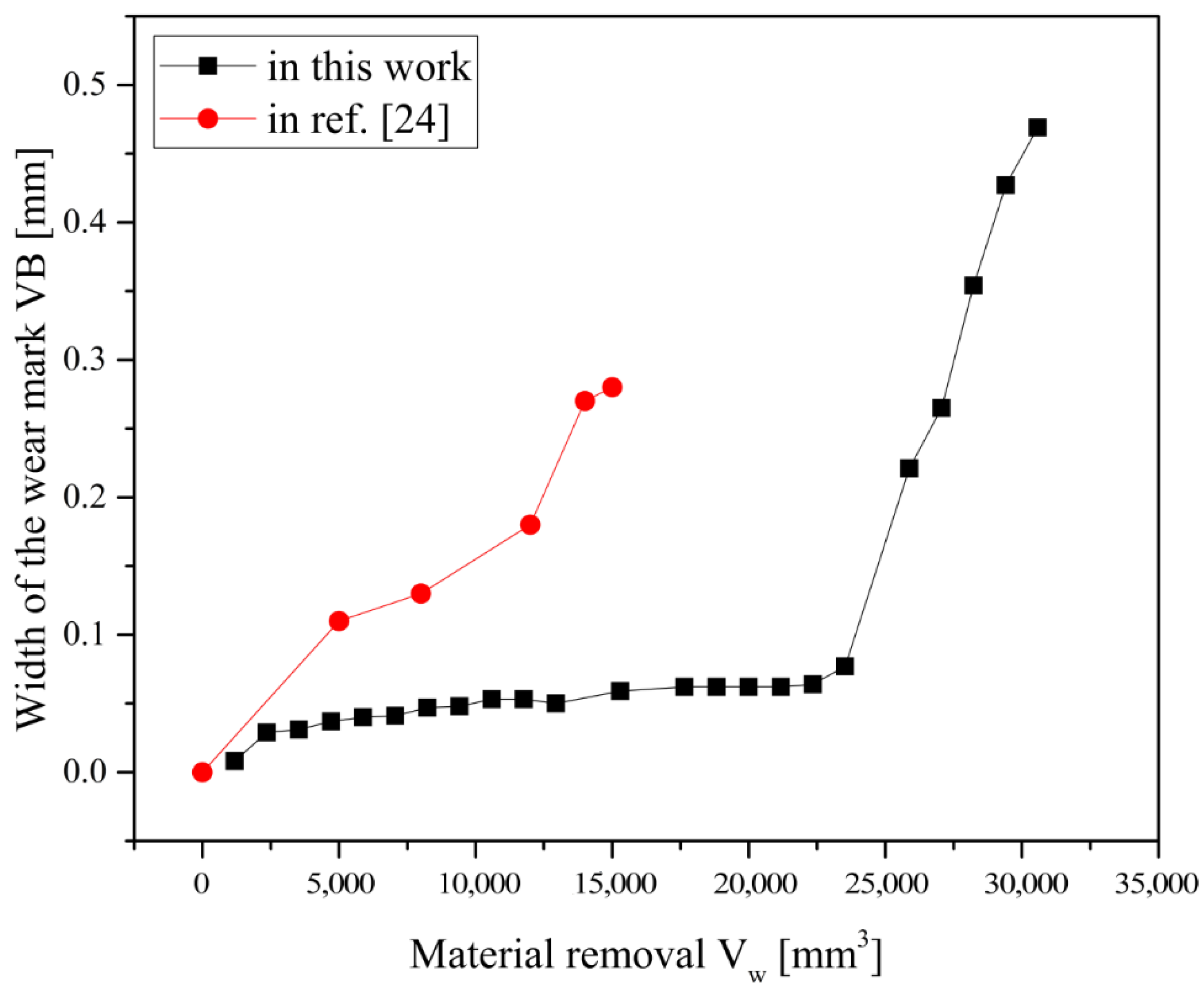

3.4. Cylindrical Turning Experiments

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Münz, W.D. Titanium aluminum nitride films: A new alternative to tin coatings. J. Vac. Sci. Technol. A 1986, 4, 2717–2725. [Google Scholar] [CrossRef]

- Knotek, O.; Münz, W.D.; Leyendecker, T. Industrial deposition of binary, ternary, and quaternary nitrides of titanium, zirconium, and aluminum. J. Vac. Sci. Technol. A 1987, 5, 2173–2179. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Prakash, M.S.; Jain, A.; Rajam, K.S. Structure, hardness and thermal stability of TiAlN and nanolayered TiAlN/CrN multilayer films. Vacuum 2005, 77, 169–179. [Google Scholar] [CrossRef]

- Shieh, J.; Hon, M.H. Nanostructure and hardness of titanium aluminum nitride prepared by plasma enhanced chemical vapor deposition. Thin Solid Films 2001, 391, 101–108. [Google Scholar] [CrossRef]

- Bressan, J.D.; Hesse, R.; Silva, E.M., Jr. Abrasive wear behavior of high speed steel and hard metal coated with TiAlN and TiCN. Wear 2001, 250, 561–568. [Google Scholar] [CrossRef]

- Yang, Q.; Seo, D.Y.; Zhao, L.R.; Zeng, X.T. Erosion resistance performance of magnetron sputtering deposited TiAlN coatings. Surf. Coat. Technol. 2004, 188–189, 168–173. [Google Scholar] [CrossRef]

- Kimura, A.; Hasegawa, H.; Yamada, K.; Suzuki, T. Effects of al content on hardness, lattice parameter and microstructure of Ti1−xAlxN films. Surf. Coat. Technol. 1999, 120–121, 438–441. [Google Scholar] [CrossRef]

- Pfeiler, M.; Fontalvo, G.A.; Wagner, J.; Kutschej, K.; Penoy, M.; Michotte, C.; Mitterer, C.; Kathrein, M. Arc evaporation of Ti–Al–Ta–N coatings: The effect of bias voltage and Ta on high-temperature tribological properties. Tribol. Lett. 2008, 30, 91–97. [Google Scholar] [CrossRef]

- Suzuki, T.; Huang, D.; Ikuhara, Y. Microstructures and grain boundaries of (Ti,Al)N films. Surf. Coat. Technol. 1998, 107, 41–47. [Google Scholar] [CrossRef]

- Sergevnin, V.S.; Blinkov, I.V.; Belov, D.S.; Volkhonskii, A.O.; Skryleva, E.A.; Chernogor, A.V. Phase formation in the Ti–Al–Mo–N system during the growth of adaptive wear-resistant coatings by arc pvd. Inorg. Mater. 2016, 52, 735–742. [Google Scholar] [CrossRef]

- Shugurov, A.R.; Akulinkin, A.A.; Panin, A.V.; Perevalova, O.B.; Sergeev, V.P. Structural modification of tialn coatings by preliminary Ti ion bombardment of a steel substrate. Tech. Phys. 2016, 61, 409–415. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Musil, J.; Hrubý, H. Superhard nanocomposite Ti1−xAlxN films prepared by magnetron sputtering. Thin Solid Films 2000, 365, 104–109. [Google Scholar] [CrossRef]

- Anikin, V.N.; Blinkov, I.V.; Volkhonskii, A.O.; Sobolev, N.A.; Tsareva, S.G.; Kratokhvil, R.V.; Frolov, A.E. Ion-plasma Ti-Al-N coatings on a cutting hard-alloy tool operating under conditions of constant and alternating-sign loads. Russ. J. Non-Ferr. Met. 2009, 50, 424–431. [Google Scholar] [CrossRef]

- Kimura, A.; Murakami, T.; Yamada, K.; Suzuki, T. Hot-pressed Ti-Al targets for synthesizing Ti1−xAlxN films by the arc ion plating method. Thin Solid Films 2001, 382, 101–105. [Google Scholar] [CrossRef]

- Stepanov, I.B.; Ryabchikov, A.I.; Ananin, P.S.; Bumagina, A.I.; Shevelev, A.E.; Shulepov, I.A.; Sivin, D.O. Investigation of filtered vacuum arc plasma application for tialn and TiSiB coatings deposition using ion beam and plasma material processing. Surf. Coat. Technol. 2016, 296, 20–25. [Google Scholar] [CrossRef]

- Quesada, F.; Mariño, A.; Restrepo, E. TiAlN coatings deposited by r.f. Magnetron sputtering on previously treated ASTM A36 steel. Surf. Coat. Technol. 2006, 201, 2925–2929. [Google Scholar] [CrossRef]

- Oliveira, J.C.; Manaia, A.; Cavaleiro, A. Hard amorphous Ti–Al–N coatings deposited by sputtering. Thin Solid Films 2008, 516, 5032–5038. [Google Scholar] [CrossRef]

- Kutschej, K.; Mayrhofer, P.H.; Kathrein, M.; Polcik, P.; Tessadri, R.; Mitterer, C. Structure, mechanical and tribological properties of sputtered Ti1−xAlxN coatings with 0.5 ≤ x ≤ 0.75. Surf. Coat. Technol. 2005, 200, 2358–2365. [Google Scholar] [CrossRef]

- Gulyaev, R.V.; Koscheev, S.V.; Malykhin, S.E. An algorithm for removing charging effects from X-ray photoelectron spectra of nanoscaled non-conductive materials. J. Electron Spectrosc. Related Phenom. 2015, 202, 89–101. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Obrosov, A.; Naveed, M.; Volinsky, A.A.; Weiß, S. Substrate frequency effects on CrxN coatings deposited by DC magnetron sputtering. J. Mater. Eng. Perform. 2017, 26, 366–373. [Google Scholar] [CrossRef]

- Uhlmann, E.; Stawiszynski, B.; Leyens, C.; Heinze, S.; Sammler, F. Hard turning of hot work and cold work steels with hipims and dcms TiAlN coated carbide inserts. Proced. CIRP 2016, 46, 591–594. [Google Scholar] [CrossRef]

- Uhlmann, E.; Stawiszynski, B.; Leyens, C.; Heinze, S. HiPIMS coated carbides with high adhesive strength for hard machining. In Proceedings of the 11th International Conference on High Speed Machining 2014, Prag, Czech Republic, 11–12 September 2014.

- Shum, P.W.; Zhou, Z.F.; Li, K.Y.; Shen, Y.G. XPS, AFM and nanoindentation studies of Ti1−xAlxN films synthesized by reactive unbalanced magnetron sputtering. Mater. Sci. Eng. B 2003, 100, 204–213. [Google Scholar] [CrossRef]

- Li, D.; Chen, J.; Zou, C.; Ma, J.; Li, P.; Li, Y. Effects of al concentrations on the microstructure and mechanical properties of Ti–Al–N films deposited by RF-ICPIS enhanced magnetron sputtering. J. Alloy. Compd. 2014, 609, 239–243. [Google Scholar] [CrossRef]

- Zhou, W.; Liang, J.; Zhang, F.; Mu, J.; Zhao, H. A comparative research on TiAlN coatings reactively sputtered from powder and from smelting tial targets at various nitrogen flow rates. Appl. Surf. Sci. 2014, 313, 10–18. [Google Scholar] [CrossRef]

- Tezuka, Y.; Shin, S.; Ishii, T.; Ejima, T.; Suzuki, S.; Sato, S. Photoemission and bremsstrahlung isochromat spectroscopy studies of TiO2 (rutile) and SrTiO3. J. Phys. Soc. Jpn. 1994, 63, 347–357. [Google Scholar] [CrossRef]

- Prieto, P.; Kirby, R.E. X-ray photoelectron spectroscopy study of the difference between reactively evaporated and direct sputter-deposited TiN films and their oxidation properties. J. Vac. Sci. Technol. A 1995, 13, 2819–2826. [Google Scholar] [CrossRef]

- Hopfengärtner, G.; Borgmann, D.; Rademacher, I.; Wedler, G.; Hums, E.; Spitznagel, G.W. XPS studies of oxidic model catalysts: Internal standards and oxidation numbers. J. Electron Spectrosc. Relat. Phenom. 1993, 63, 91–116. [Google Scholar] [CrossRef]

- Bertóti, I. Characterization of nitride coatings by XPS. Surf. Coat. Technol. 2002, 151–152, 194–203. [Google Scholar] [CrossRef]

- Dejun, K.; Haoyuan, G. Friction-wear behaviors of cathodic arc ion plating AlTiN coatings at high temperatures. Tribol. Int. 2015, 88, 31–39. [Google Scholar] [CrossRef]

- Rizzo, A.; Mirenghi, L.; Massaro, M.; Galietti, U.; Capodieci, L.; Terzi, R.; Tapfer, L.; Valerini, D. Improved properties of tialn coatings through the multilayer structure. Surf. Coat. Technol. 2013, 235, 475–483. [Google Scholar] [CrossRef]

- Motamedi, P.; Cadien, K. XPS analysis of AlN thin films deposited by plasma enhanced atomic layer deposition. Appl. Surf. Sci. 2014, 315, 104–109. [Google Scholar] [CrossRef]

- Cai, F.; Zhang, S.; Li, J.; Chen, Z.; Li, M.; Wang, L. Effect of nitrogen partial pressure on Al–Ti–N films deposited by arc ion plating. Appl. Surf. Sci. 2011, 258, 1819–1825. [Google Scholar] [CrossRef]

- Zhou, M.; Makino, Y.; Nose, M.; Nogi, K. Phase transition and properties of Ti–Al–N thin films prepared by r.f.-plasma assisted magnetron sputtering. Thin Solid Films 1999, 339, 203–208. [Google Scholar] [CrossRef]

- Garfunkel, E.; Gusev, E.; Vul′, A. Fundamental Aspects of Ultrathin Dielectrics on Si-Based Devices; Springer Netherlands: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Yeung, W.Y.; Dub, S.N.; Wuhrer, R.; Milman, Y.V. A nanoindentatipon study of magnetron co-sputtered nanocrystalline ternanry nitride coatings. Sci. Sinter. 2006, 38, 212–214. [Google Scholar] [CrossRef]

- Patsalas, P.; Charitidis, C.; Logothetidis, S. The effect of substrate temperature and biasing on the mechanical properties and structure of sputtered titanium nitride thin films. Surf. Coat. Technol. 2000, 125, 335–340. [Google Scholar] [CrossRef]

| Deposition Temperature (°C) | N2 Flow Rate (sccm) |

|---|---|

| 200 | 20, 40, 60 |

| 500 | 20, 40, 60 |

| Temperature (°C) | Nitrogen Flow Rate (sccm) | Ti (at. %) | Al (at. %) |

|---|---|---|---|

| 200 | 20 | 51.46 | 48.54 |

| 40 | 48.47 | 51.53 | |

| 60 | 55.22 | 44.78 | |

| 500 | 20 | 56.24 | 43.76 |

| 40 | 58.04 | 41.96 | |

| 60 | 51.92 | 36.09 |

| Temperature (°C) | Nitrogen Flow Rate (sccm) | Thickness (µm) | RMS (nm) |

|---|---|---|---|

| 200 | 20 | 1.64 | 6.5 |

| 40 | 1.35 | 2.2 | |

| 60 | 0.81 | 1.0 | |

| 500 | 20 | 1.12 | 8.2 |

| 40 | 0.62 | 13.0 | |

| 60 | 0.68 | 13.9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obrosov, A.; Gulyaev, R.; Ratzke, M.; Volinsky, A.A.; Bolz, S.; Naveed, M.; Weiß, S. XPS and AFM Investigations of Ti-Al-N Coatings Fabricated Using DC Magnetron Sputtering at Various Nitrogen Flow Rates and Deposition Temperatures. Metals 2017, 7, 52. https://doi.org/10.3390/met7020052

Obrosov A, Gulyaev R, Ratzke M, Volinsky AA, Bolz S, Naveed M, Weiß S. XPS and AFM Investigations of Ti-Al-N Coatings Fabricated Using DC Magnetron Sputtering at Various Nitrogen Flow Rates and Deposition Temperatures. Metals. 2017; 7(2):52. https://doi.org/10.3390/met7020052

Chicago/Turabian StyleObrosov, Aleksei, Roman Gulyaev, Markus Ratzke, Alex A. Volinsky, Sebastian Bolz, Muhammad Naveed, and Sabine Weiß. 2017. "XPS and AFM Investigations of Ti-Al-N Coatings Fabricated Using DC Magnetron Sputtering at Various Nitrogen Flow Rates and Deposition Temperatures" Metals 7, no. 2: 52. https://doi.org/10.3390/met7020052

APA StyleObrosov, A., Gulyaev, R., Ratzke, M., Volinsky, A. A., Bolz, S., Naveed, M., & Weiß, S. (2017). XPS and AFM Investigations of Ti-Al-N Coatings Fabricated Using DC Magnetron Sputtering at Various Nitrogen Flow Rates and Deposition Temperatures. Metals, 7(2), 52. https://doi.org/10.3390/met7020052