Preparation of Metallic Iron Powder from Pyrite Cinder by Carbothermic Reduction and Magnetic Separation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Methods

2.2.1. Reduction Roasting and Magnetic Separation

2.2.2. Methods of Analysis

3. Results and Discussion

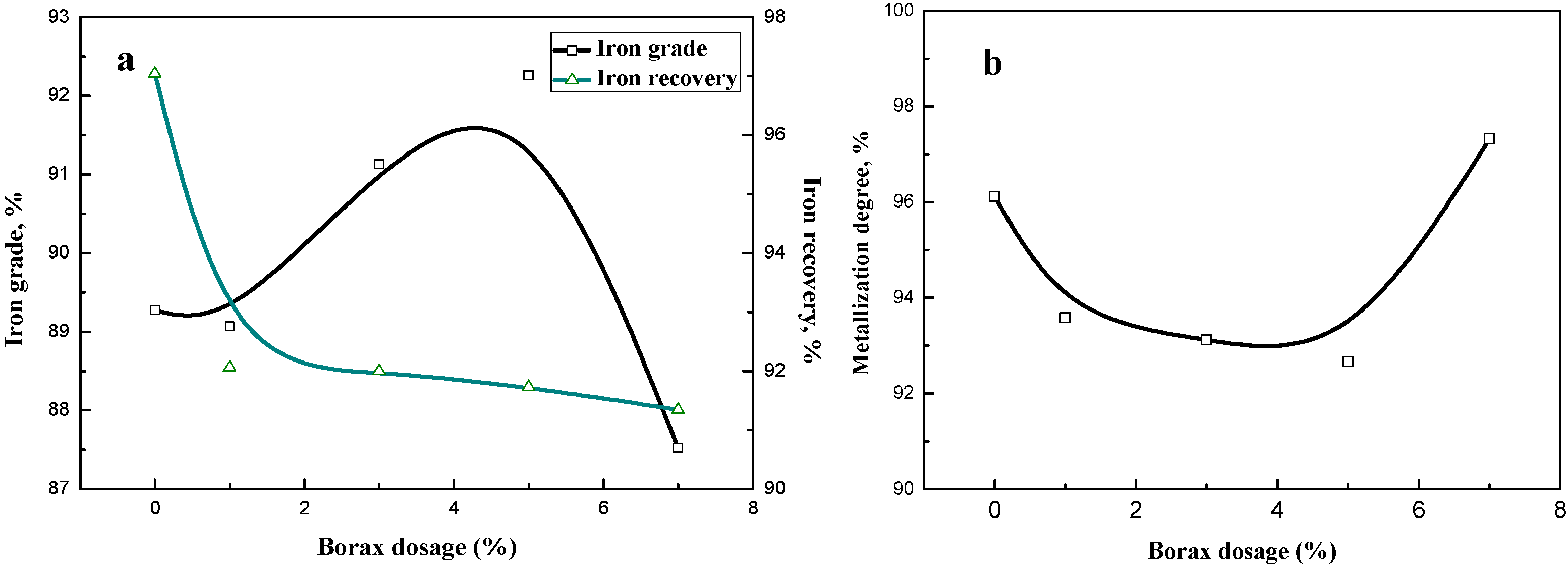

3.1. Effect of Borax Additive Dosage

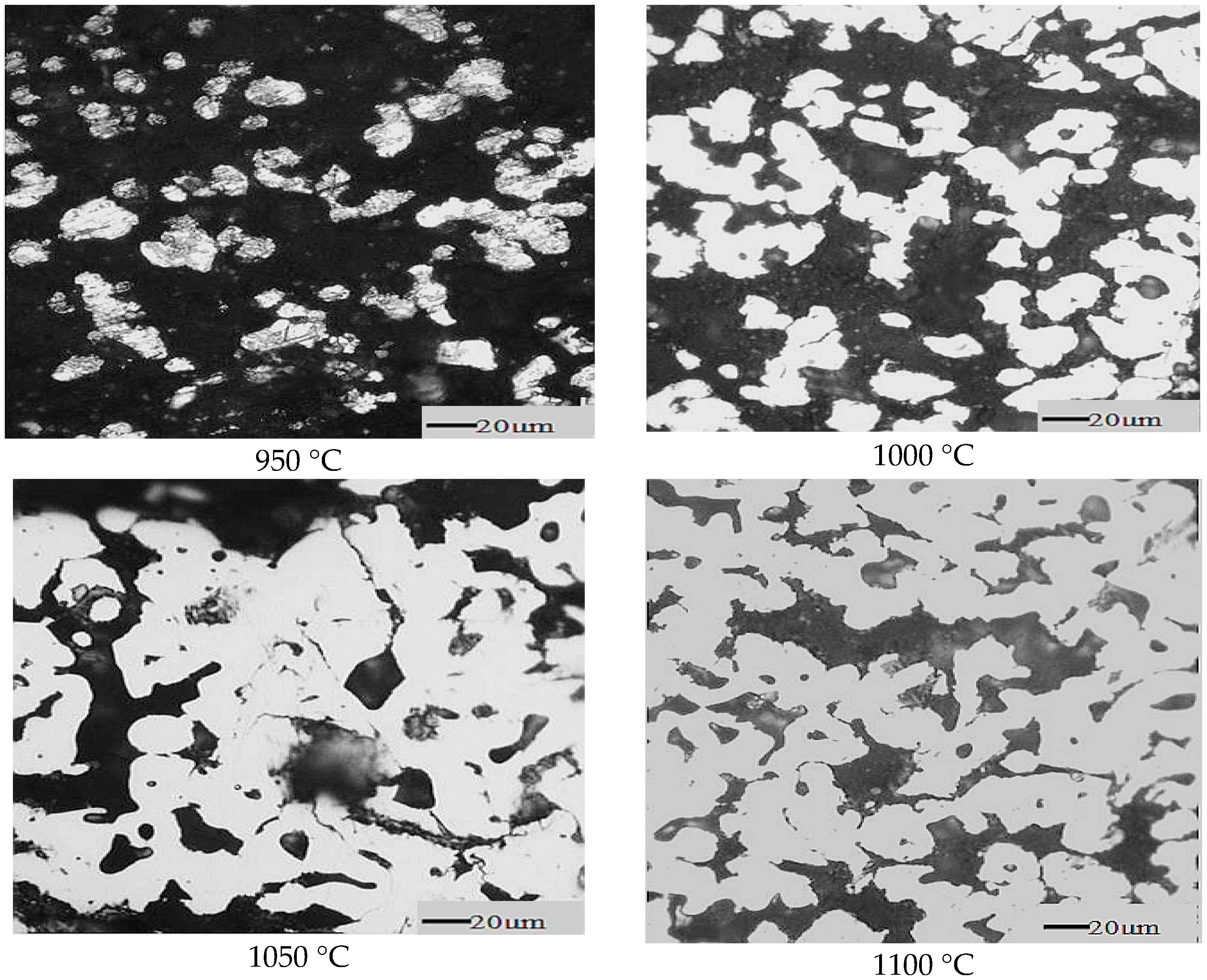

3.2. Effect of Reduction Temperature

3.3. Effect of Reduction Time

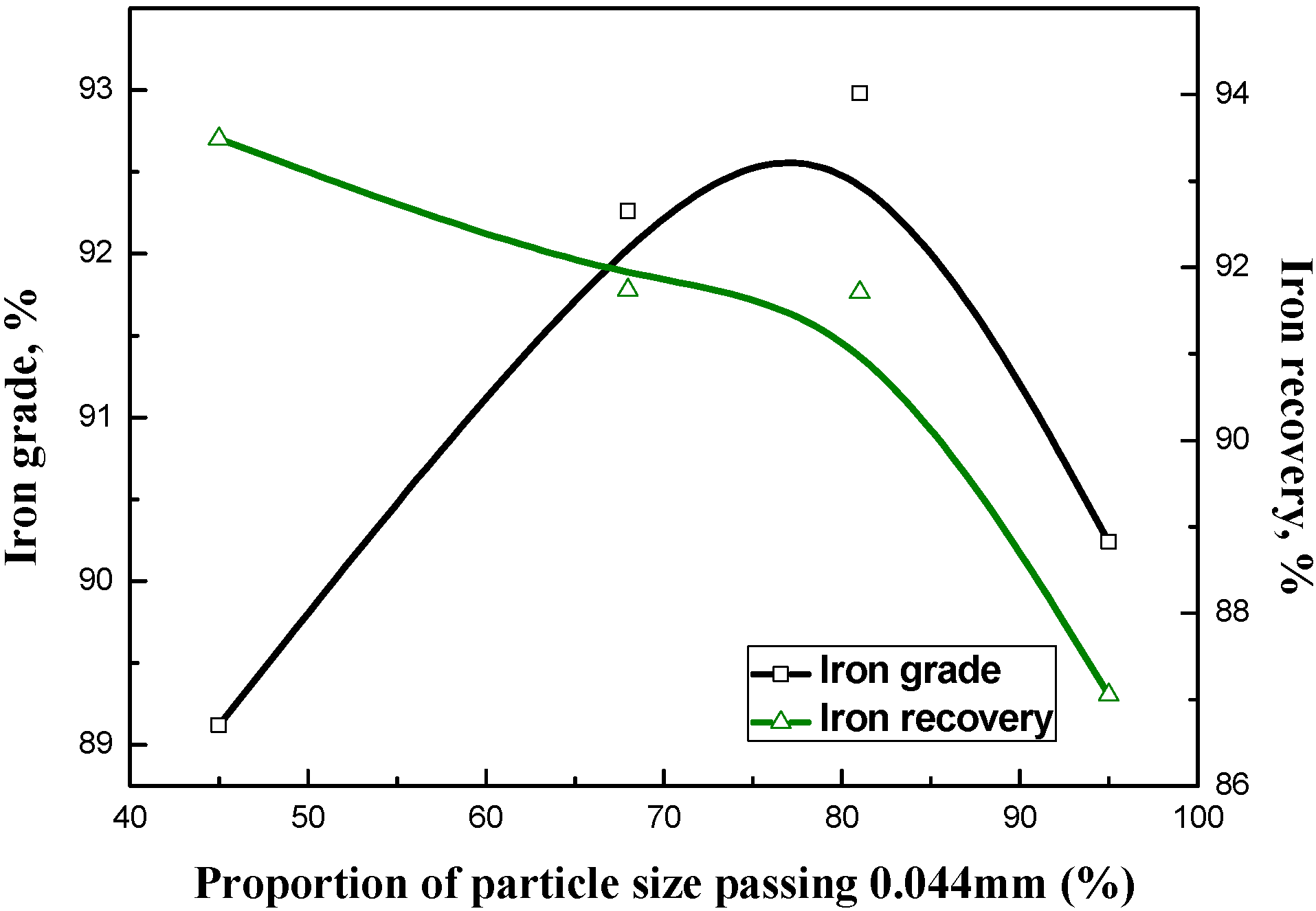

3.4. Effect of Grinding Fineness

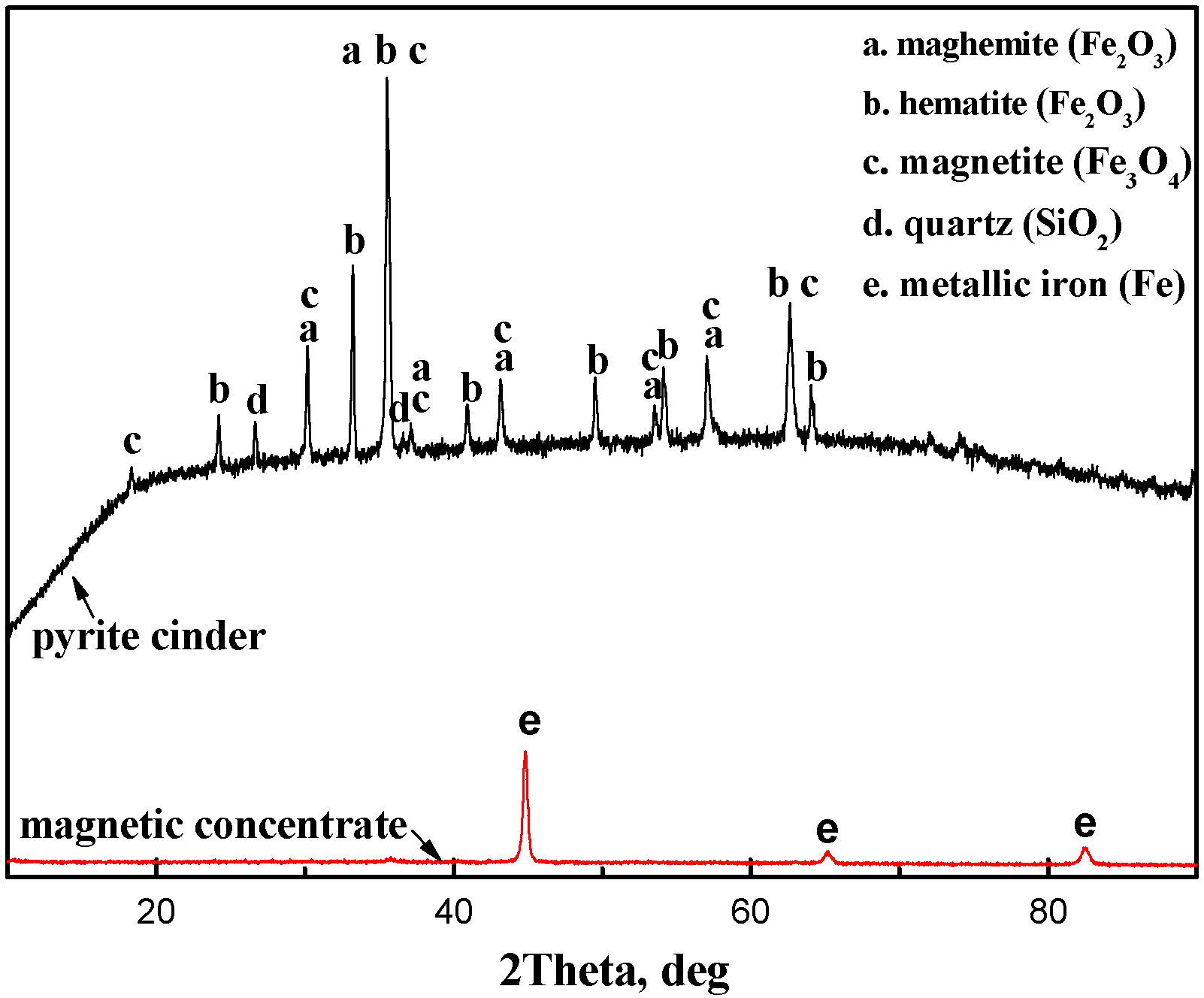

3.5. Analysis of the Final Product

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhu, D.Q.; Chun, T.J.; Pan, J.; Guo, Z.Q. Preparation of oxidised pellets using pyrite cinders as raw material. Ironmak. Steelmak. 2013, 40, 430–435. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, Z. Preparation of monodispersed micaceous iron oxide pigment from pyrite cinders. Powder Technol. 2011, 207, 335–342. [Google Scholar] [CrossRef]

- Giunti, M.; Baroni, D.; Bacci, E. Hazard assessment to workers of trace metal content in pyrite cinders. Bull. Environ. Contamin. Toxicol. 2004, 72, 352–357. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.P.; He, G.W. Research on recycling technology and waste water treatment with sulfuric acid residue. J. South China Norm. Univ. 2010, 2, 72–75. (In Chinese) [Google Scholar]

- Jin, C.; Li, D.X. Research progress on the comprehensive utilization of iron from pyrite cinder. Metal Mine 2011, 10, 162–165. [Google Scholar]

- Bi, W.L.; Wu, W.H.; Li, J. Experimental research on recovering of iron concentrate from pyrite cinder. Hydrometall. China 2011, 30, 229–230. (In Chinese) [Google Scholar]

- Wang, Q.L.; Zhou, H.Q.; Dai, Y.H. Technological research on desulfurizing flotation of pyrite cinder in Guangxi. Min. Metal. Eng. 2008, 28, 44–46. [Google Scholar]

- Zheng, Z.F.; Li, M.L. Experimental study on iron recovery from pyrite cinder. Min. Metal. Eng. 2006, 26, 29–32. [Google Scholar]

- He, B.; Tian, X.; Sun, Y.; Yang, C.; Zeng, Y.; Wang, Y.; Zhang, S.; Pi, Z. Recovery of iron oxide concentrate from high-sulfur and low-grade pyrite cinder using an innovative beneficiating process. Hydrometallurgy 2010, 104, 241–246. [Google Scholar] [CrossRef]

- Jin, C.; Wang, E.Q.; Li, D.X. Pressure reduction leaching iron from sulfate slag. Nonferr. Metals 2011, 11, 6–8. [Google Scholar]

- Long, H.M.; Meng, Q.M.; Wang, P.; Chun, T.J.; Yao, Y.L. Preparation of chromium-iron metal powder from chromium slag by reduction roasting and magnetic separation. J. IronSteel Res. Int. 2015, 22, 771–776. [Google Scholar] [CrossRef]

- Chun, T.J.; Long, H.M.; Li, J.X. Alumina-iron separation of high alumina iron ore by carbothermic reduction and Magnetic separation. Separat. Sci. Technol. 2015, 50, 760–766. [Google Scholar] [CrossRef]

- Qiu, G.Z.; Jiang, T.; Xu, T.J.; Cai, R.Z. Direct Reduction of Cold-bonded Pellets; Centre South University Press: Changsha, China, 2001; pp. 176–180. [Google Scholar]

- Zhu, D.Q.; Zhou, W.T.; Pan, J.; Chen, D. Improving pelletization of Brazilian hematite by adding boron-containing magnetite. J. Cent. South Univ. Sci. Technol. 2014, 45, 348–355. (In Chinese) [Google Scholar]

- Chun, T.J.; Zhu, D.Q.; Pan, J.; He, Z. Preparation of metallic iron powder from red mud by sodium salt roasting and magnetic separation. Can. Metal. Q. 2014, 53, 183–189. [Google Scholar] [CrossRef]

- Chen, D.; Zhu, D.Q.; Chen, Y. Preparation of prereduced pellets by pyrite cinder containing nonferrous metals with high temperature chloridizing-reduction roasting technology. ISIJ Int. 2014, 54, 2162–2168. [Google Scholar] [CrossRef]

- Zhang, K.; Nieto, A.; Kleit, A. Valuation of mining operation with uncertainty and the power of waiting—A real option method. In Mine Planning and Equipment Selection; Springer publisher: Berlin, Germany, 2014; pp. 1503–1512. [Google Scholar]

- Zhang, K.; Kleit, A.N. Mining rate optimization considering the stockpiling: A theoretical economics and real option model. Resour. Policy 2016, 31, 87–94. [Google Scholar] [CrossRef]

- Chun, T.J.; Zhu, D.Q.; Pan, J. Simultaneously roasting and magnetic separation to treat low grade siderite and hematite ores. Miner. Process. Extr. Metal. Rev. 2015, 36, 223–226. [Google Scholar] [CrossRef]

| Element | TFe | FeO | SiO2 | Al2O3 | CaO | MgO | K2O | Na2O | P | S | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content | 60.95 | 12.61 | 5.92 | 1.98 | 0.47 | 0.36 | 0.21 | 0.05 | 0.04 | 0.39 | 1.12 |

| Size | 0.15–0.106 mm | 0.106–0.074 mm | 0.074–0.044 mm | −0.044 mm |

|---|---|---|---|---|

| Content | 6.47 | 14.97 | 19.85 | 58.71 |

| Item | Fixed Carbon | Moisture | Ash | Volatiles | Sulfur |

|---|---|---|---|---|---|

| Content | 50.04 | 7.97 | 12.04 | 30.15 | 0.37 |

| Size | 5–1 mm | 1–0.5 mm | 0.5–0 mm |

|---|---|---|---|

| Content | 58.29 | 17.23 | 24.48 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, H.; Chun, T.; Di, Z.; Wang, P.; Meng, Q.; Li, J. Preparation of Metallic Iron Powder from Pyrite Cinder by Carbothermic Reduction and Magnetic Separation. Metals 2016, 6, 88. https://doi.org/10.3390/met6040088

Long H, Chun T, Di Z, Wang P, Meng Q, Li J. Preparation of Metallic Iron Powder from Pyrite Cinder by Carbothermic Reduction and Magnetic Separation. Metals. 2016; 6(4):88. https://doi.org/10.3390/met6040088

Chicago/Turabian StyleLong, Hongming, Tiejun Chun, Zhanxia Di, Ping Wang, Qingmin Meng, and Jiaxin Li. 2016. "Preparation of Metallic Iron Powder from Pyrite Cinder by Carbothermic Reduction and Magnetic Separation" Metals 6, no. 4: 88. https://doi.org/10.3390/met6040088