1. Introduction

With the progress of nuclear fusion research, the need for new, advanced materials is becoming more urgent. For the International Thermonuclear Experimental Reactor (ITER), the choice of materials has been made. Thus, the area of the ITER’s first wall will be covered by armor produced from beryllium and the exhaust components will be covered by tungsten. However, materials for the next step of reactors will have to satisfy strict requirements for the lifetime and safety levels. Thus, nontoxic, highly durable and functional materials would be the prime choice for tokamak such as DEMO tokamak.

Until recently, pure tungsten was considered the most suitable plasma-facing material for the future reactor’s first wall. Its superiority over other materials was granted by the following group of properties: high resistance to sputtering, high melting point, good thermal conductivity, low thermal expansion and low tritium retention. Nevertheless, tungsten also has certain disadvantages, with thermally induced grain growth (depending on its thermomechanical history, starting at temperatures as low as 1000 °C) among the most serious. Thus, in the conditions of fusion plasma and plasma disruptions, excessive grain growth leads to the degradation of mechanical properties, which subsequently causes premature failure of the plasma-facing component during heat cycling. A further problem arises during exposure of the tungsten to the irradiated particles, such as those of helium and deuterium present in the fusion plasma. The particles penetrate into the material bulk and under specific conditions, such as high particle fluencies, the crystalline lattice becomes supersaturated which leads to blister or helium fuzz formation [

1] and, therefore, the further degradation of the mechanical properties. Another concern of tungsten’s behavior is related to the formation of tungsten oxides in the presence of oxygen. Tungsten trioxide represents a serious risk in the case of reactor accidents under which oxygen or oxygen-containing compounds (such as coolant water) enter the reactor chamber. The formation of volatile tungsten trioxide could lead to radiation escaping into the surrounding environment. Thus, efforts to develop a smart tungsten material that can suppress thermal and radiation degradation as well as the formation of volatile oxides have emerged recently.

Most recent attempts to improve tungsten properties have been conducted through the modification of tungsten’s microstructure and the addition of minor alloying elements. Many of the developed materials show promising results. For example, some studies point out that ultrafine-grained tungsten not only has better mechanical properties but is also significantly more resistant to irradiation from ions [

2]. In order to stabilize the grain size at higher temperatures, tungsten with a particle dispersion has been developed. In the case of tungsten, usually small amounts of oxides, e.g., Y

2O

3, La

2O

3 (ODS—oxide dispersion strengthening), or carbides of transition metals, e.g., TiC (CDS, carbide dispersion strengthening), are added [

3,

4]. The suppression of the formation of volatile tungsten oxide has been suggested by the formation of tungsten self-passivating alloys [

5] consisting of W with the addition of Cr and Ti or Si. In the oxidation atmosphere, complex Cr-W oxide layers are formed, encapsulating the tungsten oxides at the surface of the armor. However, the effect of the various alloying elements is still being studied.

Since the melting temperature of tungsten is the highest among the chemical elements, the powder metallurgy accompanied by mechanical alloying is the obvious choice of alloying method. The spark plasma sintering method provides the exceptional advantage of fast heating/cooling rates when compared to conventional sintering methods. Therefore, a high sintering temperature is achieved simultaneously with the suppression of unwanted grain growth. In the present study, we attempted to prepare W-Ti alloys with the addition of HfC or Hf by means of mechanical alloying. According to our experience, HfC has a tendency to oxidize either during mechanical alloying or during sintering to form HfO2. In this way, the mitigation of Ti oxidation was approached. The alloys were analyzed for their phase composition during each individual step of the preparation. Thus, the alloying process can be better understood and used for further tailoring of the alloys. The phases were correlated with the microstructural information. Basic mechanical properties of the prepared alloys were analyzed and the effect of the addition of Ti was discussed. The effect of the alloying elements on room- and high-temperature thermal conductivity was studied as it remains overlooked in the majority of published studies due to the low amounts of alloying elements.

2. Materials and Methods

The powder batches of composition W-3 wt. % Ti-2 wt. % HfC, W-7 wt. % Ti-2 wt. % HfC, W-3 wt. % Ti-2 wt. % Hf and W-7 wt. % Ti-2 wt. % Hf (see

Table 1) were prepared in a planetary ball mill Pulverisette 5 (Fritsch, Germany). The starting powders were W (99.9% purity, 1.2 μm average powder size), Ti (99.4% purity, 5 µm average powder diameter size), Hf (bimodal powder diameter size distribution, 15 µm and 45 µm) and HfC (bimodal powder diameter size distribution, 5 µm and 20 µm). For the ball milling process, the powders were loaded in tungsten carbide bowls with tungsten carbide grinding balls in the ball to powder ratio (BPR) 11:1. High purity argon was used as protective atmosphere in order to prevent oxidation during the milling process. The summary of the milling parameters can be found in

Table 1. The powders were consolidated by pulsed electric current sintering machine SPS 10-4 (Thermal Technology, Santa Rosa, CA, USA) under similar sintering conditions, i.e., sintering temperature 1750 °C, pressure of 70 MPa, vacuum of 10 Pa and sintering time of 3 min. Sintering was performed in graphite molds and graphite foils or graphite foils covered by hexagonal boron nitride (BN). All milling and sintering parameters are summarized in

Table 1.

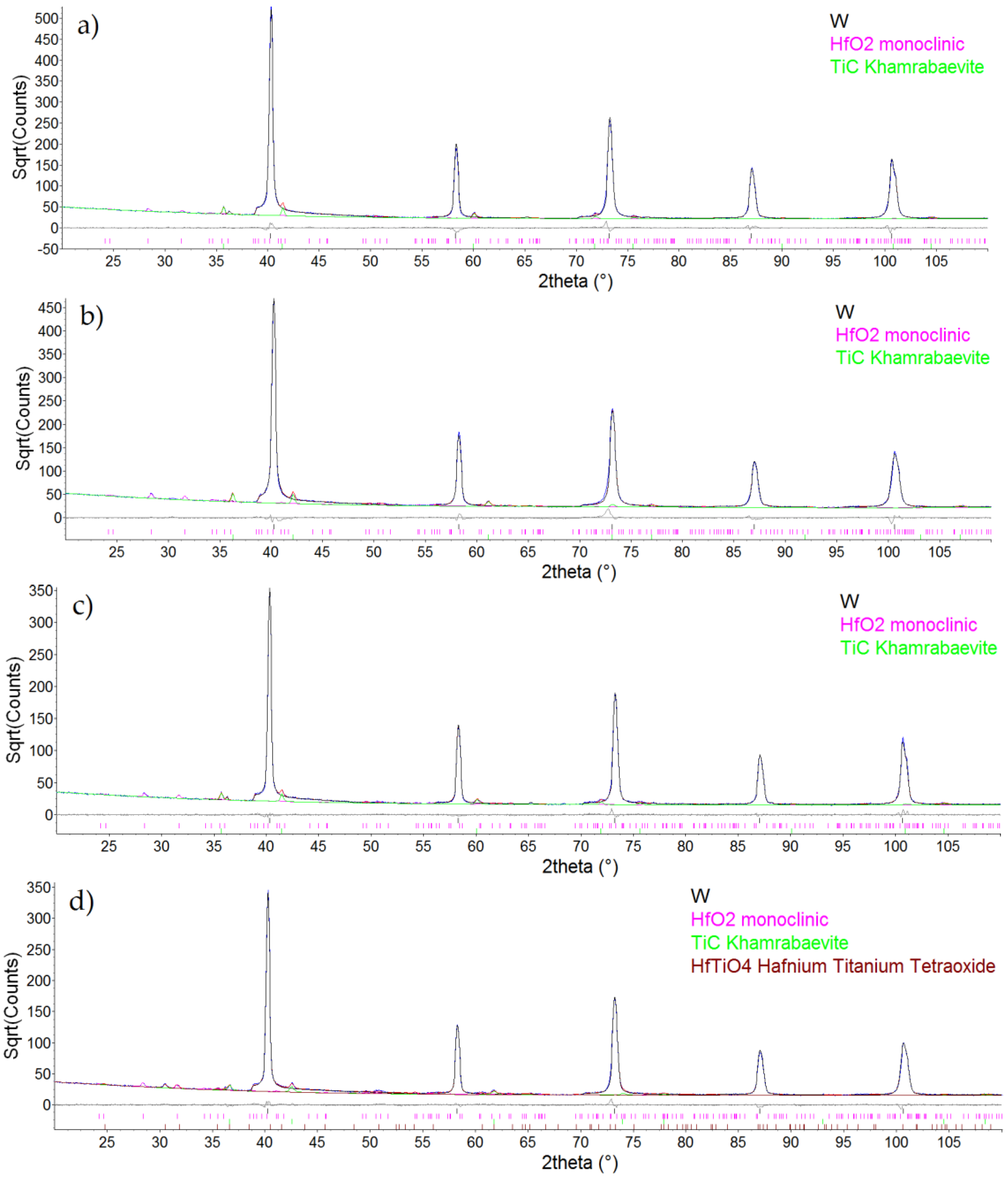

Phase compositions and lattice parameters were determined from X-ray diffraction (XRD) patterns obtained at room temperature by CuKα (divergent beam was used for mechanically alloyed powders and parallel beam of 1 mm diameter in the middle of the cross section cut was used for sintered samples) and 1D LynxEye detector (Bruker, Karlsruhe, Germany) (Ni β filter in front of the detector) mounted on Bruker D8 Discover (Bruker, Karlsruhe, Germany) and subsequent Rietveld refinement [

6] was performed in TOPAS 5 (Bruker, Karlsruhe, Germany) [

7].

The flexure strength was measured using universal tensile test machine Instron 1362 (Instron, High Wycombe, UK) with support diameter of 5 mm, support span of 14.55 mm and loading rate of 0.2 mm/min.

The hardness was evaluated on a universal hardness tester Nexus 4504 (Innovatest, Maastricht, The Netherland) using Vickers indenter, load equivalent to 1 kg and dwell time of 10 s.

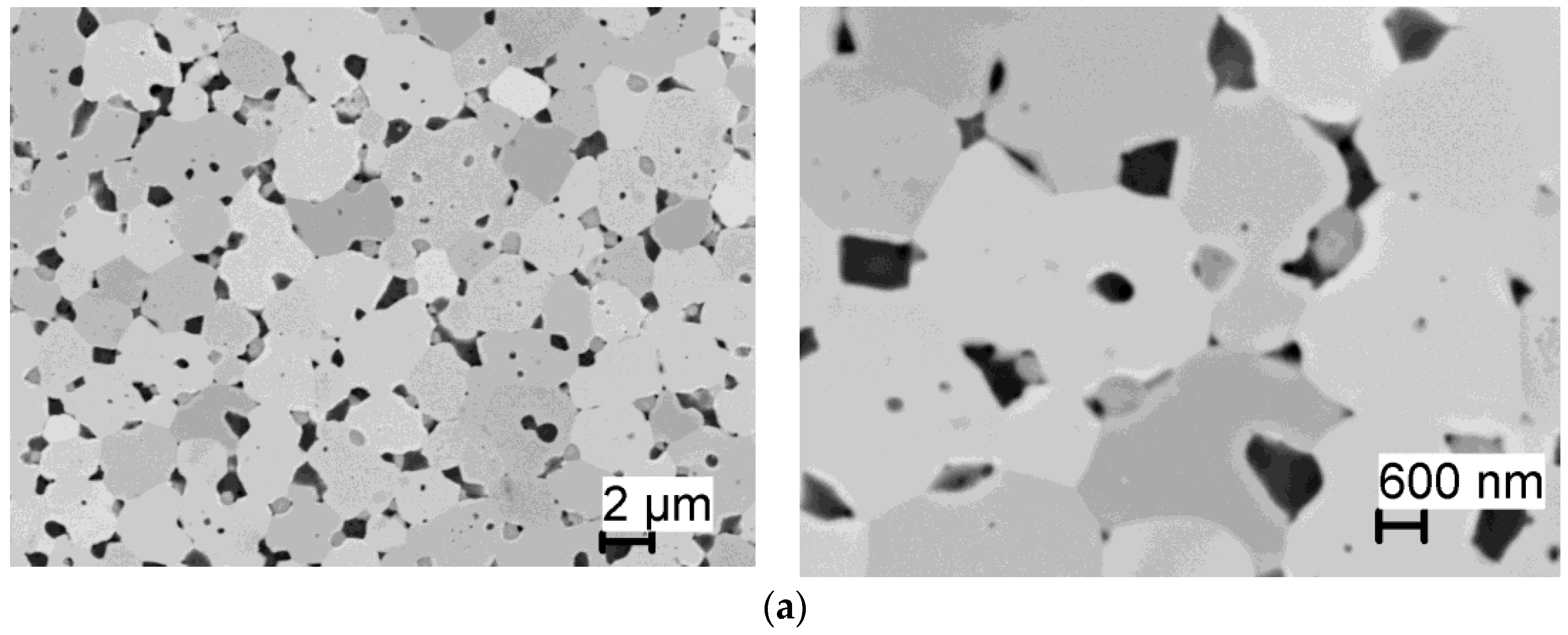

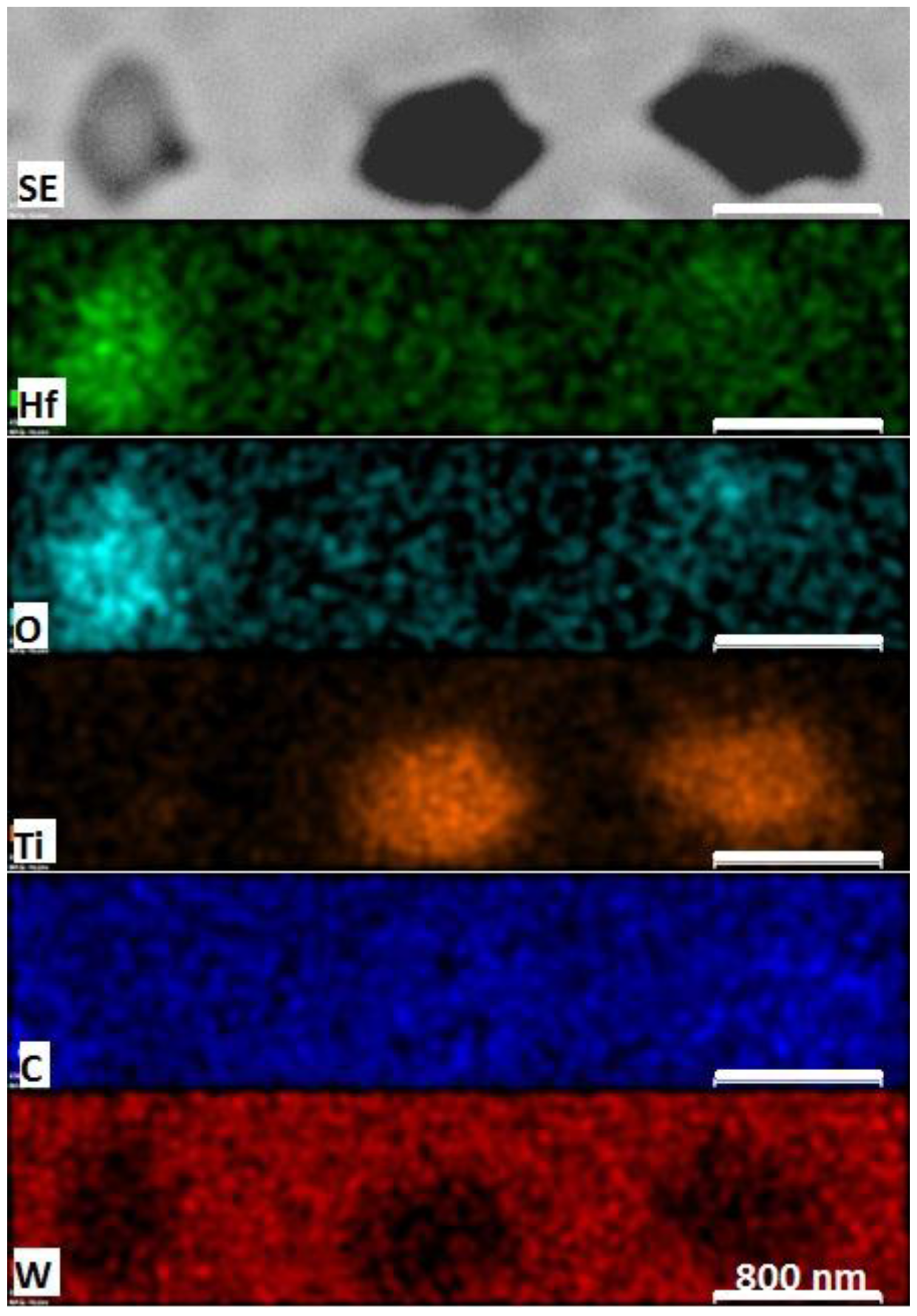

The microstructure was evaluated on polished cross-sections using SEM EVO MA 15 (Carl Zeiss SMT, Oberkochen, Germany) in backscattered mode and equipped with EDS detector XFlash® 5010 (Bruker, Karlsruhe, Germany).

The thermal diffusivity (α) and specific heat capacity (Cp) of the samples were measured by a laser-flash method on an LFA 1000 apparatus (Linseis, Selb, Germany) in vacuum at RT, 100, 300, 500, 700, 900, 1100 and 1300 °C. The thermal conductivity (λ) was calculated utilizing the relationship λ = ραCp, where ρ is material density. The samples were cut into 10 mm × 10 mm size and thickness was approximately 2 mm. Data were averaged from at least four measurements at each temperature.

4. Discussion

After the sintering of the alloyed powders, new phases emerged, i.e., (Ti,W,Hf)C and HfO

2. Micrographs of the sintered materials proved the TiC phase was located at grain boundaries, where it can play an important role together with HfO

2 in grain stabilization at high temperatures by pinning grain boundaries. The dispersion of TiC particles supports the assumption of carbon surface diffusion through the powder materials and carbon grain boundary diffusion (in the later stage of sintering). The high affinity of carbon to titanium caused the depletion of excess Ti from the W-Ti matrix. Alloys with 7% Ti contained higher number of larger (Ti,W,Hf)C particles, as the higher amount of Ti led to particle coarsening. Besides the W-Ti solid solution, (Ti,W,Hf)C and HfO

2 (and HfTiO

4 in one case), the presence of additional phases was not confirmed. A number of research results reported on the formation of Ti-rich phases in W-Ti, e.g., Ti pools in W-2 wt. %Ti-0.5%Y

2O

3 and W-4 wt. %Ti-0.5%Y

2O

3 [

12], in W-10 wt. %Ti [

13] and in WCr12Ti2.5 [

5]. Considering the potential high-temperature applications of the alloys, the formation of Ti pools or Ti-rich solid solution is undesirable due to the low melting point of such phases (for pure titanium it is 1668 °C). The materials studied in this work maintained a high melting point, as the only Ti-rich phase confirmed by XRD was complex (Ti,W,Hf)C with a melting point most likely around that of TiC (i.e., 3160 °C), and the melting point of WC is around 2830 °C.

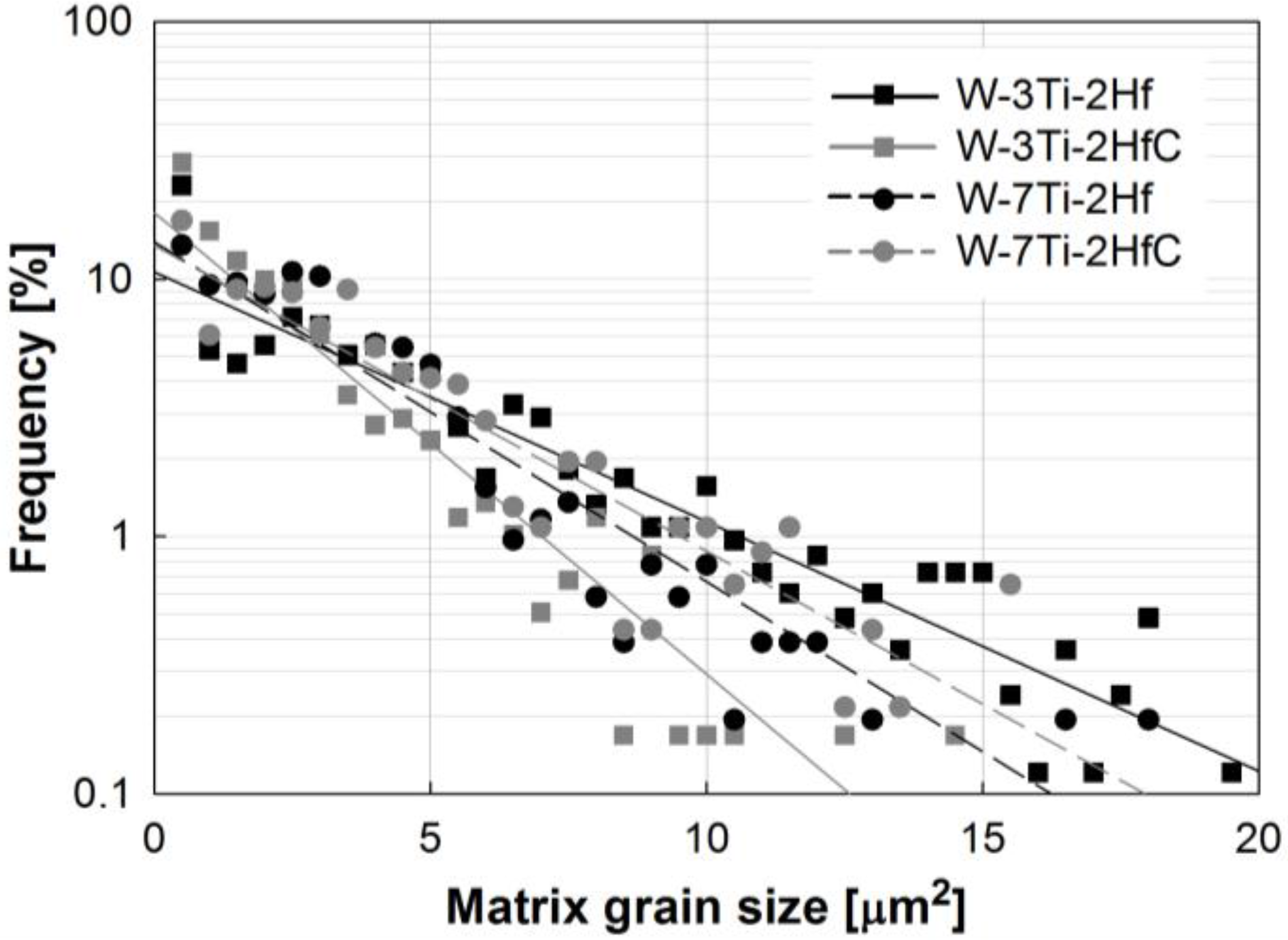

The matrix of the prepared materials consists of fine grains, mostly in the size range of 1 µm–5 µm diameter. It seems there is only a slight effect of the addition of titanium on the matrix grain size distribution. Alloys with 7% Ti have a slightly higher frequency of fine grains, likely due to higher occurrence of larger carbide particles.

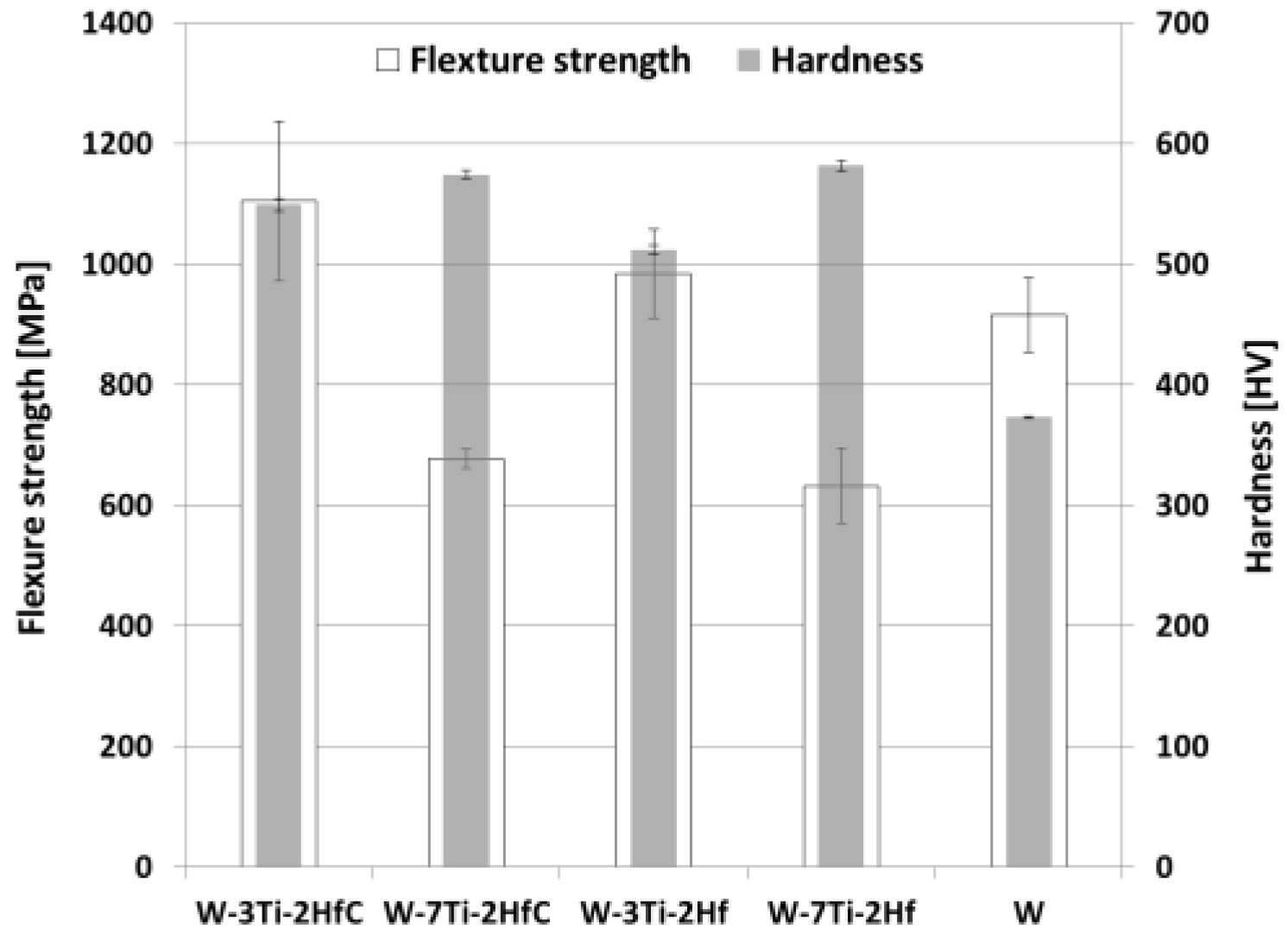

The effect of titanium on the bending strength of the prepared materials strongly depends on the added amount of Ti. It seems there is a threshold content of titanium in W, above which the bending strength starts to decrease and becomes smaller than that of pure sintered tungsten. Nevertheless, it also seems that the effect might be different when other secondary phases are added. Authors in [

14] report an opposite trend in the bending strength for W-4Ti-0.5Y

2O

3 and W-2Ti-0.47-Y

2O

3, i.e., with an increasing content of Ti, the strength increases. However, the bending strength of alloys in the mentioned study still remained below the room-temperature strength of pure tungsten. The hardness of the prepared alloys increased with respect to the pure tungsten due to the increase in the dislocation density caused by ball milling, grain refinement and mainly due to the presence of hard particle dispersion. The hardness value was slightly lower for alloys containing 3% Ti as the frequency of carbide particles in each size category was lower.

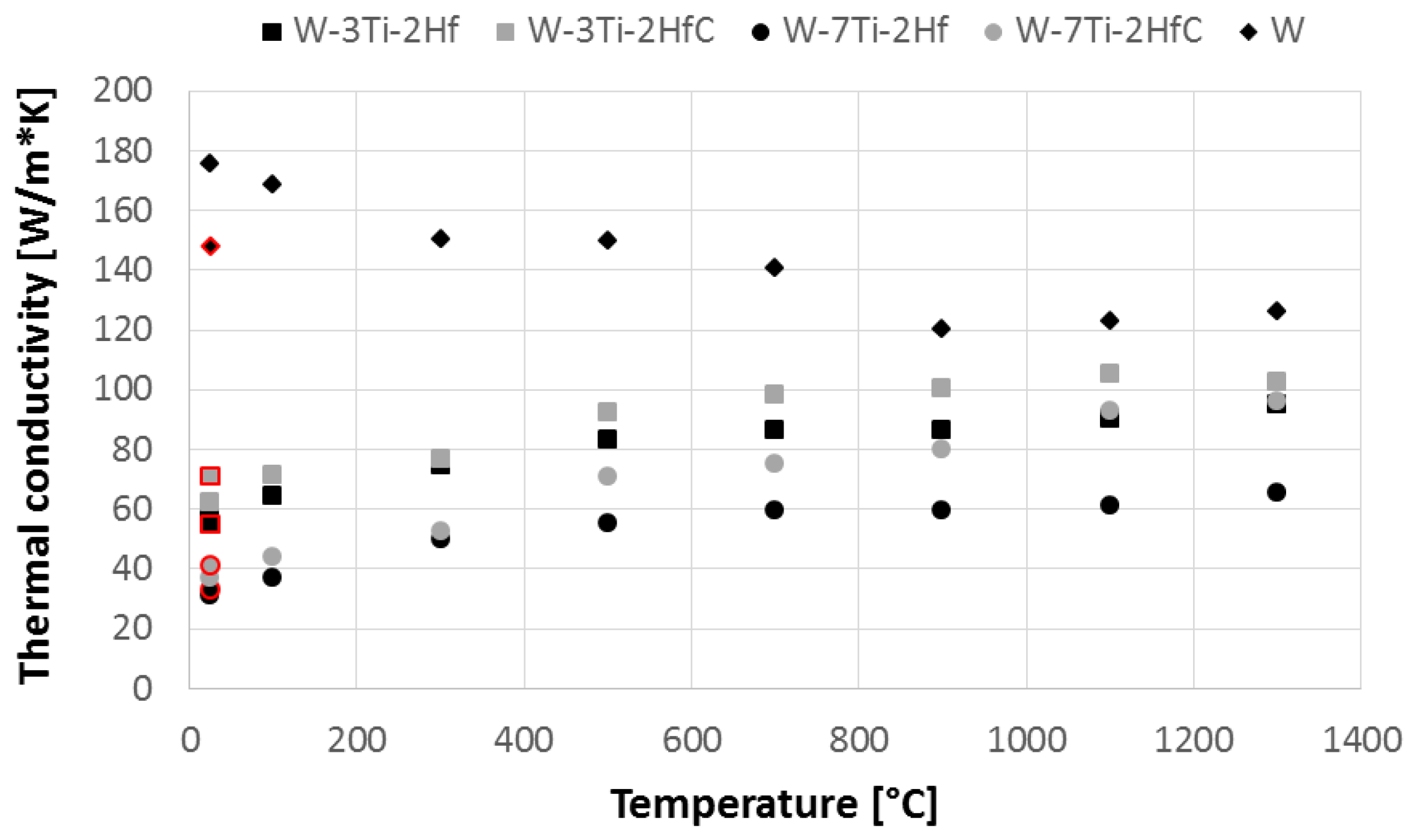

The results of the thermal conductivity showed a major decrease for the prepared alloys when compared to pure tungsten. According to the rule of mixture and the Maxwell-Garnett model applied on W-3Ti-2HfC and W-7Ti-2HfC with respect to the volumetric representation of the XRD results, the room-temperature thermal conductivity due to the second-phase dispersion should not decrease by more than 26% (according to rule of mixture the values are 155 W/(K·m) and 144 W/(K·m), respectively; according to the Maxwell-Garnett model they are 146 W/(K·m) and 133 W/(K·m), respectively) [

15]. The calculated numbers were significantly higher than the measured values which might imply a significant influence of Ti dissolved in the tungsten lattice. The thermal conductivity of the prepared materials grew with the temperature, which is a less common phenomenon. That can also be attributed to the Ti dissolved in the W matrix. However, from 900 °C the thermal conductivity of W-3Ti-HfC alloy was only 20 W/(K·m) smaller than that of pure tungsten. Although at higher temperatures the difference in the thermal conductivity was minimized, the authors believe that an additional improvement might be possible by lowering the titanium content or additional thermomechanical processing. For example, in [

16] a dramatic improvement of thermal conductivity for W-TaC alloys was reached after hot rolling.

The lower rate in the thermal conductivity increase for W-7Ti-2Hf was probably caused by the presence of HfTiO4.

Acknowledgments

This work was financially supported by the grant GAČR 15-15609S. One author, O.M., is grateful for financial support from the grant SVV-2016-260213.

Author Contributions

All the authors contributed equally to this research by conducting the experiments and by finalization of the manuscript. F.L., M.V. and T.C. contributed with preparation and finalization of manuscript, F.L. with XRD method results, M.V. with SEM method results , milling and sintering optimization, B.N. with laser-flash method, J.K. with mechanical properties testing, O.M. with powders and samples preparation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shu, W.M.; Kawasuso, A.; Yamanishi, T. Recent findings on blistering and deuterium retention in tungsten exposed to high-fluence deuterium plasma. J. Nucl. Mater. 2009, 386–388, 356–359. [Google Scholar] [CrossRef]

- El-Atwani, O.; Gonderman, S.; Efe, M.; de Temmerman, G.; Morgan, T.; Bystrov, K.; Klenosky, D.; Qiu, T.; Allain, J.P. Ultrafine tungsten as a plasma-facing component in fusion devices: Effect of high flux, high fluence low energy helium irradiation. Nucl. Fusion 2014, 54, 83013. [Google Scholar] [CrossRef]

- Rieth, M.; Boutard, J.L.; Dudarev, S.L.; Ahlgren, T.; Antusch, S.; Baluc, N.; Barthe, M.-F.; Becquart, C.S.; Ciupinski, L.; Correia, J.B.; et al. Review on the EFDA programme on tungsten materials technology and science. J. Nucl. Mater. 2011, 417, 463–467. [Google Scholar] [CrossRef]

- Vilémová, M.; Pala, Z.; Jäger, A.; Matějíček, J.; Chernyshova, M.; Kowalska-Strzęciwilk, E.; Tonarová, D.; Gribkov, V.A. Evaluation of surface, microstructure and phase modifications on various tungsten grades induced by pulsed plasma loading. Phys. Scr. 2016, 91, 34003. [Google Scholar] [CrossRef]

- López-Ruiz, P.; Ordás, N.; Iturriza, I.; Walter, M.; Gaganidze, E.; Lindig, S.; Koch, F.; García-Rosales, C. Powder metallurgical processing of self-passivating tungsten alloys for fusion first wall application. J. Nucl. Mater. 2013, 442, S219–S224. [Google Scholar] [CrossRef]

- Rietveld, H.M. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. 1967, 22, 151–152. [Google Scholar] [CrossRef]

- Coelho, A.A. TOPAS, version 5 (Computer Software); Coelho Software: Brisbane, Australia, 2016.

- Waseda, Y.; Hirata, K.; Ohtani, M. High-temperature thermal expansion of platinum, tantalum, molybdenum, and tungsten measured by X-ray diffraction. High Temp. High Press. 1975, 7, 221–226. [Google Scholar]

- Levinger, W.B. Lattice parameters of beta titanium at room temperature. J. Met. 1953, 5, 195. [Google Scholar]

- Rudy, E. Constitution of ternary titanium-tungsten-carbon alloys. J. Less Common Met. 1973, 33, 245–273. [Google Scholar] [CrossRef]

- Murray, P.; Weston, J.E. The 1700 °C isothermal section of the pseudoternary system TiC-ZrC-HfC. J. Less Common Met. 1981, 81, 173–179. [Google Scholar] [CrossRef]

- Aguirre, M.V.; Martín, A.; Pastor, J.Y.; LLorca, J.; Monge, M.A.; Pareja, R. Mechanical properties of Y2O3-doped W-Ti alloys. J. Nucl. Mater. 2010, 404, 203–209. [Google Scholar] [CrossRef]

- Dai, W.; Liang, S.; Luo, Y.; Yang, Q. Effect of W powders characteristics on the Ti-rich phase and properties of W–10 wt. % Ti alloy. Int. J. Refract. Met. Hard Mater. 2015, 50, 240–246. [Google Scholar] [CrossRef]

- Aguirre, M.V.; Martín, A.; Pastor, J.Y.; LLorca, J.; Monge, M.A.; Pareja, R. Mechanical properties of tungsten alloys with Y2O3 and titanium additions. J. Nucl. Mater. 2011, 417, 516–519. [Google Scholar] [CrossRef] [Green Version]

- Garnett, J.C.M. Colours in Metal Glasses, in Metallic Films, and in Metallic Solutions. II. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 1906, 205, 237–288. [Google Scholar] [CrossRef]

- Miao, S.; Xie, Z.M.; Yang, X.D.; Liu, R.; Gao, R.; Zhang, T.; Wang, X.P.; Fang, Q.F.; Liu, C.S.; Luo, G.N.; et al. Effect of hot rolling and annealing on the mechanical properties and thermal conductivity of W-0.5 wt. % TaC alloys. Int. J. Refract. Met. Hard Mater. 2016, 56, 8–17. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).