Effect of Creep Aging Process on Microstructures and Properties of the Retrogressed Al-Zn-Mg-Cu Alloy

Abstract

:1. Introduction

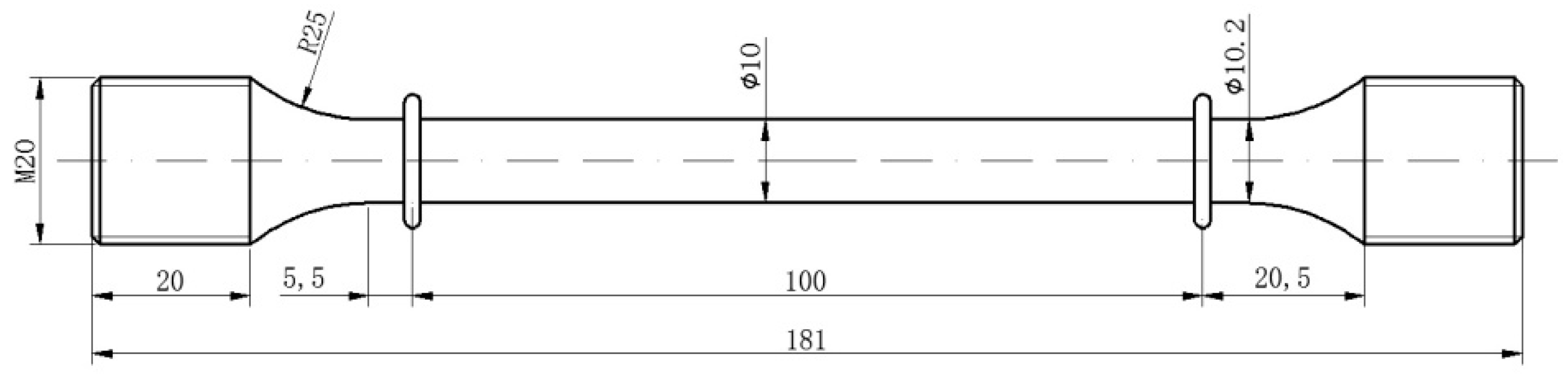

2. Materials and Methods

2.1. Material and Heat Treatments

2.2. Microstructure Characterization

2.3. Hardness and Corrosion Resistance Tests

3. Results and Discussion

3.1. TEM Observations of the 7B04 Aluminum Alloy with Various Heat Treatments

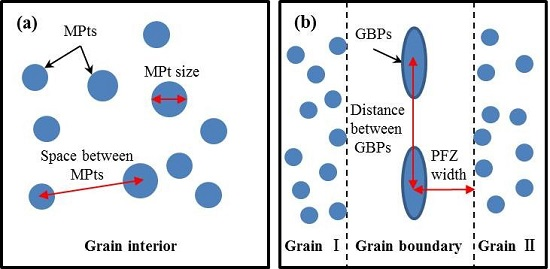

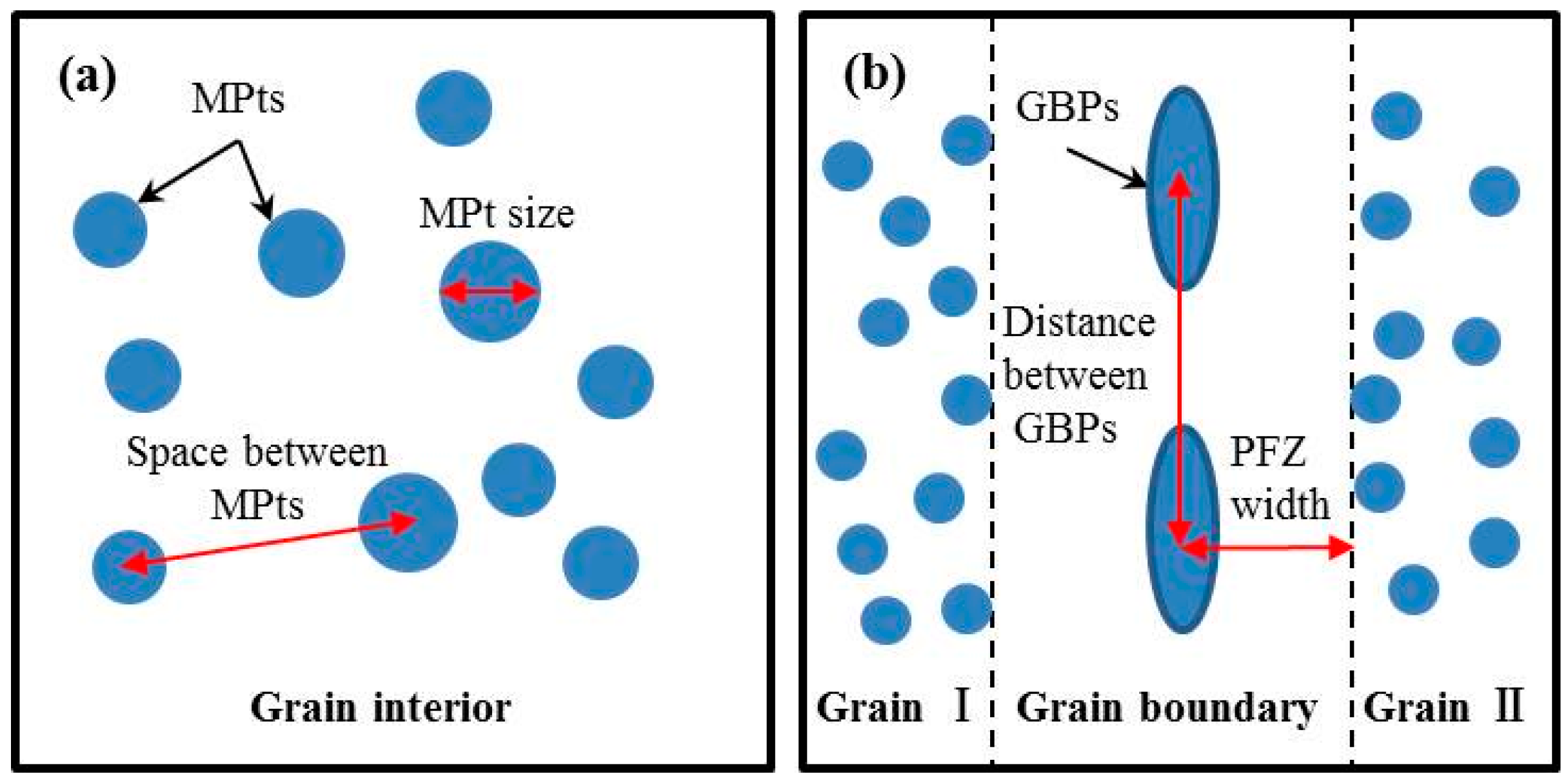

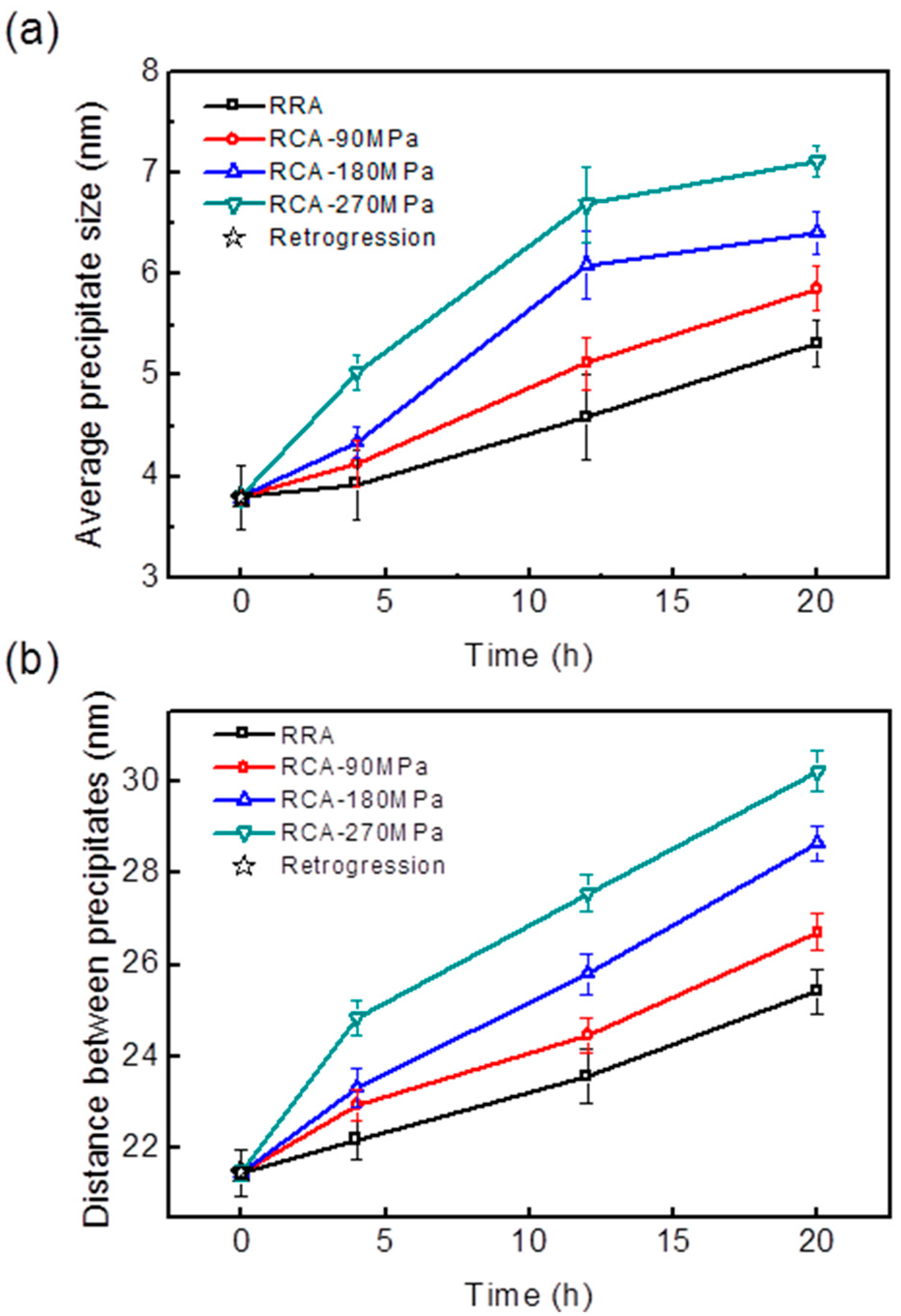

3.2. Effects of Creep Aging on Matrix Precipitate Microstructures

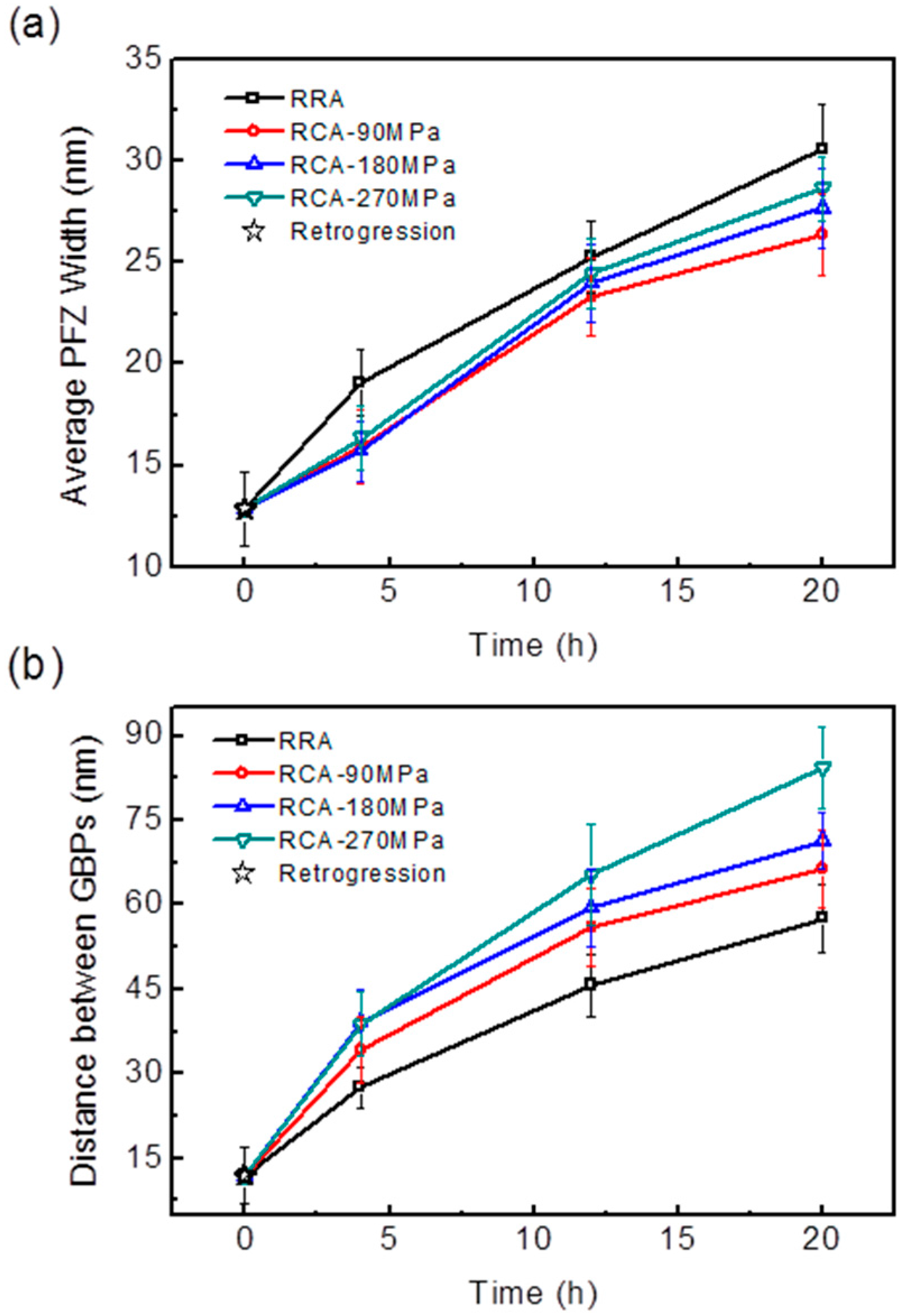

3.3. Effects of Creep Aging on Grain Boundary Microstructures

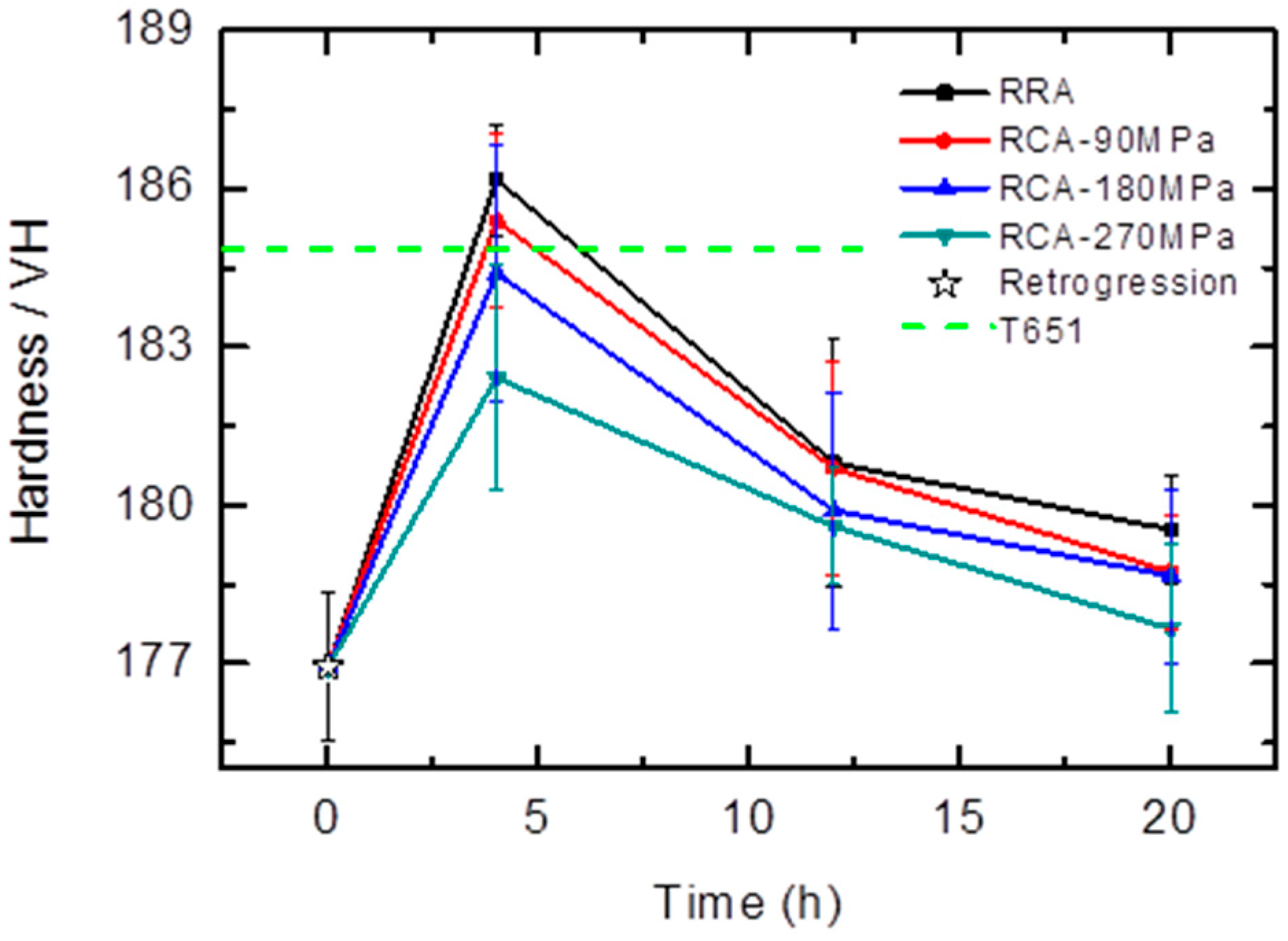

3.4. Effects of Creep Aging on Hardness

3.5. Effects of Creep Aging on Corrosion Resistance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhan, L.H.; Lin, J.G.; Dean, T.A. A review of the development of creep age forming: Experimentation, modelling and applications. Int. J. Mach. Tools Manuf. 2011, 51, 1–17. [Google Scholar] [CrossRef]

- Du, X.D. Study on ageing and creep of Al-0.1Zr alloy. Mater. Sci. Eng. A 2006, 432, 84–89. [Google Scholar] [CrossRef]

- Ho, K.C.; Lin, J.; Dean, T.A. Modelling of springback in creep forming thick aluminum sheets. Int. J. Plast. 2004, 20, 733–751. [Google Scholar] [CrossRef]

- Jeunechamps, P.-P.; Ho, K.C.; Lin, J.; Ponthot, J.-P.; Dean, T.A. A closed form technique to predict springback in creep age-forming. Int. J. Mech. Sci. 2006, 48, 621–629. [Google Scholar] [CrossRef]

- Zhan, L.H.; Lin, J.; Dean, T.A.; Huang, M.H. Experimental studies and constitutive modelling of the hardening of aluminium alloy 7055 under creep age forming conditions. Int. J. Mech. Sci. 2011, 53, 595–605. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Puiggali, M.; Zielinski, A.; Olive, J.M.; Renauld, E.; Desjardins, D.; Cid, M. Effect of microstructure on stress corrosion cracking of an Al-Zn-Mg-Cu alloy. Corros. Sci. 1988, 40, 805–819. [Google Scholar] [CrossRef]

- Marlaud, T.; Baroux, B.; Deschamps, A.; Chemin, J.L.; Henon, C. Understanding the compromise between strength and exfoliation corrosion in high strength 7000 alloys. Mater. Sci. Forum. 2006, 519–521, 455–460. [Google Scholar] [CrossRef]

- Jeshvaghani, R.A.; Emami, M.; Shahverdi, H.R.; Hadavi, S.M.M. Effects of time and temperature on the creep forming of 7075 aluminum alloy: Springback and mechanical properties. Mater. Sci. Eng. A 2011, 528, 8795–8799. [Google Scholar] [CrossRef]

- Jeshvaghani, R.A.; Shahverdi, H.R.; Hadavi, S.M.M. Investigation of the age hardening and operative deformation mechanism of 7075 aluminum alloy under creep forming. Mater. Sci. Eng. A 2012, 552, 172–178. [Google Scholar] [CrossRef]

- Guo, W.; Yang, M.; Zheng, Y.; Zhang, X.S.; Li, H.; Wen, X.Y.; Zhang, J.W. Influence of elastic tensile stress on aging process in an Al-Zn-Mg-Cu alloy. Mater. Lett. 2013, 106, 14–17. [Google Scholar] [CrossRef]

- Lin, Y.C.; Jiang, Y.Q.; Chen, X.M.; Wen, D.X.; Zhou, H.M. Effect of creep-aging on precipitates of 7075 aluminum alloy. Mater. Sci. Eng. A 2013, 588, 347–356. [Google Scholar] [CrossRef]

- Lin, Y.C.; Jiang, Y.Q.; Zhang, X.C.; Deng, J.; Chen, X.M. Effect of creep-aging processing on corrosion resistance of an Al-Zn-Mg-Cu alloy. Mater. Des. 2014, 61, 228–238. [Google Scholar] [CrossRef]

- Fribourg, G.; Bréchet, Y.; Chemin, J.L.; Deschamps, A. Evolution of precipitate microstructure during creep of an AA7449 T7651 aluminum alloy. Metall. Mater. Trans. 2011, 42, 3934–3940. [Google Scholar] [CrossRef]

- Lin, Y.C.; Zhang, J.L.; Liu, G.; Liang, Y.J. Effects of pre-treatments on aging precipitates and corrosion resistance of a creep-aged Al-Zn-Mg-Cu alloy. Mater. Des. 2015, 83, 866–875. [Google Scholar] [CrossRef]

- Li, C.; Wan, M.; Wu, X.D.; Huang, L. Constitutive equations in creep of 7B04 aluminum alloys. Mater. Sci. Eng. A 2010, 527, 3623–3629. [Google Scholar] [CrossRef]

- Zhan, L.H.; Li, Y.G.; Huang, M.H. Effects of process parameters on mechanical properties and microstructures of creep aged 2124 aluminum alloy. Trans. Nonferr. Met. Soc. China 2014, 24, 2232–2238. [Google Scholar] [CrossRef]

- Junior, P.R.C.; Neto, C.D.; Wade, D.A. Essai d’une table non-vibrante par enregistrement du mouvement brownien d’un galvanometer. Mater. Res. 2014, 17, 603–611. [Google Scholar]

- Ning, A.L.; Liu, Z.Y.; Peng, B.S.; Zeng, S.M. Redistribution and re-precipitation of solute atom during retrogression and reaging of Al-Zn-Mg-Cu alloys. Trans. Nonferr. Met. Soc. China 2007, 17, 1005–1011. [Google Scholar] [CrossRef]

- Feng, C.; Liu, Z.Y.; Ning, A.L.; Zeng, S.M. Retrogression and re-aging treatment of Al-9.99%Zn-1.72%Cu-2.5%Mg-0.13%Zr aluminum alloy. Nonferr. Met. Soc. China 2006, 16, 1163–1170. [Google Scholar] [CrossRef]

- Oliveira, A.F., Jr.; de Barros, M.C.; Cardoso, K.R.; Travessa, D.N. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminium alloys. Mater. Sci. Eng. A 2004, 379, 321–326. [Google Scholar] [CrossRef]

- Hashmi, S. Comprehensive Materials Processing. Creep Age Form. Model. Charact. 2014, 2, 150–155. [Google Scholar]

- GB/T 12966-2008. The method for determining aluminum alloys conductivity using eddy current. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China: Beijing, China, 2008.

- ASTM G 34-01. Standard test method for exfoliation corrosion susceptibility in 2XXX and 7XXX series aluminum alloys (EXCO test). American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- Marlaud, T.; Deschamps, A.; Bley, F.; Lefebvre, W.; Baroux, B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy. Acta Mater. 2010, 58, 4814–4826. [Google Scholar] [CrossRef]

- Wang, Y.L.; Pan, Q.L.; Wei, L.L.; Li, B.; Wang, Y. Effect of retrogression and reaging treatment on the microstructure and fatigue crack growth behavior of 7050 aluminum alloy thick plate. Mater. Des. 2014, 55, 857–863. [Google Scholar] [CrossRef]

- Degischer, H.P.; Lacom, W.; Zahra, A.; Zahra, C.Y. Decomposition processes in an Al-5%Zn-1%Mg alloy. II. Electronmicroscopic investigations. Z. Metallkd. 1980, 71, 231–238. [Google Scholar]

- Deschamps, A.; Livet, F.; Bréchet, Y. Influence of predeformation on ageing in an Al-Zn-Mg alloy—I. Microstructure evolution and mechanical properties. Acta Mater. 1998, 47, 281–292. [Google Scholar] [CrossRef]

- Poole, W.J.; Seter, J.A.; Skjervold, S.; Waterloo, G. A model for predicting the effect of deformation after solution treatment on the subsequent artificial aging behavior of AA7030 and AA7180 alloys. Metall. Mater. Trans. A 2000, 31, 2327–2338. [Google Scholar] [CrossRef]

- Ashby, M.F. Results and consequences of a recalculation of the frank-read and the orowan stress. Acta Metall. 1966, 14, 679–681. [Google Scholar] [CrossRef]

- Deschamps, A. Analytical Techniques for Aluminum. In Handbook of Aluminum of Volume 2: Alloy Production and Materials Manufacturing; Totten, G.E., MacKenzie, D.S., Eds.; CRC Press: Boca Raton, FL, USA, 2003; pp. 160–169. [Google Scholar]

- Chen, J.F.; Zhen, L.; Jiang, J.T.; Yang, L.; Shao, W.Z.; Zhang, B.Y. Microstructures and mechanical properties of age-formed 7050 aluminum alloy. Mater. Sci. Eng. A 2012, 539, 115–123. [Google Scholar] [CrossRef]

- Knight, S.P.; Pohl, K.; Holroyd, N.J.H.; Birbilis, N.; Rometsch, P.A.; Muddle, B.C.; Goswami, R.; Lynch, S.P. Some effects of alloy composition on stress corrosion cracking in Al-Zn-Mg-Cu alloys. Corros. Sci. 2015, 98, 50–62. [Google Scholar] [CrossRef]

- Li, J.F.; Birbilis, N.; Li, C.X.; Jia, Z.Q.; Cai, B.; Zheng, Z.Q. Influence of retrogression temperature and time on the mechanical properties and exfoliation corrosion behavior of aluminium alloy AA7150. Mater. Charact. 2009, 60, 1334–1341. [Google Scholar] [CrossRef]

- Xiao, Y.P.; Pan, Q.L.; Li, W.B.; Liu, X.Y.; He, Y.B. Influence of retrogression and re-aging treatment on corrosion behaviour of an Al-Zn-Mg-Cu alloy. Mater. Des. 2011, 32, 2149–2156. [Google Scholar] [CrossRef]

- Sun, X.Y.; Zhang, B.; Lin, H.Q.; Zhou, Y.; Sun, L.; Wang, J.Q.; Han, E.H.; Ke, W. Correlations between stress corrosion cracking susceptibility and grain boundary microstructures for an Al-Zn-Mg alloy. Corros. Sci. 2013, 77, 103–112. [Google Scholar] [CrossRef]

| Al | Zn | Mg | Cu | Fe | Si | Cr |

|---|---|---|---|---|---|---|

| Bal. | 5.97 | 2.48 | 1.51 | 0.16 | 0.07 | 0.16 |

| Applied Stress (MPa) | Aging Time (h) | EXCO Rating |

|---|---|---|

| As-received (T651) | ED | |

| Retrogression | ED− | |

| RRA(0 MPa) | 4 h | ED− |

| 12 h | EC | |

| 20 h | EC− | |

| RCA-90 MPa | 4 h | EC+ |

| 12 h | EC | |

| 20 h | EB | |

| RCA-180 MPa | 4 h | EC+ |

| 12 h | EC− | |

| 20 h | EB | |

| RCA-270 MPa | 4 h | EC+ |

| 12 h | EB | |

| 20 h | EB | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Zhan, L. Effect of Creep Aging Process on Microstructures and Properties of the Retrogressed Al-Zn-Mg-Cu Alloy. Metals 2016, 6, 189. https://doi.org/10.3390/met6080189

Xu Y, Zhan L. Effect of Creep Aging Process on Microstructures and Properties of the Retrogressed Al-Zn-Mg-Cu Alloy. Metals. 2016; 6(8):189. https://doi.org/10.3390/met6080189

Chicago/Turabian StyleXu, Yongqian, and Lihua Zhan. 2016. "Effect of Creep Aging Process on Microstructures and Properties of the Retrogressed Al-Zn-Mg-Cu Alloy" Metals 6, no. 8: 189. https://doi.org/10.3390/met6080189

APA StyleXu, Y., & Zhan, L. (2016). Effect of Creep Aging Process on Microstructures and Properties of the Retrogressed Al-Zn-Mg-Cu Alloy. Metals, 6(8), 189. https://doi.org/10.3390/met6080189