A Study on the Aging Behavior of Al6061 Composites Reinforced with Y2O3 and TiC

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

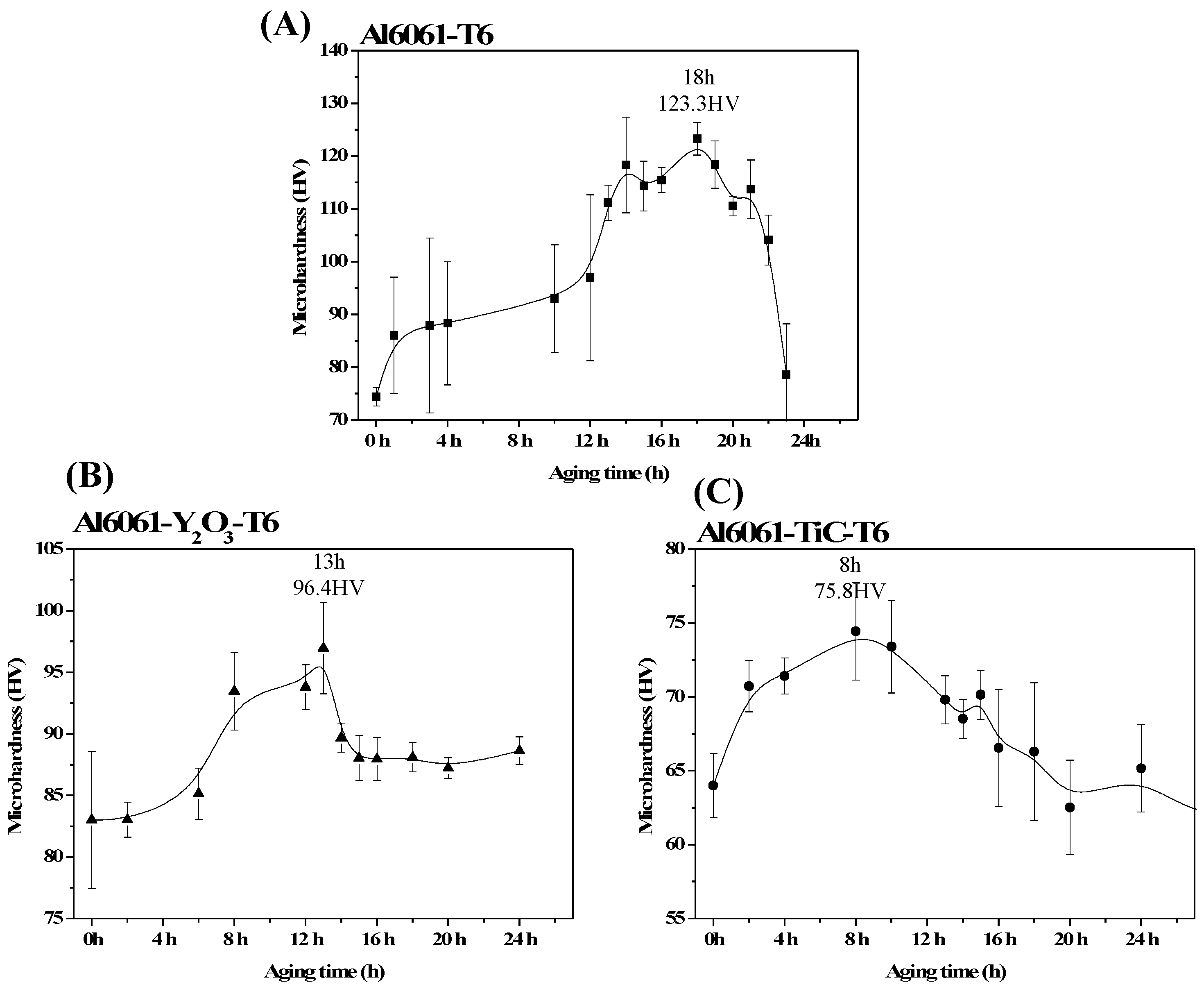

3.1. Aging Hardness

3.2. Evolution of Microstructure

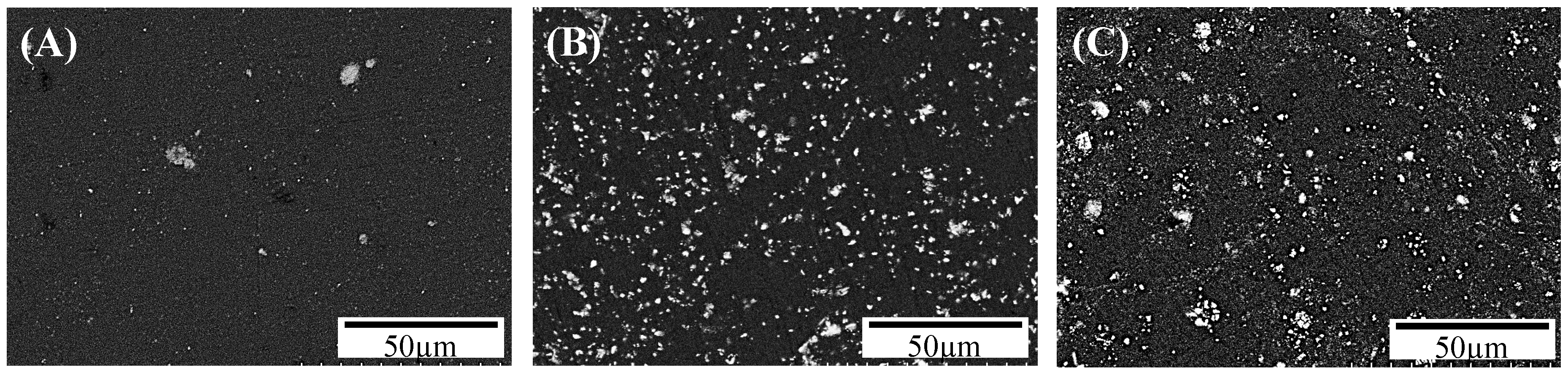

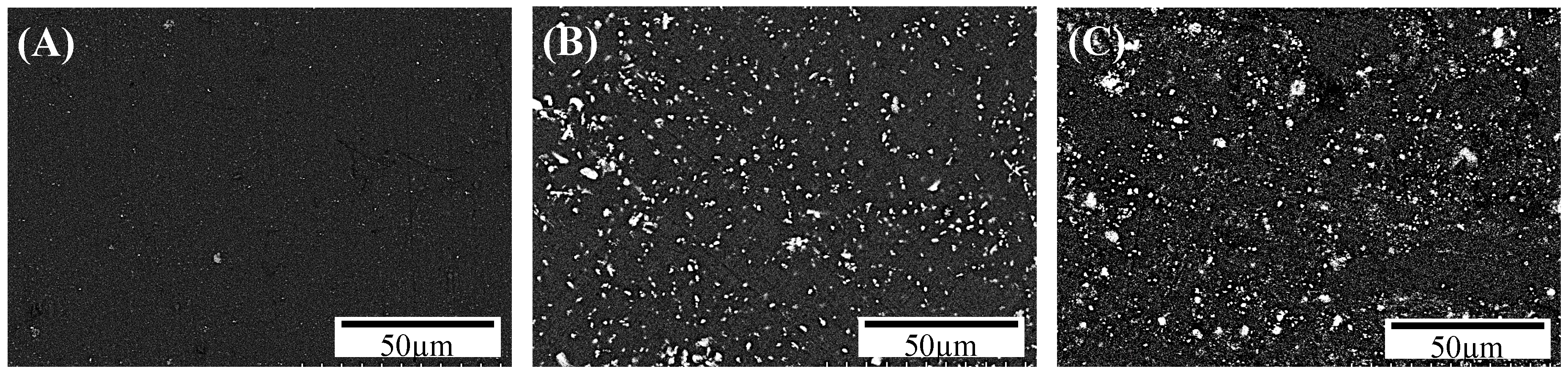

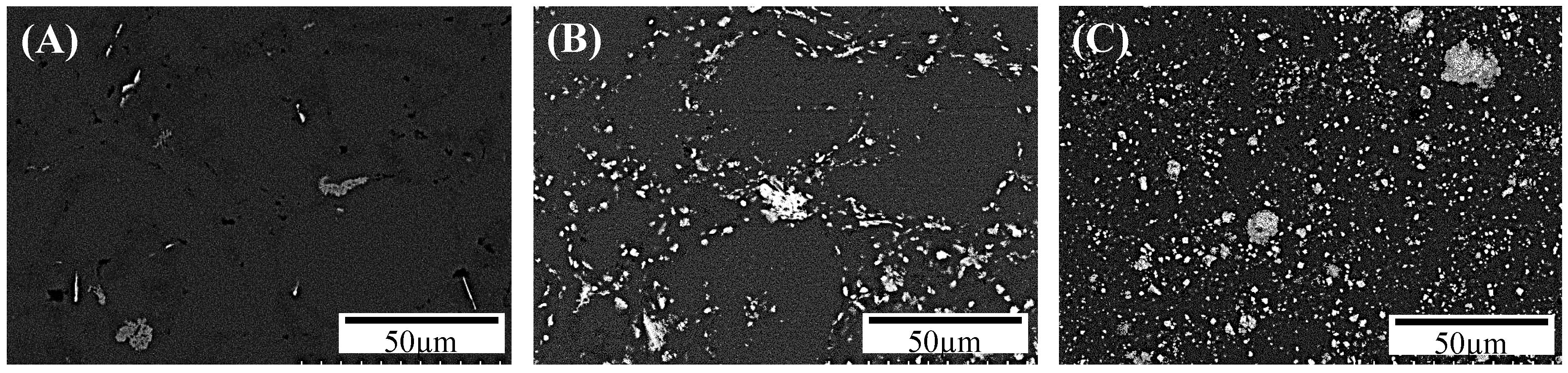

3.2.1. SEM Observation

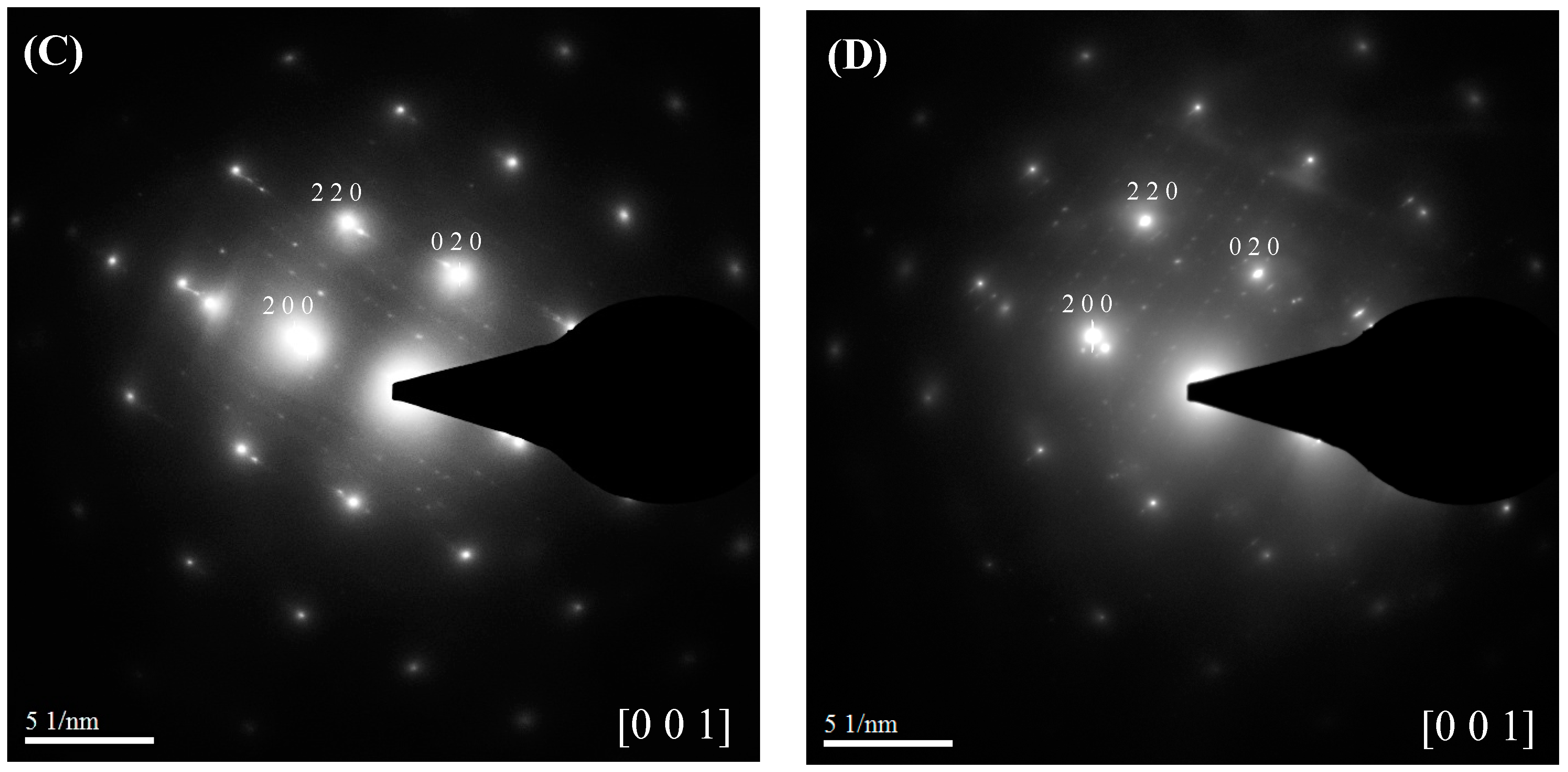

3.2.2. TEM Investigation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, Y.Q.; Cong, H.T.; Wang, W.; Sun, C.H.; Cheng, H.M. AlN nanoparticle-reinforced nanocrystalline Al matrix composites: Fabrication and mechanical properties. Mater. Sci. Eng. A 2009, 505, 151–156. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Li, Y.L.; Liang, Y.; Zheng, F.; Bi, J.; Tjong, S.C. Nanometric Si3N4 particulate-reinforced aluminum composite. Mater. Sci. Eng. A 1996, 219, 229–231. [Google Scholar] [CrossRef]

- Gupta, M.; Surappa, M.K.; Qin, S. Development of Aluminium Based Silicon Carbide Particulate Metal Matrix Composite. J. Mater. Process. Technol. 1997, 67, 94–99. [Google Scholar] [CrossRef]

- Rahimian, M.; Parvin, N.; Ehsani, N.; Mater, A. Investigation of particle size and amount of alumina on microstructure and mechanical properties of Al matrix composite made by powder metallurgy. Mater. Sci. Eng. A 2010, 527, 1031–1038. [Google Scholar] [CrossRef]

- Ahamed, H.; Senthilkumar, V. Hybrid Aluminium Metal Matrix Composites and Reinforcement Materials: A Review. Mater. Des. 2012, 37, 182–192. [Google Scholar] [CrossRef]

- Nemati, N.; Khosroshahi, R.; Emamy, M.; Zolriasatein, A. Sintering and Hardness Behavior of Fe-Al2O3 Metal Matrix Nanocomposites Prepared by Powder Metallurgy. Mater. Des. 2011, 32, 3718–3729. [Google Scholar] [CrossRef]

- Fogagnolo, J.B.; Robert, M.H.; Torralba, J.M. Mechanically alloyed AlN particle-reinforced Al-6061 matrix composites: Powder processing, consolidation and mechanical strength and hardness of the as-extruded materials. Mater. Sci. Eng. A 2006, 426, 229–231. [Google Scholar] [CrossRef]

- Krizik, P.; Balog, M.; Matko, I.; Sr, P.S.; Cavojsky, M.; Simancik, F. The effect of a particle–matrix interface on the Young’s modulus of Al–SiC composites. J. Compos. Mater. 2015, 1–10. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Schultz, B.F.; Ferguson, J.B.; Omrani, E.; Rohatgi, P.K.; Gupta, N. Functional Metal Matrix Composites: Self-lubricating, Self-healing, and Nanocomposites-An Outlook. JOM 2014, 66, 872–881. [Google Scholar] [CrossRef]

- Zhang, Z.; Topping, T.; Li, Y.; Vogt, R.; Zhou, Y.; Haines, C.; Paras, J.; Kapoor, D.; Schoenung, J.M.; Lavernia, E.J. Mechanical behavior of ultrafine-grained Al composites reinforced with B4C nanoparticles. Scr. Mater. 2011, 65, 652–655. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.; Vogt, R.; Schoenung, J.M.; Lavernia, E.J. Boundaries and interfaces in ultrafine grain composites. Acta Mater. 2011, 59, 7206–7218. [Google Scholar] [CrossRef]

- Chen, C.-L.; Lin, C.-H. Effect of Y2O3 and TiC Reinforcement Particles on Intermetallic Formation and Hardness of Al6061 Composites via Mechanical Alloying and Sintering. Metall. Mater. Trans. A 2015, 46, 3687–3695. [Google Scholar] [CrossRef]

- Li, B.; Zeng, B.L.H.; Fan, W.; Bai, Z. Effect of aging on interface characteristics of Al–Mg–Si/SiC composites. J. Alloy. Compd. 2015, 649, 495–499. [Google Scholar] [CrossRef]

- Maisonnette, D.; Suery, M.; Nelias, D.; Chaudet, P.; Epicier, T. Effects of heat treatments on the microstructure and mechanical properties of A 6061 aluminium alloy. Mater. Sci. Eng. A 2011, 528, 2718–2724. [Google Scholar] [CrossRef]

- Rao, P.N.; Singh, D.; Brokmeier, H.-G.; Jayaganthan, R. Effect of ageing on tensile behavior of ultrafine grained Al6061 alloy. Mater. Sci. Eng. A 2015, 641, 391–401. [Google Scholar] [CrossRef]

- Dong, R.; Yang, W.; Yu, Z.; Wu, P.; Hussain, M.; Jiang, L.; Wu, G. Aging behavior of 6061Al matrix composite reinforced with high content SiC nanowires. J. Alloy. Compd. 2015, 649, 1037–1042. [Google Scholar] [CrossRef]

- Lang, P.; Karadeniz, E.P.; Falahati, A.; Kozeschnik, E. Simulation of the effect of composition on the precipitation in 6xxx Al alloys during continuous heating DSC. J. Alloy. Compd. 2014, 612, 443–449. [Google Scholar] [CrossRef]

- Vissers, R.; van Huis, M.A.; Jansen, J.; Zandbergen, H.W.; Marioara, C.D.; Andersen, S.J. The crystal structure of the β′ phase in Al–Mg–Si alloys. Acta Mater. 2007, 55, 3815–3823. [Google Scholar] [CrossRef]

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.-L.; Lin, C.-H. A Study on the Aging Behavior of Al6061 Composites Reinforced with Y2O3 and TiC. Metals 2017, 7, 11. https://doi.org/10.3390/met7010011

Chen C-L, Lin C-H. A Study on the Aging Behavior of Al6061 Composites Reinforced with Y2O3 and TiC. Metals. 2017; 7(1):11. https://doi.org/10.3390/met7010011

Chicago/Turabian StyleChen, Chun-Liang, and Chen-Han Lin. 2017. "A Study on the Aging Behavior of Al6061 Composites Reinforced with Y2O3 and TiC" Metals 7, no. 1: 11. https://doi.org/10.3390/met7010011

APA StyleChen, C.-L., & Lin, C.-H. (2017). A Study on the Aging Behavior of Al6061 Composites Reinforced with Y2O3 and TiC. Metals, 7(1), 11. https://doi.org/10.3390/met7010011