Effect of Heat Treatment on the In-Plane Anisotropy of As-Rolled 7050 Aluminum Alloy

Abstract

:1. Introduction

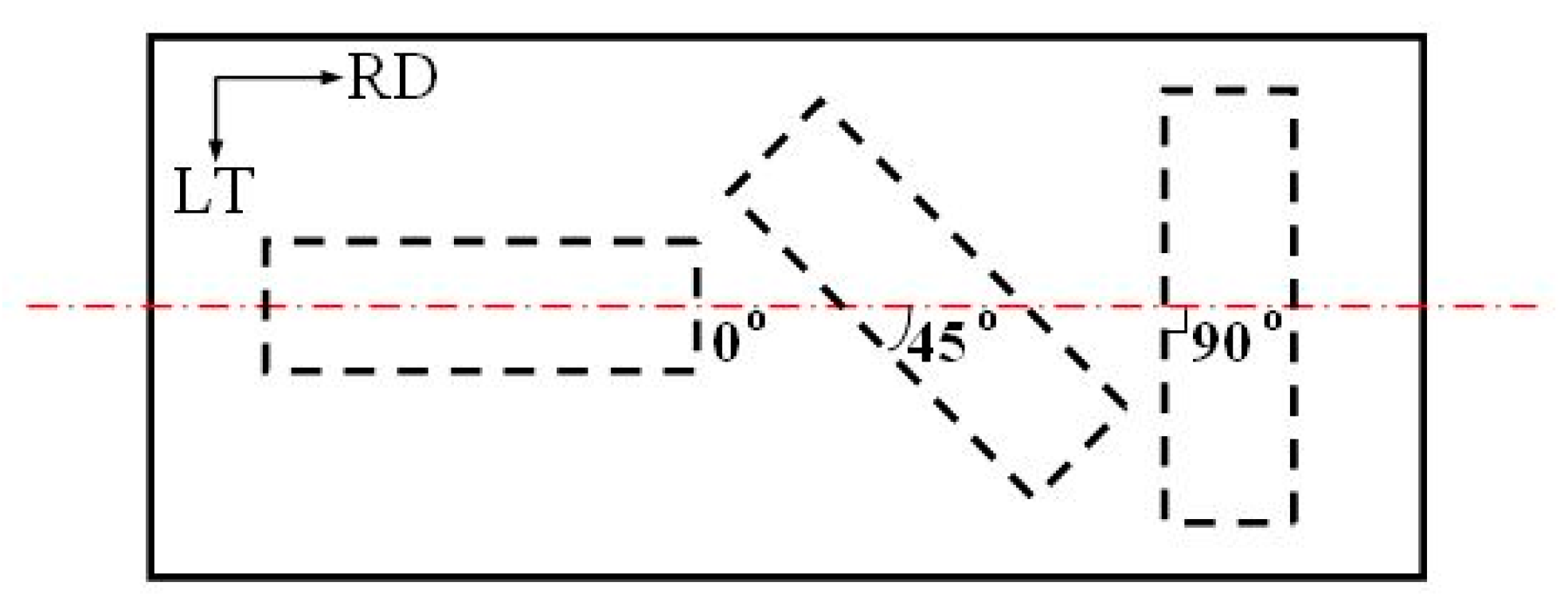

2. Experimental Section

3. Results

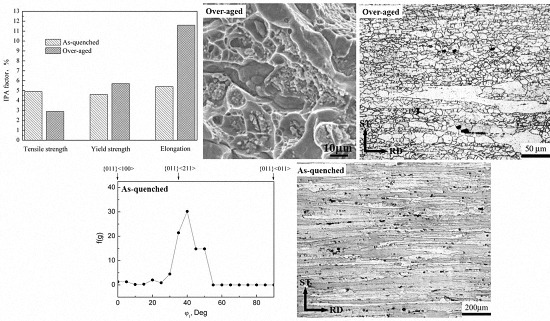

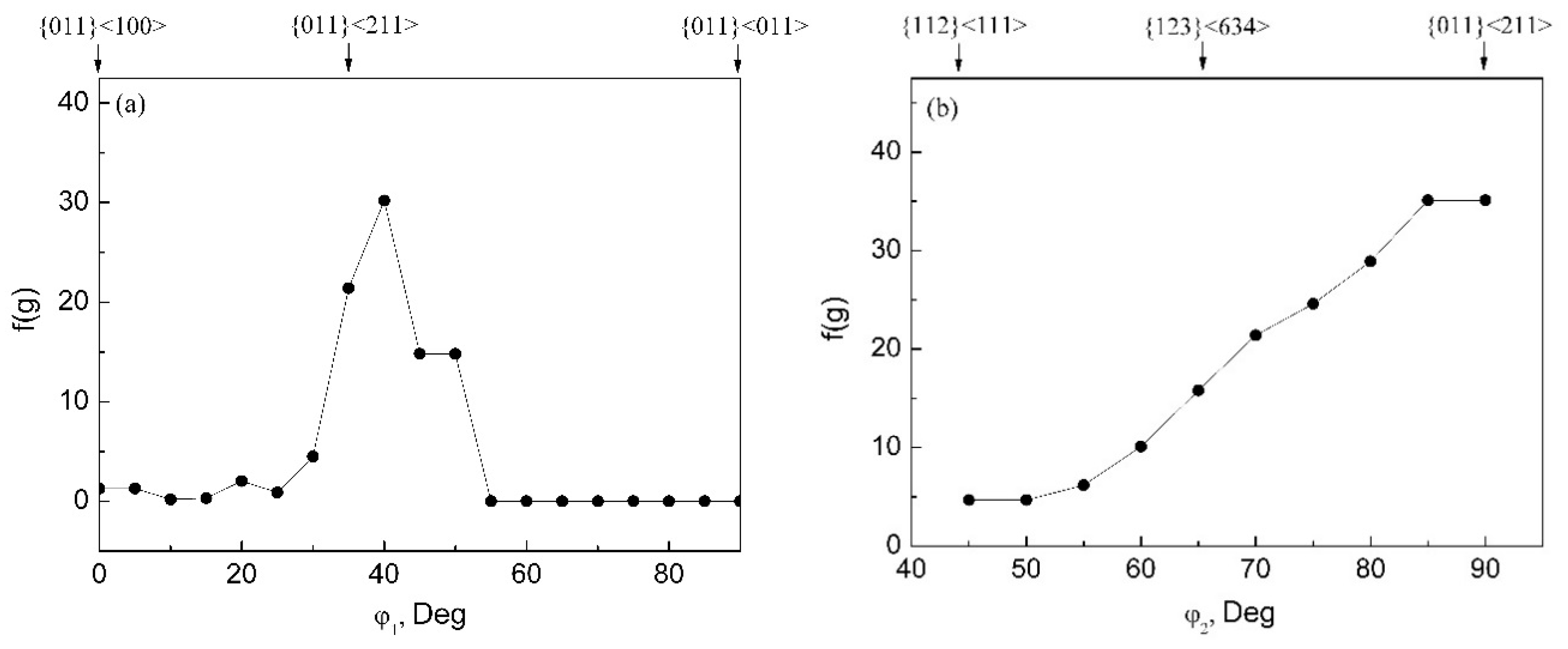

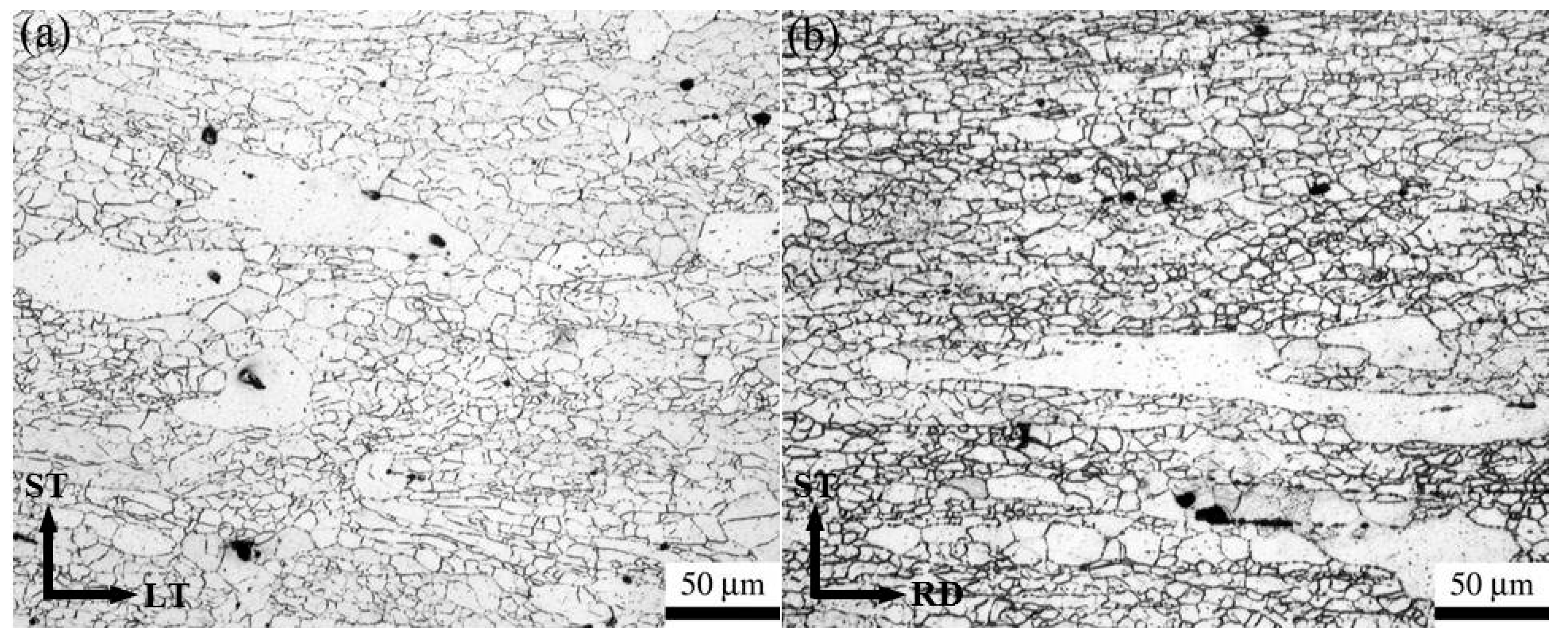

3.1. Textures and Grain Microstructures

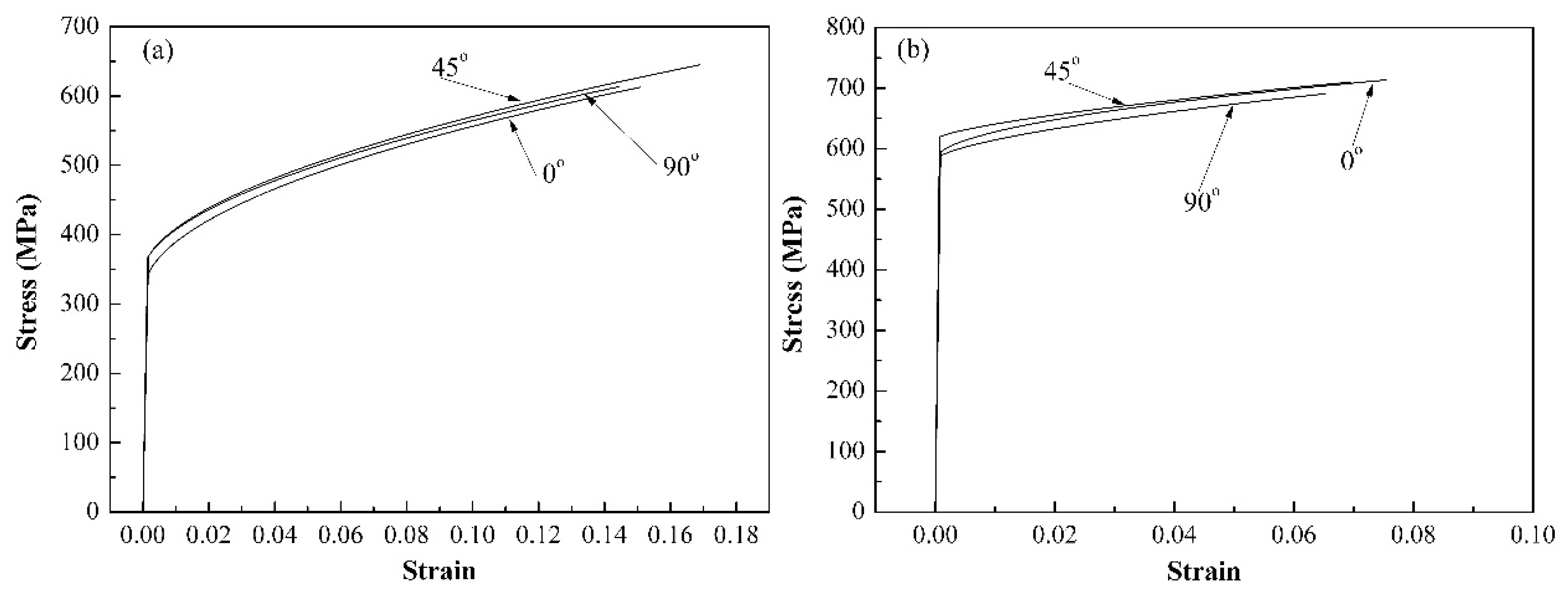

3.2. Mechanical Properties

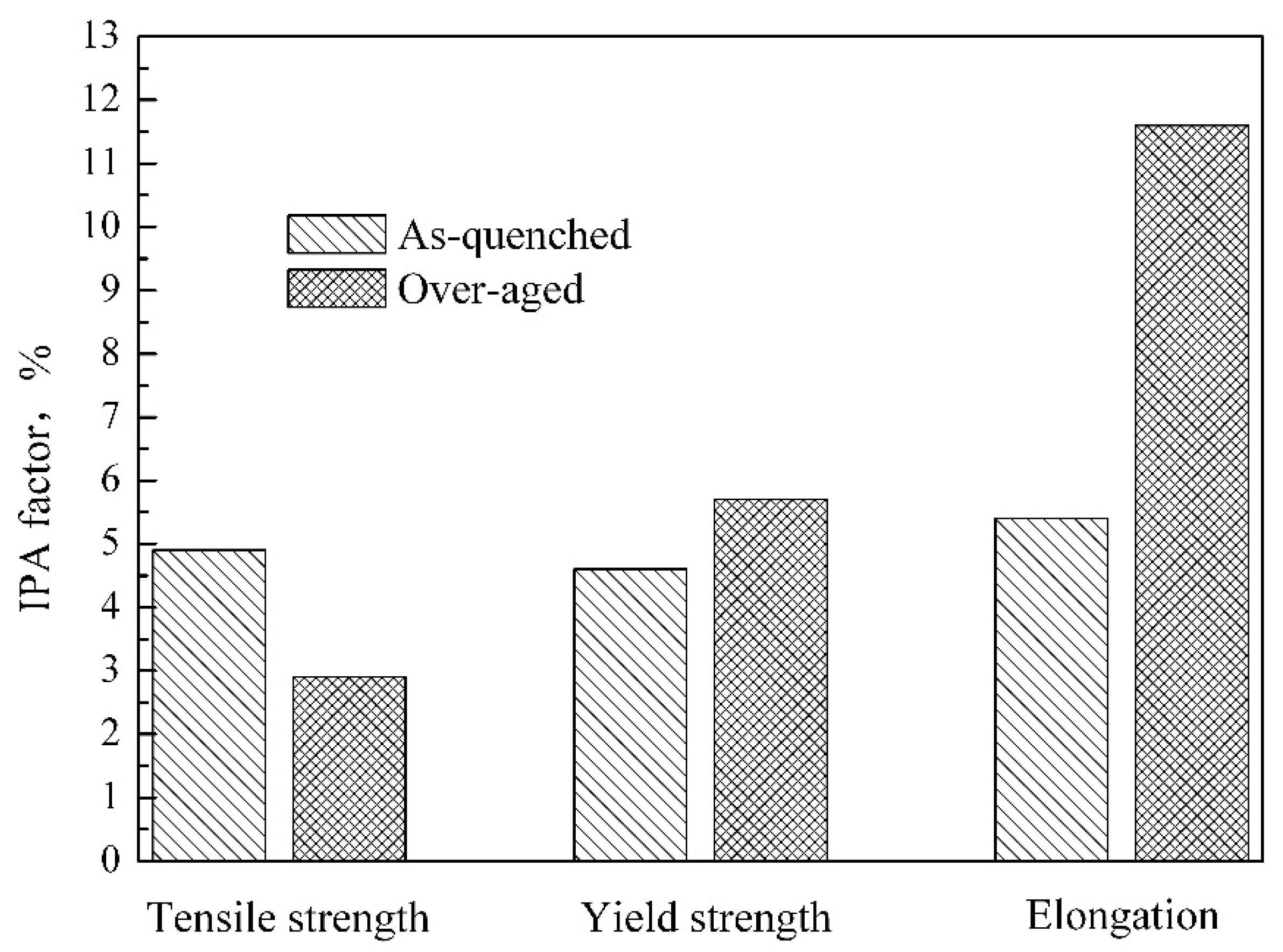

3.3. In-Plane Anisotropy

4. Discussion

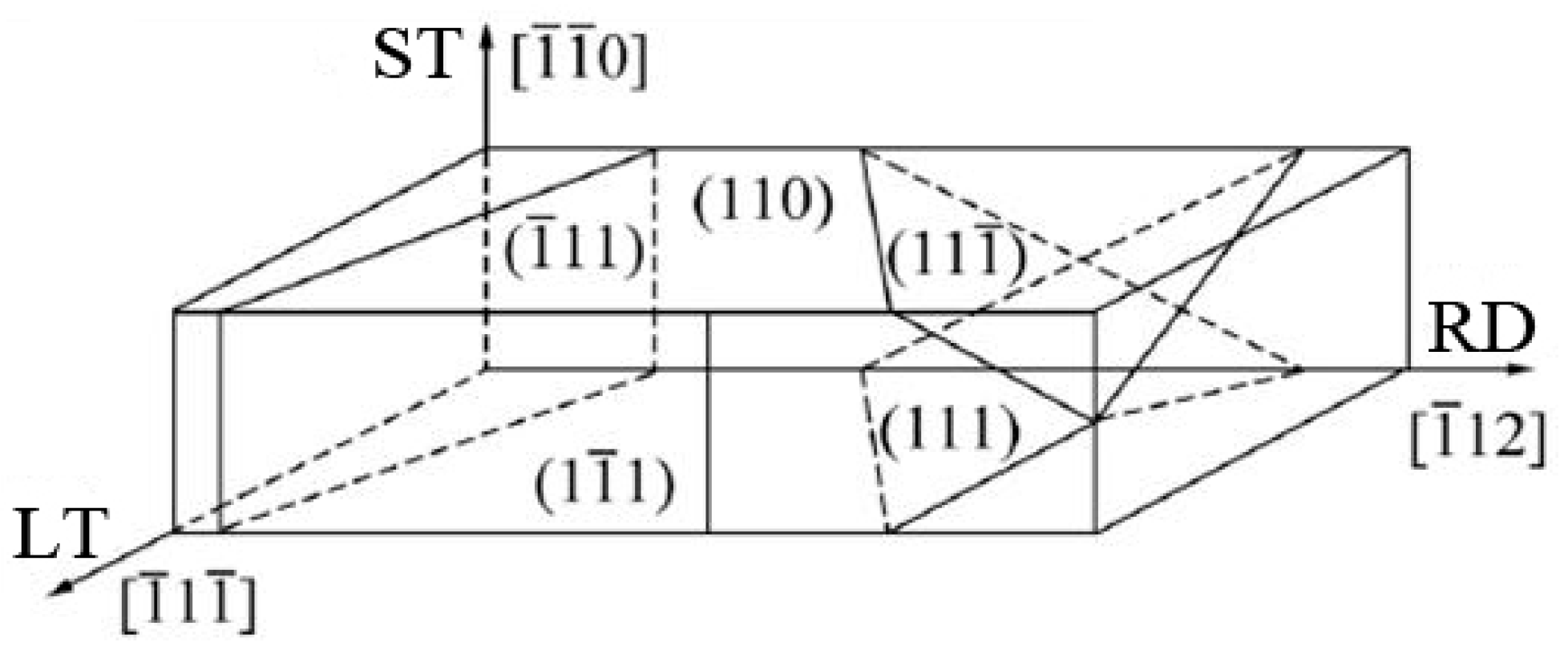

4.1. In-Plane Anisotropy of the As-Quenched 7050 Aluminum Alloy

4.2. In-Plane Anisotropy of the Over-Aged 7050 Aluminum Alloy

5. Conclusions

- (1)

- For the as-quenched 7050 aluminum alloy, the tensile direction has little effect on anisotropies of mechanical properties, and the IPA factors of tensile strength, yield strength and elongation fluctuate in the vicinity of 5%.

- (2)

- For the over-aged 7050 aluminum alloy, the difference of IPA factors of mechanical properties is apparent. The tensile direction has a significant effect on the elongation, and the IPA factor of elongation reaches 11.6%.

- (3)

- The intensity of the Brass orientation {011}<211> in the as-quenched 7050 aluminum alloy is much higher than those of the other texture components. The influence of texture on the in-plane anisotropy of the as-quenched 7050 aluminum alloy is revealed by building the relationship between the elongation and the Brass orientation {011}<211> using the single crystal analysis based on the Schmid factor method.

- (4)

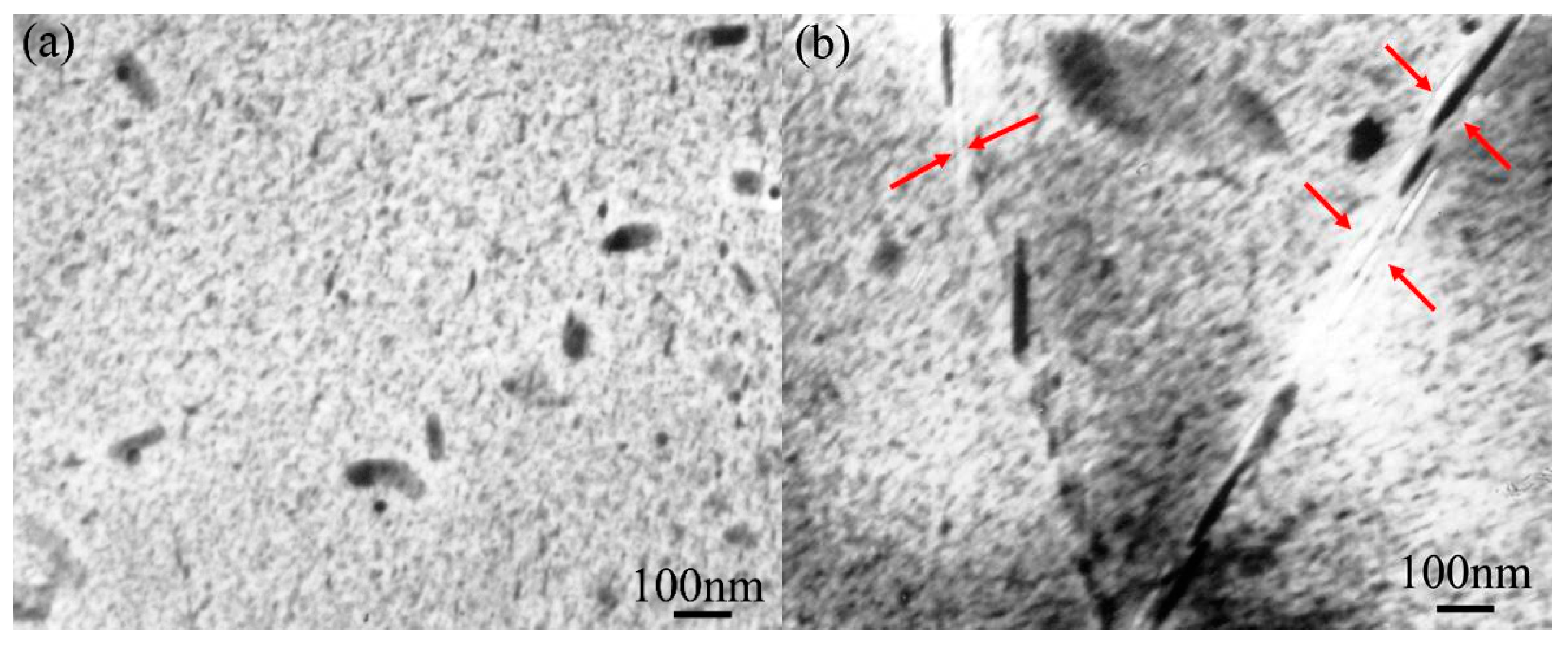

- The microstructures of the over-aged 7050 aluminum alloy are characterized by obvious PFZs and coarse precipitates in (sub)grain boundaries. Deformation is easier to take place in PFZs than that inside grains. The shapes of PFZs, viz. grains’ and subgrains’ shapes, are the primary cause of the in-plane anisotropy in the over-aged 7050 aluminum alloy.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Deschamps, A.; Brechet, Y. Influence of quench and heating rates on the ageing response of an Al-Zn-Mg-(Zr) alloy. Mater. Sci. Eng. A 1998, 251, 200–207. [Google Scholar] [CrossRef]

- Tajally, M.; Emadoddin, E. Mechanical and anisotropic behaviors of 7075 aluminum alloy sheets. Mater. Des. 2011, 32, 1594–1599. [Google Scholar] [CrossRef]

- Hu, H.E.; Zhen, L.; Chen, J.Z.; Yang, L.; Zhang, B.Y. Microstructure evolution in hot deformation of 7050 aluminium alloy with coarse elongated grains. Mater. Sci. Technol. 2008, 24, 281–286. [Google Scholar] [CrossRef]

- Ranganathal, R.; Anilkumar, V.; Nandi, V.S.; Bhat, R.R.; Muralidhara, B.K. Multi-stage heat treatment of aluminum alloy AA7049. Trans. Nonferrous. Met. Soc. China 2013, 23, 1570–1575. [Google Scholar]

- Crumbach, M.; Neumann, L.; Goerdeler, M.; Aretz, H.; Gottstein, G. Through-process modelling of texture and anisotropy in AA5182. Modell. Simul. Mater. Sci. Eng. 2006, 14, 835–856. [Google Scholar] [CrossRef]

- Engler, O.; An, Y.G. Correlation of texture and plastic anisotropy in the Al-Mg alloy AA 5005. Solid State Phenom. 2005, 105, 277–284. [Google Scholar] [CrossRef]

- Beaudon, A.J.; Dawson, P.R.; Mathur, K.K. A hybrid finite element formulation for polycrystal plasticity with consideration of macrostructural and microstructural linking. Int. J. Plast. 1995, 11, 501–521. [Google Scholar] [CrossRef]

- Van Houtte, P. Treatment of elastic and plastic anisotropy of polycrystalline materials with texture. Mater. Sci. Forum 1998, 273–275, 67–75. [Google Scholar] [CrossRef]

- Engler, O. Texture and anisotropy in the Al-Mg alloy AA5005—Part I: Texture evolution during rolling and recrystallization. Mater. Sci. Eng. A 2014, 618, 654–662. [Google Scholar] [CrossRef]

- Engler, O.; Aegerter, J. Texture and anisotropy in the Al-Mg alloy AA5005—Part II: Correlation of texture and anisotropic properties. Mater. Sci. Eng. A 2014, 618, 663–671. [Google Scholar] [CrossRef]

- Crooks, R.; Wang, Z.; Levit, V.I.; Shenoy, R.N. Microtexture, micro structure and plastic anisotropy of AA2195. Mater. Sci. Eng. A 1998, 257, 145–152. [Google Scholar] [CrossRef]

- Yang, Y.B.; Xie, Z.P.; Zhang, Z.M.; Li, X.B.; Wang, Q.; Zhang, Y.H. Processing maps for hot deformation of the extruded 7075 aluminum alloy bar: Anisotropy of hot workability. Mater. Sci. Eng. A 2014, 615, 183–190. [Google Scholar] [CrossRef]

- Bois-Brochu, A.; Blais, C.; Goma, F.A.T.; Larouche, D.; Boselli, J.; Brochu, M. Characterization of Al-Li 2099 extrusions and the influence of fiber texture on the anisotropy of static mechanical properties. Mater. Sci. Eng. A 2014, 597, 62–69. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Tomé, C.N.; Maudlin, P.J. A self-consistent formulation for the prediction of the anisotropic behavior of viscoplastic polycrystals with voids. J. Mech. Phys. Solid 2004, 52, 249–278. [Google Scholar] [CrossRef]

- Choi, S.H.; Brem, J.C.; Barlat, F.; Oh, K.H. Macroscopic anisotropy in AA5019A sheets. Acta Mater. 2000, 48, 1853–1863. [Google Scholar] [CrossRef]

- Delannay, L.; Melchior, M.A.; Signorelli, J.W.; Remacle, J.F.; Kuwabara, T. Influence of grain shape on the planar anisotropy of rolled steel sheets—Evaluation of three models. Compos. Mater. Sci. 2009, 45, 739–743. [Google Scholar] [CrossRef]

- Bate, P.; Roberts, W.T.; Wilson, D.V. The plastic anisotropy of two-phase aluminium alloys—I. Anisotropy in unidirectional deformation. Acta Metall. 1981, 29, 1797–1814. [Google Scholar] [CrossRef]

- Choi, S.H.; Barlat, F.; Liu, J. Effect of precipitates on plastic anisotropy for polycrystalline aluminum alloys. Metall. Mater. Trans. A 2001, 32, 2239–2247. [Google Scholar] [CrossRef]

- Peeters, B.; Seefeldt, M.; Kalidindi, S.R.; van Houtte, P.; Aernoudt, E. The incorporation of dislocation sheets into a model for plastic deformation of b.c.c. polycrystals and its influence on r values. Mater. Sci. Eng. A 2001, 319–321, 188–191. [Google Scholar] [CrossRef]

- Mahesh, S.; Tome, C.N.; McCabe, R.J.; Kaschner, G.C.; Beyerlein, I.J.; Misra, A. Application of a substructure-based hardening model to copper under loading path changes. Metall. Mater. Trans. A 2004, 35, 3763–3774. [Google Scholar] [CrossRef]

- Li, Z.J.; Winther, G.; Hansen, N. Anisotropy in rolled metals induced by dislocation structure. Acta Mater. 2006, 54, 401–410. [Google Scholar] [CrossRef]

- Wang, X.Y.; Hu, H.E.; Xia, J.C. Effect of deformation condition on plastic anisotropy of as-rolled 7050 aluminum alloy plate. Mater. Sci. Eng. A 2009, 515, 1–9. [Google Scholar]

- Engler, O. Texture and anisotropy in cold rolled and recovery annealed AA 5182 sheets. Mater. Sci. Technol. 2015, 31, 1058–1065. [Google Scholar]

- Rometsch, P.A.; Zhang, Y.; Knight, S. Heat treatment of 7xxx series aluminium alloys—Some recent developments. Trans. Nonferrous. Met. Soc. China 2014, 24, 2003–2017. [Google Scholar] [CrossRef]

- Zheng, Y.; Yin, Z.M.; Zhu, Y.Z. Microstructure investigation of a new type super high strength aluminum alloy at different heat-treated conditions. Rare Metal. 2004, 23, 377–384. [Google Scholar]

- Cao, W.Q.; Godfrey, A.; Liu, Q. Annealing behavior of aluminium deformed by equal channel angular pressing. Mater. Lett. 2003, 57, 3767–3774. [Google Scholar] [CrossRef]

- Singh, R.K.; Singh, A.K.; Prasad, N.E. Texture and mechanical property anisotropy in an Al-Mg-Si-Cu alloy. Mater. Sci. Eng. A 2000, 277, 114–122. [Google Scholar] [CrossRef]

- Jata, K.V.; Hopking, A.K.; Rioja, R.T. The ainsotropy and texture of Al-Li alloy. Mater. Sci. Forum 1996, 217–222, 647–652. [Google Scholar] [CrossRef]

- Melton, K.N.; Cutler, C.P.; Edington, J.W. Anisotropy during superplastic deformation of the Sn-Pb eutectic alloy. Scr. Metall. 1975, 9, 515–520. [Google Scholar] [CrossRef]

- Hu, H.E.; Zhen, L.; Yang, L.; Shao, W.Z.; Zhang, B.Y. Deformation behavior and microstructure evolution of 7050 aluminum alloy during high temperature deformation. Mater. Sci. Eng. A 2008, 488, 64–71. [Google Scholar] [CrossRef]

- Zhen, L.; Hu, H.E.; Wang, X.Y.; Zhang, B.Y.; Shao, W.Z. Distribution characterization of boundary misorientation angle of 7050 aluminum alloy after high-temperature compression. J. Mater. Process. Technol. 2009, 209, 754–761. [Google Scholar] [CrossRef]

| Heat Treatment | As-Quenched | Over-Aged | ||||

|---|---|---|---|---|---|---|

| Tensile Directions | 0° | 45° | 90° | 0° | 45° | 90° |

| Rm/MPa | 610 | 641 | 609 | 717 | 705 | 687 |

| Rp0.2/MPa | 315 | 345 | 346 | 581 | 616 | 581 |

| A/% | 15.44 | 15.6 | 14.08 | 11.68 | 11.08 | 9.56 |

| Slip Plane | Slip Direction | 0° | 45° | 90° |

|---|---|---|---|---|

| [110] | 0 | 0 | 0 | |

| [011] | 0 | 0.4330 | 0 | |

| 0 | 0.4330 | 0 | ||

| [110] | 0 | 0 | 0 | |

| 0.1361 | 0.3368 | 0.2722 | ||

| [101] | 0.1361 | 0.3368 | 0.2722 | |

| (111) | 0.2722 | 0.0962 | 0.2722 | |

| 0.1361 | 0.0364 | 0.2722 | ||

| 0.4082 | 0.0598 | 0 | ||

| 0.2722 | 0.0962 | 0.2722 | ||

| [011] | 0.4082 | 0.0598 | 0 | |

| [101] | 0.1361 | 0.0364 | 0.2722 |

| Slip System/Direction | RD | ST | LT |

|---|---|---|---|

| 1/2 | |||

| [101] | −1/2 | ||

| (111) | 0 | ||

| (111) | 1/2 | ||

| 0 | |||

| [101] | −1/2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Wang, X. Effect of Heat Treatment on the In-Plane Anisotropy of As-Rolled 7050 Aluminum Alloy. Metals 2016, 6, 79. https://doi.org/10.3390/met6040079

Hu H, Wang X. Effect of Heat Treatment on the In-Plane Anisotropy of As-Rolled 7050 Aluminum Alloy. Metals. 2016; 6(4):79. https://doi.org/10.3390/met6040079

Chicago/Turabian StyleHu, Huie, and Xinyun Wang. 2016. "Effect of Heat Treatment on the In-Plane Anisotropy of As-Rolled 7050 Aluminum Alloy" Metals 6, no. 4: 79. https://doi.org/10.3390/met6040079

APA StyleHu, H., & Wang, X. (2016). Effect of Heat Treatment on the In-Plane Anisotropy of As-Rolled 7050 Aluminum Alloy. Metals, 6(4), 79. https://doi.org/10.3390/met6040079