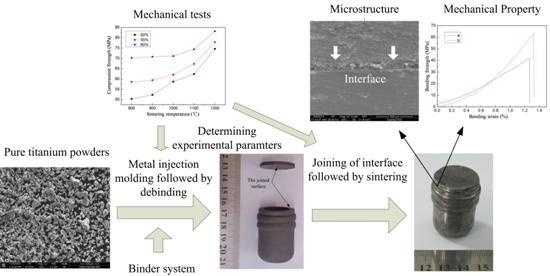

Influencing Factors for the Microstructure and Mechanical Properties of Micro Porous Titanium Manufactured by Metal Injection Molding

Abstract

:1. Introduction

2. Materials and Experimental Procedures

3. Results and Discussion

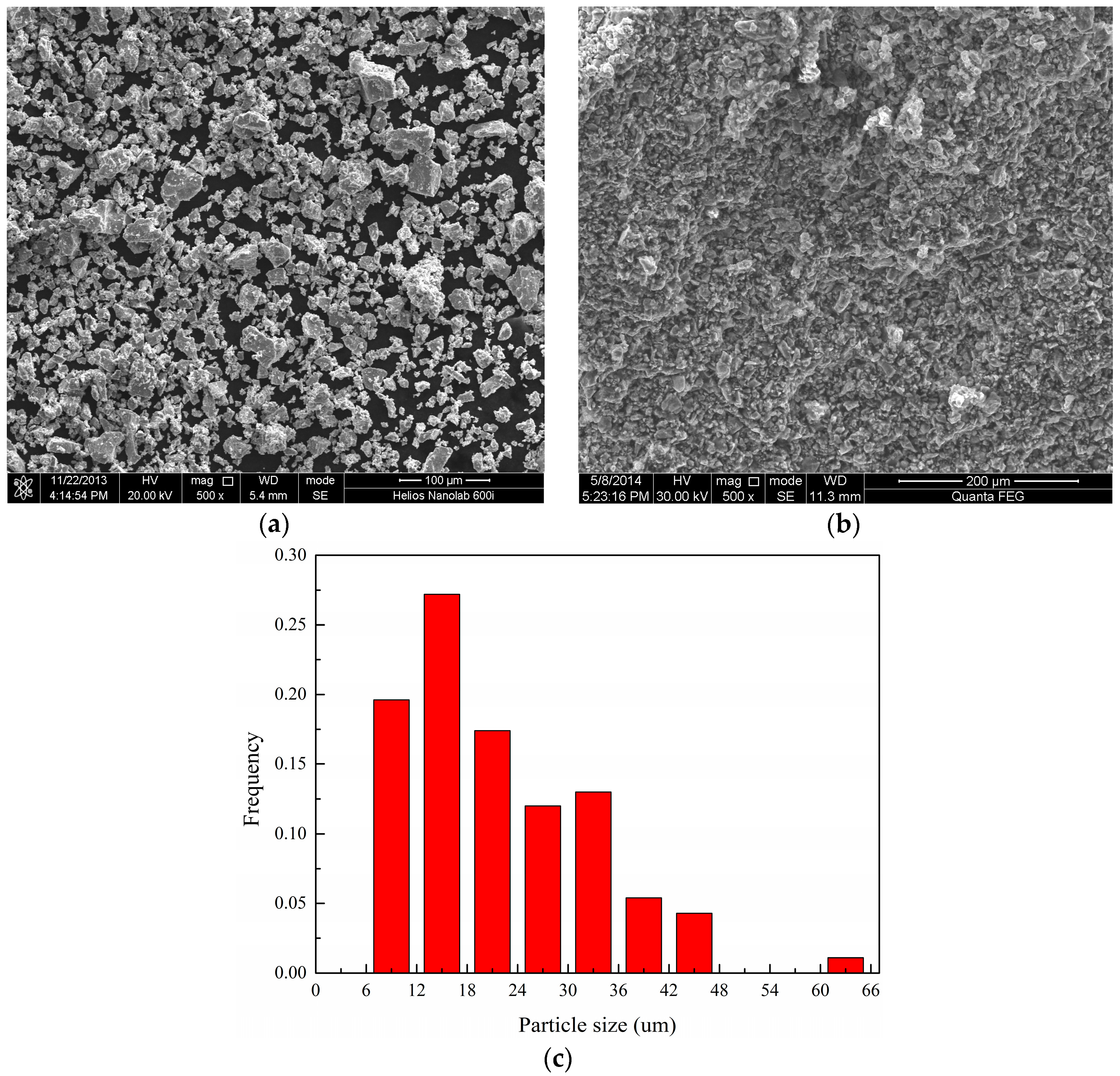

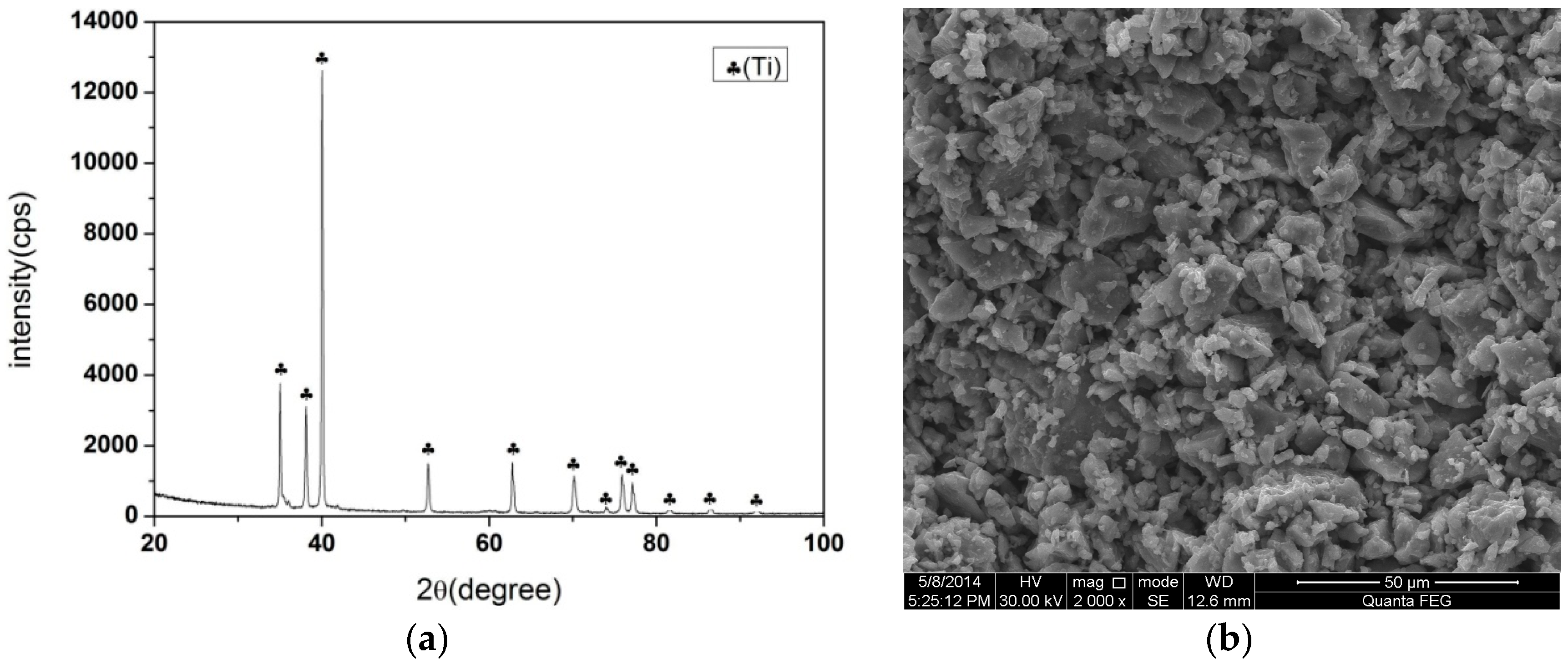

3.1. Component and Morphology of Porous Titanium Prepared by MIM

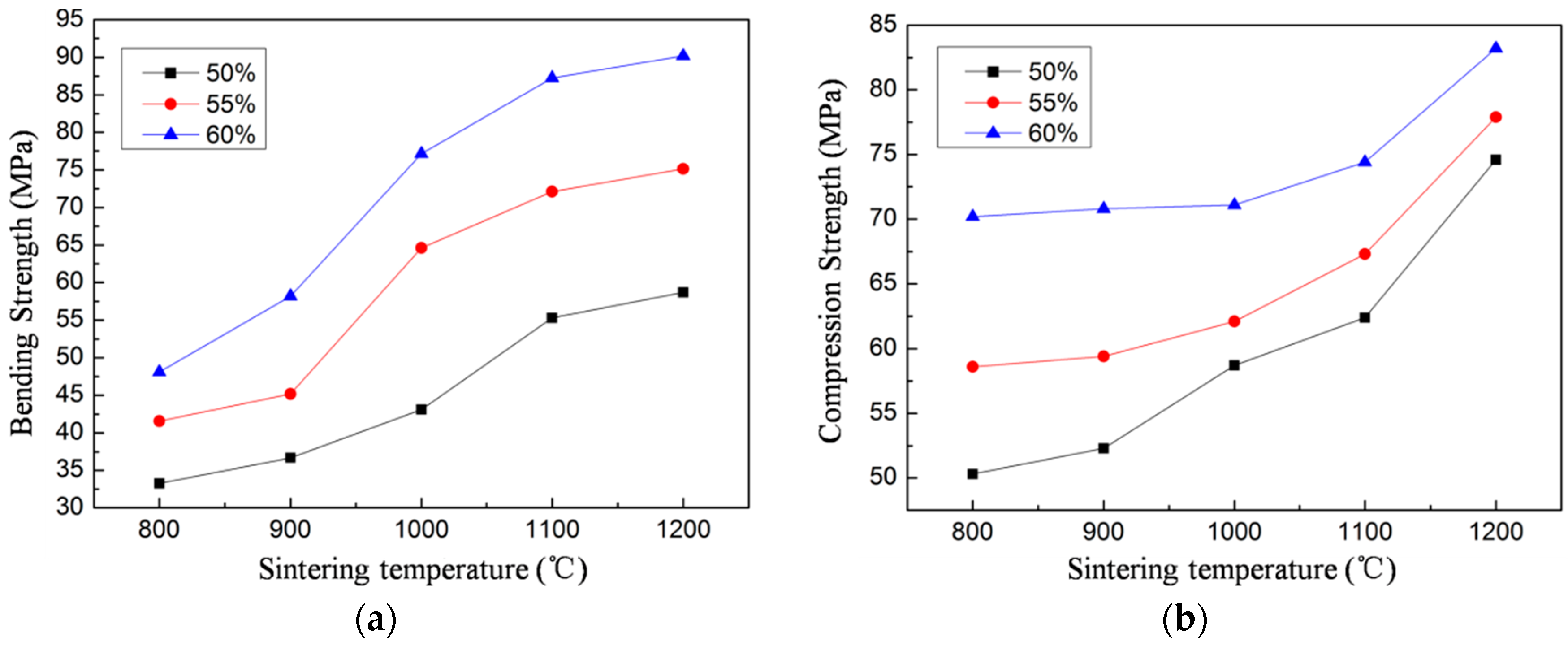

3.2. Porosity and Mechanical Property Analysis of Porous Titanium

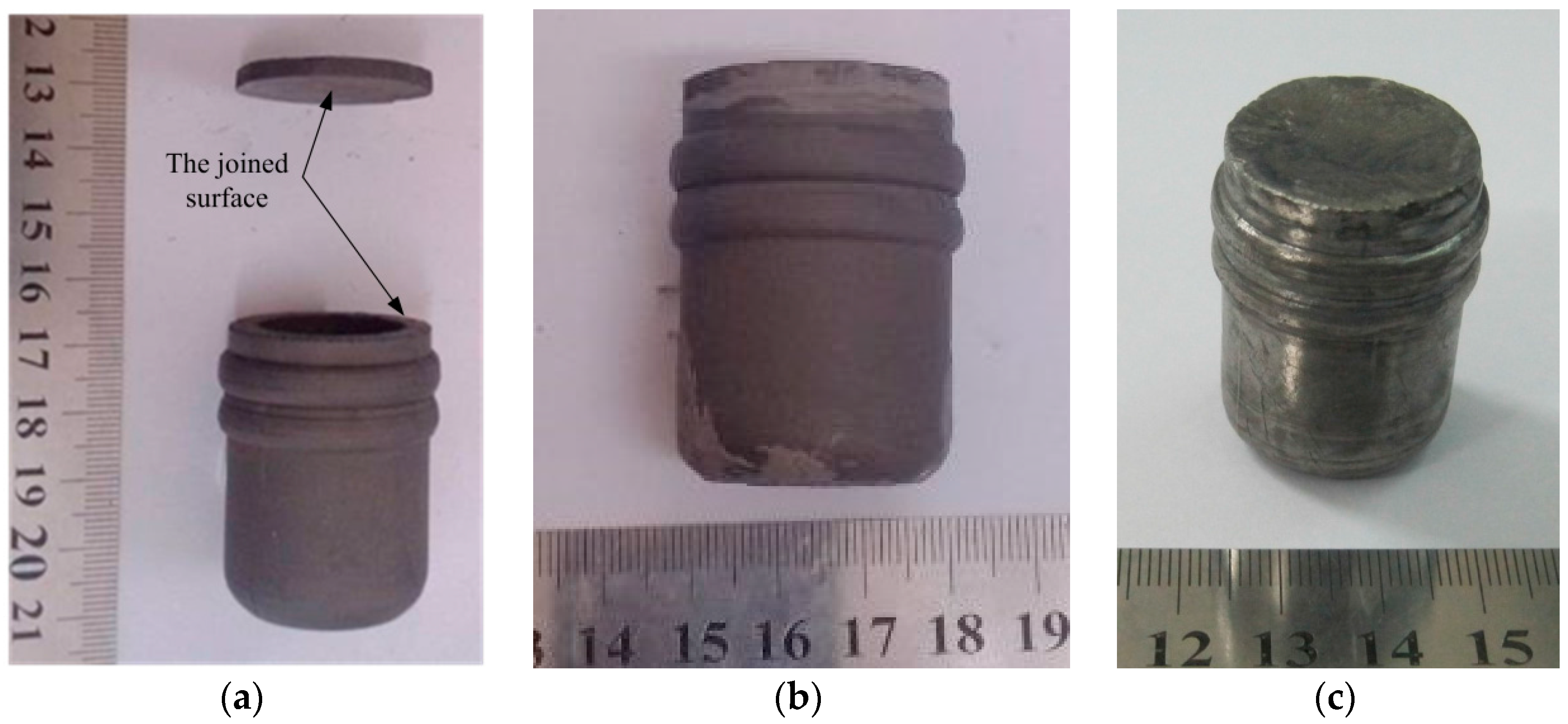

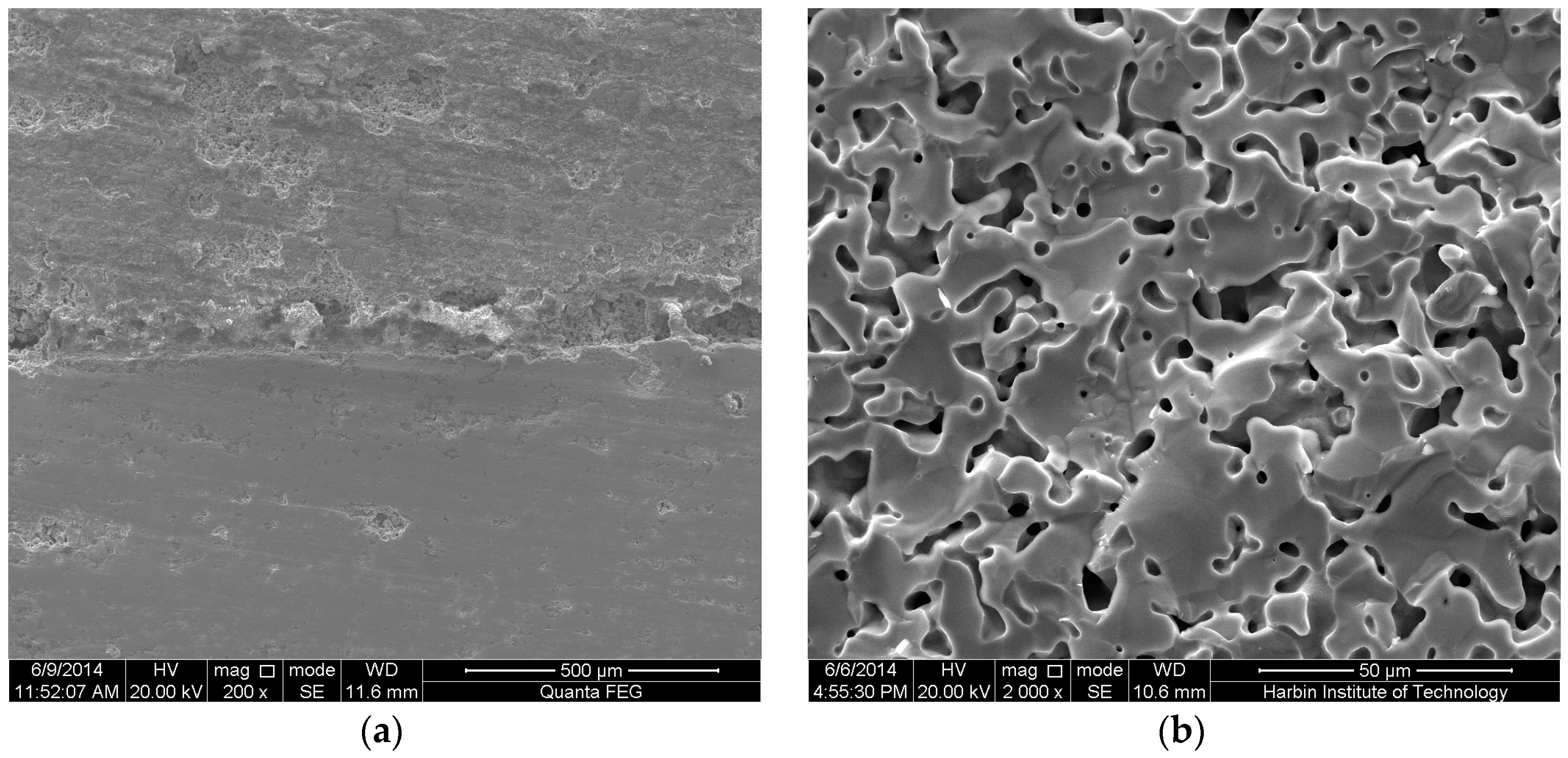

3.3. Joining Technology and Interface Analysis of Porous Titanium

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lefebvre, L.P.; Banhart, J.; Dunand, D.C. Porous metals and metallic foams: Current status and recent developments. Adv. Eng. Mater. 2008, 10, 775–787. [Google Scholar] [CrossRef] [Green Version]

- Schiefer, H.; Bram, M.; Buchkremer, H.P.; Stover, D. Mechanical examinations on dental implants with porous titanium coating. J. Mater. Sci. Mater. Med. 2009, 20, 1763–1770. [Google Scholar] [CrossRef] [PubMed]

- Wally, Z.; van Grunsven, W.; Claeyssens, F.; Goodall, R.; Reilly, G. Porous Titanium for Dental Implant Applications. Metals 2015, 5, 1902–1920. [Google Scholar] [CrossRef]

- Mohammad, A.; Alahmari, A.; Moiduddin, K.; Mohammed, M.; Alomar, A.; Renganayagalu, R. Porous γ-TiAl Structures Fabricated by Electron Beam Melting Process. Metals 2016, 6, 25:1–25:17. [Google Scholar] [CrossRef]

- Ran, H.; Feng, P.; Liu, Z.; Wang, X.; Niu, J.; Zhang, H. Complex-Shaped Porous Cu Bodies Fabricated by Freeze-Casting and Vacuum Sintering. Metals 2015, 5, 1821–1828. [Google Scholar] [CrossRef]

- Deing, A.; Luthringer, B.; Laipple, D.; Ebel, T.; Willumeit, R. A porous TiAl6V4 implant material for medical application. Int. J. Biomater. 2014. [Google Scholar] [CrossRef] [PubMed]

- Tuncer, N.; Bram, M.; Laptev, A.; Becka, T.; Mosera, A.; Buchkremer, H.P. Study of metal injection molding of highly porous titanium by physical modeling and direct experiments. J. Mater. Process. Technol. 2014, 214, 1352–1360. [Google Scholar] [CrossRef]

- Shbeh, M.M.; Goodall, R. Design of water debinding and dissolution stages of metal injection molded porous Ti foam production. Mater. Des. 2015, 87, 295–302. [Google Scholar]

- German, R.; Bose, A. Injection Molding of Metals & Ceramics; Metal Powder Industries Federation: Princeton, NJ, USA, 1997; pp. 209–210. [Google Scholar]

- Nowacki, J.; Moraniec, K. Welding of metallic AlSi foams and AlSi-SiC composite foams. Arch. Civ. Mech. Eng. 2015, 15, 940–950. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, J.; Jiang, C.; Hao, C.; Zhang, J.; Rouxel, T. Joining of Porous Alumina with a CaO-Al2O3-SiO2 Glass-Ceramic. J. Am. Ceram. Soc. 2013, 96, 1738–1744. [Google Scholar] [CrossRef]

- Wang, Z.F.; Seah, Y.P.; Wang, Z.P. Seamless joining of porous membrane with thermoplastic microfluidic devices. Microelectron. Eng. 2013, 110, 386–391. [Google Scholar] [CrossRef]

| Sintering Temperature (°C) | 800 | 900 | 1000 | 1100 | 1200 |

|---|---|---|---|---|---|

| Porosity (%) | 39.69 | 38.22 | 32.28 | 10.33 | 9.20 |

| Density (g/cm3) | 2.72 | 2.79 | 3.05 | 4.04 | 4.14 |

| Relative density (%) | 60.31 | 61.78 | 67.72 | 89.67 | 91.80 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Z.; Huang, Z.; Jiang, S.; Liu, W.; Zhang, K. Influencing Factors for the Microstructure and Mechanical Properties of Micro Porous Titanium Manufactured by Metal Injection Molding. Metals 2016, 6, 83. https://doi.org/10.3390/met6040083

Lu Z, Huang Z, Jiang S, Liu W, Zhang K. Influencing Factors for the Microstructure and Mechanical Properties of Micro Porous Titanium Manufactured by Metal Injection Molding. Metals. 2016; 6(4):83. https://doi.org/10.3390/met6040083

Chicago/Turabian StyleLu, Zhen, Zhenhan Huang, Shaosong Jiang, Wei Liu, and Kaifeng Zhang. 2016. "Influencing Factors for the Microstructure and Mechanical Properties of Micro Porous Titanium Manufactured by Metal Injection Molding" Metals 6, no. 4: 83. https://doi.org/10.3390/met6040083

APA StyleLu, Z., Huang, Z., Jiang, S., Liu, W., & Zhang, K. (2016). Influencing Factors for the Microstructure and Mechanical Properties of Micro Porous Titanium Manufactured by Metal Injection Molding. Metals, 6(4), 83. https://doi.org/10.3390/met6040083