Microstructure, Mechanical and Corrosion Properties of Friction Stir Welding High Nitrogen Martensitic Stainless Steel 30Cr15Mo1N

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

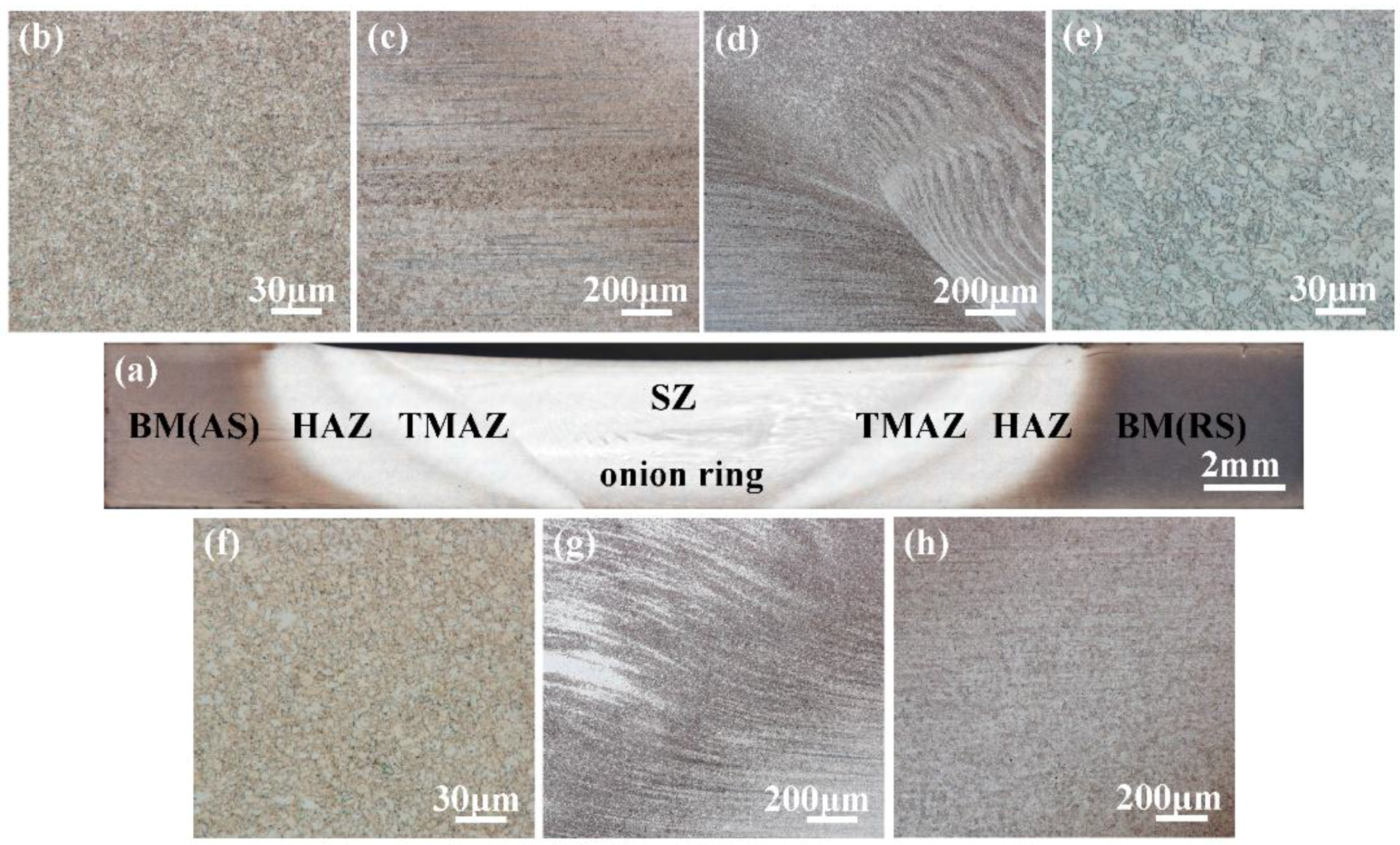

3.1. Macro- and Microstructure Observation

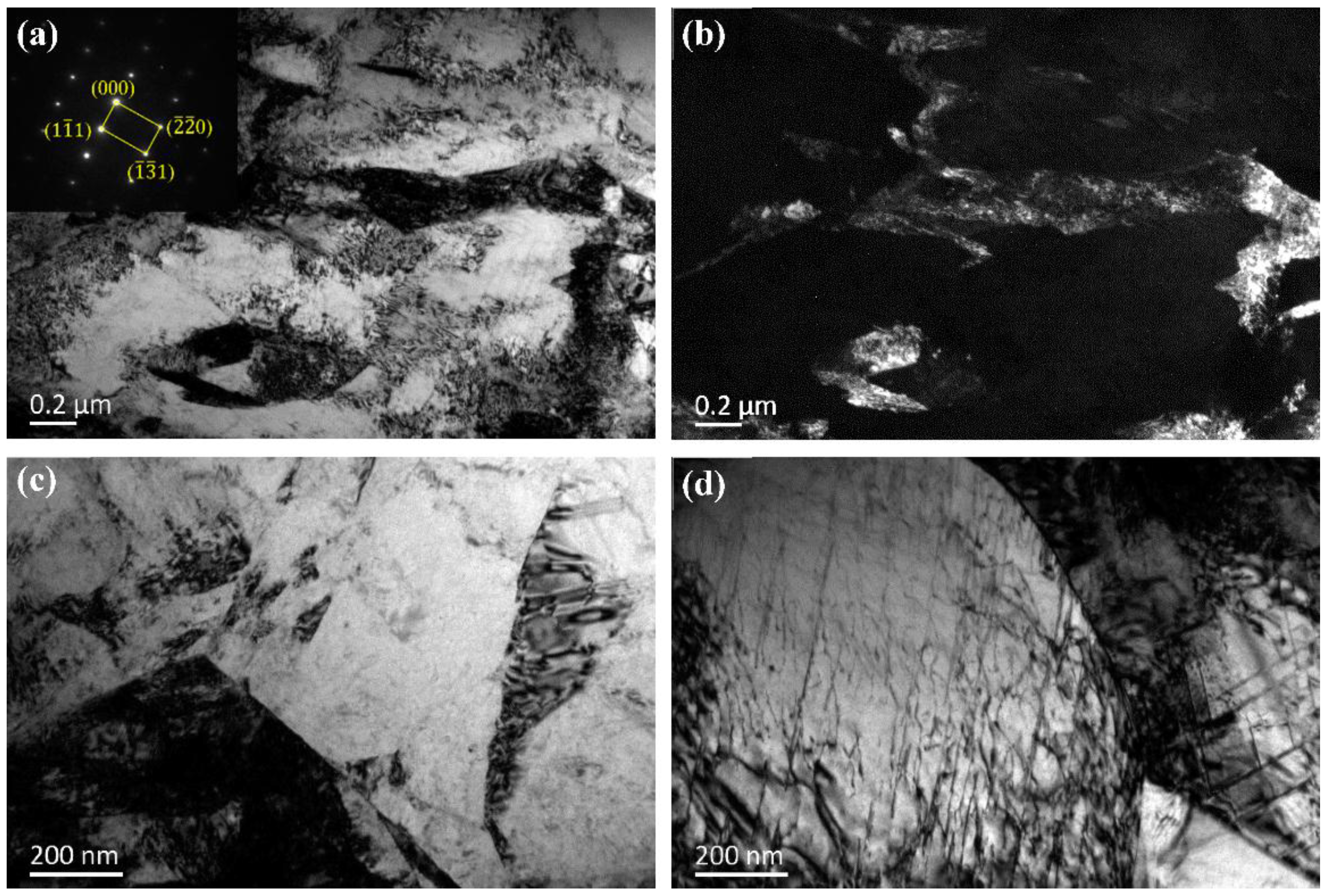

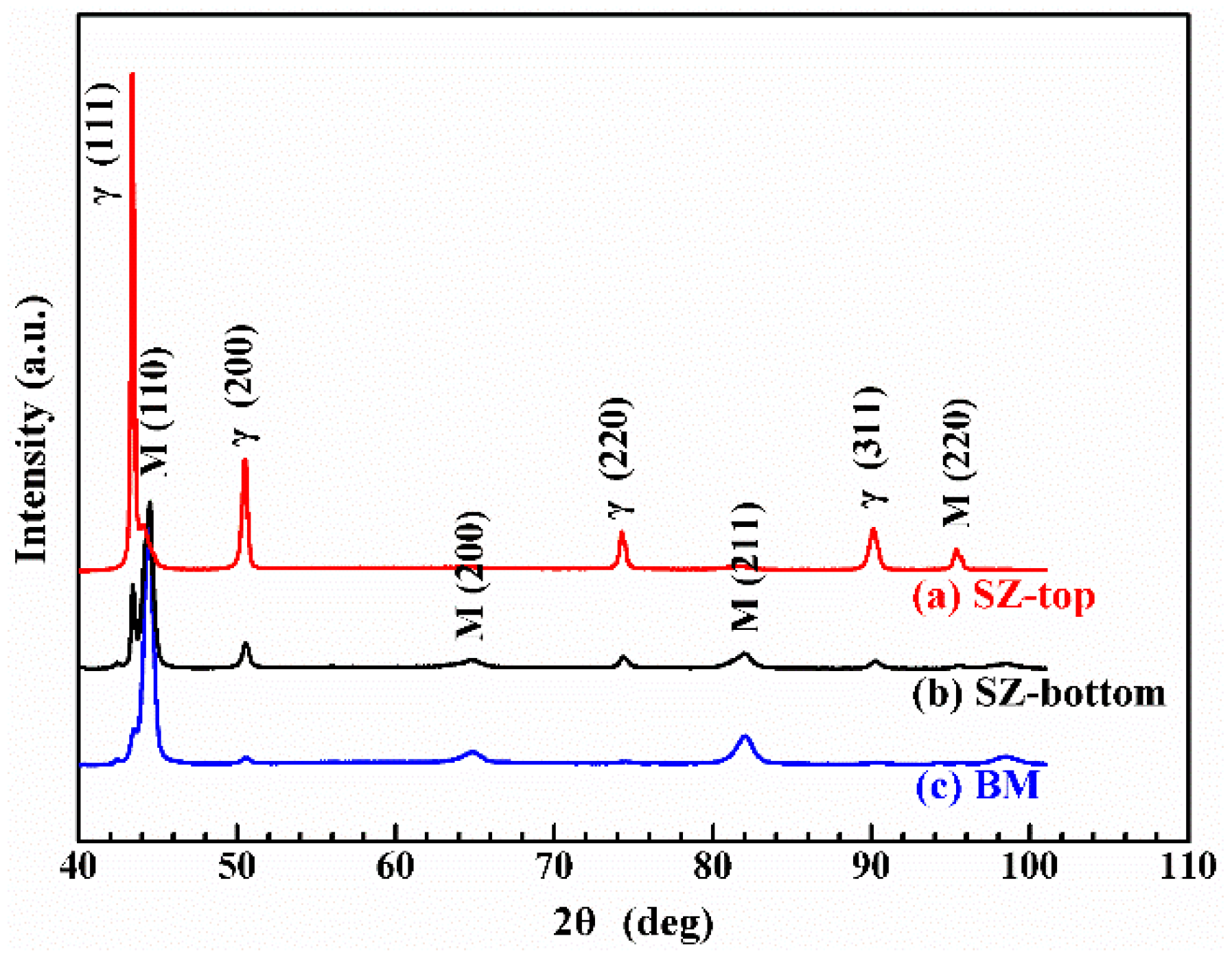

3.2. X-ray Diffraction and EBSD Test

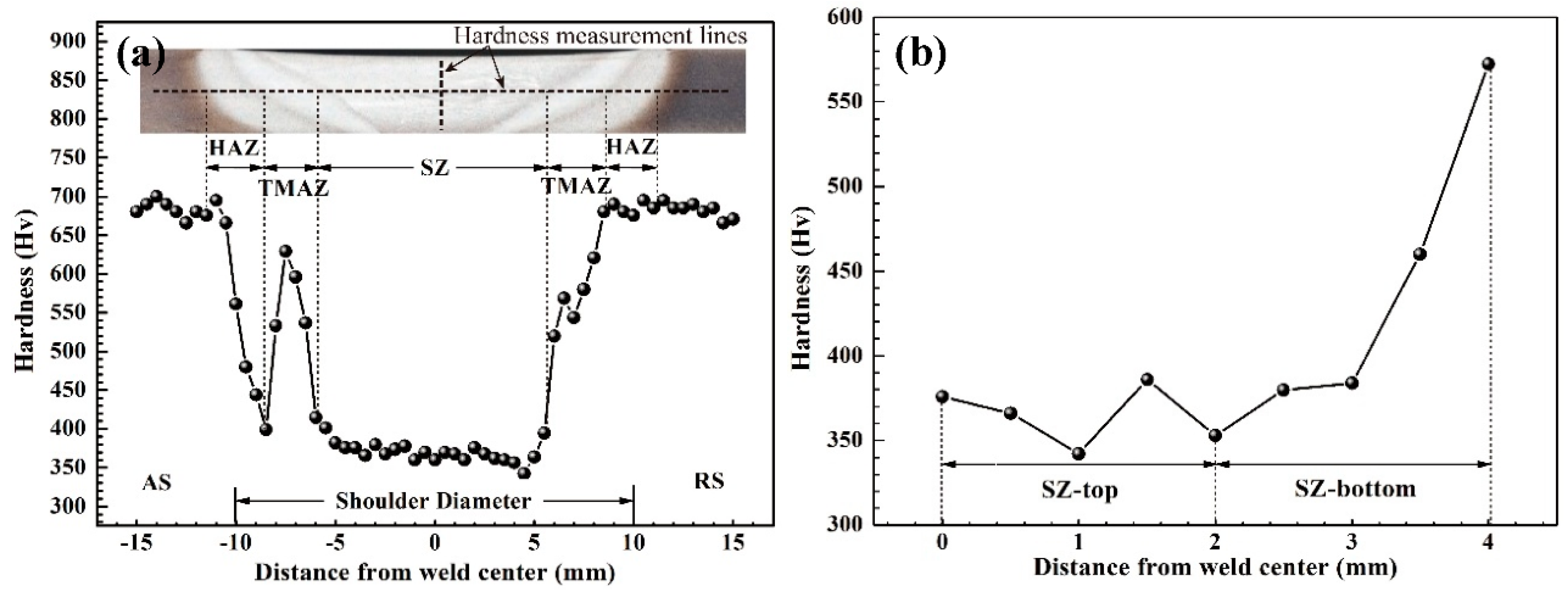

3.3. Micro-Hardness Distribution

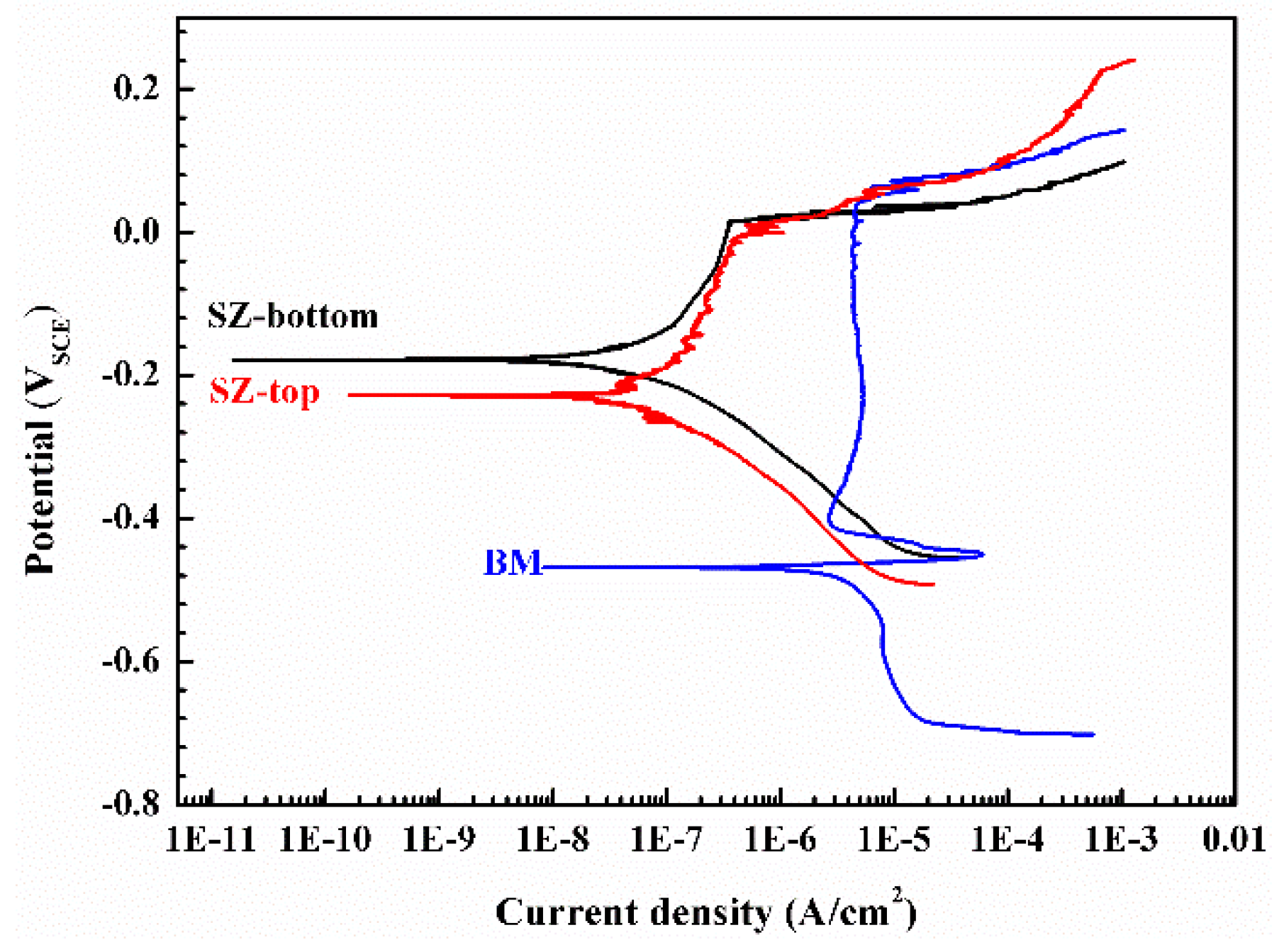

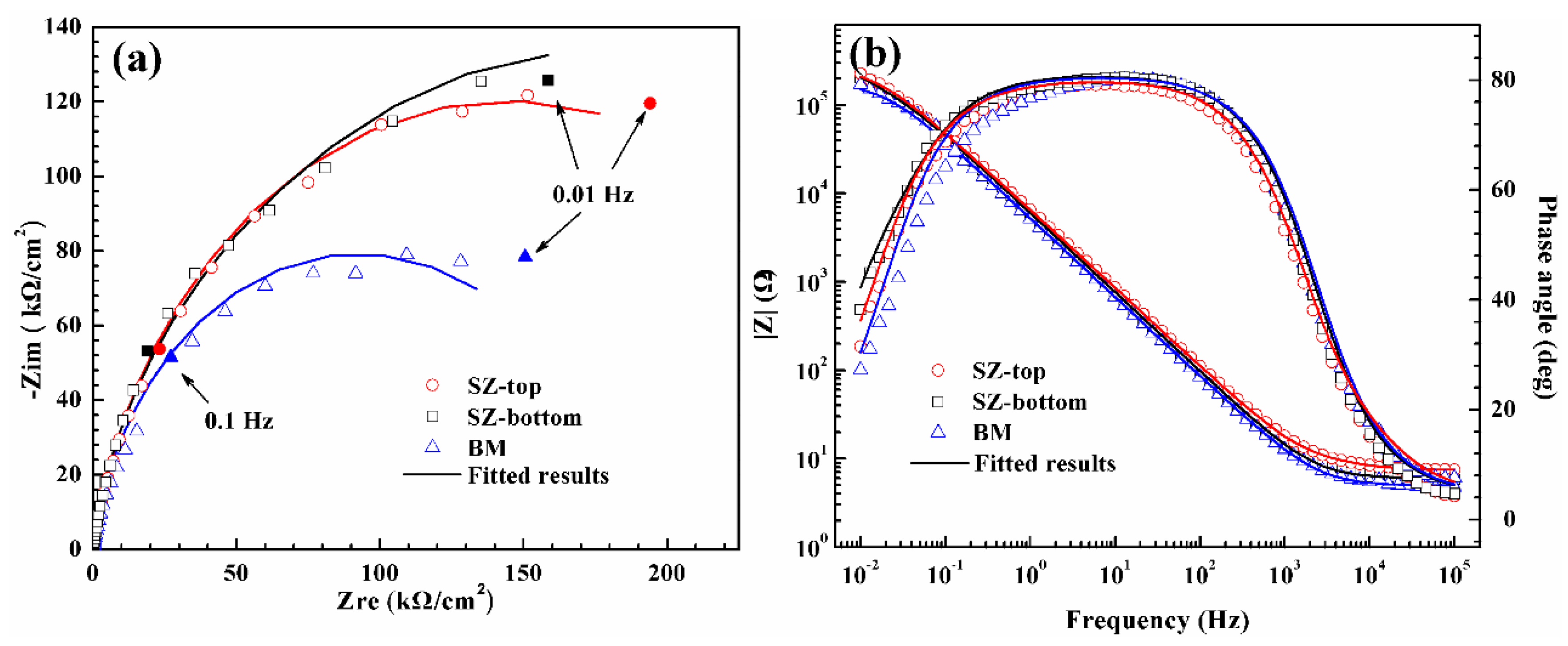

3.4. Corrosion Behavior

4. Conclusions

- (1)

- A sound FSW joint was successfully obtained without any defects. The SZ was characterized by coarse-grained microstructure, and no significant nitrogen loss occurred during FSW process.

- (2)

- The grain size of SZ is larger than that of the BM and the case of SZ-top is the largest. The “onion ring” formed in the middle of SZ. Some carbides and nitrides rich in chromium were found in BM while not observed in SZ.

- (3)

- Based on the TEM, XRD and EBSD analysis, the martensitic phase in SZ could transform into austenite phase during FSW process and the higher peak temperature, the greater degree of transformation.

- (4)

- The hardness of SZ is significantly lower than that of the BM. An abrupt change of hardness defined as hard zone (HZ) was found in TMAZ on AS, and the HZ is attributed to a combination result of temperature, deformation, and material flow behavior.

- (5)

- The corrosion resistance of SZ is superior to that of BM, which can be attributed to lower precipitation and more LABs. The case of SZ-bottom is slightly higher than that of SZ-top because of the finer grained structure.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Degallaix, S.; Foct, J.; Hendry, A. Mechanical behaviour of high-nitrogen stainless steels. Mater. Sci. Technol. 1986, 2, 946–950. [Google Scholar] [CrossRef]

- Gavriljuk, V.G. Nitrogen in iron and steel. ISIJ Int. 1996, 36, 738–745. [Google Scholar] [CrossRef]

- Ma, X.P.; Wang, L.J.; Liu, C.M.; Subramanian, S.V. Microstructure and properties of 13Cr5Ni1Mo0.025Nb0.09V0.06N super martensitic stainless steel. Mater. Sci. Eng. A 2012, 539, 271–279. [Google Scholar] [CrossRef]

- Lee, T.H.; Oh, C.S.; Kim, S.J.; Takaki, S. Brittle fracture in austenitic steel. Acta Mater. 2007, 55, 3649–3662. [Google Scholar] [CrossRef]

- Berns, H.; Lueg, J. Corrosion behavior and mechanical properties of martensitic stainless steels containing nitrogen. In Proceedings of the First International Conference on High Nitrogen Steels-HNS88, Lille, France, 18–20 May 1988; p. 288.

- Woo, I.; Kikuchi, Y. Research on the properties of TIG welded joints of high nitrogen nickel-free austenitic stainless steel and welding wire. ISIJ Int. 2002, 42, 1334–1343. [Google Scholar] [CrossRef]

- Ogawa, M.; Hiraoka, K.; Katada, Y.; Sagara, M.; Tsukamoto, S. Chromium Nitride Precipitation Behavior in Weld Heat-affected Zone of High Nitrogen Stainless Steel. ISIJ Int. 2002, 42, 1391–1398. [Google Scholar] [CrossRef]

- Ogawa, T.; Hiraoka, K.; Katada, Y.; Sagara, M.; Tsukamoto, S.; Shiga, C. Chromium nitride precipitation behavior in weld heat-affected zone of high nitrogen stainless steel. ISIJ Int. 2002, 20, 107–113. [Google Scholar] [CrossRef]

- Woo, I.; Aritoshi, M.; Kikuchi, Y. Metallurgical and Mechanical Properties of High Nitrogen Austenitic Stainless Steel Friction Welds. ISIJ Int. 2002, 42, 401–406. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H.; Okamoto, K.; Hirano, S.; Inagaki, M. Rapid formation of the sigma phase in 304 stainless steel during friction stir welding. Scr. Mater. 2003, 49, 1175–1180. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needhman, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Stir Butt Welding. Int. Pat. Appl. PCT/GB92/02203, 6 December 1991. [Google Scholar]

- Celik, S.; Cakir, R. Effect of friction stir welding parameters on the mechanical and microstructure properties of the Al-Cu butt joint. Metals 2016, 6, 133. [Google Scholar] [CrossRef]

- Sun, Y.; Tsuji, N.; Fujii, H. Microstructure and mechanical properties of dissimilar friction stir welding between ultrafine grained 1050 and 6061-T6 aluminum alloys. Metals 2016, 6, 249. [Google Scholar] [CrossRef]

- Reynolds, A.P.; Tang, W.; Herold, T.G.; Prask, H. Structure, properties and residual stress of 304L stainless steel friction stir welds. Scr. Mater. 2003, 48, 1289–1294. [Google Scholar] [CrossRef]

- Sato, Y.S.; Nelson, T.W.; Sterling, C.J. Recrystallization in type 304L stainless steel during friction stirring. Acta Mater. 2005, 53, 637–645. [Google Scholar] [CrossRef]

- Sato, Y.S.; Nelson, T.W.; Sterling, C.J.; Steel, R.J.; Peterson, C.O. Microstructure and mechanical properties of friction stir welded SAF 2507 super duplex stainless steel. Mater. Sci. Eng. A 2005, 397, 376–384. [Google Scholar] [CrossRef]

- Fujii, H.; Cui, L.; Tsuji, N.; Maeda, M.; Nakata, K.; Nogi, K. Friction stir welding of carbon steels. Mater. Sci. Eng. A 2006, 429, 50–57. [Google Scholar] [CrossRef]

- Sato, Y.S.; Yamanoi, H.; Kokawa, H.; Furuhara, T. Microstructural evolution of ultrahigh carbon steel during friction stir welding. Scr. Mater. 2007, 57, 557–560. [Google Scholar] [CrossRef]

- Chung, Y.D.; Fujii, H.; Ueji, R.; Tsuji, N. Friction stir welding of high carbon steel with excellent toughness and ductility. Scr. Mater. 2010, 63, 223–226. [Google Scholar] [CrossRef]

- Ueji, R.; Fujii, H.; Cui, L.; Nishiokac, A.; Kunishigea, K.; Nogib, K. Friction stir welding of ultrafine grained plain low-carbon steel formed by the martensitic process. Metall. Mater. Trans. A 2006, 423, 324–330. [Google Scholar]

- Meshram, S.D.; Madhusudhan Reddy, G.; Pandey, S. Friction stir welding of maraging steel. Mater. Des. 2013, 49, 58–64. [Google Scholar] [CrossRef]

- Han, L.; Li, H.; Zhu, Z.; Barbaro, F.; Jiang, L.; Xu, H.; Ma, L. Microstructure and mechanical properties of friction stir welded 18Cr-2Mo ferritic stainless steel thick plate. Mater. Des. 2014, 63, 238–246. [Google Scholar] [CrossRef]

- Esmailzadeh, M.; Shamanian, M.; Kermanpur, A.; Saeid, T. Microstructure and mechanical properties of friction stir welded lean duplex stainless steel. Mater. Sci. Eng. A 2013, 561, 486–491. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mab, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Krishnan, K.N. On the formation of onion rings in friction stir welds. Mater. Sci. Eng. A 2002, 327, 246–251. [Google Scholar] [CrossRef]

- Jeon, J.J.; Mironov, S.; Sato, Y.S.; Kokawa, H.; Park, S.H.C.; Hirano, S. Grain structure development during friction stir welding of single-crystal austenitic stainless steel. Metall. Mater. Trans. A 2013, 44, 3157–3166. [Google Scholar] [CrossRef]

- Du, D.; Fu, R.; Li, Y.; Jing, L.; Ren, Y.; Yang, K. Gradient characteristics and strength matching in friction stir welded joints of Fe–18Cr–16Mn–2Mo–0.85N austenitic stainless steel. Mater. Sci. Eng. A 2014, 616, 246–251. [Google Scholar] [CrossRef]

- Miyano, Y.; Fujii, H.; Sun, Y.; Katada, Y.; Kuroda, S.; Kamiya, O. Mechanical properties of friction stir butt welds of high nitrogen-containing austenitic stainless steel. Mater. Sci. Eng. A 2011, 528, 2917–2921. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H. Microstructural characterisation of stir zone containing residual ferrite in friction stir welded 304 austenitic stainless steel. Sci. Technol. Weld. Join. 2005, 10, 550–556. [Google Scholar] [CrossRef]

- Savolainen, K.; Saukkonen, T.; Hänninen, H. Banding in copper friction stir weld. Sci. Technol. Weld. Join. 2012, 17, 111–115. [Google Scholar] [CrossRef]

- Li, H.B.; Jiang, Z.H.; Feng, H.; Zhang, S.C.; Li, L.; Han, P.D.; Misra, R.D.K.; Li, J.Z. Microstructure, mechanical and corrosion properties of friction stir welded high nitrogen nickel-free austenitic stainless steel. Mater. Des. 2015, 84, 291–299. [Google Scholar] [CrossRef]

- Ahn, B.W.; Choi, D.H.; Kim, D.J.; Jung, S.B. Microstructures and properties of friction stir welded 409L stainless steel using a Si3N4 tool. Mater. Sci. Eng. A 2012, 532, 476–479. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enmoto, M.; Jogan, S. Microstructural evolution of 6063 aluminum during friction-stir welding. Metall. Mater. Trans. A 1999, 30, 2429. [Google Scholar] [CrossRef]

- Heinz, B.; Skrotzki, B. Characterization of a friction-stir-welded aluminum alloy 6013. Metall. Mater. Trans. B 2002, 33, 489–498. [Google Scholar] [CrossRef]

- Jata, K.V.; Sankaran, K.K.; Ruschau, J.J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Metall. Mater. Trans. A 2000, 31, 2181–2192. [Google Scholar] [CrossRef]

- Arbegast, W.J.; Hartley, P.J. Friction stir weld technology development at Lockheed Martin Michoud space systems—An overview. In Proceedings of the Fifth International Conference on Trends in Welding Research, Pine Mountain, GA, USA, 1–5 June 1998; p. 541.

- Ghosh, M.; Kumar, K.; Mishra, R.S. Analysis of microstructural evolution during friction stir welding of ultrahigh-strength steel. Scr. Mater. 2010, 63, 851–854. [Google Scholar] [CrossRef]

- Prado, R.A.; Murr, L.E.; Shindo, D.J.; Sota, K.F. Tool wear in the friction-stir welding of aluminum alloy 6061 + 20% Al2O3: A preliminary study. Scr. Mater. 2001, 45, 75–80. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X.; Hughes, D.A. Microstructural evolution and hardening parameters. Mater. Sci. Eng. A 2001, 317, 3–11. [Google Scholar] [CrossRef]

- Fujii, H.; Ueji, R.; Takada, Y.; Kitahara, H.; Tsuji, N.; Nakata, K.; Nogi, K. Friction Stir Welding of Ultrafine Grained Interstitial Free Steels. Mater. Trans. JIM 2006, 47, 239–242. [Google Scholar] [CrossRef]

- Lee, H.; Kim, C.; Song, J.H. An evaluation of global and local tensile properties of friction-stir welded DP980 dual-phase steel joints using a digital image correlation method. Metals 2015, 8, 8424–8436. [Google Scholar] [CrossRef]

- Sato, Y.S.; Park, S.H.C.; Kokawa, H. Distribution of tensile property and microstructure in friction stir weld of 6063 aluminum. Metall. Mater. Trans. A 2001, 32, 3023–3031. [Google Scholar] [CrossRef]

- Jeon, J.; Mironov, S.; Sato, Y.S.; Kokawa, H.; Park, S.H.C.; Hirano, S. Friction stir spot welding of single-crystal austenitic stainless steel. Acta Mater. 2011, 59, 7439–7449. [Google Scholar] [CrossRef]

- Ozekcin, A.; Jin, H.W.; Koo, J.Y.; Bangaru, N.V.; Ayer, R. A Microstructural Study of Friction Stir Welded Joints of Carbon Steels. Int. J. Offshore Polar Eng. 2004, 14, 284–288. [Google Scholar]

- Sowards, J.W.; Herold, T.G.; McColskey, J.D.; Pereira, V.F.; Ramirez, A.J. Characterization of mechanical properties, fatigue-crack propagation, and residual stresses in a microalloyed pipeline-steel friction-stir weld. Mater. Des. 2015, 88, 632–642. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X.; Hughes, D.A. Effect of Grain Boundaries and Grain Orientation on Structure and Properties. Mater. Sci. Eng. A 2001, 317, 3–11. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N. Effect of Grain Size on Corrosion: A Review. Corrosion 2010, 66, 075005–075013. [Google Scholar] [CrossRef]

- Dinh, L.; Earthman, J.C.; Lund, I.; Mohamed, F.A.; Roy, I.; Yang, H.W. Possible origin of superior corrosion resistance for nanocrystalline Ni. Scr. Mater. 2008, 59, 305–308. [Google Scholar]

- Gupta, R.K.; Raman, R.K.S.; Koch, C.C.; Murty, B.S. Effect of nanocrystalline structure on the corrosion of a Fe20Cr alloy. Int. J. Electrochem. Sci. 2013, 8, 6791–6806. [Google Scholar]

- Lu, A.Q.; Zhang, Y.; Li, Y.; Liu, G.; Zang, Q.H.; Liu, C.M. Effect of nanocrystalline and twin boundaries on corrosion behavior of 316 stainless steel using SMAT. Acta Metall. Sin. Engl. Lett. 2006, 19, 183–189. [Google Scholar] [CrossRef]

| C | Cr | Mo | N | Ni | Mn | Si | Fe |

|---|---|---|---|---|---|---|---|

| 0.306 | 15.38 | 1.04 | 0.38 | 0.08 | 0.43 | 0.5 | Bal. |

| Specimens | Rs/(Ω·cm−2) | CPE | Rp/(Ω·cm−2) | |

|---|---|---|---|---|

| n(0–1) | Q0/(S·sn·cm−2) | |||

| BM | 4.913 | 0.8939 | 3.673 × 10−5 | 1.852 × 105 |

| SZ-top | 7.693 | 0.8815 | 3.037 × 10−5 | 2.881 × 105 |

| SZ-bottom | 3.801 | 0.8783 | 3.358 × 10−5 | 3.018 × 105 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, X.; Feng, H.; Jiang, Z.; Li, H.; Zhang, B.; Zhang, S.; Wang, Q.; Li, J. Microstructure, Mechanical and Corrosion Properties of Friction Stir Welding High Nitrogen Martensitic Stainless Steel 30Cr15Mo1N. Metals 2016, 6, 301. https://doi.org/10.3390/met6120301

Geng X, Feng H, Jiang Z, Li H, Zhang B, Zhang S, Wang Q, Li J. Microstructure, Mechanical and Corrosion Properties of Friction Stir Welding High Nitrogen Martensitic Stainless Steel 30Cr15Mo1N. Metals. 2016; 6(12):301. https://doi.org/10.3390/met6120301

Chicago/Turabian StyleGeng, Xin, Hao Feng, Zhouhua Jiang, Huabing Li, Binbin Zhang, Shucai Zhang, Qi Wang, and Jizhong Li. 2016. "Microstructure, Mechanical and Corrosion Properties of Friction Stir Welding High Nitrogen Martensitic Stainless Steel 30Cr15Mo1N" Metals 6, no. 12: 301. https://doi.org/10.3390/met6120301