1. Introduction

Nickel based superalloys are materials with remarkable combination of mechanical and physical properties that contribute to their wide application, from gas turbine, aero and rocket engines to chemical processing plants, as presented by Pollock and Tin [

1]. Nimonic alloys are the group of Ni-based superalloys, which are widely used for high performance applications, such as disks and blades of either aircraft engines or land-based gas turbines, at temperatures ranging from 650 °C to 1050 °C and in aggressive atmospheres [

2]. Nimonic alloy 263 is an important precipitation hardening nickel base superalloy, with high creep strength and oxidation resistance, designed for stationary components like combustion chambers, casings, liners, exhaust ducting, bearing housings and many others [

3]. Since the components of this alloy are primarily degraded by creep damage, as presented by Park

et al. [

4], when it is exposed to the influence of harsh environment, it is necessary to retard intergranular cracking and propagation for better performance at elevated temperatures.

Lasers have been used for high precision material processing in micro- and nano-manufacturing operations due to a specific nature of the laser light, high intensity and possibility of controlled surface modification. In the last few decades, surface modifications of different metals and their alloys performed by various types of lasers has gained significant attention. Milanovic

et al. [

5] presented the surface modification of titanium based implant by picosecond laser at both 1064 nm and 532 nm, and found periodic surface structures. Treatment of nickel based superalloys’ surfaces by laser irradiation can induce specific changes in the microstructure, which result in improved mechanical properties of the material, as discussed by Petronic

et al. [

6].

The principle of laser shock peening (LSP) implies usage of high intensity laser beam and suitable overlays to generate high pressure shock waves on the surface of a workpiece. Laser shock processing of steel was studied by Yilbas

et al. [

7]. They showed that dislocations are governing mechanism in hardening of the alloy, and the hardness of peened alloy increased 1.7 times compared to the base material. A review on laser shock processing was carried out by Peyre and Fabbro [

8]. They presented physical principles of laser shock and induced mechanical effects, and found that higher pressures can be achieved with confinement as compared to direct ablation.

Laser shock processing of metallic surfaces and its applications were presented by Devaux

et al. [

9], theoretically and experimentally. The transient shock waves induce microstructure changes near the surface and alter the stress level, which improve the mechanical properties of material, such as hardness and fatigue strength. Peyre

et al. [

10] presented analytical models for the confined ablation, plastically affected depths and residual stresses induced at the surface. Hong and Chengye [

11] showed the improvement in fatigue strength due to the surface residual stresses, while Clauer and Holbrook [

12] showed that improvement in hardness is the result of dislocations and other phases’ formation arisen by laser shock peening. During LSP process strain rates could reach as high as 10

6 s

−1, which is very high compared to the conventional strain rates. Amarchinta

et al. [

13] used a finite element technique to predict the residual stresses induced by LSP process, which was followed by comparison between experimental results and simulation. Peyre

et al. [

14] demonstrated that a finite element modeling procedure could be successfully applied to the prediction of residual stresses induced by laser shock processing. Sibalija

et al. [

15] used a hybrid designed method, based on the artificial intelligence techniques, to optimize LSP parameters in order to improve several characteristics of the processed Nimonic 263 sheets: surface characteristics, microstructure, roughness, microhardness and microstructural transformations.

The beneficial effects of LSP include improvement of microstructure, surface quality,

etc., which delays the fatigue crack initiation. The surface morphology of metals has a great effect on fatigue behavior, and many laser peened materials showed improvements in fatigue life with LSP, as shown by Ding and Ye [

16]. Surface condition has considerable influence on fatigue strength, and the following factors have the most significant effects: surface roughness, residual stresses in the surface layer, work hardening or softening in the surface layer, and change or transformation of the microstructure due to plastic deformation, as presented by Schijve [

17].

Although in the last few decades many investigations were devoted to the laser shock peening, most of them were performed in nanosecond laser beam regime. Since the invention of laser, there has been a constant development in terms of shorter pulse times. Some investigation were carried out in femtosecond regime [

18,

19], including the effect of wavelength on the microstructure characteristics [

20]. There is an emerging interest in employing picosecond laser for LSP application, but picosecond laser regime has been rarely discussed in the literature. Therefore, this paper aims to contribute to the investigation of the microstructure features introduced by picosecond LSP. The investigation includes analysis of surface condition after LSP of material, discussion of microstructural changes arisen by the laser treatment, and microhardness testing after LSP. In particular, the impact of 1064 and 532 nm laser irradiation of the superalloy is discussed in detail. The rest of the paper is organized as follows. After the introduction, the experimental set up is presented in the second section. Results of the experiment are presented, analyzed and discussed in the third section, which is divided into three parts: (i) discussion of the microstructural and surface changes arisen by 1064 nm wavelength laser beam; (ii) discussion of the microstructural and surface changes arisen by 532 nm wavelength laser beam; and (iii) comparison of influence of these two wavelengths on the microstructure. The last section brings the main and most important conclusions from the above analysis.

4. Conclusions

In this paper, the surface microstructural changes of superalloy Nimonic 263 induced by picosecond laser mechanical treatment were discussed. Laser shock peening was performed in different regimes. Special attention was dedicated to the effects of 532 nm and 1064 nm wavelength laser treatments. The following conclusions can be drawn from this study.

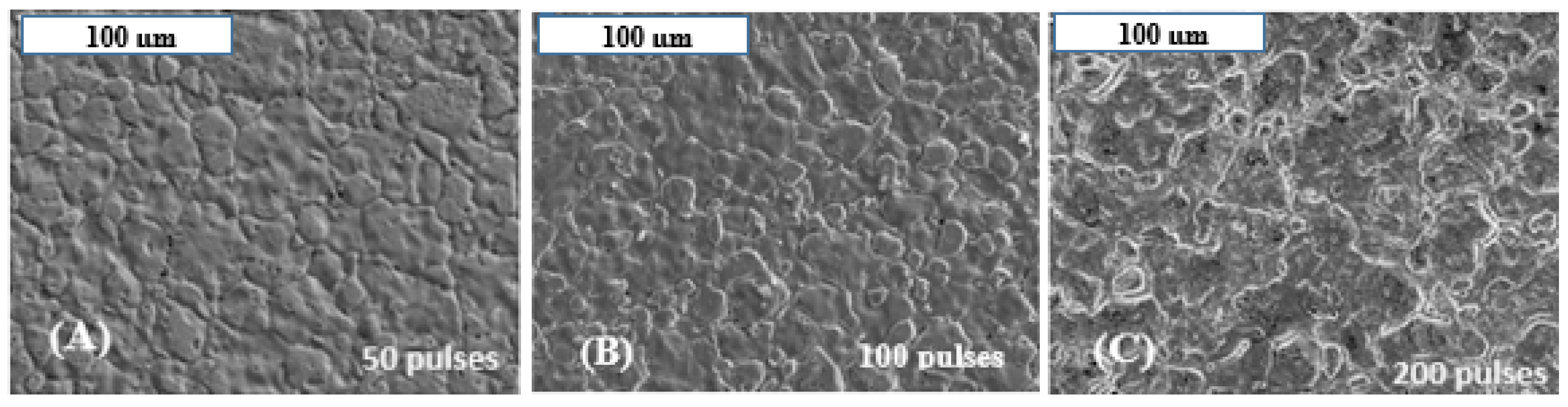

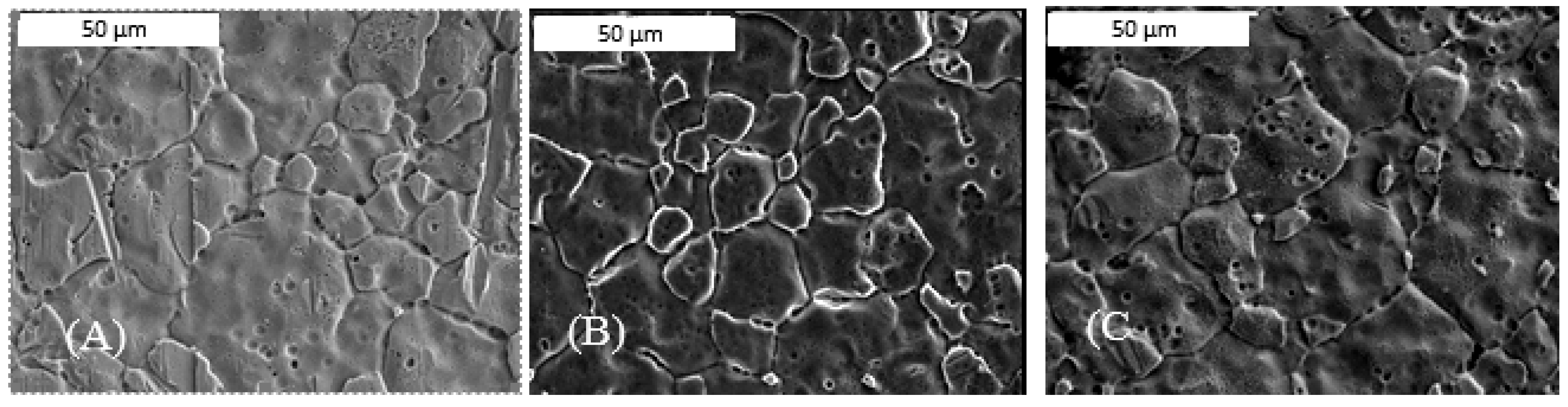

After LSP by picosecond laser, the microstructure is finer (the grains are smaller) and more uniform, compared to the base material.

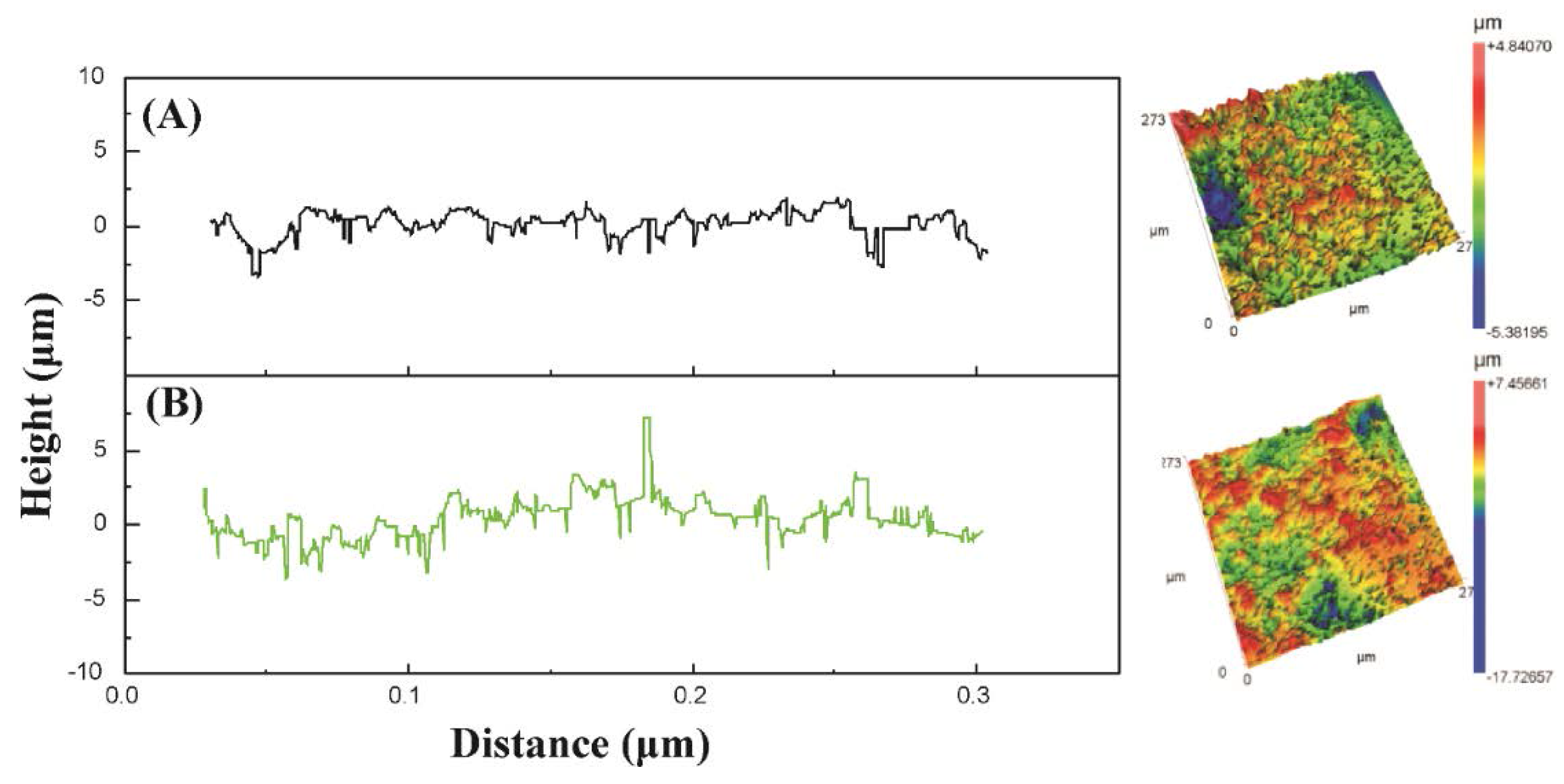

The laser action at two different wavelengths has different impact on material characteristics/morphology/surface. The laser at 1064 nm wavelength produces finer structure and lower roughness than the laser action at 532 nm wavelength. At both wavelengths, LSP processing induced favorable phases, but during 1064 nm treatment unwanted phases, Ti carbides, occurred that might cause initiation of crack formation.

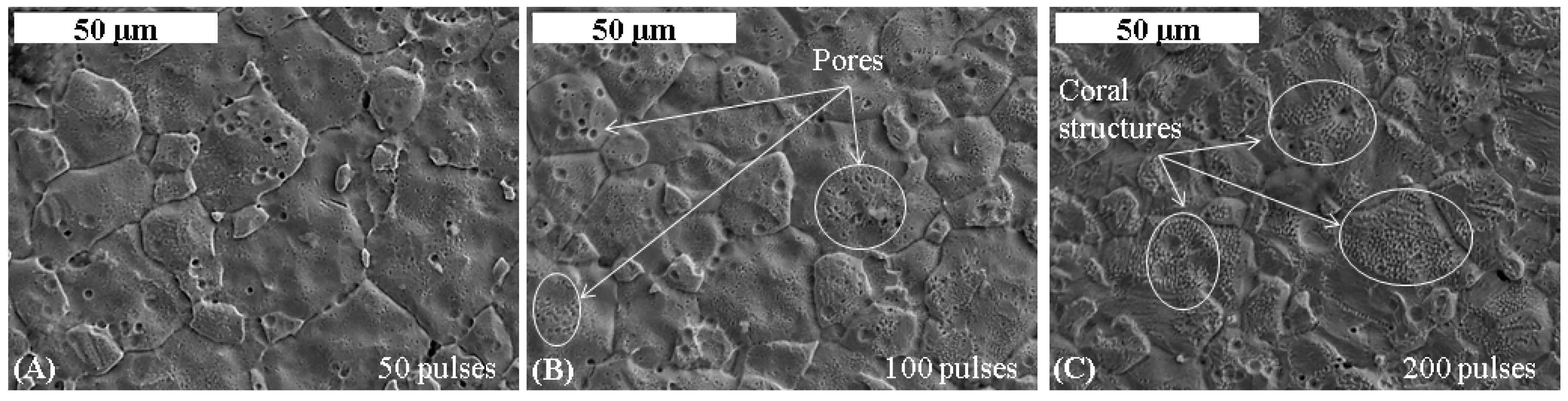

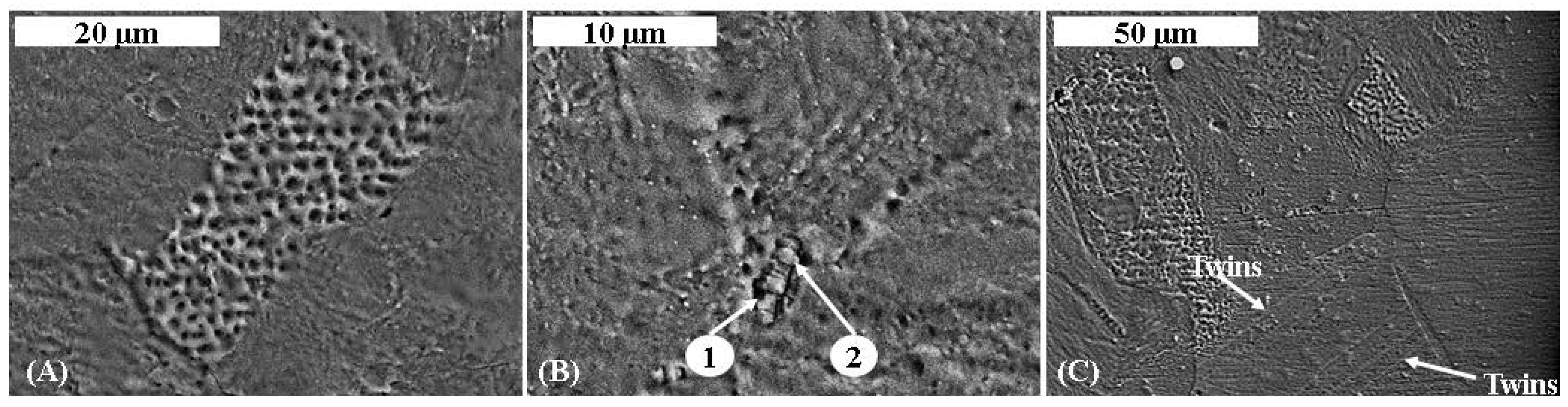

At wavelength 532 nm, with an increase in pulse energy and number of accumulated pulses, the pores start to form and create a coral-like structure. The grain boundaries are more pronounced, they start to segregate, and carbides are formed at the grain boundaries.

At wavelength 1064 nm, the finest structure is obtained for pulse energy 10 mJ, while the further increase in energy causes the formation of pores. By increasing the pulse numbers, the grains become finer; however, at 200 pulses, melting occurs.

Overall, picosecond LSP treatment of Nimonic 263 improved microhardness of superalloy’s surface. These results show that LSP by picosecond laser presents a promising technique for superalloy’s surface processing, which aims to obtain beneficial mechanical characteristics of the observed material.

Further research might include residual stresses measurements and analysis, as well as the investigation of the same process using different lasers and processing different materials.

Acknowledgments

The work was supported by the Ministry of Education and Science of the Republic of Serbia, under grant numbers TR 35040 and ON 172019.

Author Contributions

S. Petronic and M. Burzic conceived and designed the experiments; S. Polic performed the experiments; T. Sibalija and K. Colic analyzed the data; D. Milovanovic contributed materials and analysis tools; and S. Petronic and T. Sibalija wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pollock, M.T.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure, and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Shahriari, D.; Sadeghi, M.H.; Akbarzadeh, A.; Cheraghzade, M. The influence of heat treatment and hot deformation conditions on γ′ precipitate dissolution of Nimonic 115 superalloy. J. Adv. Manuf. Technol. 2009, 45, 841–850. [Google Scholar] [CrossRef]

- Singh, P.N.; Singh, V. Influence of ageing treatment on work hardening behavior of Ni-base superalloy. Scr. Mater. 1996, 34, 1861–1865. [Google Scholar] [CrossRef]

- Park, N.K.; Kim, I.S.; Na, Y.S.; Yeom, J.T. Hot forging of a nickel-base superalloy. J Mater. Process. Technol. 2001, 111, 98–102. [Google Scholar] [CrossRef]

- Milovanovic, D.S.; Radak, B.B.; Gakovic, B.M.; Batani, D.; Momcilovic, M.D.; Trtica, M.S. Surface morphology modifications of titanium based implant induced by 40 picosecond laser pulses at 266 nm. J. Alloy Compd. 2010, 501, 89–92. [Google Scholar] [CrossRef]

- Petronic, S.; Milovanovic, D.; Milosavljevic, A.; Momcilovic, M.; Petrusko, D. Influence of picosecond laser irradiation on nickel-based superalloy surface microstructure. Phys Scr. 2012. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Shuja, S.Z.; Arif, A.; Gondal, M.A. Laser-shock processing of steel. J. Mater. Proc. Technol. 2003, 135, 6–17. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R. Laser shock processing: A review of the physics and applications. Opt. Quantum Electr. 1995, 27, 1213–1229. [Google Scholar]

- Devaux, D.; Fabbro, R.; Tollier, L.; Bartnicki, E. Generation of shock waves by laser-induced plasma in confined geometry. J. Appl. Phys. 1993, 74, 2268–2273. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R.; Berthe, L.; Dubouchet, C. Laser shock processing of materials, physical processes involved and examples of application. J. Laser Appl. 1996, 8, 135–141. [Google Scholar] [CrossRef]

- Zhong, H.; Yu, C. Laser shock processing of 2024-T62 aluminum alloy. Mater. Sci. Eng. A 1998, 257, 322–327. [Google Scholar]

- Clauer, A.H.; Holbrook, J.H.; Fairand, B.P. Effects of laser induced shock waves. In Shock Waves and High-Strain, Phenomena in Metals; Meyers, M.A., Murr, L.E., Eds.; Plenum Press: New York, NY, USA, 1981; pp. 675–703. [Google Scholar]

- Amarchinta, H.K.; Grandhi, R.V.; Clauer, A.H.; Langer, K.; Stargel, D.S. Simulation of residual stress induced by a laser peening process through inverse optimization of material models. J. Mater. Process. Technol. 2010, 210, 1997–2006. [Google Scholar] [CrossRef]

- Peyre, P.; Chaieb, I.; Braham, C. FEM calculation of residual stresses induced by laser shock processing in stainless steels. Model. Simul. Mater. Sci. Eng. 2007, 15, 205–221. [Google Scholar] [CrossRef]

- Sibalija, T.; Petronic, S.; Majstorovic, V.; Milosavljevic, A. Modelling and optimisation of laser shock peening using an integrated simulated annealing-based method. Int. J. Adv. Manuf. Technol. 2014, 73, 1141–1158. [Google Scholar] [CrossRef]

- Ding, K.; Ye, L. Laser Shock Peening, Performance and Process Simulation; Woodhead Publishing Limited: Cambridge, UK, 2006; pp. 50–53. [Google Scholar]

- Schijve, J. Fatigue of Structures and Materials; Kluwer Academic Publisher: Dordrecth, The Netherlands, 2001; pp. 71–78. [Google Scholar]

- Lee, D. Feasibility Study on Laser Microwelding and Laser Shock Peening Using Femtosecond Laser Pulses. Ph.D. Thesis, University of Michigen, Ann Arbor, MI, USA, 2008. [Google Scholar]

- Semaltianos, N.G.; Perrie, W.; French, P.; Sharp, M.; Dearden, G.; Logothetidis, S.; Watkins, K.G. Femtosecond laser ablation characteristics of nickel-based superalloy C263. Appl. Phys. A 2009, 94, 999–1009. [Google Scholar] [CrossRef]

- Gomez-Rosas, G.; Rubio-Gonzalez, C.; Ocaña, J.L.; Molpeceres, C.; Porro, J.A.; Morales, M.; Casillas, F.J. Laser Shock Processing of 6061-T6 Al alloy with 1064 nm and 532 nm wavelengths. Appl. Surf. Sci. 2010, 256, 5828–5831. [Google Scholar] [CrossRef]

- Schumann, H. Metallographie; Deutscher Verlag fuer Grundstoffindustrie: Leipzig, Germany, 1974; p. 15. [Google Scholar]

- Petronic, S.; Burzic, M.; Milovanovic, D.; Colic, K.; Radovanovic, Z. Picosecond laser shock peening of base material Nimonic 263 material and laser welded Nimonic 263 alloy. Weld. Weld. Struct. 2015, 60, 149–155. [Google Scholar]

- Petronic, S.; Kovacevic, A.G.; Milosavljevic, A.; Sedmak, A. Microstructural changes of Nimonic 263 superalloy caused by laser beam action. Phys. Scr. 2012. [Google Scholar] [CrossRef]

- Bauerle, D. Laser Processing and Chemistry; Springer Verlag: Berlin, Germany, 2003; pp. 13–256. [Google Scholar]

- Peyre, P.; Berthe, L.; Scherpereel, X.; Fabbro, R.; Bartniki, E. Experimental Study of Laser-Driven Shock Waves in Stainless Steels. J. Appl. Phys. 1998, 84, 5985–5992. [Google Scholar] [CrossRef]

- Niehofff, H.S.; Vollertsen, F. Laser induced shock waves in deformation processing. J. Metall. 2005, 11, 183–194. [Google Scholar]

- Berthe, L.; Fabbro, R.; Peyre, P.; Tollier, L.; Bartnicki, E. Shock waves from a water-confined laser-generated plasma. J. Appl. Phys. 1997, 82, 2826–2832. [Google Scholar] [CrossRef]

- Drobnjak. Physical metallurgy; Faculty of Technology and Metallurgy, University of Belgrade: Belgrade, Serbia, 1981; pp. 75–77. [Google Scholar]

- Matijasevic, B.; Kinder, J.; Radovic, N.A.; Volkov-Husovic, T. Shot-peening induced twinning in ship-building steel. Metalurgija 2002, 8, 149–155. [Google Scholar]

- Zhang, Y.K.; Lu, J.Z.; Ren, X.D.; Yao, H.B.; Yao, H.X. Effect of laser shock processing on the mechanical properties and fatigue lives of the turbojet engine blades manufactured by LY2 aluminum alloy. Mater. Des. 2009, 30, 1697–1703. [Google Scholar] [CrossRef]

- Schneider, M.S.; Kad, B.; Kalantar, D.H.; Remington, B.A.; Kenik, E.; Jarmakani, H.; Meyers, M.A. Laser shock compression of copper and copper-aluminum alloys. Int. J. Impact Eng. 2005, 32, 473–507. [Google Scholar] [CrossRef]

- Reed, R. The Superalloys—Fundamentals and Applications; Cambridge University Press: New York, NY, USA, 2006. [Google Scholar]

- Chena, C.Y.; Yena, H.W.; Kaoa, F.H.; Li, W.C.; Huang, C.Y.; Yanga, J.R.; Wang, S.H. Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides. Mater. Sci. Eng. A 2009, 499, 162–166. [Google Scholar] [CrossRef]

- Jang, J.H.; Lee, C.H.; Heo, Y.U.; Suh, D.H. Stability of (Ti, M)C (M = Nb, V, Mo and W) Carbide in Steels using First-Principles Calculations. Acta Mater. 2012, 60, 208–217. [Google Scholar] [CrossRef]

- Ren, X.D.; Zhang, Y.K.; Zhang, T.; Jiang, D.W.; Yongzhuo, H.F.; Jiang, Y.F.; Chen, K.M. Comparison of the simulation and experimental fatigue crack behaviours in the nanoseconds laser shocked aluminum alloy. Mater. Des. 2011, 32, 1138–1143. [Google Scholar] [CrossRef]

- Warren, A.W.; Guo, Y.B.; Chen, S.C. Massive parallel laser shock peening: Simulation, analysis, and validation. Int. J. Fatigue 2008, 30, 188–197. [Google Scholar] [CrossRef]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 1990. [Google Scholar] [CrossRef]

- Grinspan, A.S.; Gnanamoorthy, R. Surface modification by oil jet peening in Al alloys, AA6063-T6 and AA6061-T4 Part 2: Surface morphology, erosion, and mass loss. Appl. Surf. Sci. 2006, 253, 997–1005. [Google Scholar] [CrossRef]

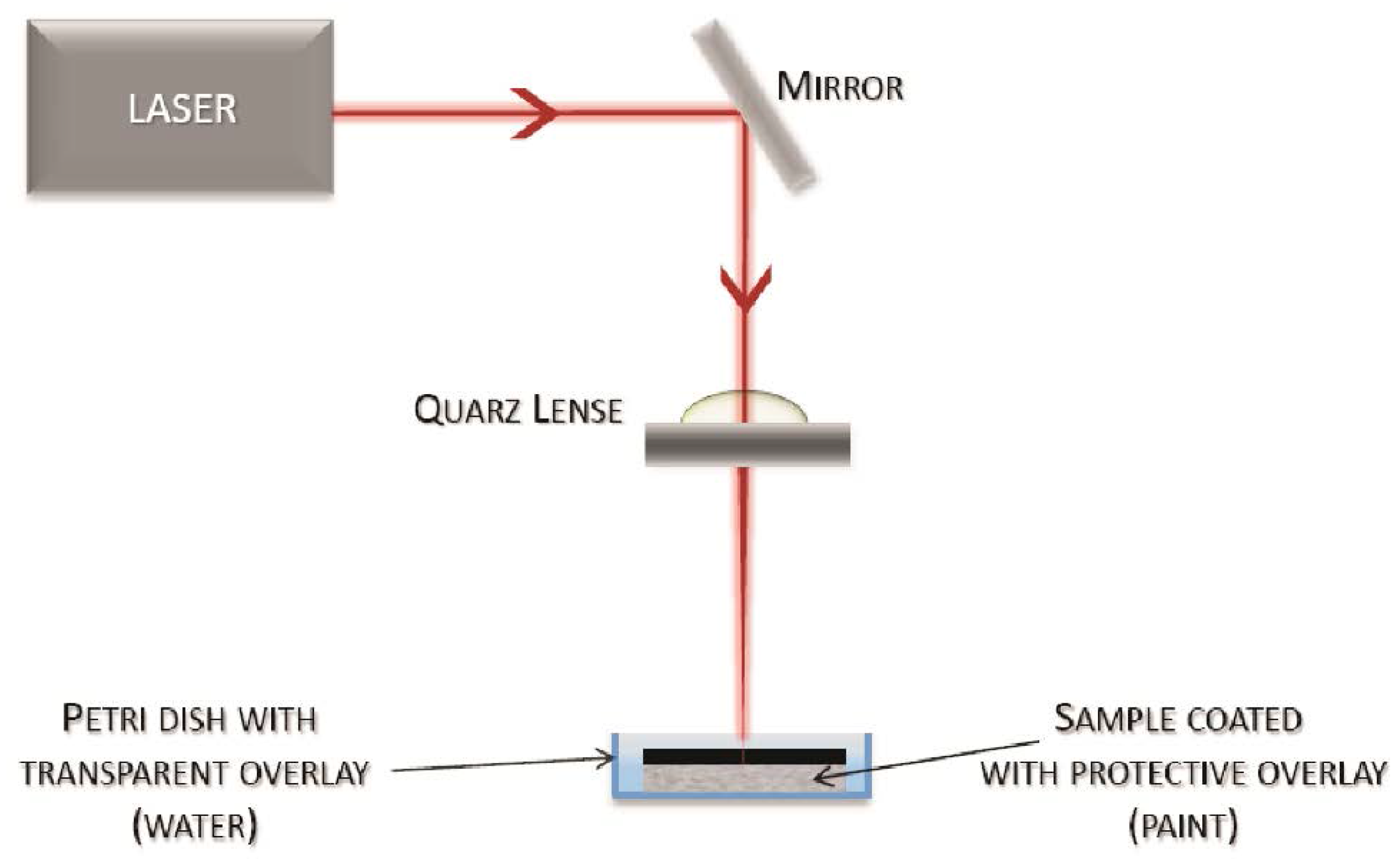

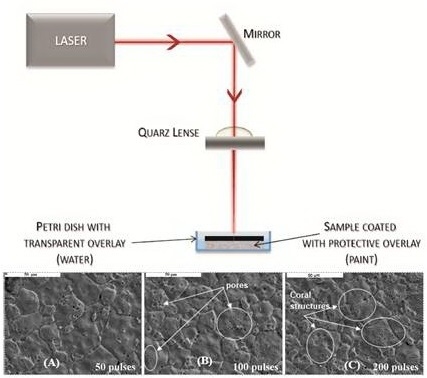

Figure 1.

The experimental setup for laser shock peening.

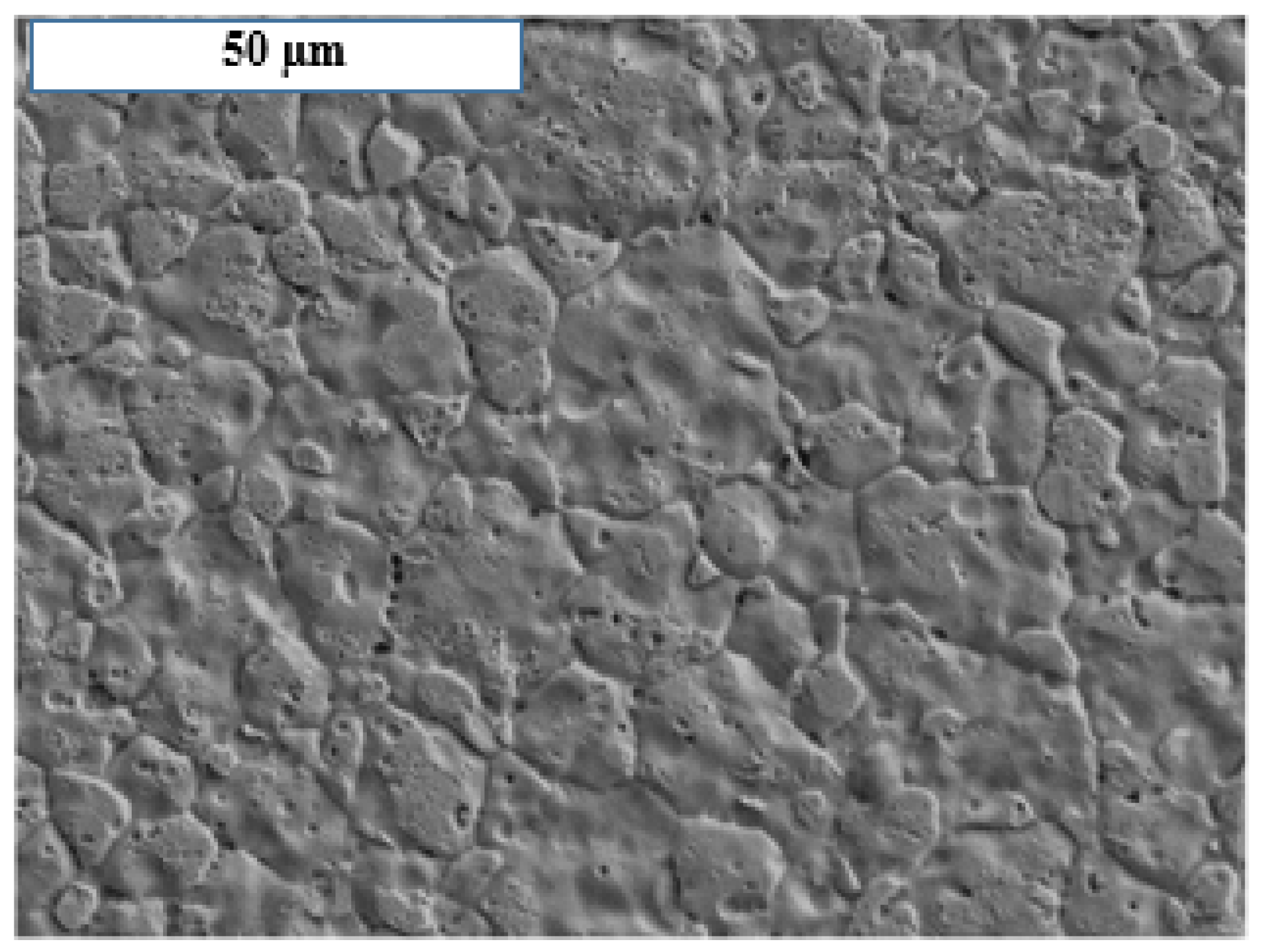

Figure 2.

SEM of Nimonic 263 sample prior to application of the paint overlay.

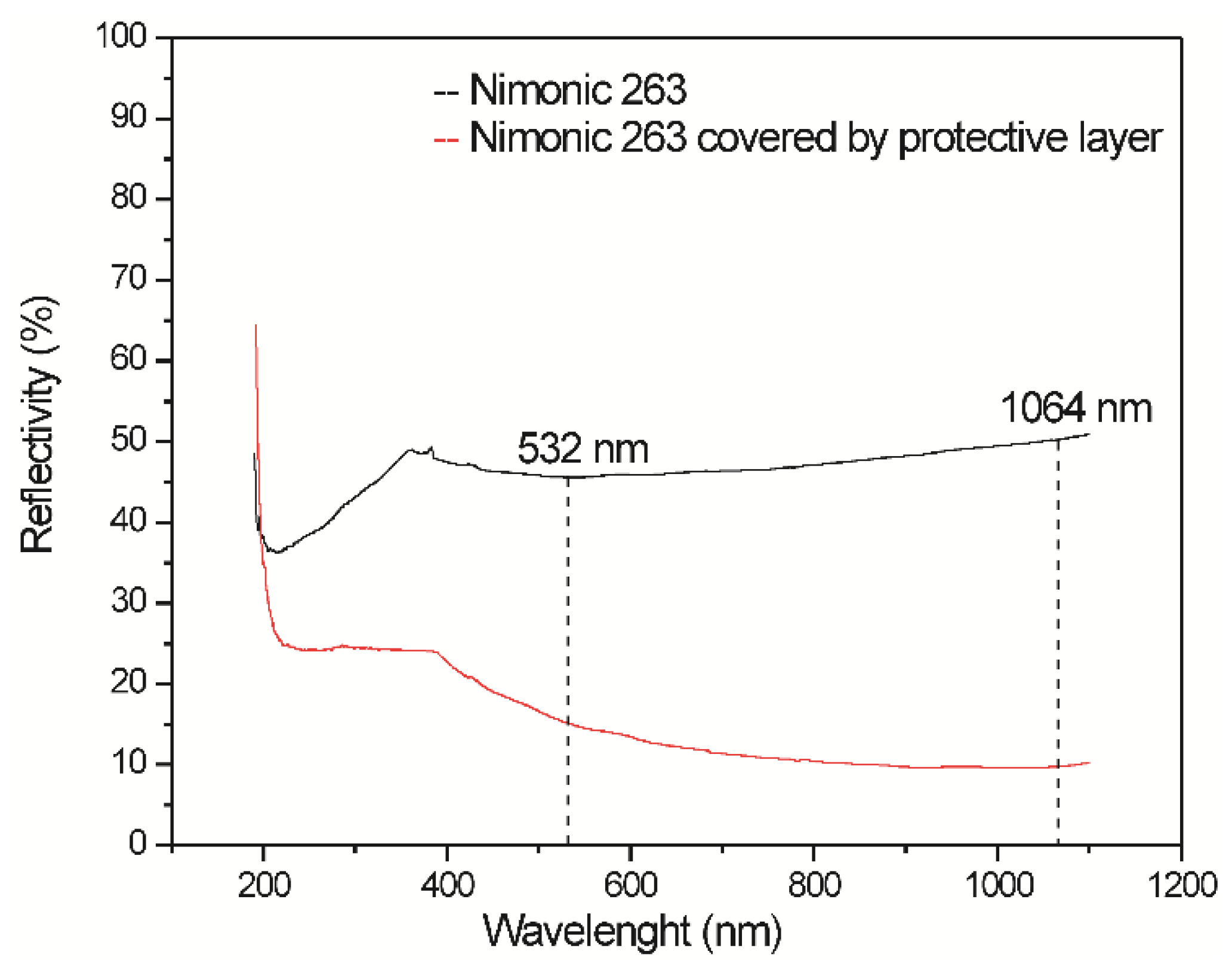

Figure 3.

Comparative reflectance spectra of Nimonic 263 surface with and without protective paint layer.

Figure 4.

The microstructure of Nimonic 263 after LSP by laser pulse energy of 10 mJ (F = 0.2 J·cm−2), wavelength of 1064 nm, and number of pulses 50 (A); 100 (B) and 200 (C), respectively (power density 3.3 GW/cm2).

Figure 5.

SEM of the microconstituents formed during LSP at 1064 nm, E = 10 mJ, and number of accumulated pulses: (a) 100; (b) 100; (c) 50 and (d) 50. Power density: 3.3 GW/cm2.

Figure 6.

The microstructure of Nimonic 263 after LSP processing by laser energy of 25 mJ and wavelength of 532 nm (power density 2.6 GW/cm2), and number of pulses 50 (A); 100 (B) and 200 (C).

Figure 7.

Nimonic 263 surface, processed by laser energy of 25 mJ at wavelength of 532 nm and 50 accumulated pulses (power density 2.4 GW/cm2): (A) microstructure; (B) grains; and (C) twinned grains.

Figure 8.

The microstructures of Nimonic 263, recorded by SEM: (A) base material; (B) laser treated material with 1064 nm, 50 pulses, 10 mJ (power density 3.3 GW/cm2); and (C) laser treated material with 532 nm, 50 pulses, 25 mJ.

Figure 9.

3D maps and 2D profiles of the areas modified with 50 accumulated laser pulses: (A) at 1064 nm wavelength and output laser energy of 10 mJ (power density 3.3 GW/cm2); and (B) at 532 nm wavelength and pulse laser energy of 25 mJ.

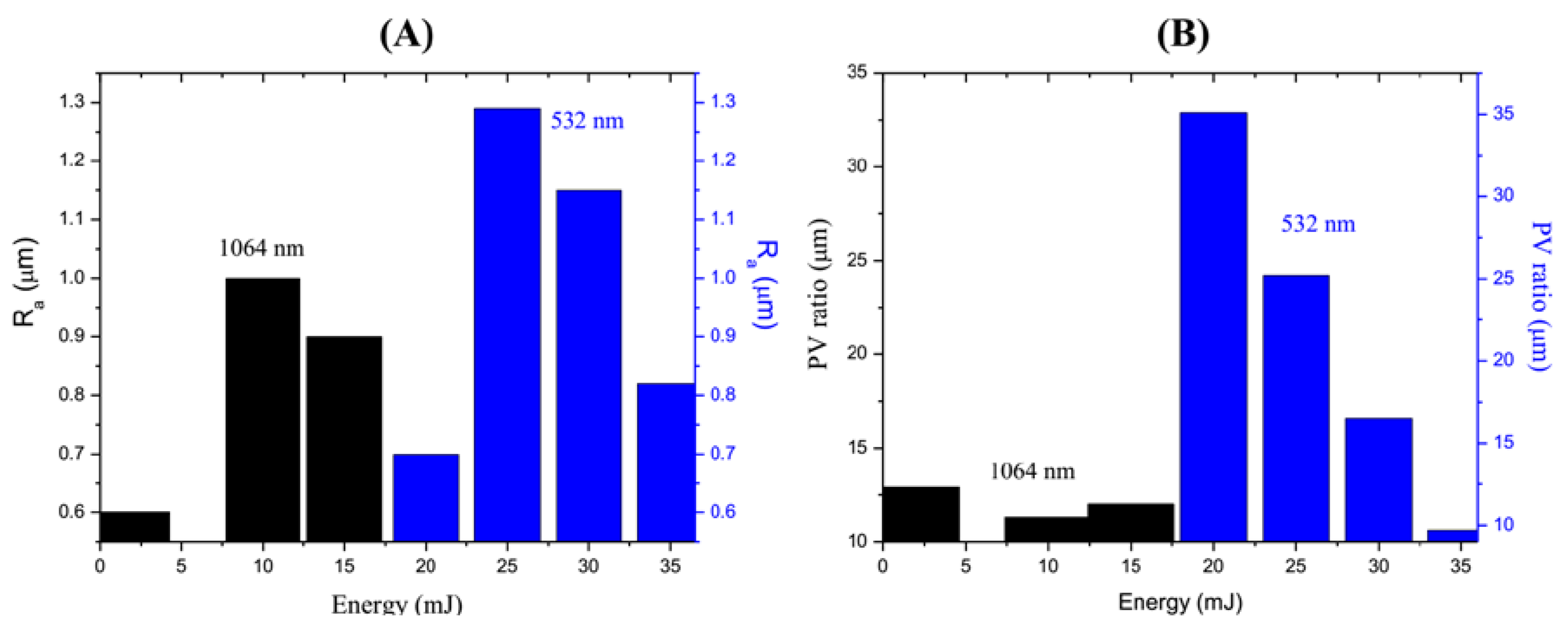

Figure 10.

Diagrams of Nimonic 263 surface morphology parameters with respect to the laser energy, after 50 accumulated pulses: (A) average roughness (Ra) and (B) peak to valley (PV) ratio.

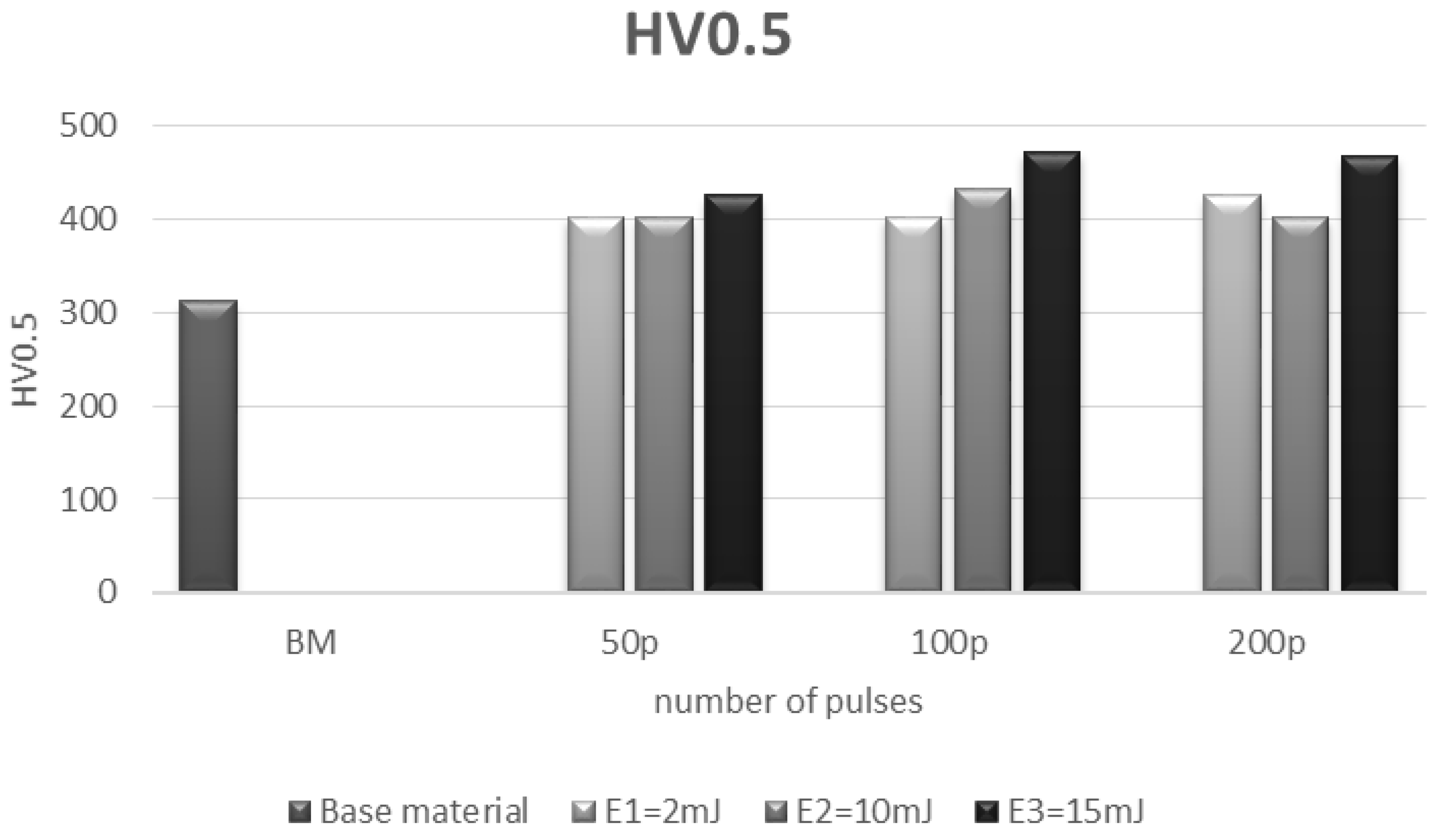

Figure 11.

The microhardness measurements of LSP processed areas by laser energies: E1 = 2 mJ, E2 = 10 mJ and E3 = 15 mJ, at wavelength 1064 nm.

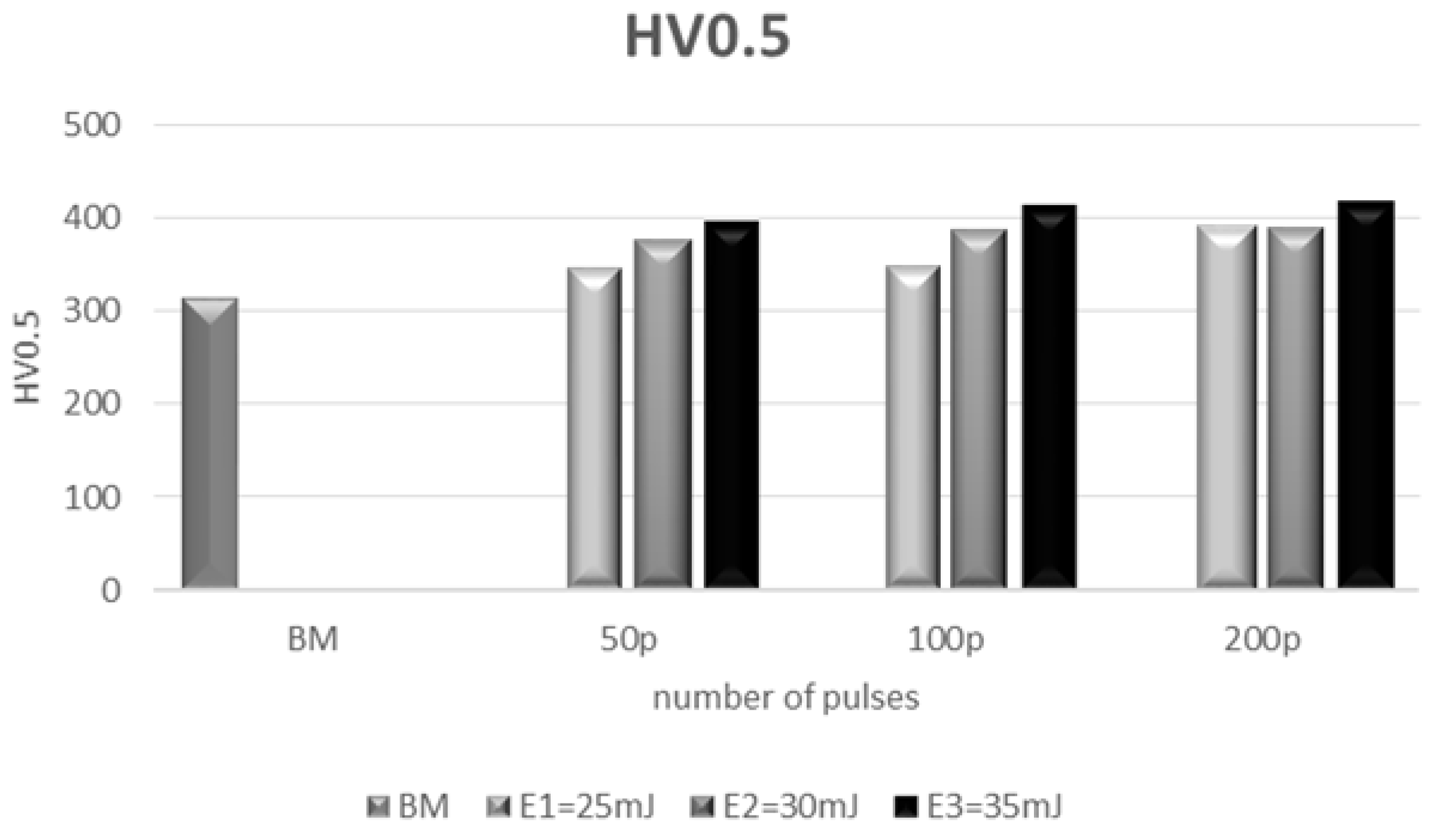

Figure 12.

The microhardness measurements of LSP processed areas by laser energies: E1 = 25 mJ, E2 = 30 mJ and E3 = 35 mJ, at wavelength 532 nm.

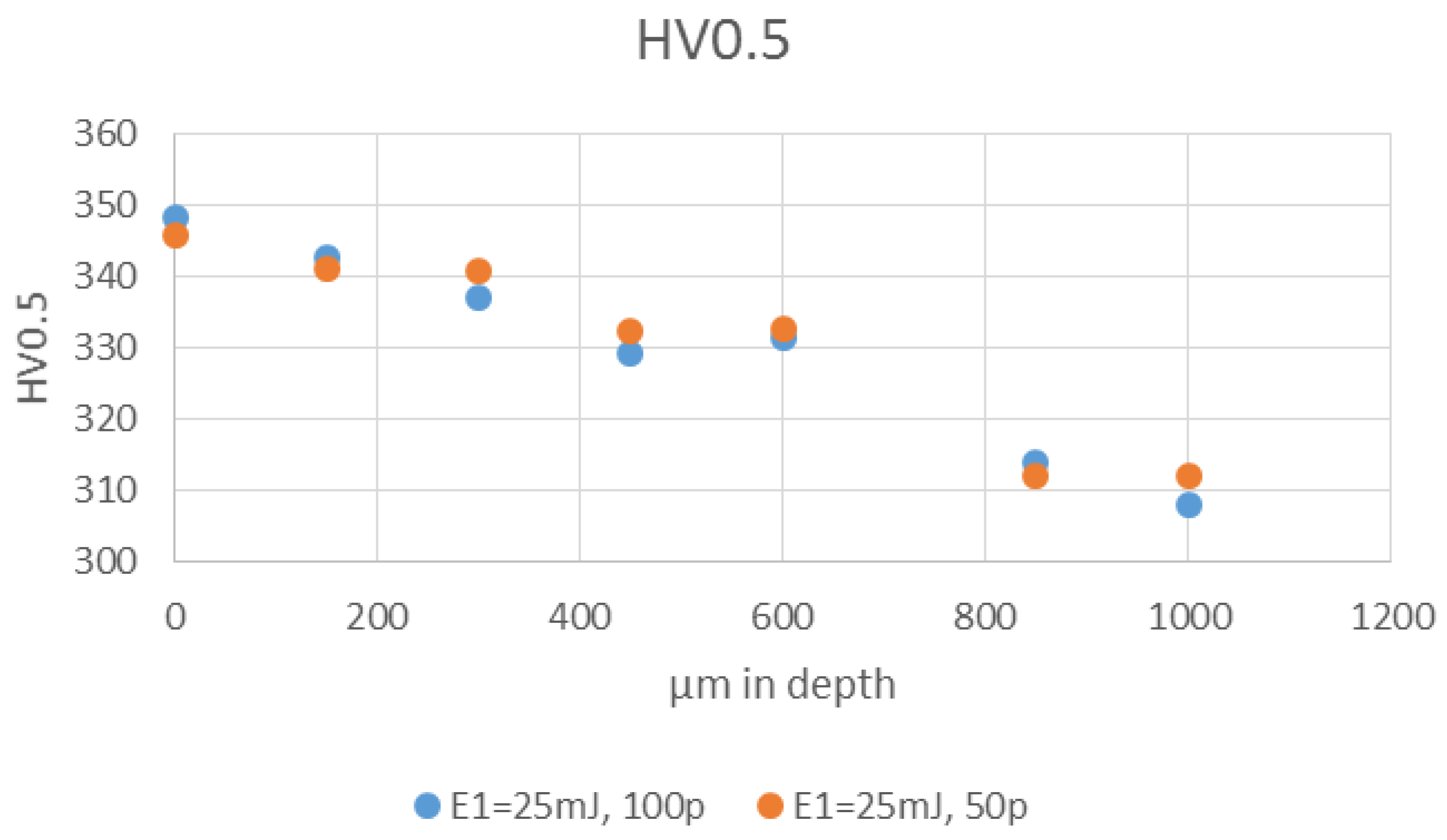

Figure 13.

The microhardness measurments in depth of LSP areas treated by laser energy E1 = 25 mJ and number of pulses 50 and 100, at wavelength 532 nm.

Table 1.

Chemical composition of alloy Nimonic 263.

| Element | C | Si | Mn | Al | Co | Cr | Cu | Fe | Mo | Ti | Ni |

|---|

| % | 0.06 | 0.3 | 0.5 | 0.5 | 20 | 20 | 0.1 | 0.5 | 5.9 | 2.2 | 49.94 |

Table 2.

The characteristics of EKSPLA picosecond laser.

| Laser | Nd:YAG |

|---|

| Wavelenght | 532 nm, 1064 nm |

| Pulse duration | 150 ps |

| Mode | about TEM00 |

| Repetition rate | 10 Hz |

Table 3.

Reflectivity of Nimonic 263 with and without protective paint layer.

| Wavelength (nm) | Reflectivity (%) |

|---|

| Nimonic 263 | Nimonic 263 with protective layer |

|---|

| 532 | 45.6 | 15.0 |

| 1064 | 50.2 | 9.8 |

Table 4.

EDS analysis of the spots denoted in Figure 5.

| Spectrum | C | Al | Si | Ti | Cr | Mn | Fe | Co | Ni | Mo |

|---|

| Spectrum 1 | 11.79 | 0.11 | 0.15 | 49.87 | 6.96 | 0.20 | 0.19 | 7.41 | 18.79 | 4.52 |

| Spectrum 2 | 14.56 | 0.13 | 0.19 | 13.36 | 11.56 | 1.00 | 0.33 | 13.22 | 34.04 | 12.19 |

| Spectrum 3 | 12.84 | 0.25 | 0.20 | 4.67 | 14.25 | 0.54 | 0.30 | 16.82 | 44.75 | 5.38 |

| Spectrum 4 | 18.29 | 1.02 | 0.94 | 21.59 | 9.62 | 0.35 | 0.24 | 10.67 | 27.73 | 9.54 |

Table 5.

EDS analysis of the area presented in Figure 7a and the spots shown in Figure 7b.

| Spectrum | C | O | Al | Si | Ti | Cr | Mn | Fe | Co | Ni | Mo |

|---|

| Figure 7a | 11.49 | 6.92 | 0.28 | 0.23 | 1.58 | 15.59 | 0.45 | 0.43 | 16.69 | 41.79 | 4.57 |

| Spectrum 1 | 13.25 | - | 0.13 | 0.2 | 25.94 | 9.66 | 0.34 | 0.24 | 8.82 | 21.98 | 19.45 |

| Spectrum 2 | 12.96 | - | 0.18 | 0.25 | 20.15 | 11.50 | 0.37 | 0.29 | 11.12 | 27.43 | 15.77 |

Table 6.

Estimated values of peak pressure for different pulse energies at two different wavelength.

| Wavelength (nm) | 532 | 1064 |

|---|

| Pulse energy (mJ) | 25 | 30 | 35 | 2 | 10 | 15 |

| Power density(GW/cm2) | 0.6 | 3.3 | 5.0 | 1.9 | 2.4 | 2.8 |

| Peak pressure (GPa) | 2.2 | 2.4 | 2.7 | 1.3 | 2.9 | 3.6 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).