Hot Deformation Behavior and Microstructural Evolution Characteristics of Ti-44Al-5V-1Cr Alloy Containing (γ + α2 + B2) Phases

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

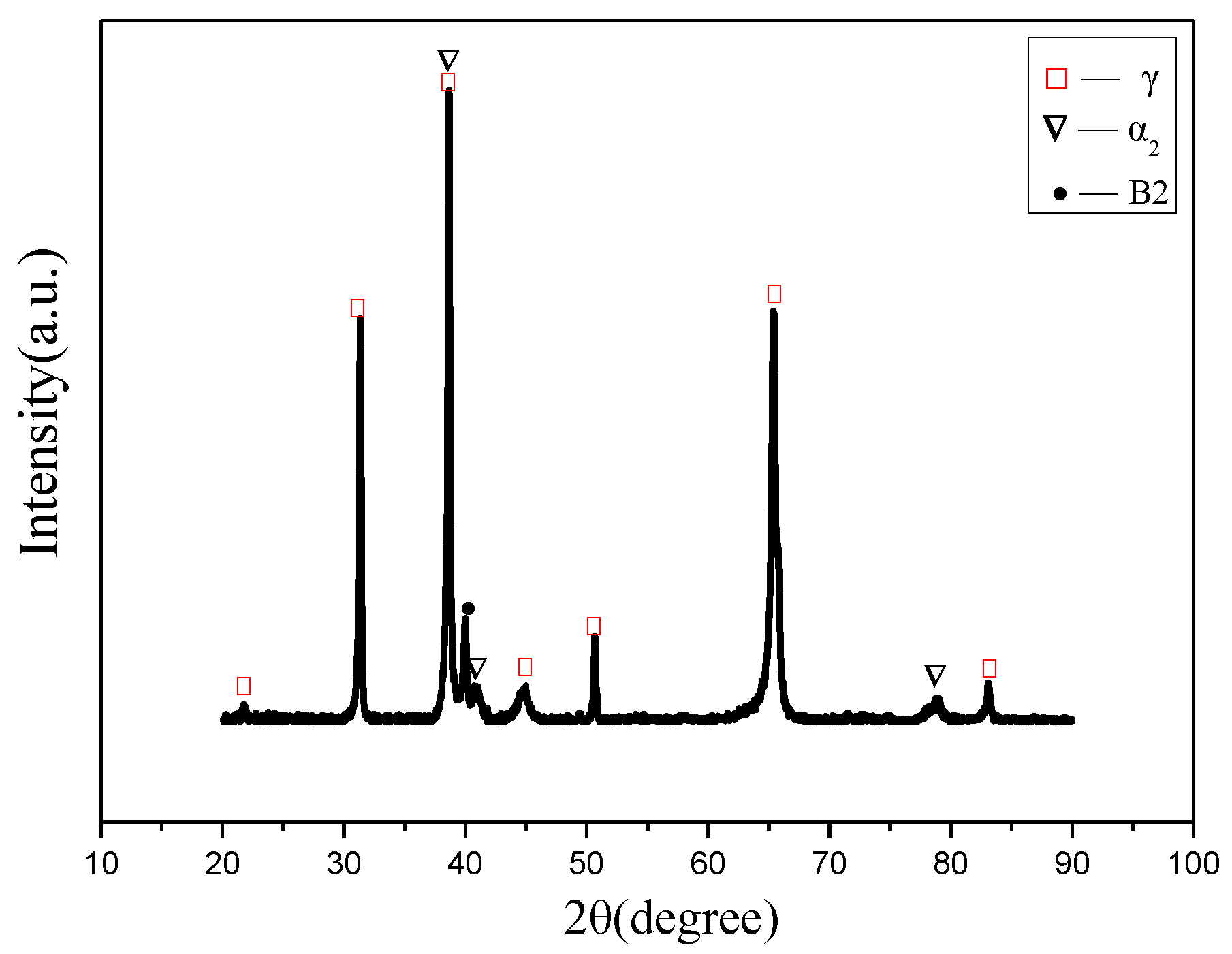

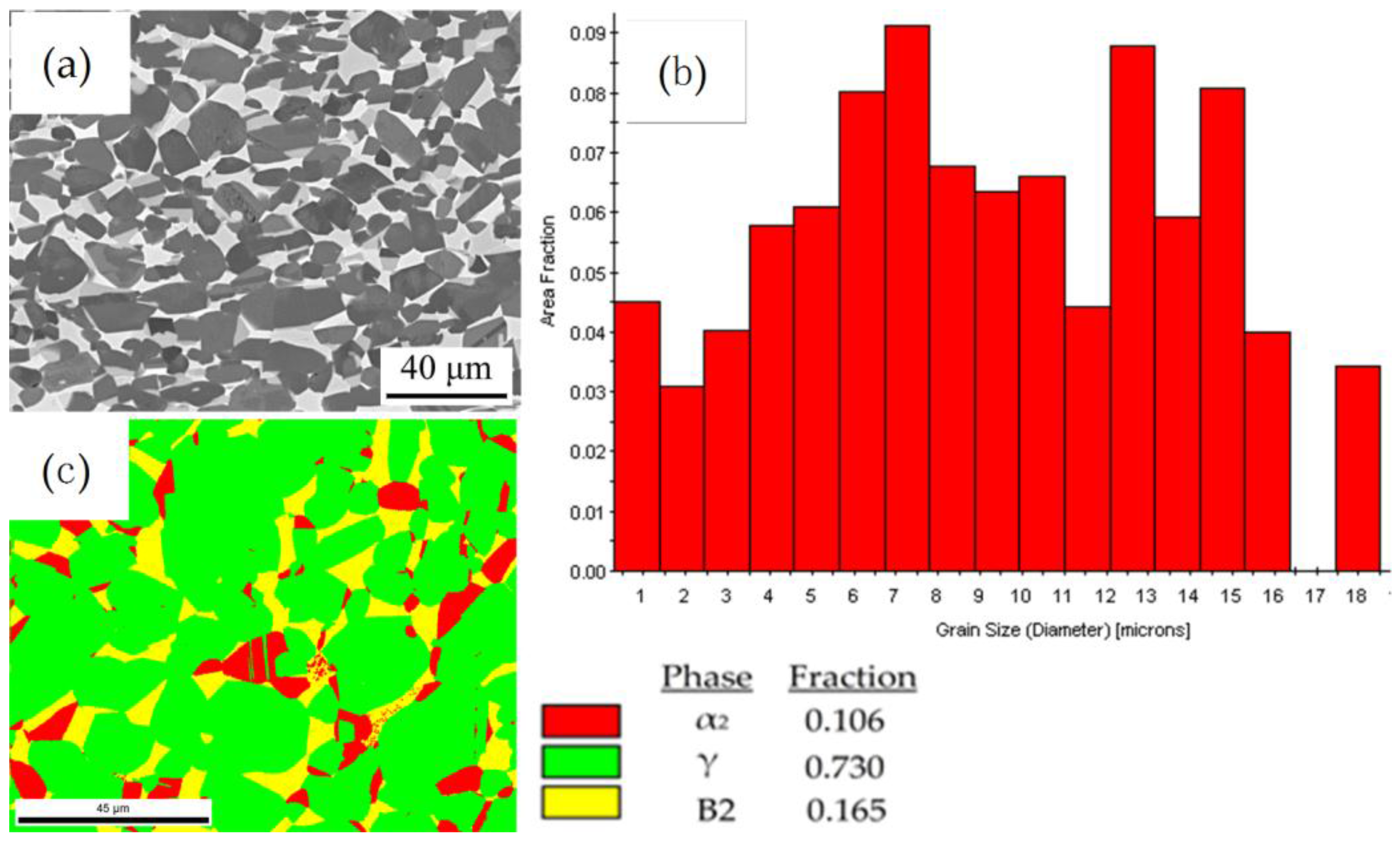

3.1. As-Cast Microstructure

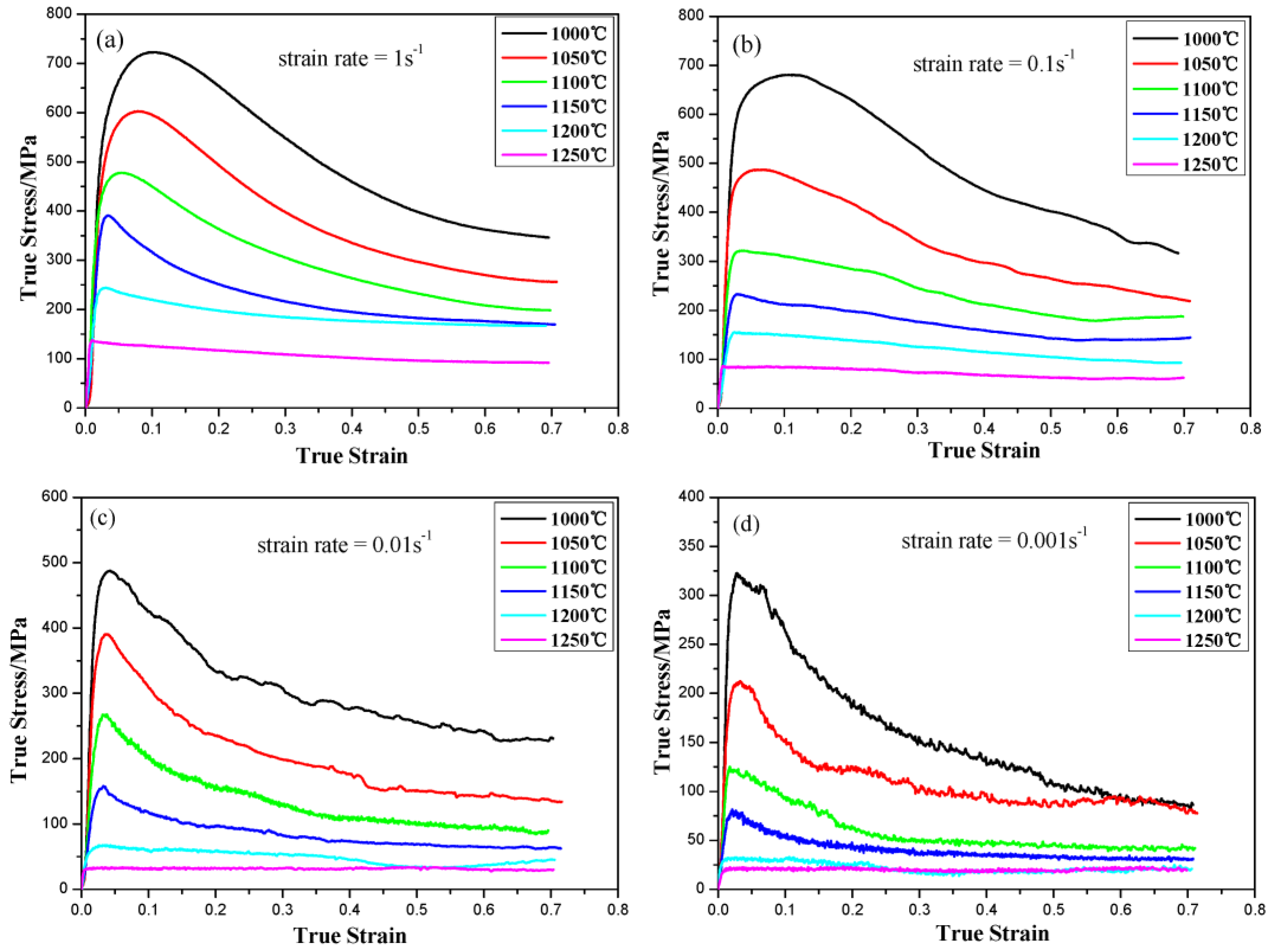

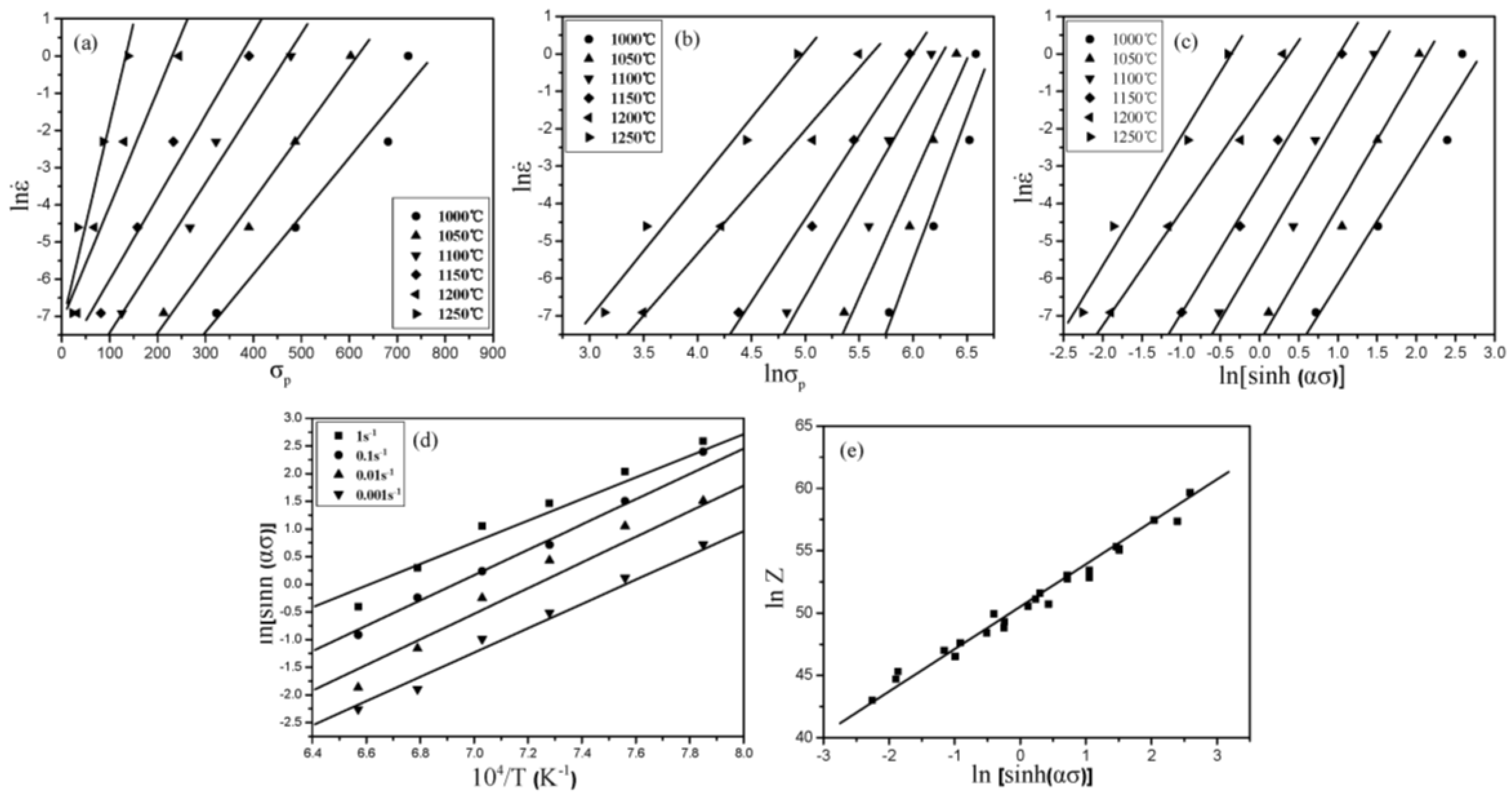

3.2. Flow Behavior and Constitutive Equation

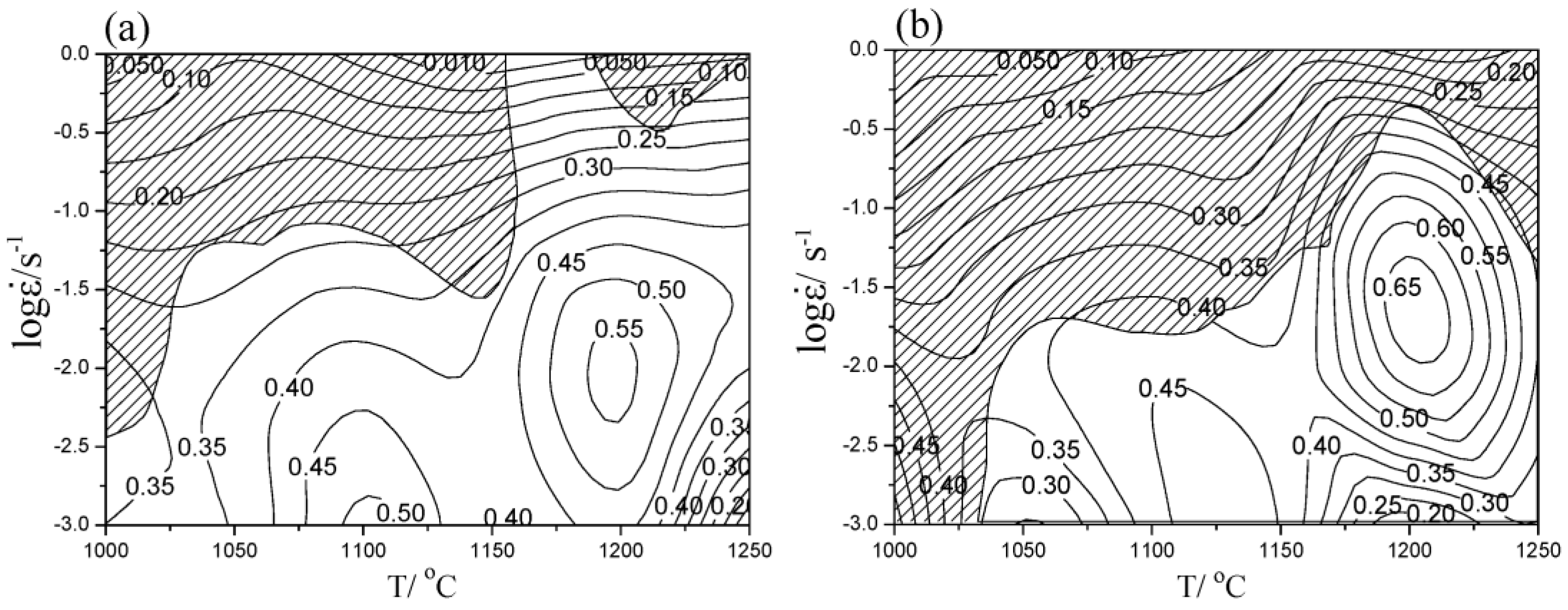

3.3. Hot Processing Map

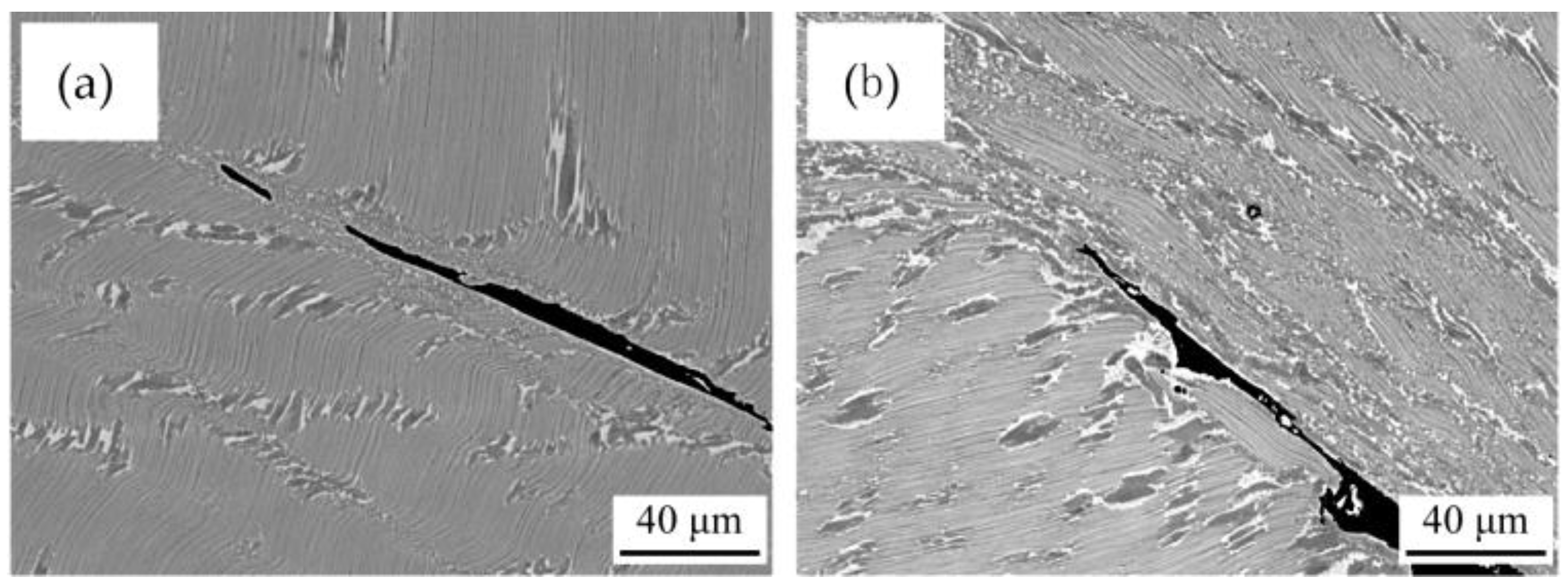

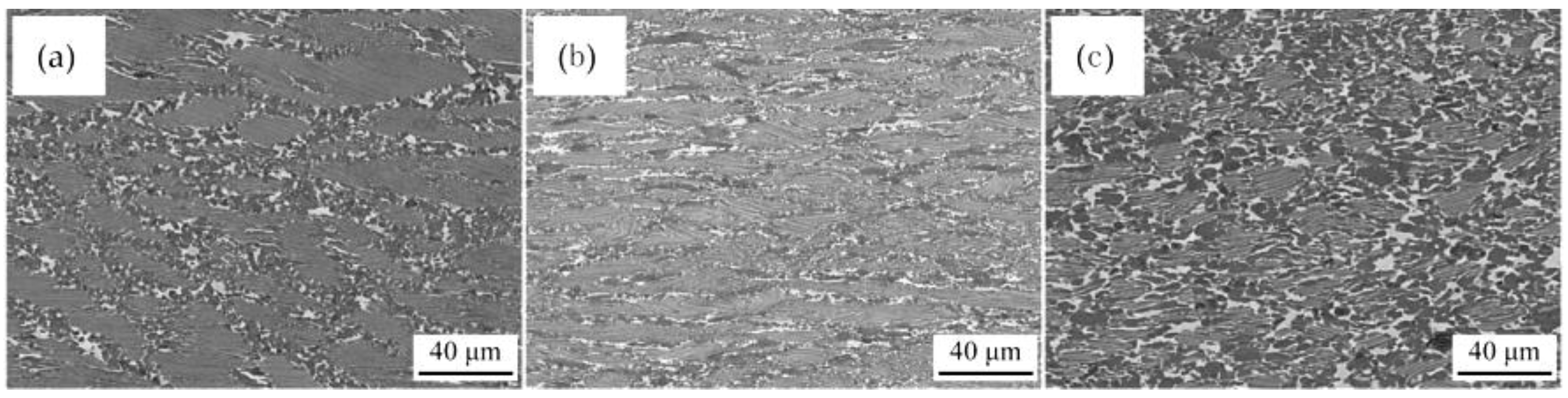

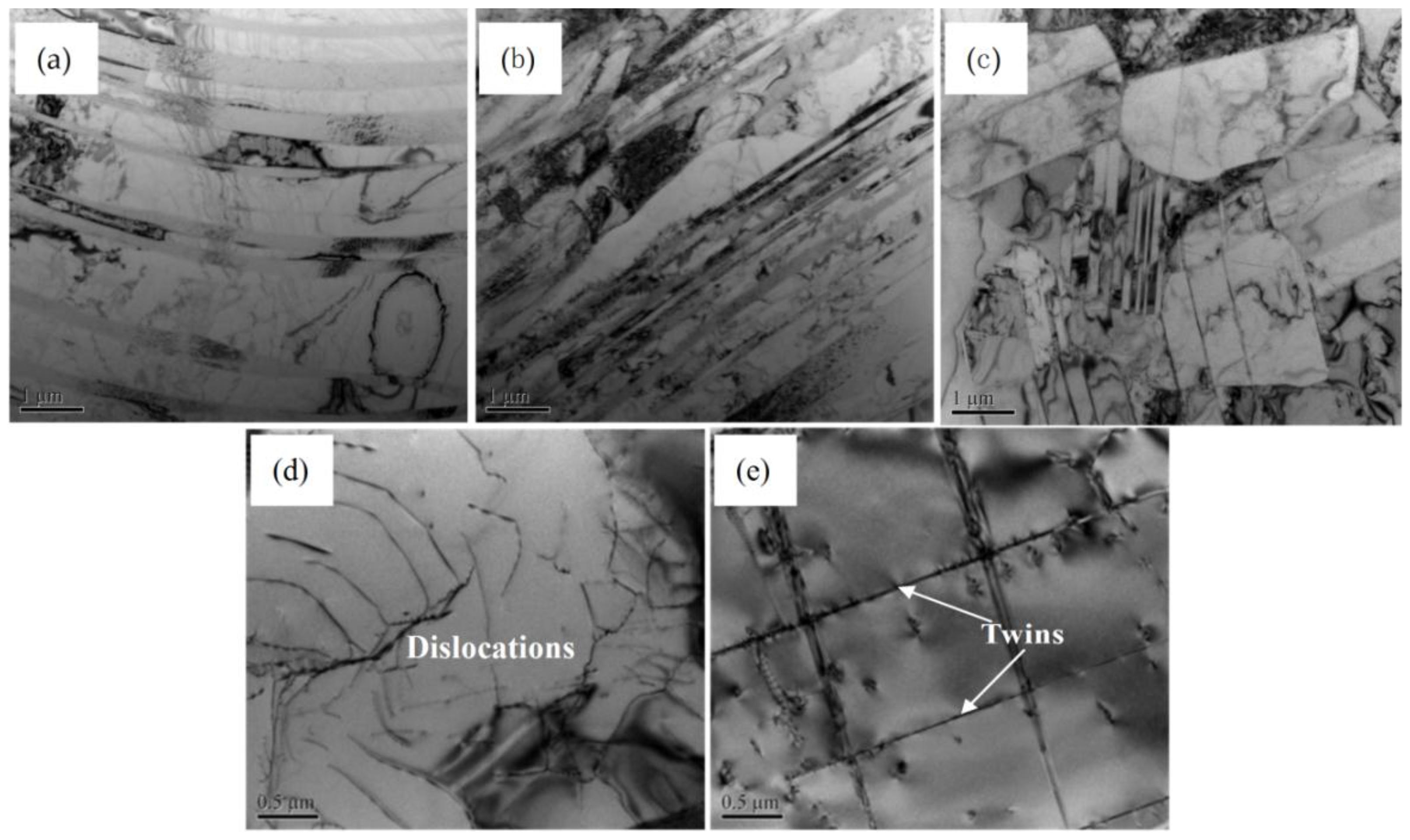

3.4. Microstructural Evolution

3.5. Large-Size TiAl Bars with Uniform and Fine Grains Produced by Hot Extrusion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yamaguchi, M.; Inui, H.; Ito, K. High-temperature structural intermetallics. Acta Mater. 2000, 48, 307–322. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Paul, J.D.H.; Lorenz, U.; Oehring, M.; Appel, F. Up-scaling the size of TiAl components made via ingot metallurgy. Intermetallics 2013, 32, 318–328. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kaji, S.; Kobayashi, S.; Takeyama, M. Fabrication of TiAl components by means of hot forging and machining. Intermetallics 2005, 13, 971–978. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Lindemann, J.; Stark, A.; Mayer, S. Hot-working behavior of an advanced intermetallic multi-phase γ-TiAl based alloy. Mater. Sci. Eng. A 2014, 614, 297–310. [Google Scholar] [CrossRef]

- Cui, N.; Kong, F.; Wang, X.; Chen, Y.; Zhou, H. Microstructural evolution, hot workability, and mechanical properties of Ti-43Al-2Cr-2Mn-0.2Y alloy. Mater. Des. 2016, 89, 1020–1027. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Yang, G.Y.; Li, J.B.; Liu, B.; Wang, J.W.; Li, H.Z. Hot deformation behaviors of β phase containing Ti-43Al-4Nb-1.4W-based alloy. Mater. Sci. Eng. A 2013, 577, 210–217. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.; Li, Y.P.; Zhang, W.; Chiba, A. Thermomechanical characterization of β-stabilized Ti-45Al-7Nb-0.4W-0.15B alloy. Intermetallics 2011, 19, 1184–1190. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.; Huang, L.; Li, H.; He, Y. Characterization of phase transformation during hot compressive deformation in a β-stabilized Ti-45Al-7Nb-0.4W-0.15B alloy. Mater. Charact. 2015, 105, 113–117. [Google Scholar] [CrossRef]

- Seetharaman, V.; Semiatin, S.L. Effect of the lamellar grain size on plastic flow behavior and microstructure evolution during hot working of a gamma titanium aluminide alloy. Metall. Mater. Trans. A 2002, 33, 3817–3830. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Xiao, S.L.; Xu, L.J. Microstructure evolution and mechanical properties of a novel beta γ-TiAl alloy. Intermetallics 2012, 31, 225–231. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Kim, J.H.; Chang, Y.W.; Lee, C.S.; Ha, T.K. High-temperature deformation behavior of a gamma TiAl alloy—Microstructural evolution and mechanisms. Metall. Mater. Trans. A 2003, 34, 2165. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Met. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Jonas, J.J.; Sellars, C.M.; Tegart, W.J.M. Strength and structure under hot-working conditions. Metall. Rev. 1969, 14, 1–24. [Google Scholar] [CrossRef]

- Sun, C.; Xiang, Y.; Zhou, Q.; Politis, D.J.; Sun, Z.; Wang, M. Dynamic Recrystallization and Hot Workability of 316LN Stainless Steel. Metals 2016, 6, 152. [Google Scholar] [CrossRef]

- Sun, C.; Zuo, X.; Xiang, Y.; Yang, J. Investigation on Hot Deformation Behavior and Hot Processing Map of BSTMUF601 Super-Alloy. Metals 2016, 6, 70. [Google Scholar] [CrossRef]

- Jonas, J.J.; Holt, R.A.; Coleman, C.E. Plastic stability in tension and compression. Acta Metall. 1976, 24, 911–918. [Google Scholar] [CrossRef]

- Raj, R. Development of a Processing Map for Use in Warm-Forming and Hot-Forming Processes. Metall. Trans. A 1981, 12, 1089–1097. [Google Scholar] [CrossRef]

- Montheillet, F.; Jonas, J.J.; Neale, K.W. Modeling of dynamic material behavior: A critical evaluation of the dissipator power co-content approach. Metall. Mater. Trans. A 1996, 27, 232–235. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Rao, B.N. Ziegler’s Criterion on the Instability Regions in Processing Maps. J. Mater. Sci. Lett. 1998, 17, 1203–1205. [Google Scholar] [CrossRef]

- Dao, M.; Kad, B.K.; Asaro, R.J. Deformation and fracture under compressive loading in lamellar TiAl microstructures. Philos. Mag. A 1996, 74, 569–591. [Google Scholar] [CrossRef]

- Appel, F. Diffusion assisted dislocation climb in intermetallic gamma TiAl. Mater. Sci. Eng. A 2001, 317, 115–127. [Google Scholar] [CrossRef]

- Imayev, R.M.; Imayev, V.M.; Oehring, M.; Appel, F. Microstructural evolution during hot working of Ti aluminide alloys: Influence of phase constitution and initial casting texture. Metall. Mater. Trans. A 2005, 36, 859–867. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Rong, R.; Gao, F.; Li, Z.; Liu, Y.; Wang, Q. Hot Deformation Behavior and Microstructural Evolution Characteristics of Ti-44Al-5V-1Cr Alloy Containing (γ + α2 + B2) Phases. Metals 2016, 6, 305. https://doi.org/10.3390/met6120305

Liu H, Rong R, Gao F, Li Z, Liu Y, Wang Q. Hot Deformation Behavior and Microstructural Evolution Characteristics of Ti-44Al-5V-1Cr Alloy Containing (γ + α2 + B2) Phases. Metals. 2016; 6(12):305. https://doi.org/10.3390/met6120305

Chicago/Turabian StyleLiu, Hongwu, Rong Rong, Fan Gao, Zhenxi Li, Yanguo Liu, and Qingfeng Wang. 2016. "Hot Deformation Behavior and Microstructural Evolution Characteristics of Ti-44Al-5V-1Cr Alloy Containing (γ + α2 + B2) Phases" Metals 6, no. 12: 305. https://doi.org/10.3390/met6120305

APA StyleLiu, H., Rong, R., Gao, F., Li, Z., Liu, Y., & Wang, Q. (2016). Hot Deformation Behavior and Microstructural Evolution Characteristics of Ti-44Al-5V-1Cr Alloy Containing (γ + α2 + B2) Phases. Metals, 6(12), 305. https://doi.org/10.3390/met6120305