Hot Tensile and Fracture Behavior of 35CrMo Steel at Elevated Temperature and Strain Rate

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

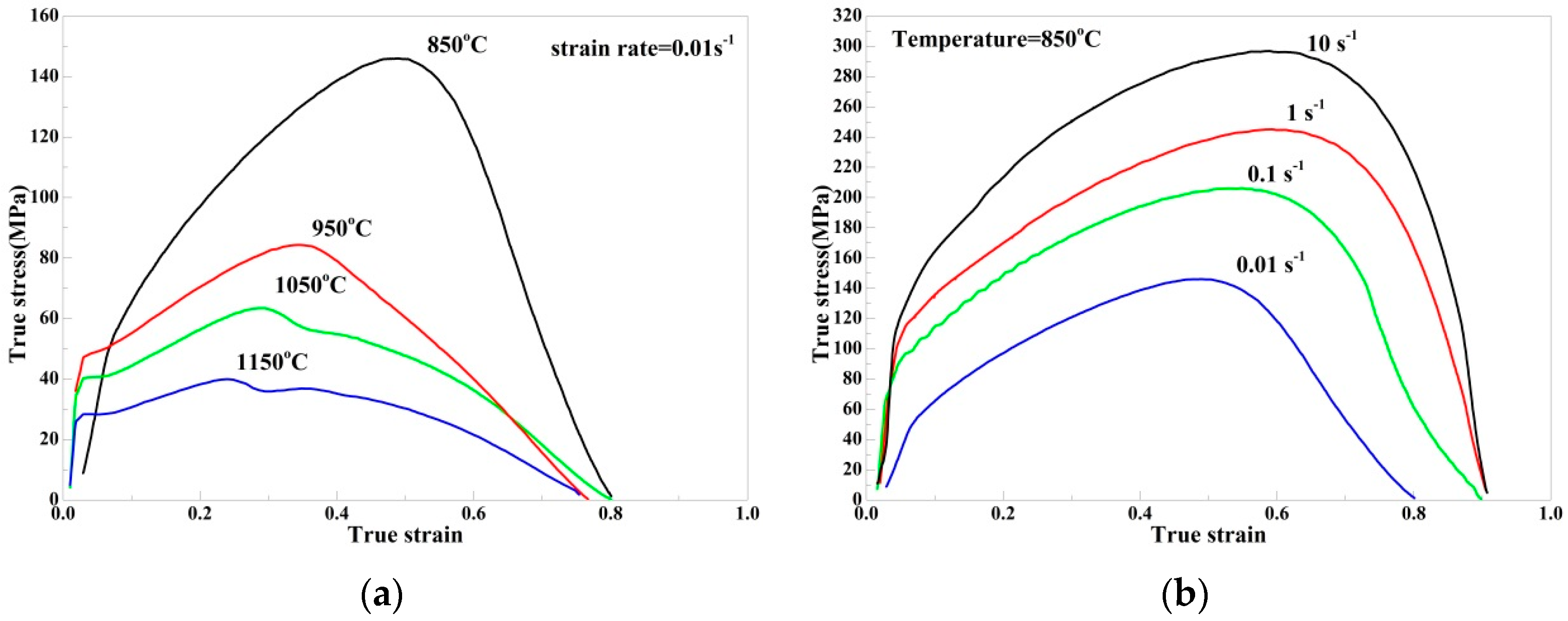

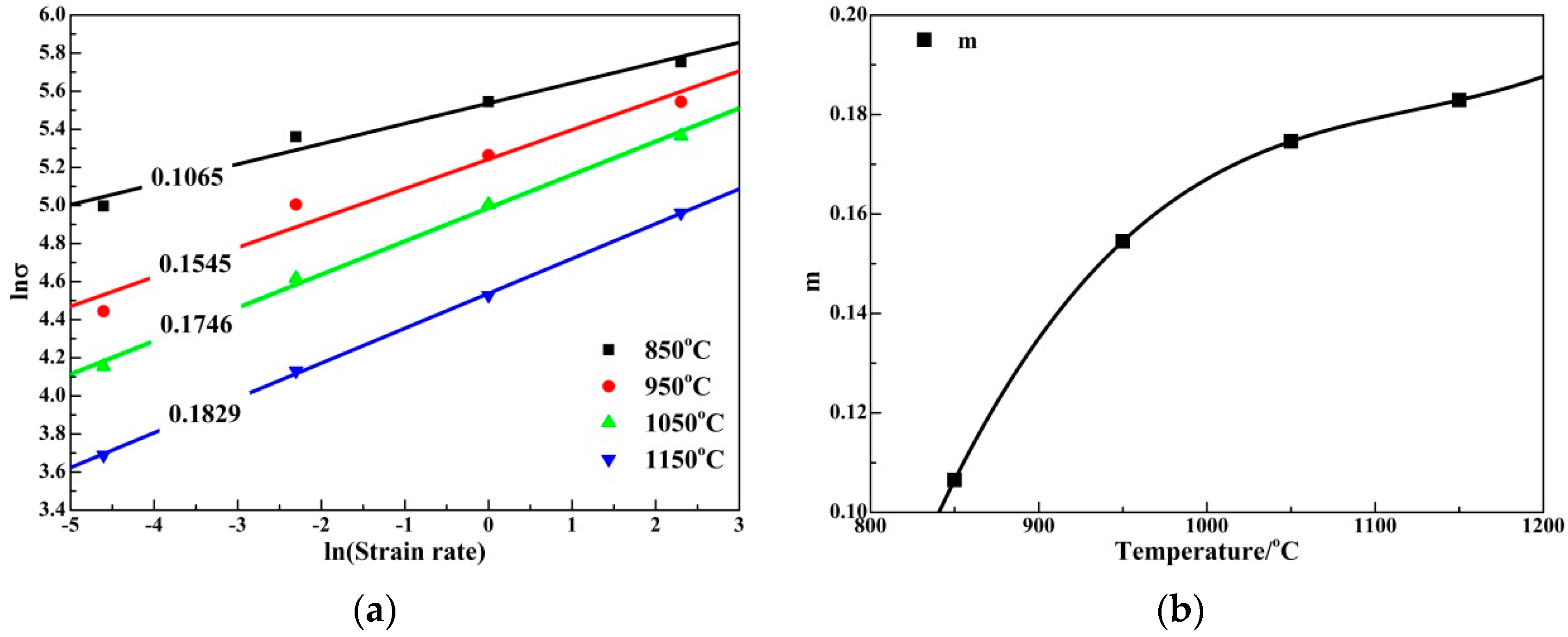

3.1. Hot Tensile Behavior

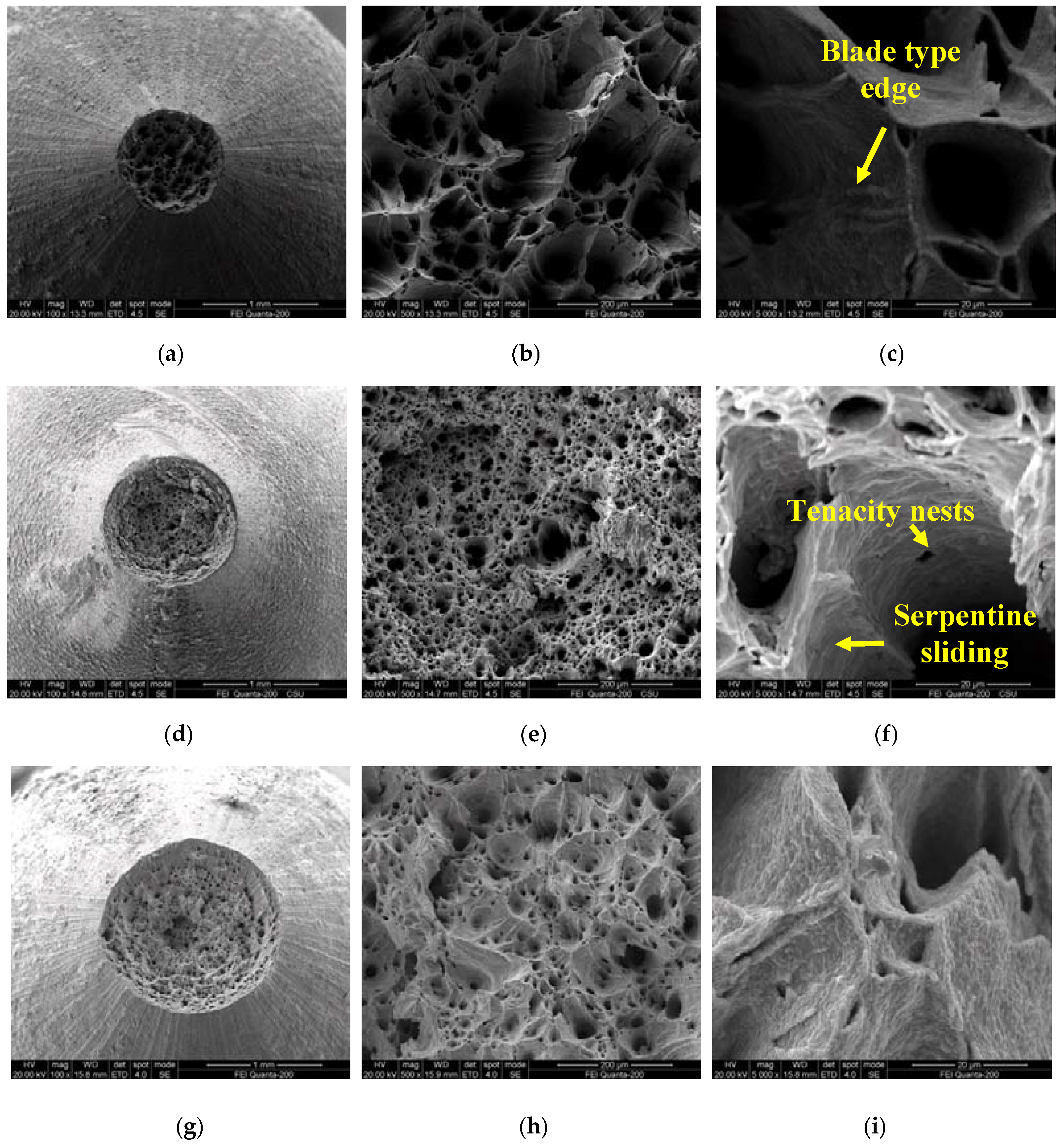

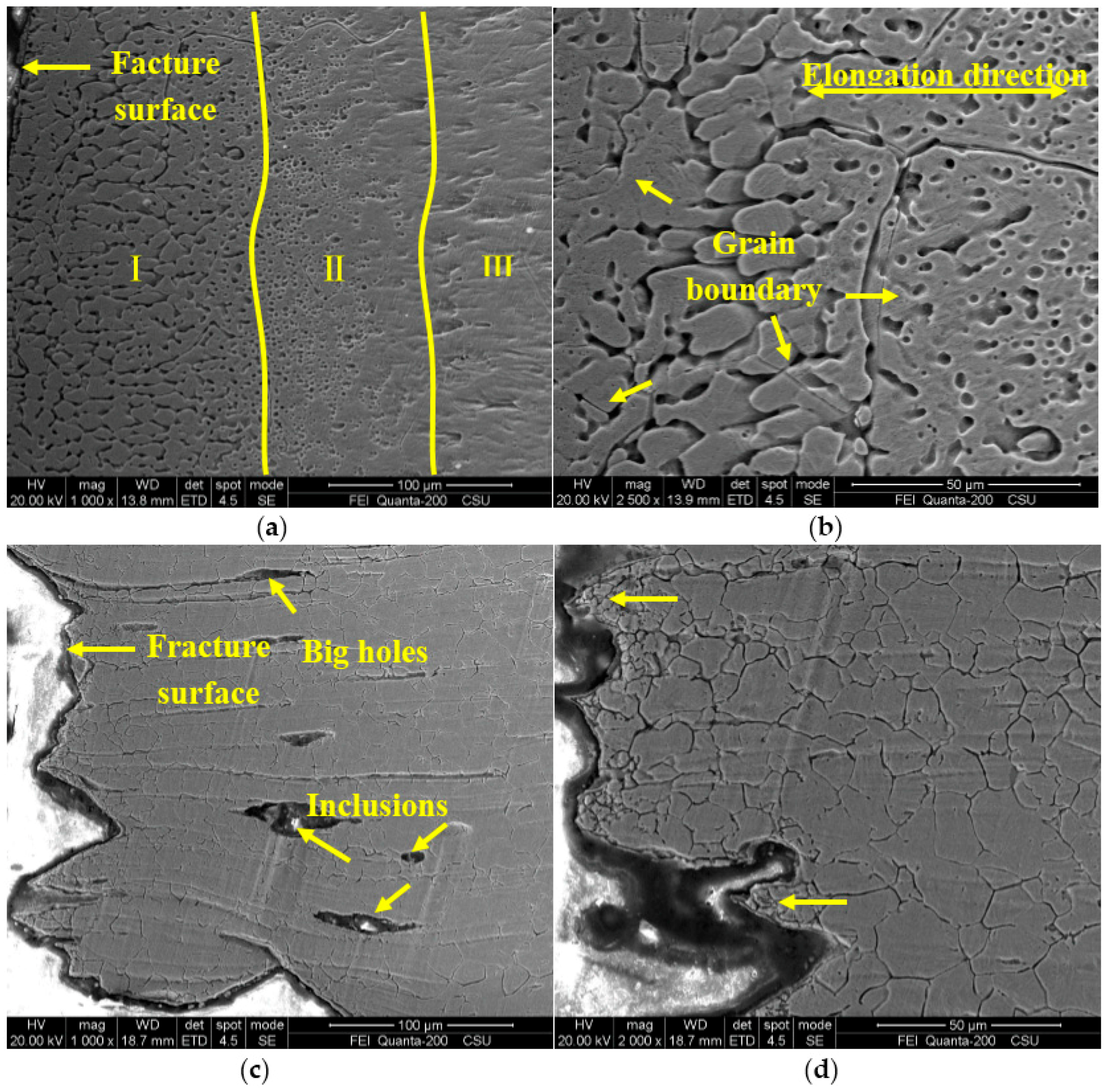

3.2. Fracture Morphology Analysis

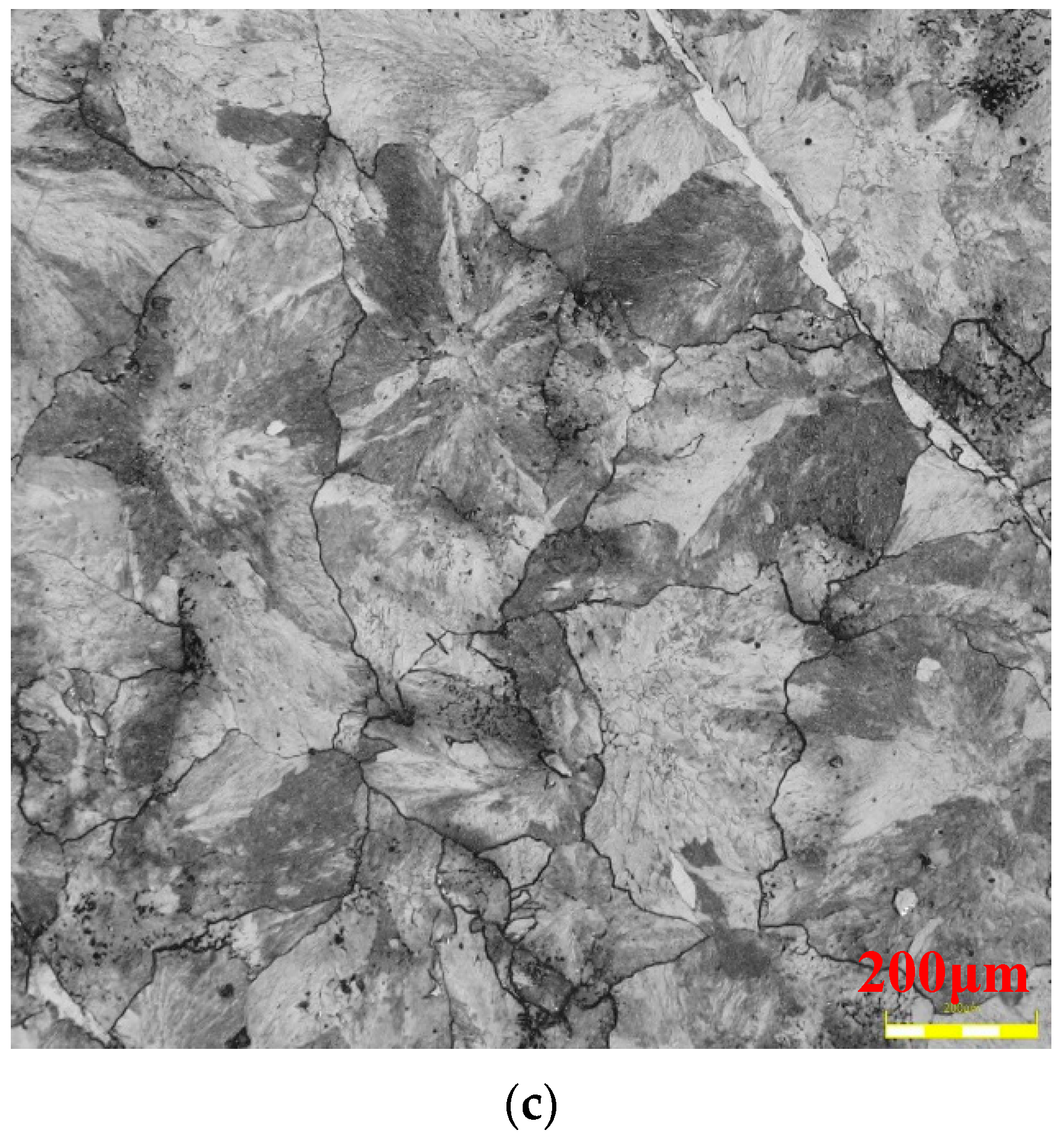

3.3. Microstructure Analysis

4. Conclusions

- The true stress-strain curves indicated that the hot tensile deformation behavior of 35CrMo is sensitive to the temperature and strain rate, and the resistance stress decreases when the temperature increases or the strain rate decreases. Further, neck transferability and workability of 35CrMo steel can be improved by increasing the tensile temperature.

- DRX is accompanied by the formation of cavities, and the cavitations are easier to initiate in the recrystallized grains rather than at the grain boundaries. The grain size reduces for the decreased deformation temperature and the increased strain rate, which makes the generation and coalescence of the cavities more difficult, and voids form around the inclusions, leading to the fracture surfaces covered with numerous small dimples. However, for the increased mobility of the atoms and boundaries and prolonged time, void combination is apparently easier under a high temperature and low strain rate, leading to fracture surfaces with a small number of big dimples.

- The fracture mechanism of 35CrMo steel includes the nucleation, growth, and combination of the microvoids during hot tensile testing. Damage tolerance can be improved with increased deformation temperature and decreased strain rate. To reduce the probability of the formation of cavitation in the matrix, deformation after the completion of DRX for 35CrMo steel should be carefully controlled.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, J.W.; Lu, L.T.; Wu, P.B.; Ma, J.J.; Wang, G.G.; Zhang, W.H. Inclusion size evaluation and fatigue strength analysis of 35CrMo alloy railway axle steel. Mater. Sci. Eng. A 2013, 562, 211–217. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Khomutov, M.G.; Solonin, A.N.; Pozdniakov, A.V.; Churyumova, T.A.; Minyaylo, B.F. Hot deformation behaviour and fracture of 10CrMoWNb ferritic-martensitic steel. Mater. Des. 2015, 74, 44–54. [Google Scholar] [CrossRef]

- Khamei, A.A.; Dehghani, K. Effects of strain rate and temperature on hot tensile deformation of severe plastic deformed 6061 aluminum alloy. Mater. Sci. Eng. A 2015, 627, 1–9. [Google Scholar] [CrossRef]

- Sun, C.Y.; Guo, N.; Fu, M.W.; Liu, C. Experimental investigation and modeling of ductile fracture behavior of trip780 steel in hot working conditions. Int. J. Mech. Sci. 2016, 110, 108–115. [Google Scholar] [CrossRef]

- Shore, F.M.; Morakabati, M.; Abbasi, S.M.; Momeni, A. Hot deformation behavior of incoloy 901 through hot tensile testing. J. Mater. Eng. Perform. 2014, 23, 1424–1433. [Google Scholar] [CrossRef]

- Deng, J.; Lin, Y.C.; Li, S.-S.; Chen, J.; Ding, Y. Hot tensile deformation and fracture behaviors of AZ31 magnesium alloy. Mater. Des. 2013, 49, 209–219. [Google Scholar] [CrossRef]

- Bai, G.; Li, J.; Hu, R.; Tang, Z.; Xue, X.; Fu, H. Effect of temperature on tensile behavior of Ni-Cr-W based superalloy. Mater. Sci. Eng. A 2011, 528, 1974–1978. [Google Scholar] [CrossRef]

- Novella, M.F.; Ghiotti, A.; Bruschi, S.; Bariani, P.F. Ductile damage modeling at elevated temperature applied to the cross wedge rolling of AA6082-T6 bars. J. Mater. Process. Technol. 2015, 222, 259–267. [Google Scholar] [CrossRef]

- Wang, L.; Yu, H.; Lee, Y.-S.; Kim, M.-S.; Kim, H.-W. Effect of microstructure on hot tensile deformation behavior of 7075 alloy sheet fabricated by twin roll casting. Mater. Sci. Eng. A 2016, 652, 221–230. [Google Scholar] [CrossRef]

- Ghavam, M.H.; Morakabati, M.; Abbasi, S.M.; Badri, H. Flow behavior modeling of IMI834 titanium alloy during hot tensile deformation. Trans. Nonferr. Met. Soc. China 2015, 25, 748–758. [Google Scholar] [CrossRef]

- Liu, G.; Wang, K.; He, B.; Huang, M.; Yuan, S. Mechanism of saturated flow stress during hot tensile deformation of a TA15 Ti alloy. Mater. Des. 2015, 86, 146–151. [Google Scholar] [CrossRef]

- Cao, F.; Xia, F.; Xue, G. Hot tensile deformation behavior and microstructural evolution of a Mg-9.3Li-1.79Al-1.61Zn alloy. Mater. Des. 2016, 92, 44–57. [Google Scholar] [CrossRef]

- Zhou, M.; Lin, Y.C.; Deng, J.; Jiang, Y.Q. Hot tensile deformation behaviors and constitutive model of an Al-Zn-Mg-Cu alloy. Mater. Des. 2014, 59, 141–150. [Google Scholar] [CrossRef]

- Ashok, K.; Maruthupandian, K.; Kumar, K.G.; Vishal, C.S. Micro-mechanical behaviour of AA2014 alloy during hot tensile testing. Trans. Indian Inst. Met. 2015, 68, 19–24. [Google Scholar] [CrossRef]

- Lv, Y. Influence of laser surface melting on the micropitting performance of 35CrMo structural steel gears. Mater. Sci. Eng. A 2013, 564, 1–7. [Google Scholar] [CrossRef]

- Zhang, J.W.; Lu, L.T.; Shiozawa, K.; Zhou, W.N.; Zhang, W.H. Effect of nitrocarburizing and post-oxidation on fatigue behavior of 35CrMo alloy steel in very high cycle fatigue regime. Int. J. Fatigue 2011, 33, 880–886. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, L.; Cui, G.; Shen, X.; Yi, H.; Zhang, W. Effect of process temperature on the microstructure and properties of gas oxynitrocarburized 35CrMo alloy steel. Mater. Des. 2010, 31, 2654–2658. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, H.; Ruan, X. Dynamic recrystallization behavior of 35CrMo structural steel. J. Cent. South Univ. Technol. 2003, 10, 13–19. [Google Scholar] [CrossRef]

- Xiao, Z.; Huang, Y.; Liu, Y. Plastic deformation behavior and processing maps of 35CrMo steel. J. Mater. Eng. Perform. 2016, 25, 1219–1227. [Google Scholar] [CrossRef]

- Williams, B.P. The effect of nonuniformities of stress at the neck of a tension specimen. In Studies in Large Plastic Flow and Fracture; Harvard University Press: Cambridge, MA, USA, 1964; pp. 9–37. [Google Scholar]

- Lin, Y.C.; Deng, J.; Jiang, Y.; Wen, D.; Liu, G. Hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy. Mater. Des. 2014, 55, 949–957. [Google Scholar] [CrossRef]

- Hutchinson, J.W.; Neale, K.W. Influence of strain-rate sensitivity on necking under uniaxial tension. Acta Metall. 1977, 25, 839–846. [Google Scholar] [CrossRef]

- Li, D.; Wei, Y.; Liu, C.; Hou, L. Hot deformation behaviors of Fe-30Mn-3Si-3Al twip steel during compression at elevated temperature and strain rate. Steel Res. Int. 2013, 84, 740–750. [Google Scholar] [CrossRef]

- Torabinejad, V.; ZareiHanzaki, A.; Moemeni, S. An analysis to the kinetics of austenite recrystallization in Fe-30Mn-5Al steel. Mater. Manuf. Process. 2012, 28, 36–41. [Google Scholar] [CrossRef]

- Sugandhi, R.; Warrier, M.; Chaturvedi, S. Identification of best fit parameters of void nucleation and growth model using particle swarm technique. Appl. Soft Comput. 2015, 35, 113–122. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, K.; Jiang, S.; Zhou, H.; Zhao, C.; Yang, X. Dynamic recrystallization behavior of a γ′-hardened nickel-based superalloy during hot deformation. J. Alloy. Compd. 2015, 623, 374–385. [Google Scholar] [CrossRef]

- Sun, Y.; Xie, J.; Hao, S.; Wang, A.; Liu, P.; Li, M. Dynamic recrystallization model of 30%SiCp/Al composite. J. Alloy. Compd. 2015, 649, 865–871. [Google Scholar] [CrossRef]

- Quan, G.Z.; Luo, G.C.; Liang, J.T.; Wu, D.S.; Mao, A.; Liu, Q. Modelling for the dynamic recrystallization evolution of Ti-6Al-4V alloy in two-phase temperature range and a wide strain rate range. Comput. Mater. Sci. 2015, 97, 136–147. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Z.; Huang, Y.; Liu, H.; Wang, S. Hot Tensile and Fracture Behavior of 35CrMo Steel at Elevated Temperature and Strain Rate. Metals 2016, 6, 210. https://doi.org/10.3390/met6090210

Xiao Z, Huang Y, Liu H, Wang S. Hot Tensile and Fracture Behavior of 35CrMo Steel at Elevated Temperature and Strain Rate. Metals. 2016; 6(9):210. https://doi.org/10.3390/met6090210

Chicago/Turabian StyleXiao, Zhengbing, Yuanchun Huang, Hui Liu, and Sanxing Wang. 2016. "Hot Tensile and Fracture Behavior of 35CrMo Steel at Elevated Temperature and Strain Rate" Metals 6, no. 9: 210. https://doi.org/10.3390/met6090210