The Effect of Ultrafast Heating in Cold-Rolled Low Carbon Steel: Recrystallization and Texture Evolution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Steel and Heat Treatment

2.2. Characterization

2.3. Data Post-Processing and Analysis

3. Results

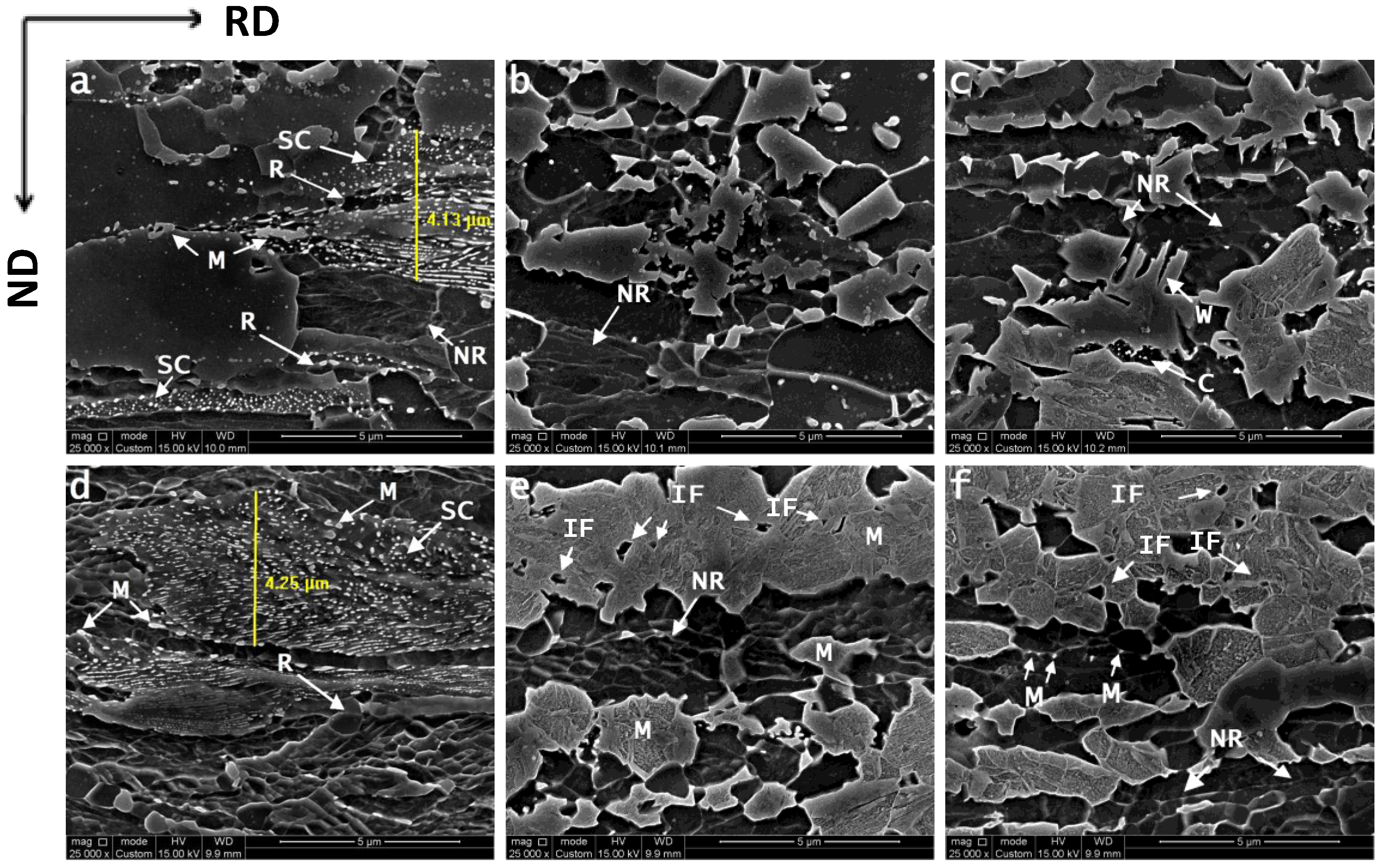

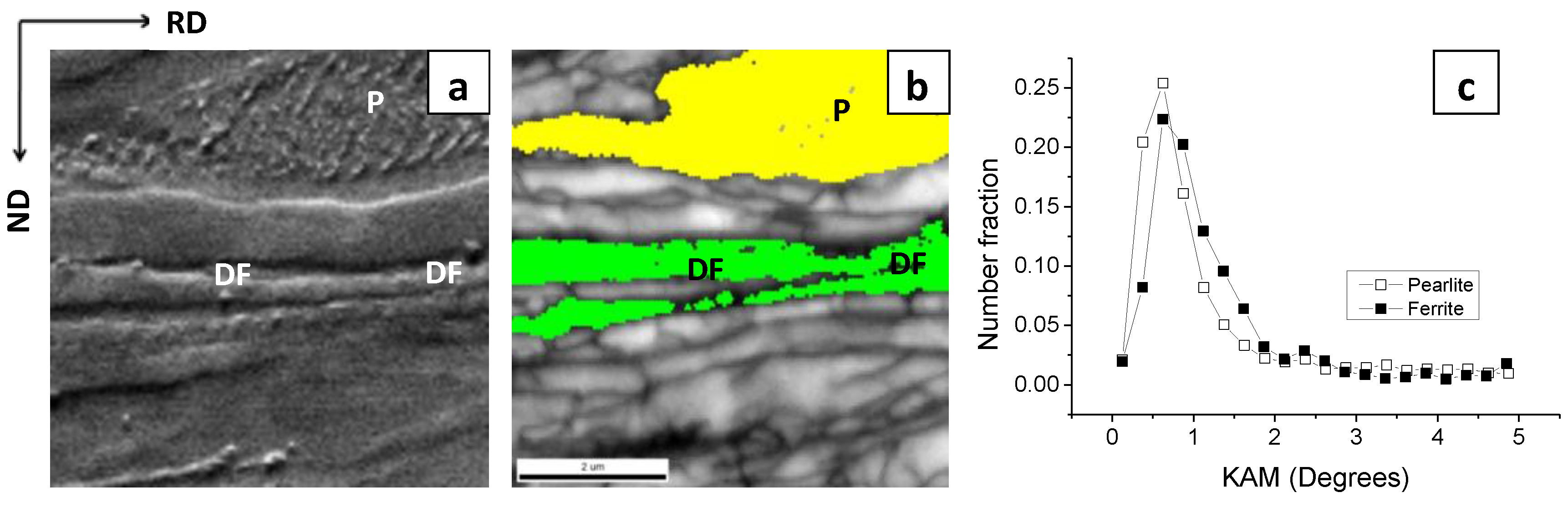

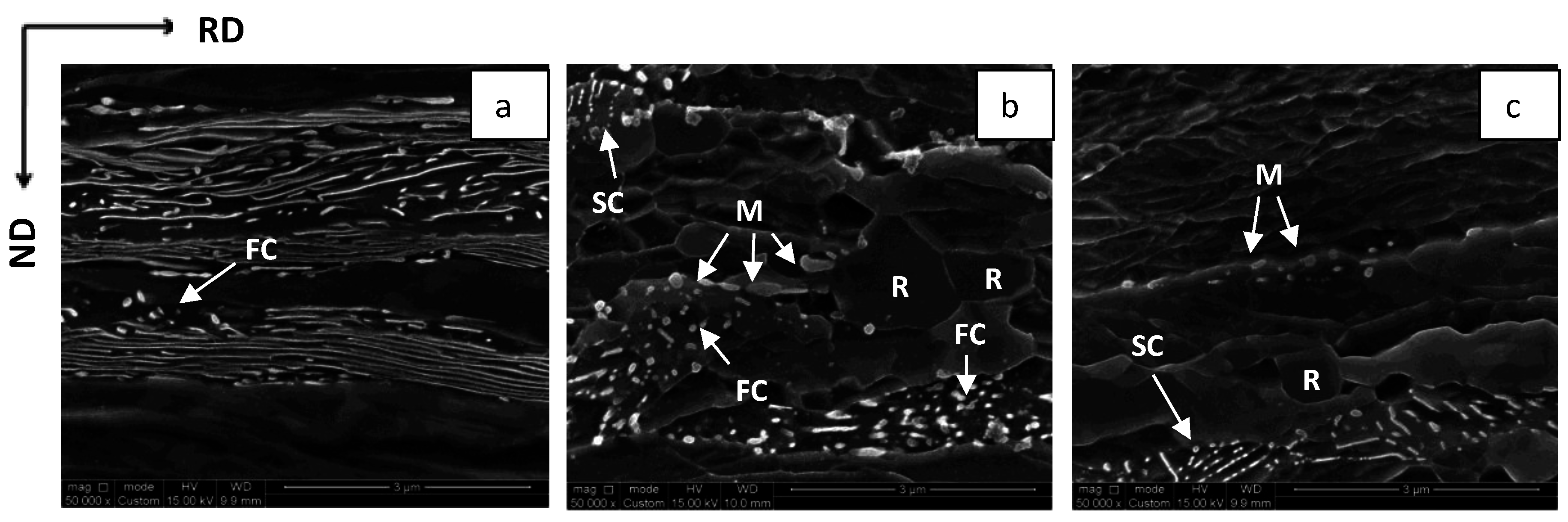

3.1. Microstructure after Cold-Rolling and Ultrafast Heating

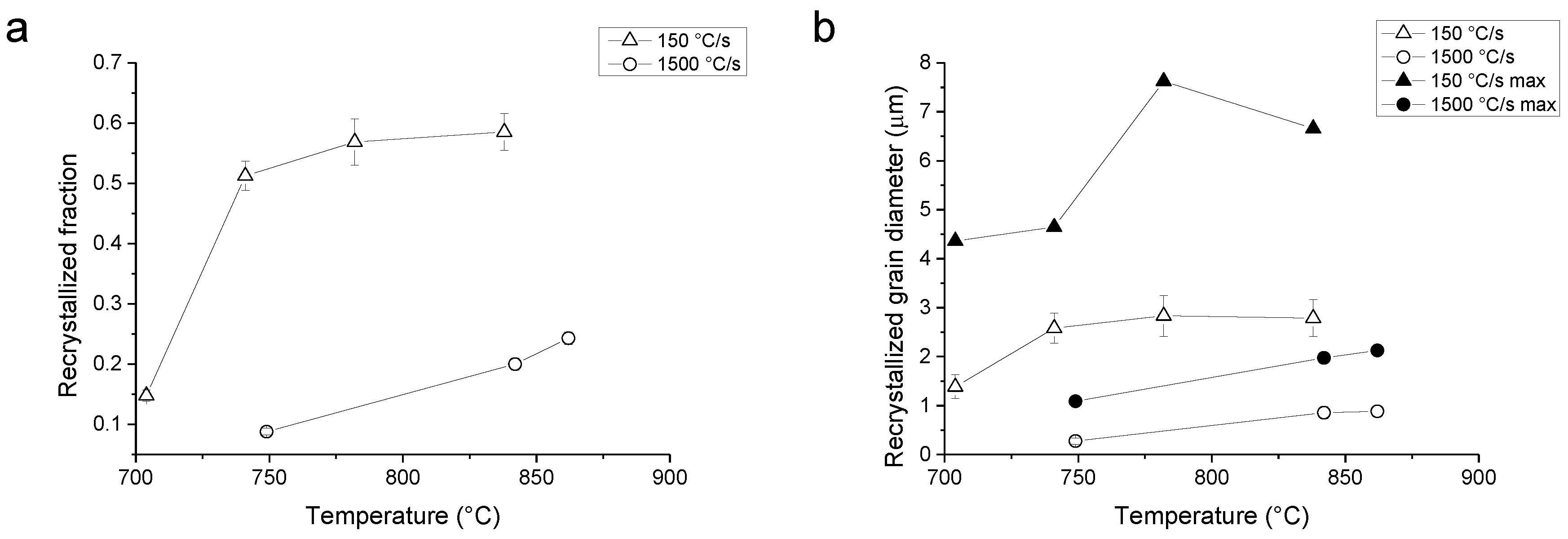

3.2. Anisothermal Recrystallization of Ferrite

3.3. Textures

4. Discussion

Recrystallization of Ferrite

Textures in Recrystallized Ferrite

5. Conclusions

- The recrystallization was not 100% complete before the complete formation of austenite for both heating rates.

- The shear band nucleation of ferrite took place at higher temperatures in samples heated at 1500 °C/s, compared to samples heated at 150 °C/s. The effect of heating rate in carbon diffusion can justify the observed nucleation of recrystallized ferritic grains and thus the appearance of recrystallized grains in the vicinity of the rotated Goss {110}<110> component.

- The continuous nucleation of recrystallized ferrite is enhanced by applying ultrafast heating rates.

- The texture of ferrite in early stages of recrystallization in samples heated at 1500 °C/s is taking place close to ND {111}<uvw> fiber components as well as in the vicinity of {110}<110> high stored energy components. When the time for the release of stored energy is comparatively longer (as in the case of samples heated at 150 °C/s), the orientations in recrystallized ferrite are mainly close to ND {111}<uvw> and RD {hkl}<011> fiber components.

- Cementite plates and spheres might act as a barrier for the advance of the α/α interface during recrystallization.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lolla, T.; Cola, G.; Narayanan, B.; Alexandrov, B.; Babu, S.S. Development of rapid heating and cooling (flash processing) process to produce advanced high strength steel microstructures. Mater. Sci. Technol. 2011, 27, 863–875. [Google Scholar] [CrossRef]

- Meng, Q.; Li, J.; Zheng, H. High-efficiency fast-heating annealing of a cold-rolled dual-phase steel. Mater. Des. 2014, 58, 194–197. [Google Scholar] [CrossRef]

- De Knijf, D.; Puype, A.; Föjer, C.; Petrov, R. The influence of ultra-fast annealing prior to quenching and partitioning on the microstructure and mechanical properties. Mater. Sci. Eng. A 2015, 627, 182–190. [Google Scholar] [CrossRef]

- Puype, A. Developing of Advanced High Strength Steel via Ultrafast Annealing. Master’s Thesis, Ghent University, Gent, Belgium, July 2013. [Google Scholar]

- Kestens, L.; Reis, A.C.C.; Kaluba, W.J.; Houbaert, Y. Grain Refinement and Texture Change in Interstitial Free Steels after Severe Rolling and Ultra-Short Annealing. Mater. Sci. Forum 2004, 467–470, 287–292. [Google Scholar] [CrossRef]

- Petrov, R.; Sidor, J.; Kaluba, W.J.; Kestens, L. Grain Refinement of a Cold Rolled TRIP Assisted Steel after Ultra Short Annealing. Mater. Sci. Forum 2012, 715–716, 661–666. [Google Scholar] [CrossRef]

- Petrov, R.H.; Puype, A.; De Knijf, D.; Kestens, L. Ultrafast Heating of Advanced High Strength Steels. In Proceedings of the International Conference on Solid-Solid Phase Transformations in Inorganic Materials 2015, Whistler, BC, Canada, 2015; pp. 1157–1158.

- Castro Cerda, F.M.; Goulas, C.; Sabirov, I.; Papaefthymiou, S.; Monsalve, A.; Petrov, R.H. Microstructure, texture and mechanical properties in a low carbon steel after ultrafast heating. Mater. Sci. Eng. A 2016, 672, 108–120. [Google Scholar] [CrossRef]

- Griffay, G.; Anderhuber, M.; Klinkenberg, P.; Tusset, V. New Continuous Annealing Technology with High-Speed Induction Heating Followed by Ultra-Fast Cooling; ECSC steel publications: Brussels, Belgium, 2002. [Google Scholar]

- Atkinson, M. Bifurcation of thermal restoration processes in deformed iron and steel. Mater. Sci. Eng. A 1999, 262, 33–38. [Google Scholar] [CrossRef]

- Ferry, M.; Muljono, D.; Dunne, D.P. Recrystallization Kinetics of Low and Ultra Low Carbon Steels during High-rate Annealing. ISIJ Int. 2001, 41, 1053–1060. [Google Scholar] [CrossRef]

- Muljono, D.; Ferry, M.; Dunne, D.P. Influence of heating rate on anisothermal recrystallization in low and ultra-low carbon steels. Mater. Sci. Eng. A 2001, 303, 90–99. [Google Scholar] [CrossRef]

- Atkinson, M. On the credibility of ultra rapid annealing. Mater. Sci. Eng. A 2003, 354, 40–47. [Google Scholar] [CrossRef]

- Stockemer, J.; Brande, P. Vanden Recrystallization of a cold-rolled low-carbon steel by cold-plasma-discharge rapid annealing. Metall. Mater. Trans. A 2003, 34, 1341–1348. [Google Scholar] [CrossRef]

- Senuma, T.; Kawasaki, K.; Takemoto, Y. Recrystallization Behavior and Texture Formation of Rapidly Annealed Cold-Rolled Extralow Carbon Steel Sheets. Mater. Trans. 2006, 47, 1769–1775. [Google Scholar] [CrossRef]

- Yoshinaga, N.; Kestens, L.; De Cooman, B.C. α → γ → α Transformation Texture Formation at Cold-Rolled Ultra Low Carbon Steel Surfaces. Mater. Sci. Forum 2005, 495–497, 1267–1272. [Google Scholar] [CrossRef]

- Petrov, R.; Kestens, L.; Houbaert, Y. Recrystallization of a Cold Rolled Trip-assisted Steel during Reheating for Intercritical Annealling. ISIJ Int. 2001, 41, 883–890. [Google Scholar] [CrossRef]

- Petrov, R.; Kestens, L.; Kaluba, W.J.; Houbaert, Y. Recrystallization and austenite formation in a cold rolled TRIP steel during ultra fast heating. Steel Grips 2003, 1, 289–293. [Google Scholar]

- Ray, R.K.; Jonas, J.J.; Hook, R.E. Cold rolling and annealing textures in low carbon and extra low carbon steels. Int. Mater. Rev. 1994, 39, 129–172. [Google Scholar] [CrossRef]

- Ray, R.K.; Jonas, J.J. Transformation Textures in Steels. Int. Mater. Rev. 1990, 35, 1–36. [Google Scholar] [CrossRef]

- Petrov, R.H.; Kestens, L.A.I. Advanced High-Strength Steels: Electron Backscatter Diffraction (EBSD). In Encyclopedia of Iron, Steel, and Their Alloys; CRC Press: Boca Ratón, FL, USA, 2016; pp. 46–69. [Google Scholar]

- Pinard, P.T.; Schwedt, A.; Ramazani, A.; Prahl, U.; Richter, S. Characterization of Dual-Phase Steel Microstructure by Combined Submicrometer EBSD and EPMA Carbon Measurements. Microsc. Microanal. 2013, 19, 996–1006. [Google Scholar] [CrossRef] [PubMed]

- Cerda, F.M.C.; Vercruysse, F.; Minh, T.N.; Kestens, L.A.I.; Petrov, R.H. The Effect of Heating Rate on the Recrystallization Behavior in Cold Rolled Ultra Low Carbon Steel. Steel Res. Int. 2016. [Google Scholar] [CrossRef]

- Kang, J.Y.; Bacroix, B.; Réglé, H.; Oh, K.H.; Lee, H.C. Effect of deformation mode and grain orientation on misorientation development in a body-centered cubic steel. Acta Mater. 2007, 55, 4935–4946. [Google Scholar] [CrossRef]

- Hutchinson, W.B. Development and control of annealing textures in low-carbon steels. Int. Met. Rev. 1984, 29, 25–42. [Google Scholar] [CrossRef]

- Minh, T.N.; Sidor, J.J.; Petrov, R.H.; Kestens, L.A.I. Occurrence of shear bands in rotated Goss ({110}<110>) orientations of metals with bcc crystal structure. Scr. Mater. 2012, 67, 935–938. [Google Scholar] [CrossRef]

- Gobernado, P.; Petrov, R.H.; Kestens, L.A.I. Recrystallized {311}<136> orientation in ferrite steels. Scr. Mater. 2012, 66, 623–626. [Google Scholar] [CrossRef]

- Wang, X.; Zurob, H.S.; Xu, G.; Ye, Q.; Bouaziz, O.; Embury, D. Influence of Microstructural Length Scale on the Strength and Annealing Behavior of Pearlite, Bainite, and Martensite. Metall. Mater. Trans. A 2013, 44, 1454–1461. [Google Scholar] [CrossRef]

- Hono, K.; Ohnuma, M.; Murayama, M.; Nishida, S.; Yoshie, A.; Takahashi, T. Cementite decomposition in heavily drawn pearlite steel wire. Scr. Mater. 2001, 44, 977–983. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Oxford, UK, 2004. [Google Scholar]

- Smith, C.S. Grains, Phases, and Interfaces—An Interpretation of Microstructure. Trans. AIME 1948, 175, 15–51. [Google Scholar]

- Kang, J.Y.; Kim, D.I.; Lee, H.C. Texture development in low carbon sheet steels for automotive application. In Microstructure and Texture in Steels: And Other Materials; Springer: London, UK, 2009; pp. 85–101. [Google Scholar]

- Dillamore, I.L.; Morris, P.L.; Smith, C.J.E.; Hutchinson, W.B. Transition Bands and Recrystallization in Metals. Proc. R. Soc. Lond. Ser. A 1972, 329, 405–420. [Google Scholar] [CrossRef]

- Ushioda, K.; Hutchinson, W.B.; Ågren, J.; von Schlippenbach, U. Investigation of structure and texture development during annealing of low-carbon steel. Mater. Sci. Technol. 1986, 2, 807–815. [Google Scholar] [CrossRef]

| C | Mn | Si | S | P | Fe |

|---|---|---|---|---|---|

| 0.14 | 2.05 | 1.20 | 0.001 | 0.012 | Rest |

| Heating Rate, °C/s | Peak Temperature, °C | ||||

|---|---|---|---|---|---|

| 150 | 704 | 741 | 782 | 838 | 1000 |

| 1500 | 749 | 842 | 862 | 1000 | 1050 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castro Cerda, F.M.; Kestens, L.A.I.; Monsalve, A.; Petrov, R.H. The Effect of Ultrafast Heating in Cold-Rolled Low Carbon Steel: Recrystallization and Texture Evolution. Metals 2016, 6, 288. https://doi.org/10.3390/met6110288

Castro Cerda FM, Kestens LAI, Monsalve A, Petrov RH. The Effect of Ultrafast Heating in Cold-Rolled Low Carbon Steel: Recrystallization and Texture Evolution. Metals. 2016; 6(11):288. https://doi.org/10.3390/met6110288

Chicago/Turabian StyleCastro Cerda, Felipe M., Leo A. I. Kestens, Alberto Monsalve, and Roumen H. Petrov. 2016. "The Effect of Ultrafast Heating in Cold-Rolled Low Carbon Steel: Recrystallization and Texture Evolution" Metals 6, no. 11: 288. https://doi.org/10.3390/met6110288