Tensile Properties and Microstructures of a 2024-T351 Aluminum Alloy Subjected to Cryogenic Treatment

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Cryogenic Treatments and Microstructure Observations

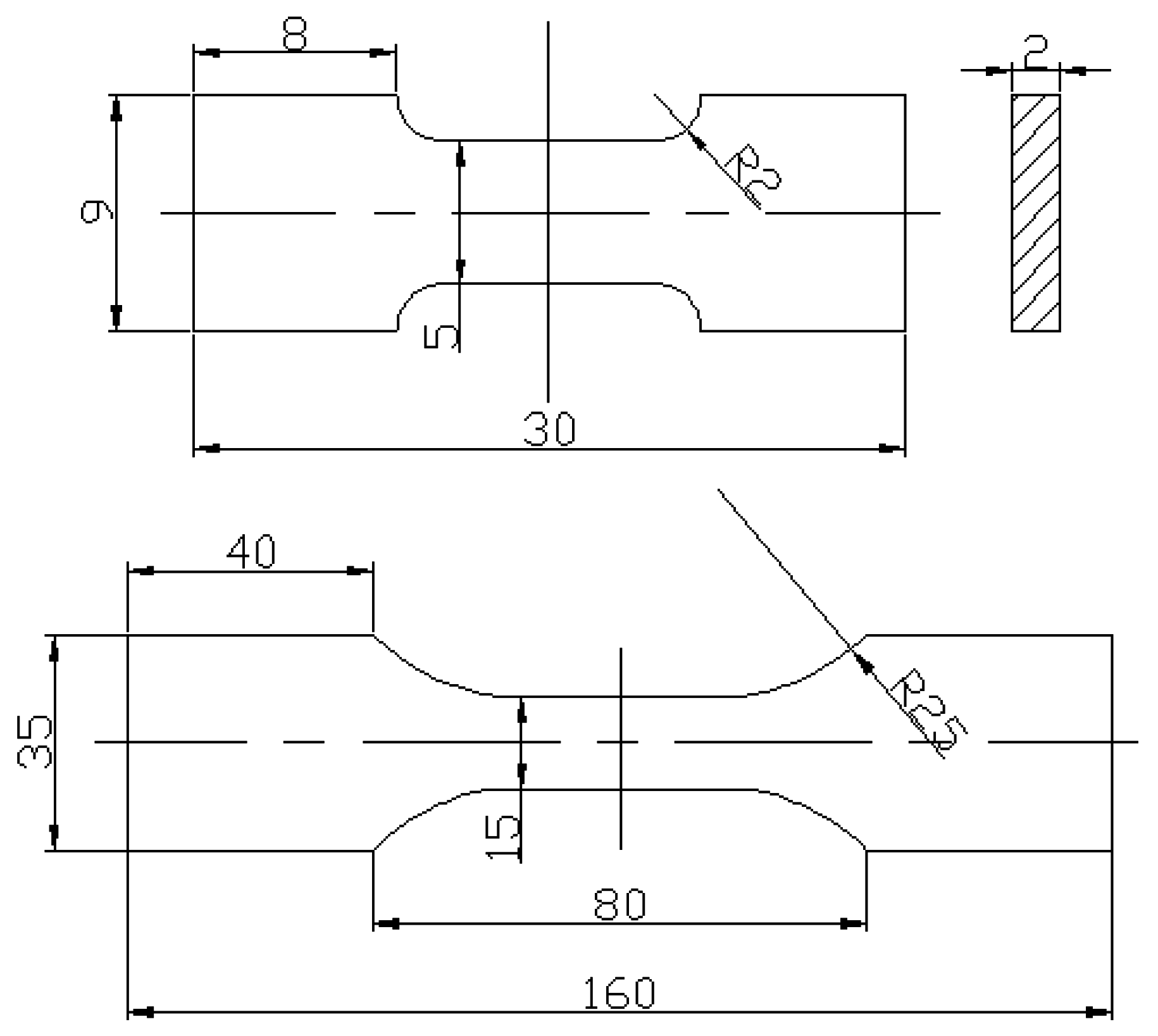

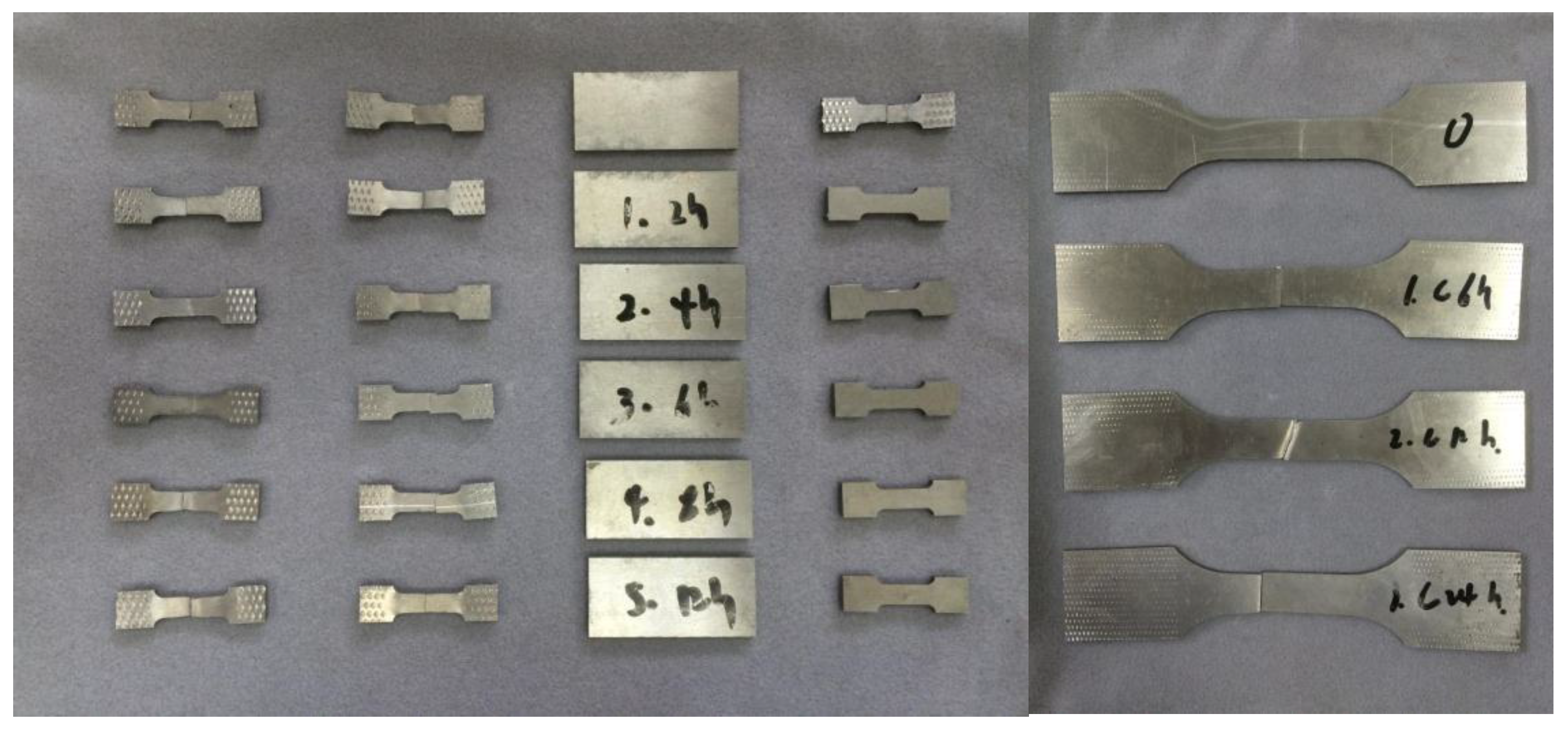

2.3. Tensile Tests and Fracture Observation

2.4. Measurements of Residual Stress

3. Results and Discussion

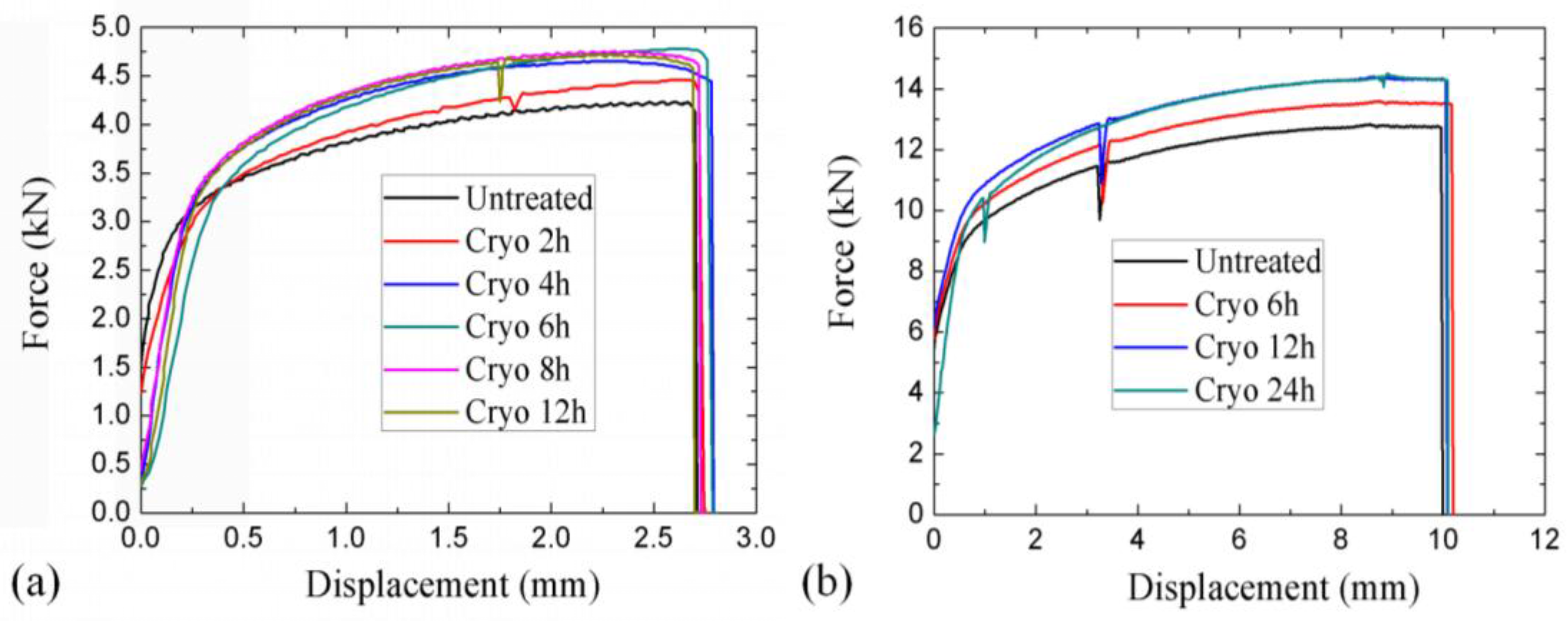

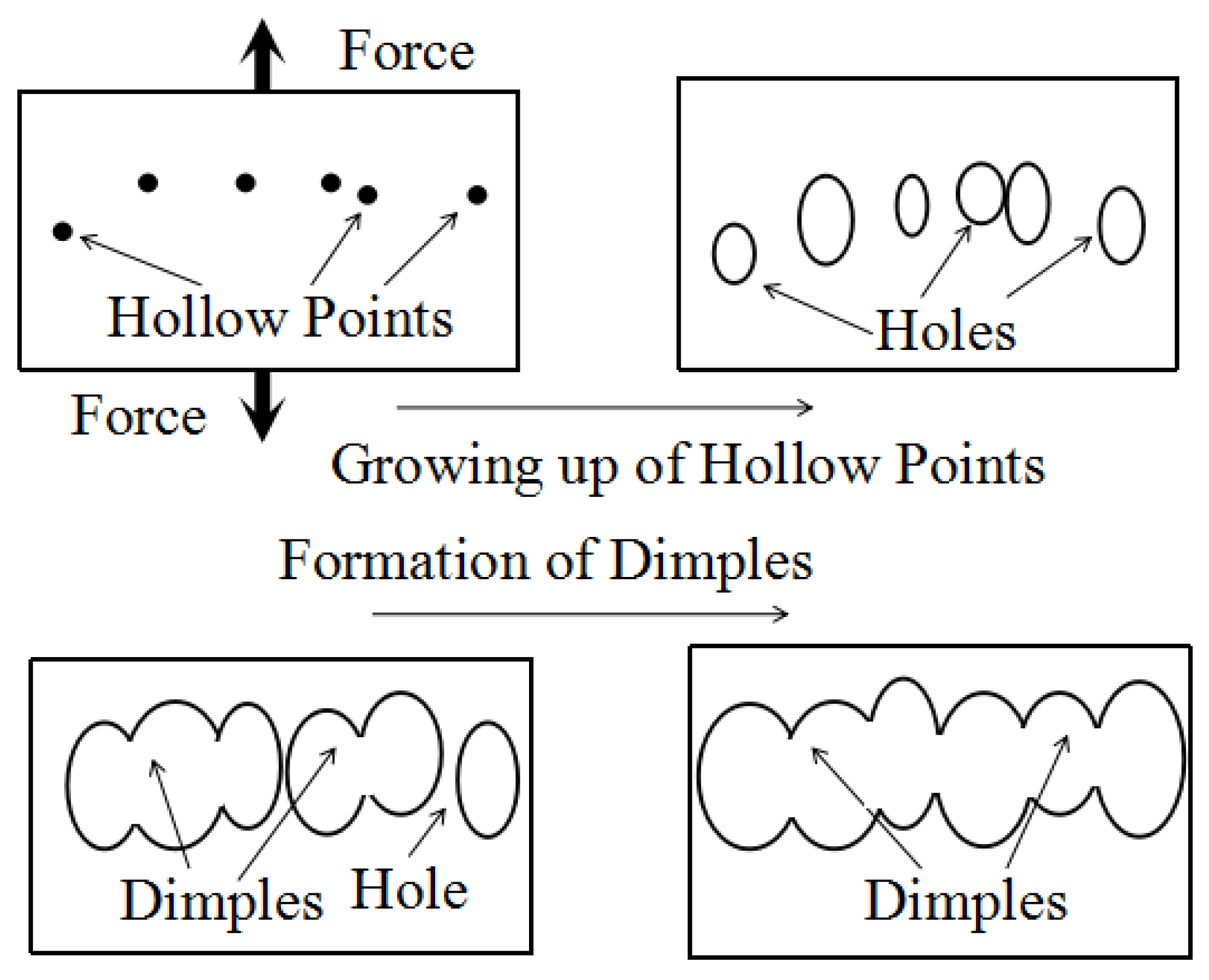

3.1. Tensile Tests and Fracture Analysis

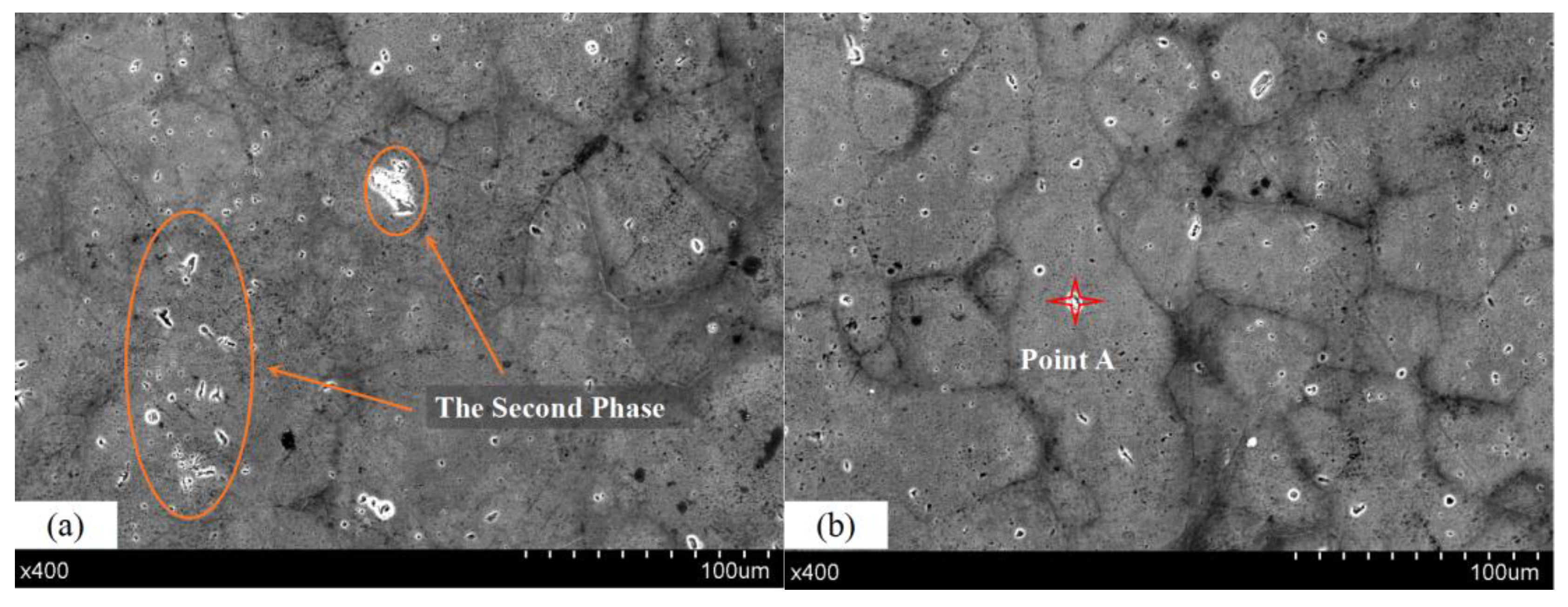

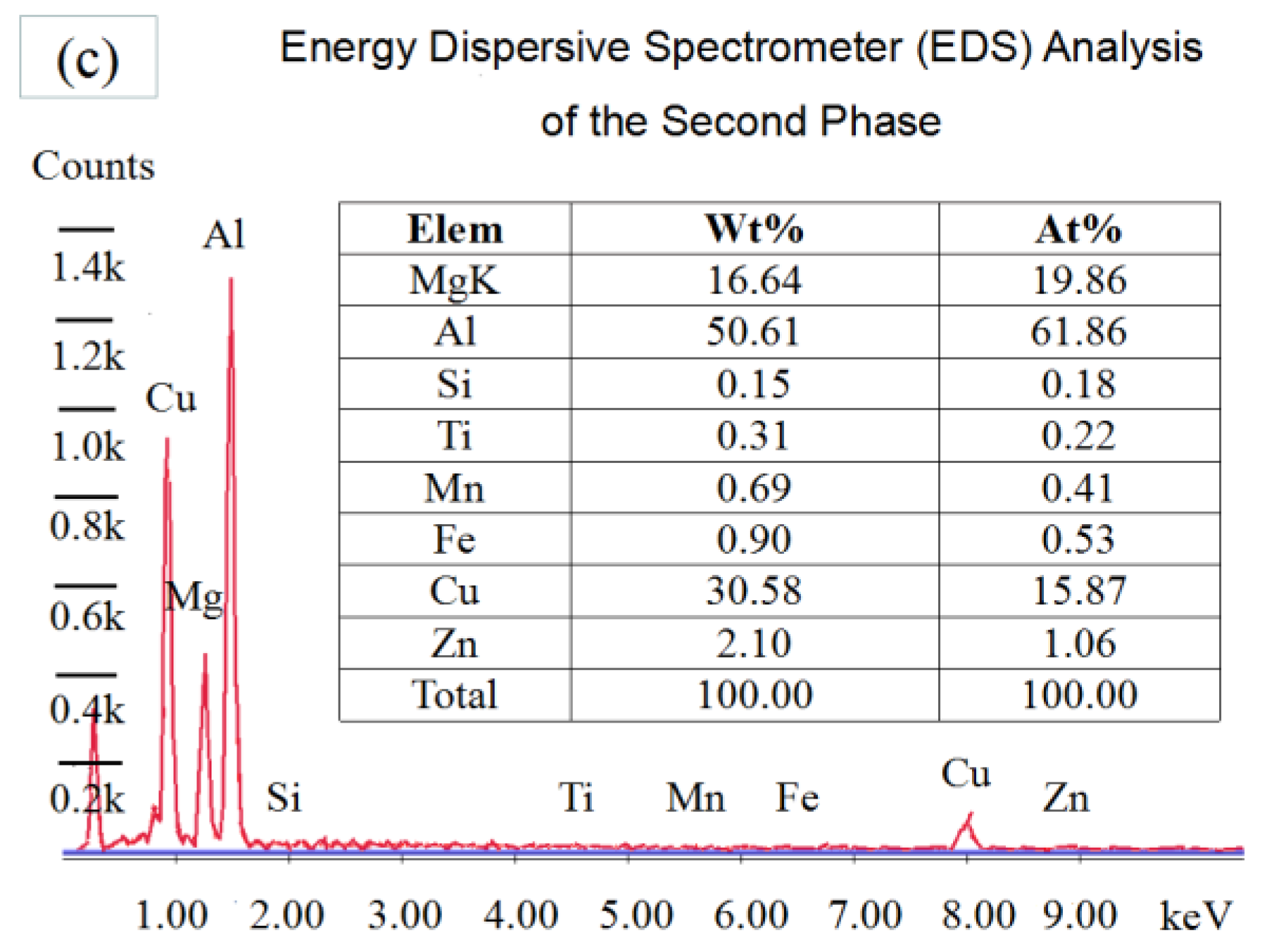

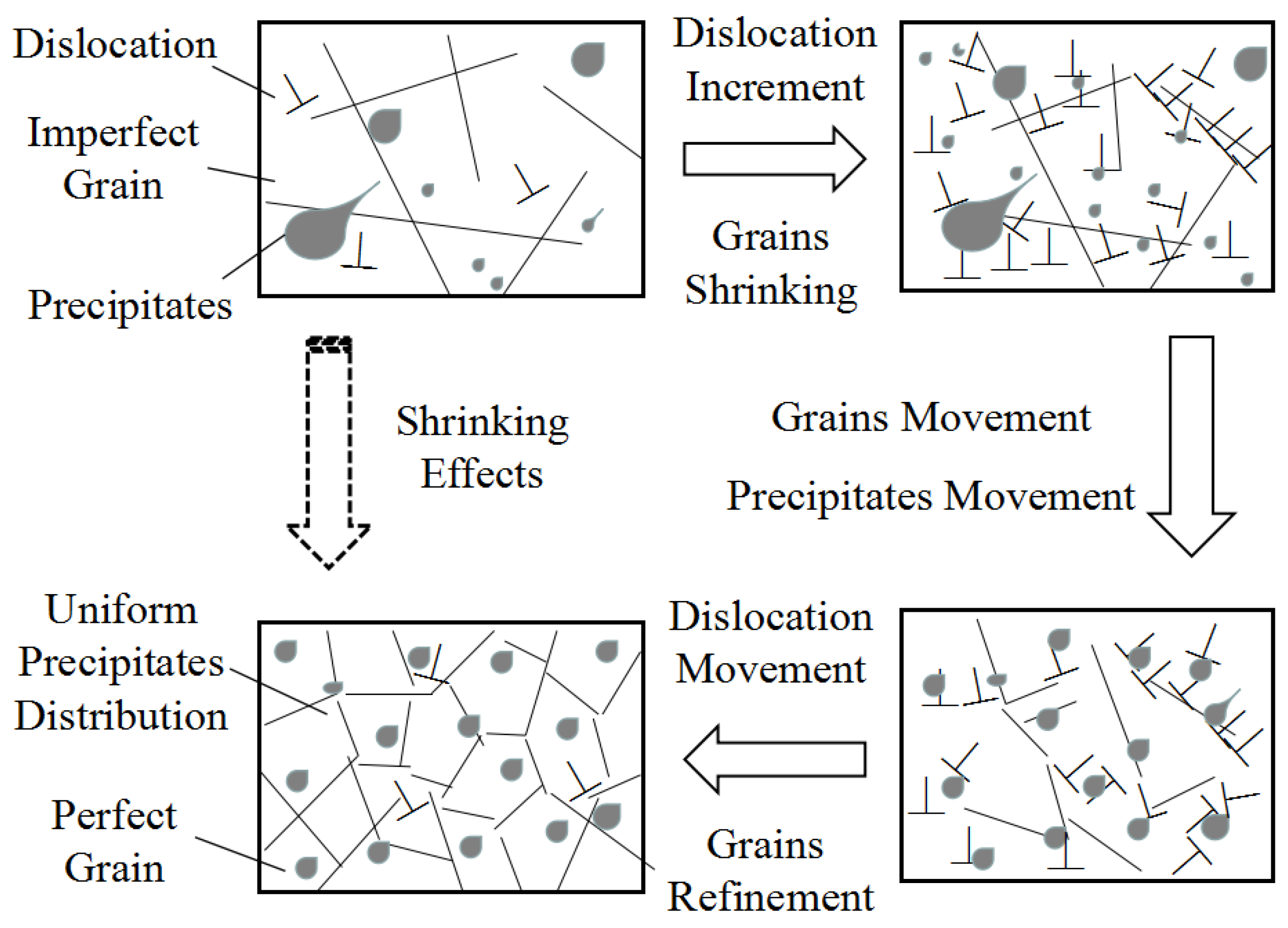

3.2. Microstructure before and after CT

3.3. Discussion of Residual Stress

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Cui, C.Y.; Sun, G.F.; Zhou, J.Z.; Zhang, L.; You, J.; Chen, K.M.; Zhong, J.W. Grain refinement of LY2 aluminum alloy induced by ultra-high plastic strain during multiple laser shock processing impacts. Acta Mater. 2010, 58, 3984–3994. [Google Scholar] [CrossRef]

- Zaroog, O.S.; Ali, A.; Sahari, B.B.; Zahari, R. Modeling of residual stress relaxation of fatigue in 2024-T351 aluminium alloy. Int. J. Fatigue 2011, 33, 279–285. [Google Scholar] [CrossRef]

- Rodopoulos, C.A.; Kermanidis, A.T.; Statnikov, E.; Vityazev, V.; Korolkov, O. The Effect of Surface Engineering Treatments on the Fatigue Behavior of 2024-T351 Aluminum Alloy. J. Mater. Eng. Perform. 2007, 16, 30–34. [Google Scholar] [CrossRef]

- Qin, J.; Chen, G.; Ji, X.; Song, X.; Hu, N.; Han, F. Effect of reaction temperature on the microstructures and mechanical properties of high-intensity ultrasonic assisted in-situ Al3Ti/2024 Al composites. J. Alloy. Compd. 2016, 666, 58–64. [Google Scholar] [CrossRef]

- Emamy, M.; Oliayee, M.; Tavighi, K. Microstructures and tensile properties of Al/2024–Al4Sr composite after hot extrusion and T6 heat treatment. Mater. Sci. Eng. A 2015, 625, 303–310. [Google Scholar] [CrossRef]

- Hong, T.; Shen, Y.; Geng, J.; Chen, D.; Li, X.; Zhou, C. Effect of cryogenic pre-treatment on aging behavior of in-situ TiB2/Al-Cu-Mg composites. Mater. Character. 2016, 119, 40–46. [Google Scholar] [CrossRef]

- Kalita, S.J. Microstructure and corrosion properties of diode laser melted friction stir weld of aluminum alloy 2024-T351. Appl. Surf. Sci. 2011, 257, 3985–3997. [Google Scholar] [CrossRef]

- Ali, A.; An, X.; Rodopoulos, C.A.; Brown, M.W.; O′Hara, P.; Levers, A.; Gardiner, S. The effect of controlled shot peening on the fatigue behaviour of 2024-T3 aluminium friction stir welds. Int. J. Fatigue 2007, 29, 1531–1545. [Google Scholar] [CrossRef]

- Novelli, M.; Fundenberger, J.J.; Bocher, P.; Grosdidier, T. On the effectiveness of surface severe plastic deformation by shot peening at cryogenic temperature. Appl. Surf. Sci. 2016, 389, 1169–1174. [Google Scholar] [CrossRef]

- Rodopoulos, C.A.; Romero, J.S.; Curtis, S.A.; Curtis, S.A.; de los Rios, E.R.; Peyre, P. Effect of controlled shot peening and laser shock peening on the fatigue performance of 2024-T351 aluminum alloy. J. Mater. Eng. Perform. 2003, 12, 414–419. [Google Scholar] [CrossRef]

- Huang, S.; Zhou, J.Z.; Sheng, J.; Luo, K.Y.; Lu, J.Z.; Xu, Z.C.; Meng, X.K.; Dai, L.; Zuo, L.D.; Ruan, H.Y.; et al. Effects of laser peening with different coverage areas on fatigue crack growth properties of 6061-T6 aluminum alloy. Int. J. Fatigue 2013, 47, 292–299. [Google Scholar] [CrossRef]

- Montross, C.S.; Wei, T.; Ye, L.; Clark, G.; Mai, Y.W. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 24, 1021–1036. [Google Scholar] [CrossRef]

- Correa, C.; Peral, D.; Porro, J.A.; Diaz, M.; Ruiz de Lara, L.; Garcia-Beltran, A.; Ocana, J.L. Random-type scanning patterns in laser shock peening without absorbing coating in 2024-T351 Al alloy: A solution to reduce residual stress anisotropy. Opt. Laser Technol. 2015, 73, 179–187. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Cheng, G.J. A review: Warm laser shock peening and related laser processing technique. Opt. Laser Technol. 2015, 78. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Gao, H.; Kim, B.J. Dislocation pinning effects induced by nano-precipitates during warm laser shock peening: Dislocation dynamic simulation and experiments. J. Appl. Phys. 2011, 110, 023518. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, J.; Sheng, J.; Meng, X.; Huang, S.; Xie, X. Effects of Warm Laser Peening on Thermal Stability and High Temperature Mechanical Properties of A356 Alloy. Metals 2016, 6, 126. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Lin, D.; Liao, Y.; Fei, X.; Cheng, G.J. Microstructure and mechanical properties of copper subjected to cryogenic laser shock peening. J. Appl. Phys. 2011, 110, 083504. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Lin, D.; Liao, Y. Cryogenic ultrahigh strain rate deformation induced hybrid nanotwinned microstructure for high strength and high ductility. J. Appl. Phys. 2014, 115, 213519. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Lin, D.; Cheng, G.J. Deformation-induced martensite and nanotwins by cryogenic laser shock peening of AISI 304 stainless steel and the effects on mechanical properties. Philos. Mag. 2011, 92, 1–21. [Google Scholar] [CrossRef]

- Singh, A.K.; Ghosh, S.; Mula, S. Simultaneous improvement of strength, ductility and corrosion resistance of Al2024 alloy processed by cryoforging followed by ageing. Mater. Sci. Eng. A 2015, 651, 774–785. [Google Scholar] [CrossRef]

| Elements | Cu | Mg | Si | Fe | Mn | Al | Other |

|---|---|---|---|---|---|---|---|

| Composition | 4.5 | 1.6 | 0.5 | 0.5 | 0.7 | Bal. | 0.5 |

| Mechanical Properties | Value |

|---|---|

| Tensile Strength (MPa) | 421 |

| Yield Strength (MPa) | 307 |

| Elongation (d, %) | 19.6 |

| Elasticity Modulus (GPa) | 72.4 |

| Poisson Ratio | 0.33 |

| Specimen Number | Treatments | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 1-0 | Untreated | 421.8 | 307 | 19.6 |

| 1-1 | Cryogenic for 2 h | 446.5 | 312 | 19.7 |

| 1-2 | Cryogenic for 4 h | 467.6 | 335 | 19.9 |

| 1-3 | Cryogenic for 6 h | 478.2 | 339 | 19.7 |

| 1-4 | Cryogenic for 8 h | 475.3 | 336 | 19.8 |

| 1-5 | Cryogenic for 12 h | 472.9 | 335 | 19.7 |

| 2-0 | Untreated | 427.6 | 311 | 17.6 |

| 2-1 | Cryogenic for 6 h | 453.9 | 326 | 17.5 |

| 2-2 | Cryogenic for 12 h | 481.2 | 341 | 17.8 |

| 2-3 | Cryogenic for 24 h | 480.6 | 343 | 17.6 |

| Time of CT (h) | Value of RS (MPa) | Error (MPa) |

|---|---|---|

| 0 | 26 | ±8 |

| 2 | −9 | ±3 |

| 4 | −13 | ±5 |

| 6 | −8 | ±5 |

| 8 | −11 | ±6 |

| 12 | −13 | ±9 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Xu, S.; Huang, S.; Meng, X.; Sheng, J.; Zhang, H.; Li, J.; Sun, Y.; Boateng, E.A. Tensile Properties and Microstructures of a 2024-T351 Aluminum Alloy Subjected to Cryogenic Treatment. Metals 2016, 6, 279. https://doi.org/10.3390/met6110279

Zhou J, Xu S, Huang S, Meng X, Sheng J, Zhang H, Li J, Sun Y, Boateng EA. Tensile Properties and Microstructures of a 2024-T351 Aluminum Alloy Subjected to Cryogenic Treatment. Metals. 2016; 6(11):279. https://doi.org/10.3390/met6110279

Chicago/Turabian StyleZhou, Jianzhong, Suqiang Xu, Shu Huang, Xiankai Meng, Jie Sheng, Haifeng Zhang, Jing Li, Yunhui Sun, and Emmanuel Agyenim Boateng. 2016. "Tensile Properties and Microstructures of a 2024-T351 Aluminum Alloy Subjected to Cryogenic Treatment" Metals 6, no. 11: 279. https://doi.org/10.3390/met6110279