Improvement in the Design of Welded Joints of EN 235JR Low Carbon Steel by Multiple Response Surface Methodology

Abstract

:1. Introduction

2. Modelling Using the RSM

3. Welded Joint Parameters that Were Studied Using RSM

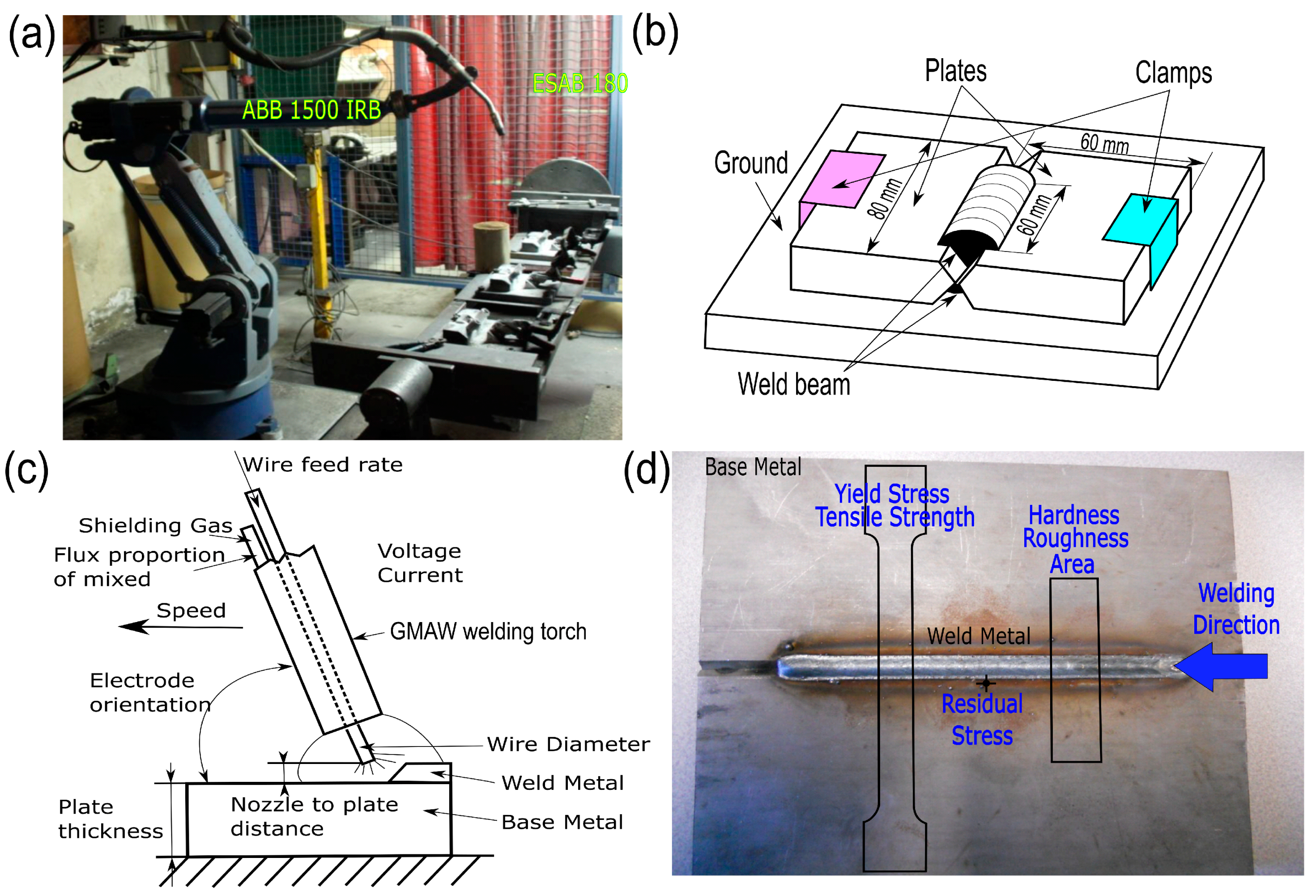

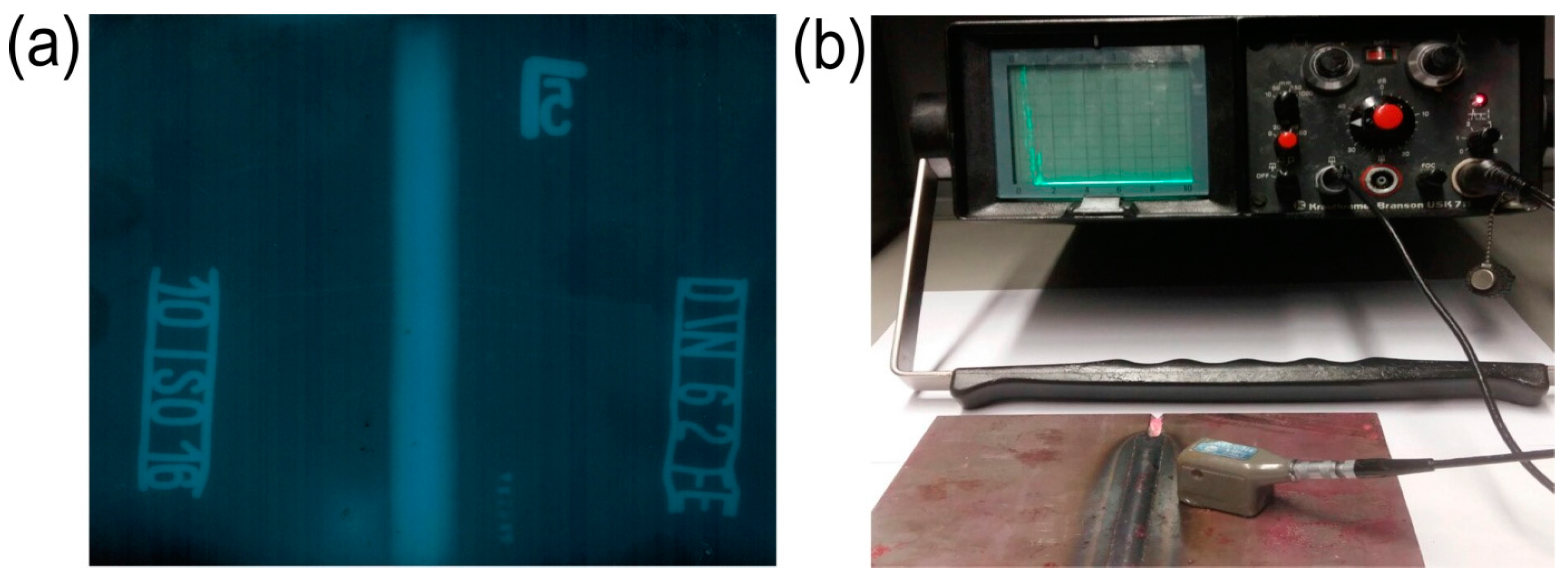

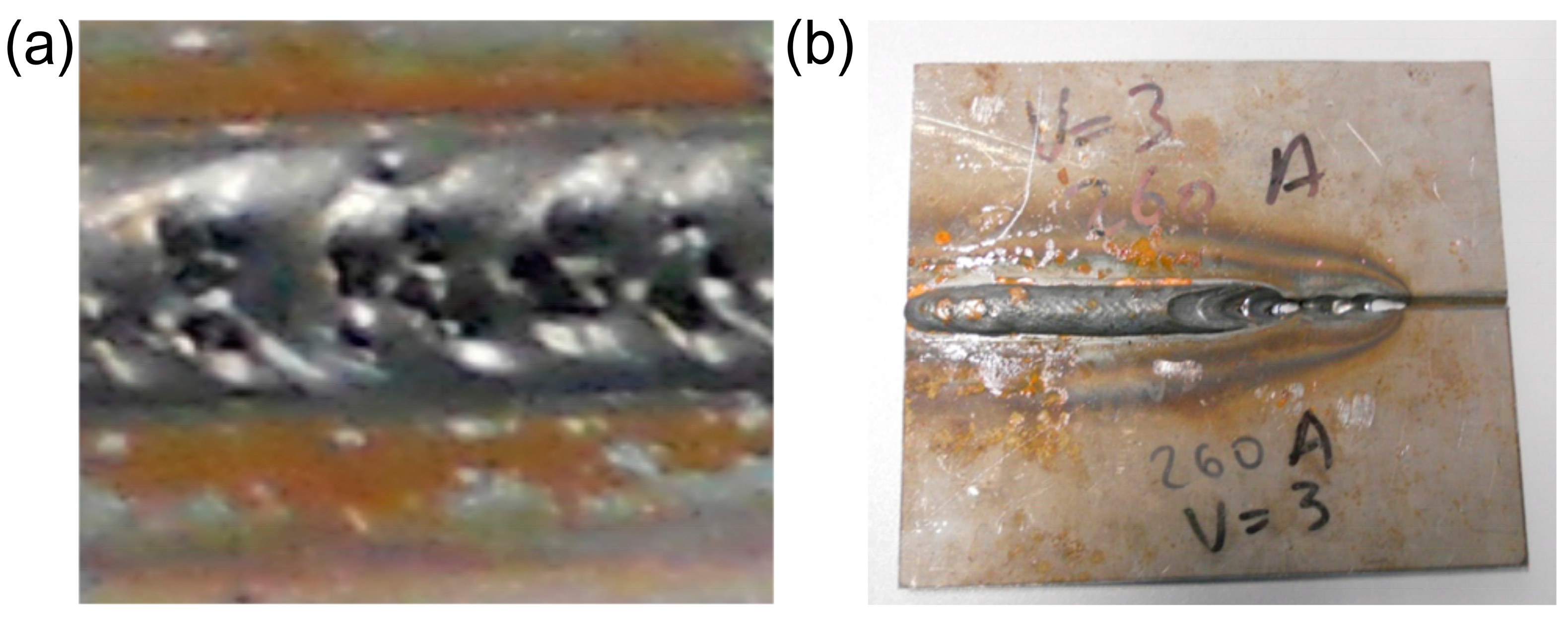

4. Experimental Setup and Results Obtained

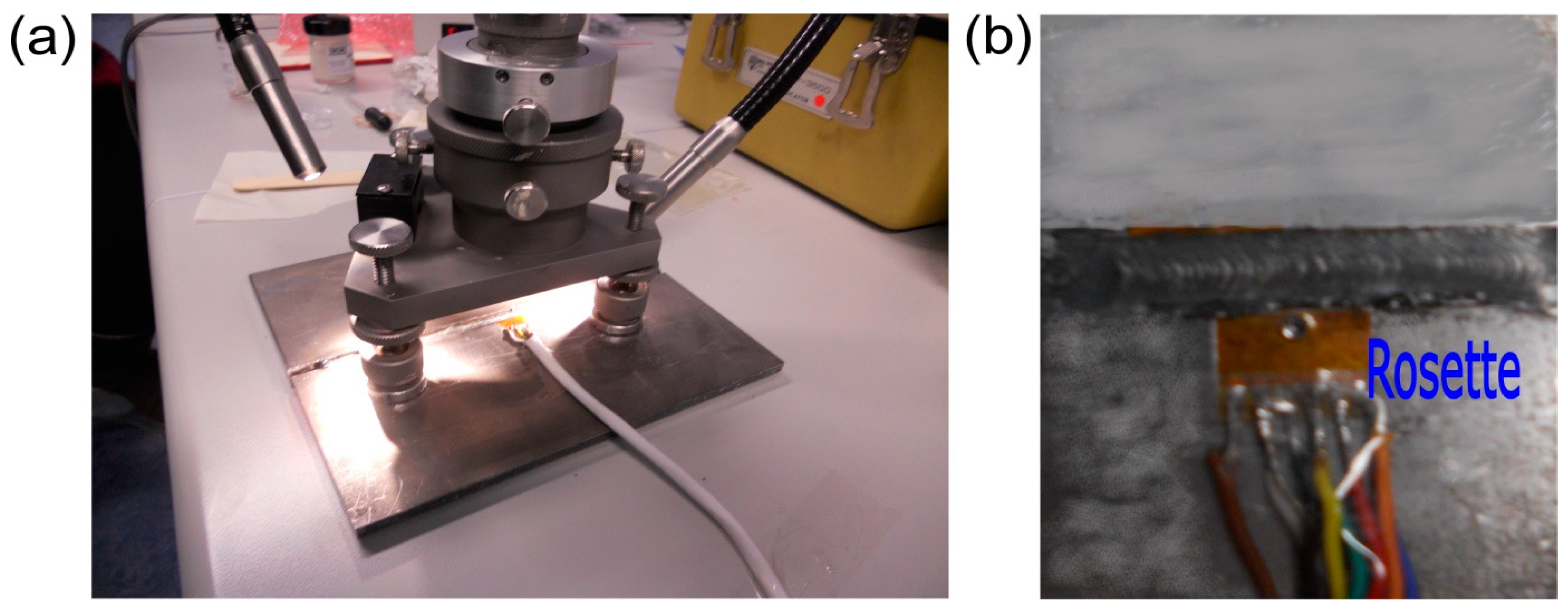

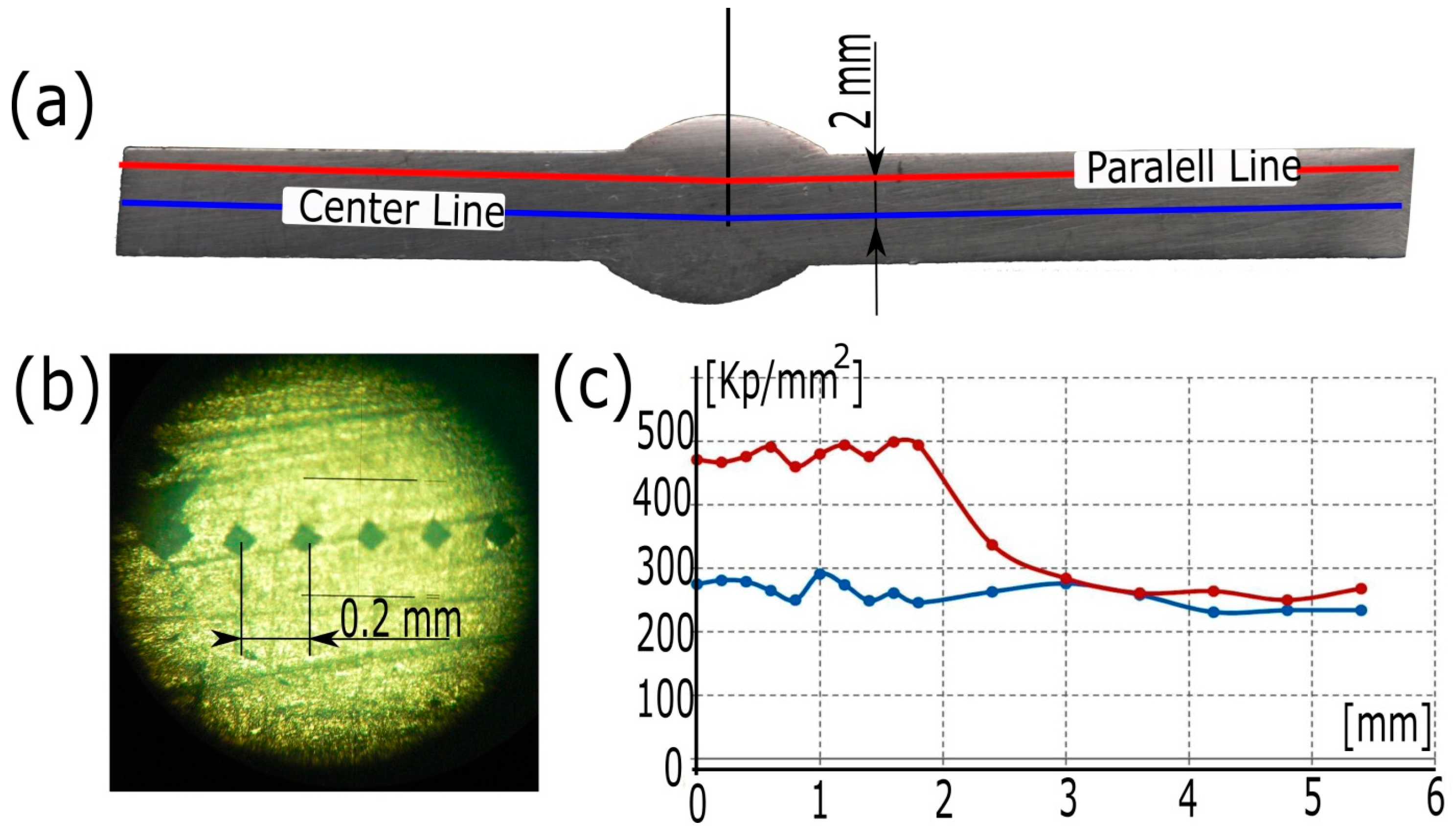

4.1. Residual Stresses

4.2. Hardness

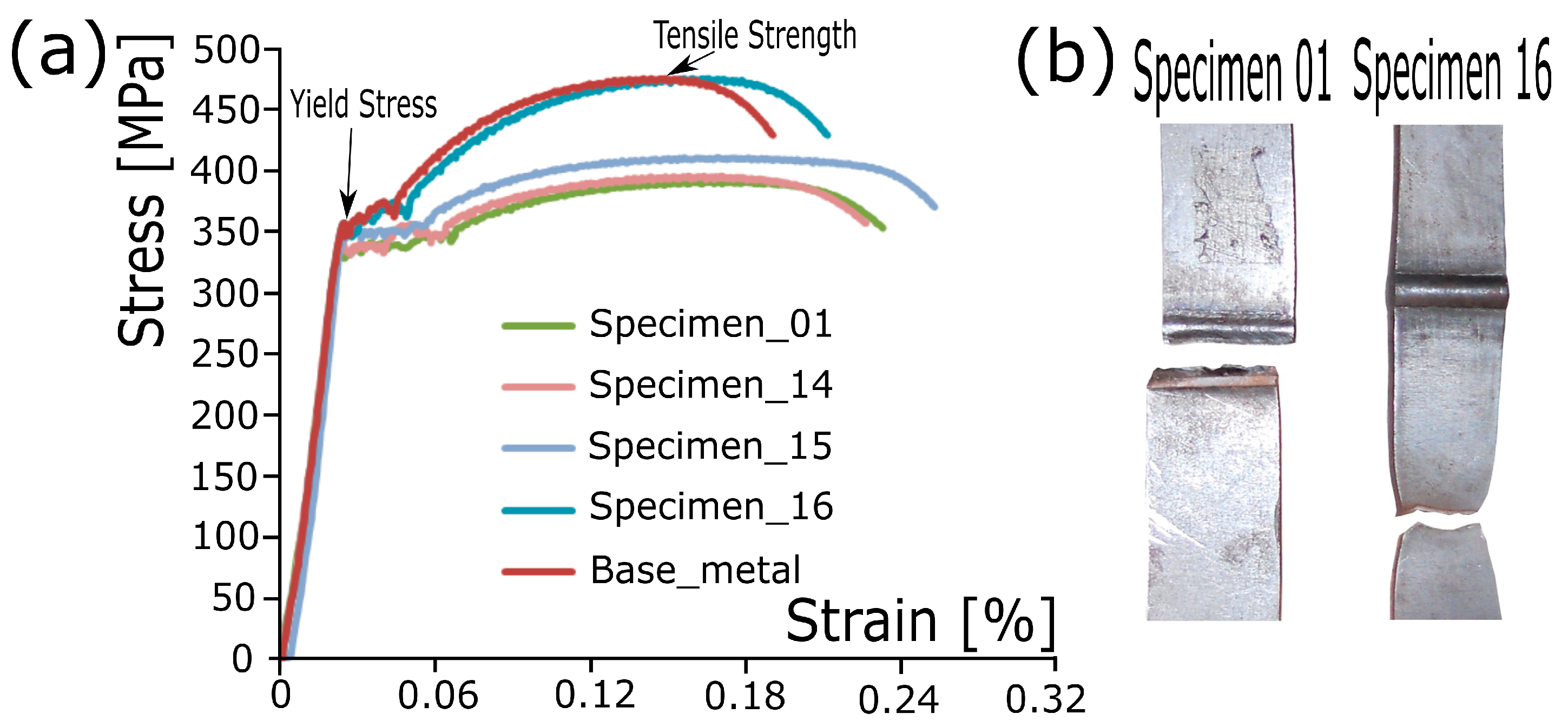

4.3. Yield Stress and Tensile Strength

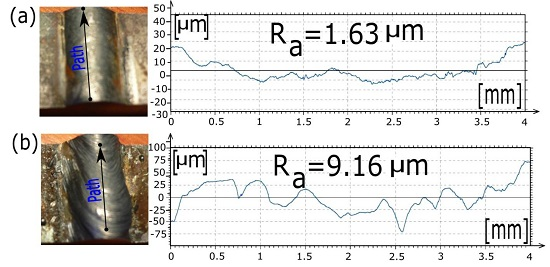

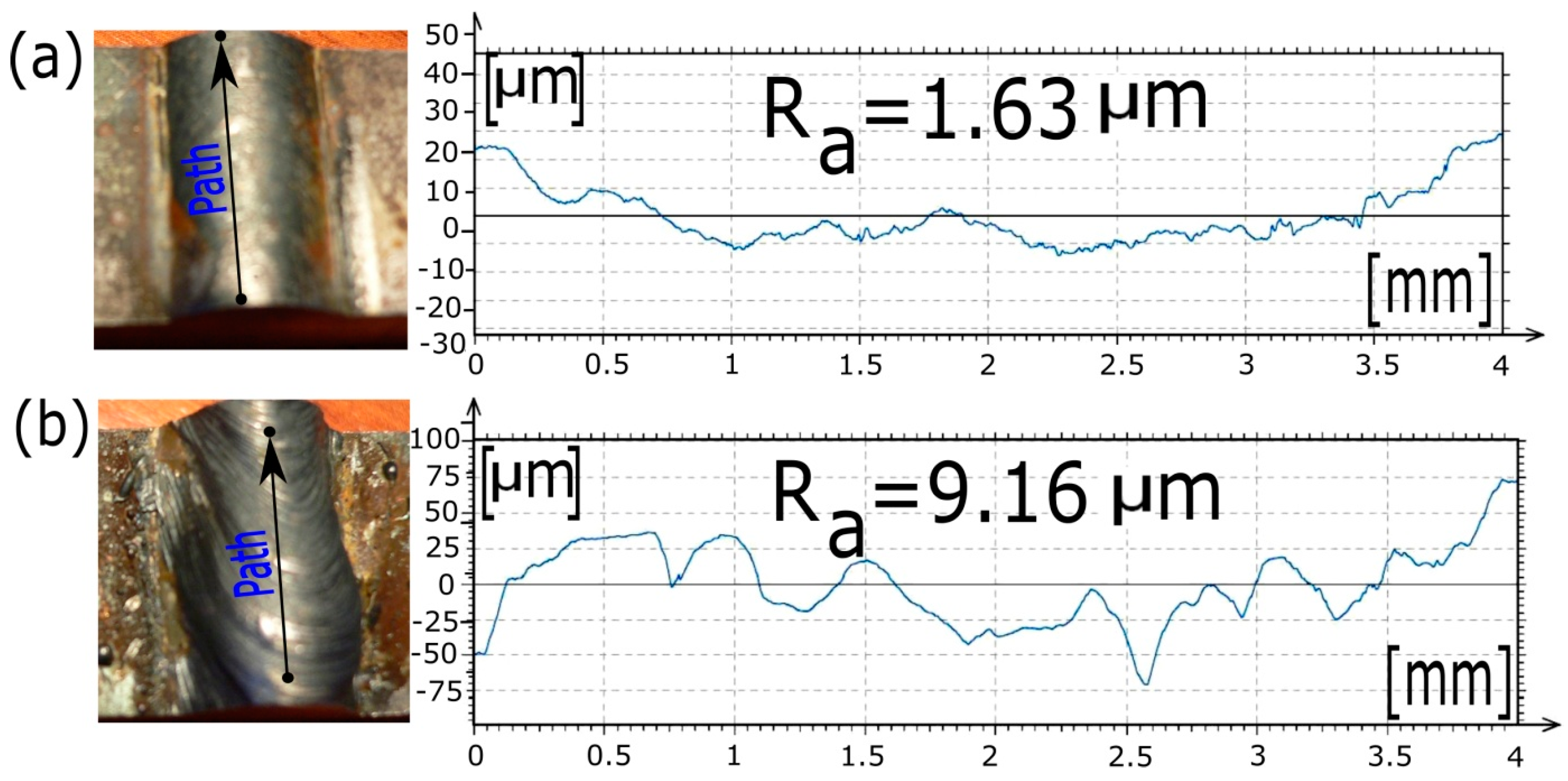

4.4. Surface Roughness

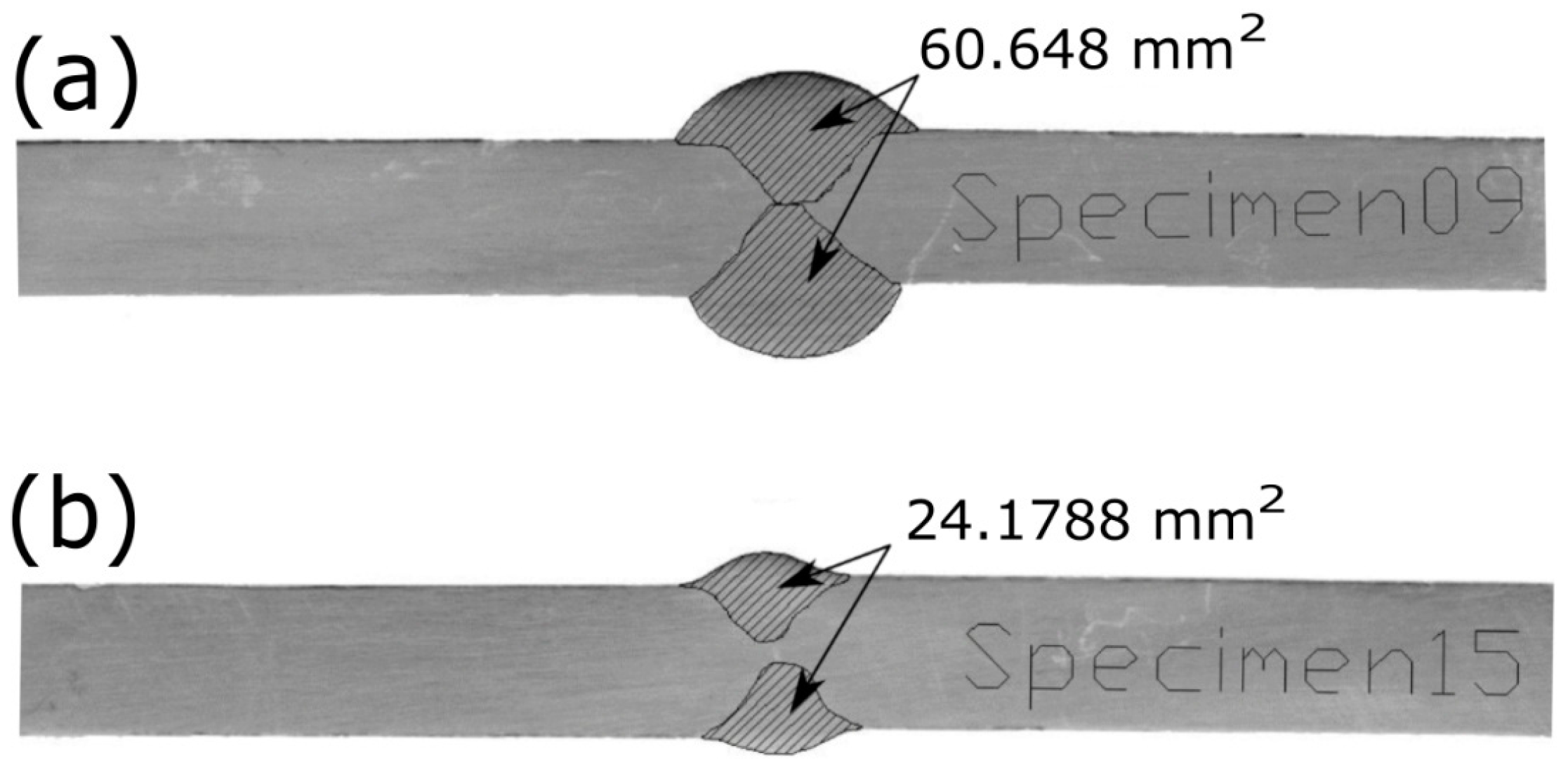

4.5. Weld Cord Area Surface Roughness

5. Design of Experiments

6. Results and Discussion

6.1. Modelling the Area, Yield Stress, Tensile Strength, Roughness and Residual Stress Using RSM

6.2. Multi-Response Optimization

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Minnick, H.M. Gas Metal Arc Welding Handbook Textbook, 1st ed.; Goodheart–Willcox: Tinley Park, IL, USA, 2007. [Google Scholar]

- Ozcelik, S.; Moore, K. Modeling, sensing and control of gas metal arc welding, 1st ed.; Elsevier: Oxford, UK, 2003. [Google Scholar]

- Lakshminarayanan, A.K.; Balasubramanian, V. An assessment of microstructure, hardness, tensile and impact strength of friction stir welded ferritic stainless steel joints. Mater. Des. 2010, 31, 4592–4600. [Google Scholar] [CrossRef]

- Olabi, A.G.; Lostado Lorza, R.; Benyounis, K.Y. Review of Microstructures, Mechanical Properties, and Residual Stresses of Ferritic and Martensitic Stainless-Steel Welded. In Comprehensive Materials Processing; Elsevier: Oxford, UK, 2014. [Google Scholar]

- Macherauch, E.; Kloos, K.H. Origin, measurements and evaluation of residual stresses. Residual Stress. Sci. Technol. 1987, 3–26. [Google Scholar]

- Da Nóbrega, J.A.; Diniz, D.D.; Silva, A.A.; Maciel, T.M.; de Albuquerque, V.H.C.; Tavares, J.M.R. Numerical evaluation of temperature field and residual stresses in an API 5L X80 steel welded joint using the finite element method. Metals 2016, 6, 28. [Google Scholar] [CrossRef]

- Eid, N. Localized corrosion at welds in structural steel under desalination plant conditions Part I: Effect of surface roughness and type of welding electrode. Desalination 1989, 73, 397–406. [Google Scholar] [CrossRef]

- Godwin, A. Welding stainless steel to meet hygienic requirements. Stainl. Steel World 1998, 10, 36–41. [Google Scholar]

- Ghazanfari, H.; Naderi, M.; Iranmanesh, M.; Seydi, M.; Poshteban, A.A. Comparative study of the microstructure and mechanical properties of HTLA steel welds obtained by the tungsten arc welding and resistance spot welding. Mater. Sci. Eng. A Struct. 2012, 534, 90–100. [Google Scholar] [CrossRef]

- Cahoon, J.R.; Broughton, W.H.; Kutzak, A.R. The determination of yield stress from hardness measurements. Metall. Trans. 1971, 2, 1979–1983. [Google Scholar]

- Challenger, K.D.; Moteff, J. Quantitative characterization of the substructure of AISI 316 stainless steel resulting from creep. Metall. Trans. 1973, 4, 749–755. [Google Scholar] [CrossRef]

- Gharibshahiyan, E.; Raouf, A.H.; Parvin, N.; Rahimian, M. The effect of microstructure on hardness and toughness of low carbon welded steel using inert gas welding. Mater. Des. 2011, 32, 2042–2048. [Google Scholar] [CrossRef]

- Reed-Hill, R.E.; Abbaschian, R. Physical metallurgy principles; PWS Publishing Company: Boston, MA, USA, 1994. [Google Scholar]

- Kaçar, R.; Kökemli, K. Effect of controlled atmosphere on the MIG-MAG arc weldment properties. Mater. Des. 2005, 26, 508–516. [Google Scholar] [CrossRef]

- Loureiro, A.J. Effect of heat input on plastic deformation of undermatched weld. J. Mater. Process Technol. 2002, 28, 240–249. [Google Scholar] [CrossRef]

- Samardžić, I.; Dunđer, M.; Klarić., Š. Hardness distribution on weld pass start and stop of propane/butane houshold pressure vessel. In Proceeding of the 11th International Scientific Conference on Production Engineering (CIM2007), Biograd, Croatia, 13–17 June 2007.

- Myers, R.H. Response Surfaces Methodology, 1st ed.; Allyn and Bacan Inc.: Boston, MA, USA, 1971. [Google Scholar]

- Fisher, R.A. The design of experiments, 1st ed.; Oliver and Boyd: Edinburgh, UK, 1935. [Google Scholar]

- Islam, M.; Buijk, A.; Rais-Rohani, M.; Motoyama, K. Process parameter optimization of lap joint fillet weld based on FEM–RSM–GA integration technique. Adv. Eng. Softw. 2015, 79, 127–136. [Google Scholar] [CrossRef]

- Lostado, R.; García, R.E.; Martinez, R.F. Optimization of operating conditions for a double-row tapered roller bearing. Int. J. Mech. Mater. Des. 2016, 12, 353–373. [Google Scholar] [CrossRef]

- Moussaoui, K.; Mousseigne, M.; Senatore, J.; Chieragatti, R.; Lamesle, P. Influence of Milling on the Fatigue Lifetime of a Ti6Al4V Titanium Alloy. Metals 2015, 5, 1148–1162. [Google Scholar] [CrossRef]

- Gopalsamy, B.M.; Mondal, B.; Ghosh, S. Taguchi method and ANOVA: An approach for process parameters optimization of hard machining while machining hardened steel. J. Sci. Ind. Res. 2009, 68, 686–695. [Google Scholar]

- Harrington, E.C. The desirability function. Ind. Qual. Control. 1965, 21, 494–498. [Google Scholar]

- Derringer, G.; Suich, R. Simultaneous Optimization of Several Response Variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar]

- Kuhn, M. Desirability: Desirabiliy Function Optimization and Ranking. R package v.1.6. Available online: http://CRAN.R-project.org/package=desirability (accessed on 25 August 2016).

- ASTM E92-16, Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. Available online: http://www.astm.org/Standards/E92 (accessed on 25 August 2016).

- Thibault, D.; Bocher, P.; Thomas, M. Residual stress and microstructure in welds of 13%Cr-4%Ni martensitic stainless steel. J. Mater. Process. Technol. 2009, 209, 2195–2202. [Google Scholar] [CrossRef]

- Inoue, N.; Muroga, T.; Nishimura, A.; Motojima, O. Correlation between microstructure and hardness of a low activation ferritic steel (JLF-1) weld joint. J. Nucl. Mater. 1998, 258, 1248–1252. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, M.; Zheng, Y.; Liu, S.; Wang, W.; Zhang, Z. Finite-Element Thermal Analysis and Grain Growth Behavior of HAZ on Argon Tungsten-Arc Welding of 443 Stainless Steel. Metals 2016, 6, 77. [Google Scholar] [CrossRef]

- Darwish, S.M.; Al-Dekhial, S.D. Micro-hardness of spot welded (BS 1050) commercial aluminium as correlated with welding variables and strength attributes. J. Mater. Process. Technol. 1999, 91, 43–51. [Google Scholar] [CrossRef]

- Jindal, S.; Chhibber, R.; Mehta, N.P. Effect of welding parameters on bead profile, microhardness and H2 content in submerged arc welding of high-strength low-alloy steel. J. Eng. Manuf. 2014, 228, 82–94. [Google Scholar] [CrossRef]

- ASTM E8 / E8M-15a, Standard Test Methods for Tension Testing of Metallic Materials. Available online: https://www.astm.org/Standards/E8.htm (accessed on 25 August 2016).

- ISO 5178:2001 Destructive tests on welds in metallic materials-Longitudinal tensile test on weld metal in fusion welded joints. Available online: http://www.iso.org/iso/catalogue_detail.htm?csnumber=32829 (accessed on 25 August 2016).

- Dwivedi, S.P.; Sharma, S. Effect of Process Parameters on Tensile Strength of 1018 Mild Steel Joints Fabricated by Microwave Welding. Metall. Microstruct. Anal. 2014, 3, 58–69. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Benyounis, K.Y.; Olabi, A.G. Methods of measuring residual stresses in components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef]

- Olabi, A.G.; Benyounis, K.Y.; Hashmi, M.S.J. Application of response surface methodology in describing the residual stress distribution in CO2 laser welding of AISI304. Strain 2007, 43, 37–46. [Google Scholar] [CrossRef]

- Olabi, A.G.; Casalino, G.; Benyounis, K.Y.; Rotondo, A. Minimisation of the residual stress in the heat affected zone by means of numerical methods. Mater. Des. 2007, 28, 2295–2302. [Google Scholar] [CrossRef]

- ASTM E837-13a, Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method. Available online: https://www.astm.org/Standards/E837.htm (accessed on 25 August 2016).

- ISO 4288:1996 Geometrical Product Specifications (GPS)—Surface Texture: Profile method—Rules and procedures for the assessment of surface texture. Available online: http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=2096 (accessed on 25 August 2016).

- Satheesh, M.; Dhas, J.; Sabarinathan, R.; Kumar, S.S.; Sankar, R. Modeling and Analysis of Weld Parameters on Micro Hardness in SA 516 Gr. 70 Steel. Proced. Eng. 2012, 38, 4021–4029. [Google Scholar] [CrossRef]

- Tzeng, Y.F. Effects of operating parameters on surface quality for the pulsed laser welding of zinc-coated steel. J. Mater. Process. Technol. 2000, 100, 163–170. [Google Scholar] [CrossRef]

- Alam, M.M.; Barsoum, Z.; Jonsén, P.; Kaplan, A.F.H.; Häggblad, H.Å. The influence of surface geometry and topography on the fatigue cracking behaviour of laser hybrid welded eccentric fillet joints. Appl. Surf. Sci. 2010, 256, 1936–1945. [Google Scholar] [CrossRef]

- Gunaraj, V.; Murugan, N. Application of response surface methodology for predicting weld bead quality in submerged arc welding of pipes. J. Mater. Process. Technol. 1999, 88, 266–275. [Google Scholar] [CrossRef]

- Benyounis, K.Y.; Olabi, A.G.; Hashmi, M.S.J. Effect of laser welding parameters on the heat input and weld-bead profile. J. Mater. Process. Technol. 2005, 164, 978–985. [Google Scholar] [CrossRef]

- Benyounis, K.Y.; Olabi, A.G.; Hashmi, M.S.J. Optimizing the laser-welded butt joints of medium carbon steel using RSM. J. Mater. Process. Technol. 2005, 164, 986–989. [Google Scholar] [CrossRef]

- Wang, X.; Song, X.; Jiang, M.; Li, P.; Hu, Y.; Wang, K.; Liu, H. Modeling and optimization of laser transmission joining process between PET and 316L stainless steel using response surface methodology. Opt. Laser Technol. 2012, 44, 656–663. [Google Scholar] [CrossRef]

- Singh, R.P.; Garg, R.K.; Shukla, D.K. Mathematical modeling of effect of polarity on weld bead geometry in submerged arc welding. J. Manuf. Process. 2016, 21, 14–22. [Google Scholar] [CrossRef]

- ISO 17636-1:2013 Non-destructive testing of welds–Radiographic testing—Part 1: X- and gamma-ray techniques with film. Available online: http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=52981 (accessed on 25 August 2016).

- ISO 11666:2010 Non-destructive testing of welds—Ultrasonic testing—Acceptance levels. Available online: http://www.iso.org/iso/catalogue_detail.htm?csnumber=50685 (accessed on 25 August 2016).

- Islam, M.; Buijk, A.; Rais-Rohani, M.; Motoyama, K. Simulation-based numerical optimization of arc welding process for reduced distortion in welded structures. Finite Elem. Anal. Des. 2014, 84, 54–64. [Google Scholar] [CrossRef]

- Vishay Precision Group. Measurement of Residual Stresses by the Hole-Drilling Strain Gage Method. Technical Note TN-503. 2010. Available online: http://www.vishaypg.com/docs/11053/tn503.pdf (accessed on 25 August 2016).

- ASTM E407-07 Standard Practice for Microetching Metals and Alloys. Available online: https://zh.scribd.com/document/259609551/ASTM-E407-07-Standard-Practice-for-Microetching-Metals-and-Alloys (accessed on 25 August 2016).

- ISO 4287:1997 Geometrical Product Specifications (GPS)–Surface texture: Profile method—Terms, definitions and surface texture parameters. Available online: http://www.iso.org/iso/iso_catalogue/catalogue_ics/catalogue_detail_ics.htm?ics1=01&ics2=040&ics3=17&csnumber=10132 (accessed on 25 August 2016).

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Box, G.E.; Behnken, D.W. Some new three level designs for the study of quantitative variables. Technometrics 1960, 2, 455–475. [Google Scholar] [CrossRef]

- RC Team R: A language and environment for statistical computing. R foundation for Statistical Computing. Available online: https://www.r-project.org/ (assecced on 25 August 2016).

- Lenth, R.V. Response-Surface Methods in R, Using rsm. J. Stat. Softw. 2009, 32, 1–17. [Google Scholar] [CrossRef]

| Input | Notation | Magnitude | Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | 1 | |||

| Current | C | amps | 120 | 150 | 180 |

| Speed | S | mm/s | 3 | 6.5 | 10 |

| Voltage | V | volts | 20 | 25 | 30 |

| Inputs | Outputs | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Exp. No. | C | S | V | A | Ra | H | YS | TS | RS |

| (amps) | (mm/s) | (volts) | (mm2) | (µm) | (MPa) | (MPa) | (MPa) | (MPa) | |

| 14 | 150 | 6.5 | 25 | 26.7219 | 2.3 | 179 | 339.229 | 396.45 | 79.3 |

| 1 | 120 | 3 | 25 | 42.342 | 1.967 | 185 | 355.449 | 404.63 | 172.991 |

| 3 | 120 | 10 | 25 | 12.3578 | 8.269 | 244 | 67.526 | 158.3 | 267.577 |

| 6 | 180 | 6.5 | 20 | 29.642 | 3.608 | 172 | 311.631 | 414.11 | 128.07 |

| 10 | 150 | 10 | 25 | 18.9386 | 5.091 | 251 | 298.46 | 341.85 | 180.314 |

| 12 | 150 | 10 | 30 | 22.5676 | 2.57 | 220 | 339.883 | 382.85 | 195.392 |

| 13 | 150 | 6.5 | 25 | 26.5941 | 2.82 | 205 | 337.921 | 359.05 | 89.451 |

| 4 | 180 | 10 | 25 | 22.454 | 2.508 | 286 | 294.12 | 334.79 | 323.307 |

| 16 | 150 | 6.5 | 25 | 28.5 | 2.58 | 205 | 356.43 | 416.5 | 83.774 |

| 8 | 180 | 6.5 | 30 | 42.934 | 5.411 | 182 | 332.603 | 364.37 | 155.425 |

| 15 | 150 | 6.5 | 25 | 24.1788 | 2.59 | 210 | 349.236 | 411.63 | 89.5 |

| 5 | 120 | 6.5 | 20 | 17.608 | 6.299 | 289 | 106.12 | 126.52 | 101.618 |

| 2 | 180 | 3 | 25 | 58.75 | 8.196 | 160 | 211.282 | 287.42 | 130.536 |

| 17 | 150 | 6.5 | 25 | 25.3 | 2.32 | 177 | 344.069 | 382.7 | 81.7 |

| 11 | 150 | 3 | 30 | 55.858 | 8.95 | 130 | 351.865 | 406.37 | 132.678 |

| 7 | 120 | 6.5 | 30 | 21.274 | 4.852 | 142 | 340.472 | 412.67 | 250.234 |

| 9 | 150 | 3 | 25 | 60.648 | 3.716 | 160 | 376.18 | 424.71 | 62.902 |

| Var. | Df | Sum of Sq. | Mean Square | F-Value | p-Value | Sig. Code |

|---|---|---|---|---|---|---|

| S | 1 | 2495 | 2495 | 285 | 3.29 × 10−9 | *** |

| C × S | 1 | 352.21 | 352.21 | 40 | 5.54 × 10−5 | *** |

| S2 | 1 | 404.02 | 404.02 | 46 | 3.00 × 10−5 | *** |

| V | 1 | 87.24 | 87.24 | 10 | 9.17 × 10−3 | ** |

| C × V | 1 | 133.55 | 133.55 | 15 | 2.465× 10−3 | ** |

| Residuals | 11 | 96.44 | 8.77 | |||

| R2 | 0.984 |

| Var. | Df | Sum of Sq. | Mean Square | F-Value | p-Value | Sig. Code |

|---|---|---|---|---|---|---|

| C | 1 | 0.346 | 0.346 | 2 | 2.394057 × 10−1 | |

| C2 | 1 | 9 | 9 | 44 | 2888 × 10−4 | *** |

| S | 1 | 2 | 2 | 12 | 1.15299 × 10−2 | * |

| C × S | 1 | 36 | 36 | 172 | 3.51 × 10−6 | *** |

| S2 | 1 | 9 | 9 | 42 | 3.458 × 10−4 | *** |

| V | 1 | 2 | 2 | 8 | 2.58224 × 10−2 | * |

| C × V | 1 | 3 | 3 | 13 | 9.3021 × 10−3 | ** |

| S × V | 1 | 19 | 19 | 89 | 3.14 × 10−5 | *** |

| V2 | 1 | 6 | 6 | 29 | 1.0289 × 10−3 | ** |

| Residuals | 7 | 1 | 0.209 | |||

| R2 | 0.991 |

| Var. | Df | Sum of Sq. | Mean Square | F-Value | p-Value | Sig. Code |

|---|---|---|---|---|---|---|

| C | 1 | 450 | 450 | 2 | 1.988151 × 10−1 | |

| S | 1 | 16,744.5 | 16,744.5 | 70 | 7.71 × 10−6 | *** |

| C × S | 1 | 1122.3 | 1122.3 | 5 | 5.48739 × 10−2 | . |

| S2 | 1 | 330.5 | 330.5 | 1 | 2.655811 × 10−1 | |

| V | 1 | 6984.7 | 6984.7 | 29 | 2.923 × 10−4 | *** |

| C × V | 1 | 6162.3 | 6162.3 | 26 | 4.692 × 10−4 | *** |

| Residuals | 10 | 2376.3 | 237.6 | |||

| R2 | 0.964 |

| Var. | Df | Sum of Sq. | Mean Square | F-Value | p-Value | Sig. Code |

|---|---|---|---|---|---|---|

| C | 1 | 9805 | 9805 | 17 | 3.4049 × 10−3 | ** |

| C2 | 1 | 35,302 | 35,302 | 61 | 5.27 × 10−5 | *** |

| S | 1 | 10,862 | 10,862 | 19 | 2.5365 × 10−3 | ** |

| C × S | 1 | 34,366 | 34,366 | 59 | 5.80 × 10−5 | *** |

| S2 | 1 | 1902 | 1902 | 3 | 1.080436 × 10−1 | |

| V | 1 | 15,245 | 15,245 | 26 | 9.059 × 10−4 | *** |

| C × V | 1 | 11,383 | 11,383 | 20 | 2.2114 × 10−3 | ** |

| S × V | 1 | 2539 | 2539 | 4 | 7.00186 × 10−2 | . |

| Residuals | 8 | 4650 | 581 | |||

| R2 | 0.981 |

| Var. | Df | Sum of Sq. | Mean Square | F-Value | p-Value | Sig. Code |

|---|---|---|---|---|---|---|

| C | 1 | 11143 | 11143 | 11 | 1.07556 × 10−2 | * |

| C2 | 1 | 26,095.2 | 26,095.2 | 26 | 9.773 × 10−4 | *** |

| S | 1 | 11,654.1 | 11,654.1 | 11 | 9.622 × 10−3 | ** |

| C × S | 1 | 21,564.9 | 21,564.9 | 21 | 1.7561 × 10−3 | ** |

| S2 | 1 | 1363.2 | 1363.2 | 1 | 2.80849 × 10−1 | |

| V | 1 | 13,132.5 | 13,132.5 | 13 | 7.09 × 10−3 | ** |

| C × V | 1 | 28,205.5 | 28,205.5 | 28 | 7.641 × 10−4 | *** |

| S × V | 1 | 1859.6 | 1859.6 | 2 | 2.137441 × 10−1 | * |

| Residuals | 8 | 8154.2 | 1019.3 | |||

| R2 | 0.966 |

| Var. | Df | Sum of Sq. | Mean Square | F-Value | p-Value | Sig. Code |

|---|---|---|---|---|---|---|

| C | 1 | 379.2 | 379.2 | 2 | 1.821709 × 10−1 | |

| C2 | 1 | 27,557 | 27,557 | 155 | 1.62 × 10−6 | *** |

| C × S | 1 | 29,079 | 29,079 | 164 | 1.32 × 10−6 | *** |

| S2 | 1 | 7656.8 | 7656.8 | 43 | 0.0001758 | *** |

| V | 1 | 11,144.2 | 11,144.2 | 63 | 4.70 × 10−5 | *** |

| C × V | 1 | 3676 | 3676 | 21 | 1.8783 × 10−3 | ** |

| S × V | 1 | 8275.1 | 8275.1 | 47 | 1345 × 10−4 | *** |

| V2 | 1 | 679.7 | 679.7 | 4 | 8.6221 × 10−2 | . |

| Residuals | 8 | 1421.5 | 177.7 | |||

| R2 | 0.992 |

| A (mm2) | Ra (µm) | H (kp/mm2) | TS (MPa) | YS (MPa) | RS (MPa) | |

|---|---|---|---|---|---|---|

| MAE | 4.223 | 3.513 | 6.597 | 4.529 | 6.826 | 2.993 |

| RMSE | 5.311 | 4.221 | 7.484 | 5.359 | 7.345 | 3.504 |

| Goal | Importance | Value | Desirability | |

|---|---|---|---|---|

| Current (C) | In range → 120.0 | 1.0 | 143.788 | 1.0 |

| Speed (S) | Maximize → 10.0 | 1.0 | 8.218 | 0.745 |

| Voltage (V) | In range → 20.0 | 1.0 | 29.999 | 1.0 |

| Area (mm2) | Minimize → 12.357 | 1.0 | 23.819 | 0.762 |

| Ra (µm) | Minimize → 1.967 | 1.0 | 3.159 | 0.829 |

| H (kp/mm2) | Minimize → 130.0 | 1.0 | 174.803 | 0.718 |

| YS (MPa) | Maximize → 376.18 | 1.0 | 376.186 | 1.0 |

| TS (MPa) | Maximize → 424.71 | 1.0 | 424.976 | 1.0 |

| RS (MPa) | Minimize → 62.92 | 1.0 | 149.859 | 0.666 |

| Overall Desirability | 0.808 | |||

| Goal | Importance | Value | Desirability | |

|---|---|---|---|---|

| Current (C) | In range → 120.0 | 1.0 | 140.593 | 1.000 |

| Speed (S) | Maximize → 10.0 | 1.0 | 8.192 | 0.741 |

| Voltage (V) | In range → 20.0 | 1.0 | 29.999 | 1.0 |

| Area (mm2) | Minimize → 12.357 | 3.0 | 22.819 | 0.480 |

| Ra (µm) | Minimize → 1.967 | 1.0 | 3.310 | 0.807 |

| H (kp/mm2) | Minimize → 130.0 | 1.0 | 170.551 | 0.744 |

| YS (MPa) | Maximize → 376.18 | 1.0 | 369.756 | 0.979 |

| TS (MPa) | Maximize → 424.71 | 1.0 | 423.210 | 0.994 |

| RS (MPa) | Minimize → 62.9 | 1.0 | 157.145 | 0.638 |

| Overall Desirability | 0.749 | |||

| Goal | Importance | Value | Desirability | |

|---|---|---|---|---|

| Current (C) | In range → 120.0 | 1.0 | 149.88 | 1.0 |

| Speed (S) | Maximize → 10.0 | 3.0 | 9.261 | 0.715 |

| Voltage (V) | In range → 20.0 | 1.0 | 29.999 | 1.0 |

| Area (mm2) | Minimize → 12.357 | 1.0 | 24.318 | 0.752 |

| Ra (µm) | Minimize → 1.967 | 1.0 | 2.656 | 0.901 |

| H (kp/mm2) | Minimize → 130.0 | 1.0 | 202.029 | 0.546 |

| YS (MPa) | Maximize → 376.18 | 1.0 | 368.234 | 0.974 |

| TS (MPa) | Maximize → 424.71 | 1.0 | 408.647 | 0.946 |

| RS (MPa) | Minimize → 62.9 | 1.0 | 167.653 | 0.597 |

| Overall Desirability | 0.759 | |||

| Goal | Importance | Value | Desirability | |

|---|---|---|---|---|

| Current (C) | In range → 120 | 1.0 | 149.086 | 1.0 |

| Speed (S) | Maximize → 10 | 1.0 | 7.139 | 0.591 |

| Voltage (V) | In range → 20 | 1.0 | 28.541 | 1.0 |

| Area (mm2) | Minimize → 12.357 | 1.0 | 26.964 | 0.697 |

| Ra (µm) | Minimize → 1.967 | 1.0 | 3.000 | 0.852 |

| H (kp/mm2) | Minimize → 130 | 1.0 | 176.750 | 0.705 |

| YS (MPa) | Maximize → 376.18 | 3.0 | 380.721 | 1.0 |

| TS (MPa) | Maximize → 424.71 | 3.0 | 424.712 | 1.0 |

| RS (MPa) | Minimize → 62.9 | 3.0 | 118.240 | 0.488 |

| Overall Desirability | 0.739 | |||

| Goal | Importance | Value | Desirability | |

|---|---|---|---|---|

| Current (C) | In range → 120 | 1.0 | 150.372 | 1.0 |

| Speed (S) | Maximize → 10 | 1.0 | 8.561 | 0.794 |

| Voltage (V) | In range → 20 | 1.0 | 29.877 | 1.0 |

| Area (mm2) | Minimize → 12.357 | 1.0 | 25.067 | 0.736 |

| Ra (µm) | Minimize → 1.967 | 3.0 | 2.472 | 0.798 |

| H (kp/mm2) | Minimize → 130 | 1.0 | 190.386 | 0.620 |

| YS (MPa) | Maximize → 376.18 | 1.0 | 379.262 | 1.0 |

| TS (MPa) | Maximize → 424.71 | 1.0 | 419.307 | 0.981 |

| RS (MPa) | Minimize → 62.9 | 1.0 | 148.494 | 0.671 |

| Overall Desirability | 0.789 | |||

| Des. Crit. | Experimental Values Obtained | |||||||

|---|---|---|---|---|---|---|---|---|

| A (mm2) | Ra (µm) | H (kp/mm2) | YS (MPa) | TS (MPa) | RS (MPa) | MAE | RMSE | |

| 1st Crit. | 22.23 | 2.85 | 169.23 | 368.29 | 418.76 | 164.95 | 0.27 | 0.28 |

| 2nd Crit. | 21.43 | 3.12 | 168.32 | 358.66 | 419.32 | 136.45 | 0.25 | 0.27 |

| 3rd Crit. | 25.28 | 2.46 | 192.95 | 371.34 | 412.65 | 149.75 | 0.21 | 0.22 |

| 4th Crit. | 25.86 | 3.11 | 181.23 | 383.68 | 427.22 | 105.23 | 0.15 | 0.16 |

| 5th Crit. | 24.87 | 2.31 | 193.50 | 384.62 | 421.37 | 128.54 | 0.15 | 0.18 |

| MAE | 0.19 | 0.19 | 0.15 | 0.23 | 0.20 | 0.28 | 0.21 | 0.21 |

| RMSE | 0.21 | 0.20 | 0.16 | 0.26 | 0.22 | 0.28 | 0.22 | 0.23 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lostado Lorza, R.; Escribano García, R.; Martínez Calvo, M.Á.; Múgica Vidal, R. Improvement in the Design of Welded Joints of EN 235JR Low Carbon Steel by Multiple Response Surface Methodology. Metals 2016, 6, 205. https://doi.org/10.3390/met6090205

Lostado Lorza R, Escribano García R, Martínez Calvo MÁ, Múgica Vidal R. Improvement in the Design of Welded Joints of EN 235JR Low Carbon Steel by Multiple Response Surface Methodology. Metals. 2016; 6(9):205. https://doi.org/10.3390/met6090205

Chicago/Turabian StyleLostado Lorza, Ruben, Ruben Escribano García, María Ángeles Martínez Calvo, and Rodolfo Múgica Vidal. 2016. "Improvement in the Design of Welded Joints of EN 235JR Low Carbon Steel by Multiple Response Surface Methodology" Metals 6, no. 9: 205. https://doi.org/10.3390/met6090205

APA StyleLostado Lorza, R., Escribano García, R., Martínez Calvo, M. Á., & Múgica Vidal, R. (2016). Improvement in the Design of Welded Joints of EN 235JR Low Carbon Steel by Multiple Response Surface Methodology. Metals, 6(9), 205. https://doi.org/10.3390/met6090205