Aluminium Foam and Magnesium Compound Casting Produced by High-Pressure Die Casting

Abstract

:1. Introduction

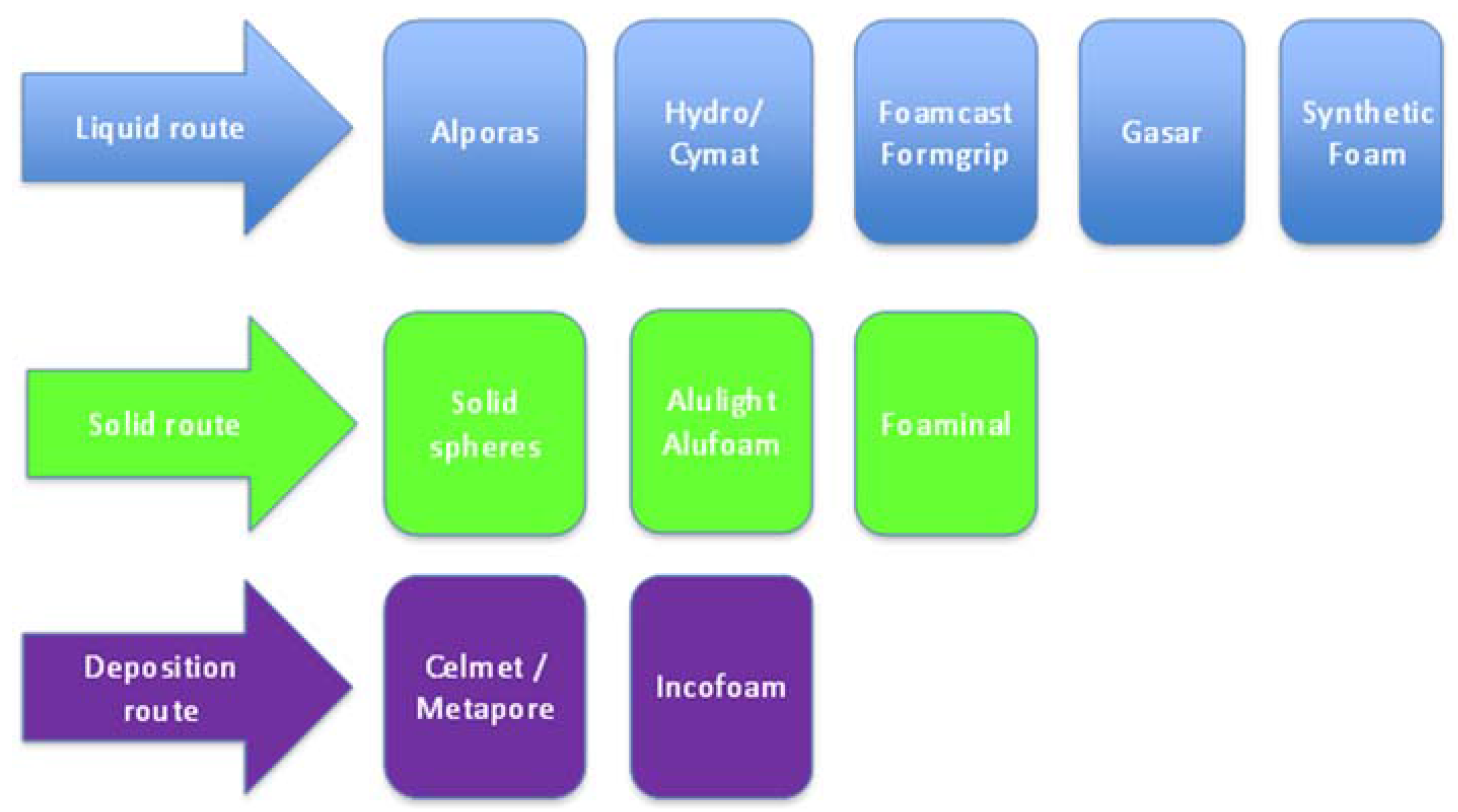

| Production Route | Advantages | Disadvantages |

|---|---|---|

| Liquid |

|

|

| Solid |

|

|

| Deposition |

|

|

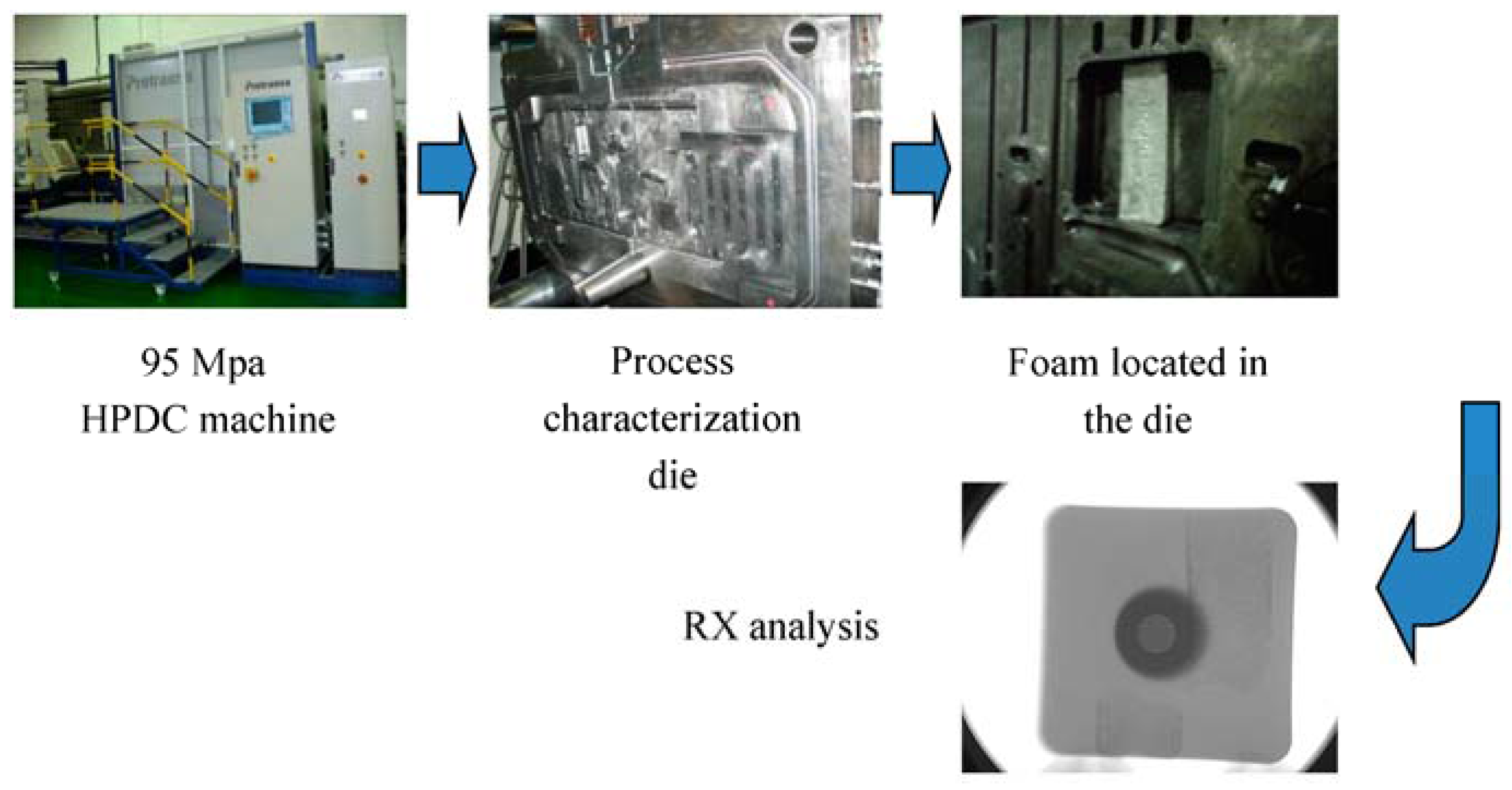

2. Experimental Section

| Properties/Requirements | Result |

|---|---|

| Weight reduction | 35% |

| External appearance | Without external defects |

| Porosity | Low |

| Material | Al | Mn | Zn | Si | Fe | Cu | Ni | Be | Mg |

|---|---|---|---|---|---|---|---|---|---|

| AM60B | 6.06 | 0.305 | 0.012 | 0.0085 | <0.0012 | 0.0011 | 0.001 | 10 ppm | Bal |

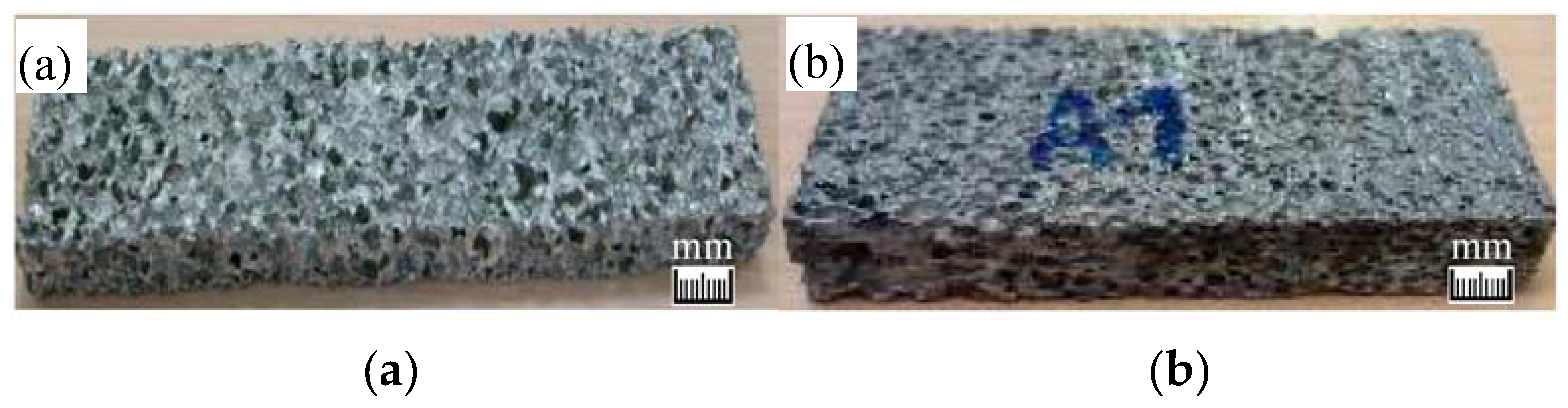

3. Results

3.1. Determination of Metal Casting Temperature

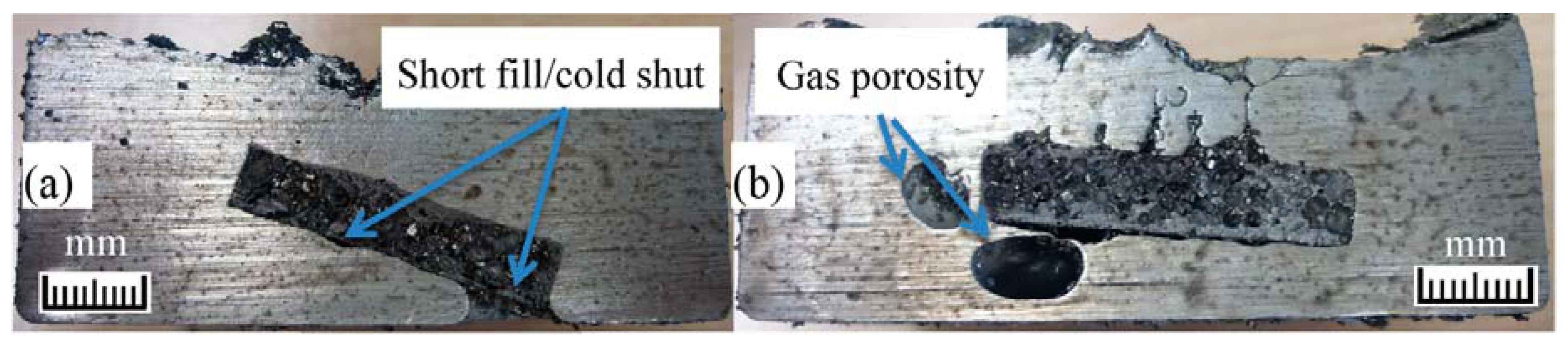

3.2. Determination of Injection Pressure

| Process | Density (Kg/dm3) | Integrity at 16 MPa | Integrity at 40 MPa |

|---|---|---|---|

| Alporas | 0.25–0.4 | NO | NO |

| Formgrip | 0.4–0.55 | NO | NO |

| Alulight | 0.54–1.55 | YES | YES |

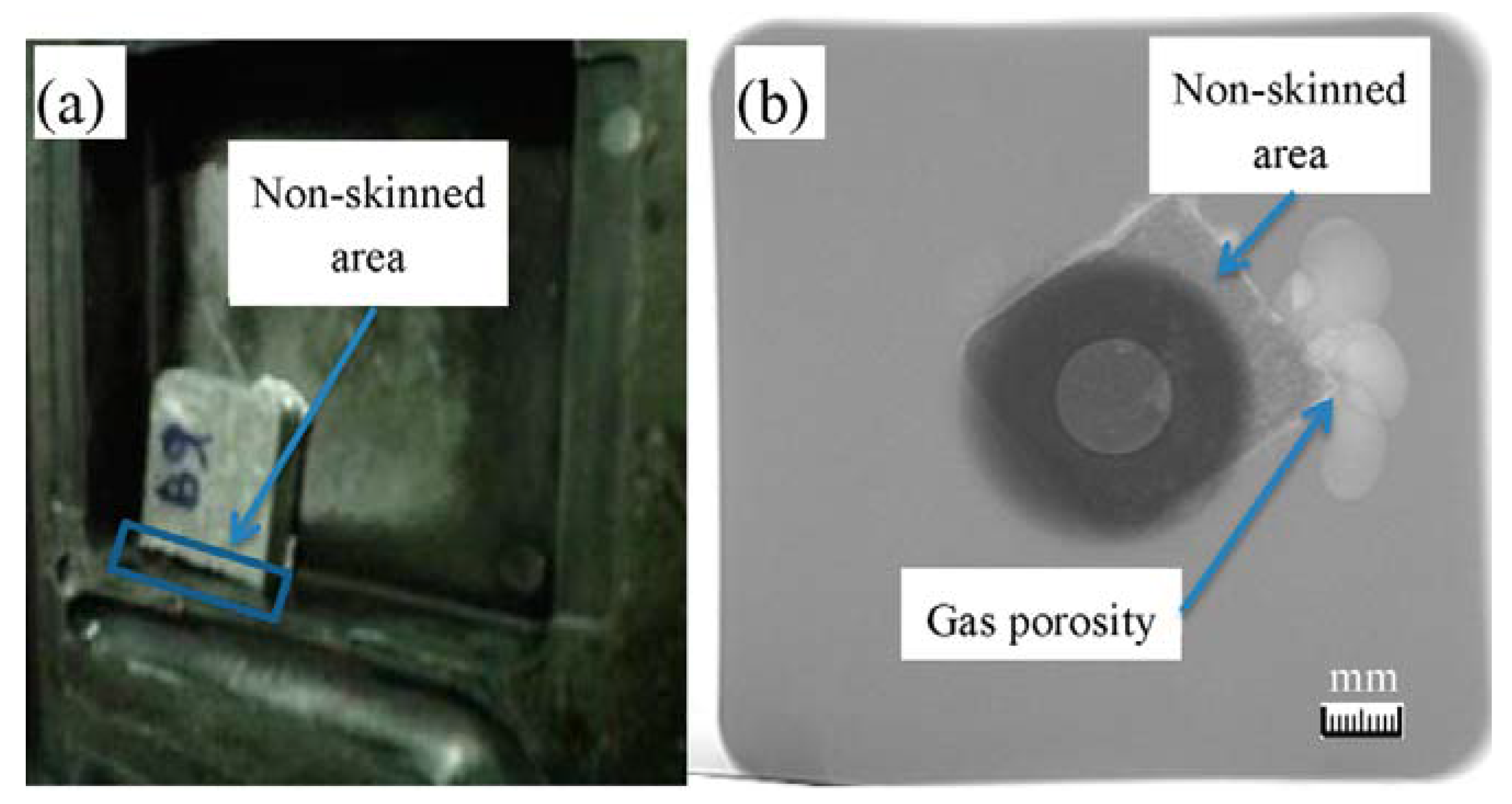

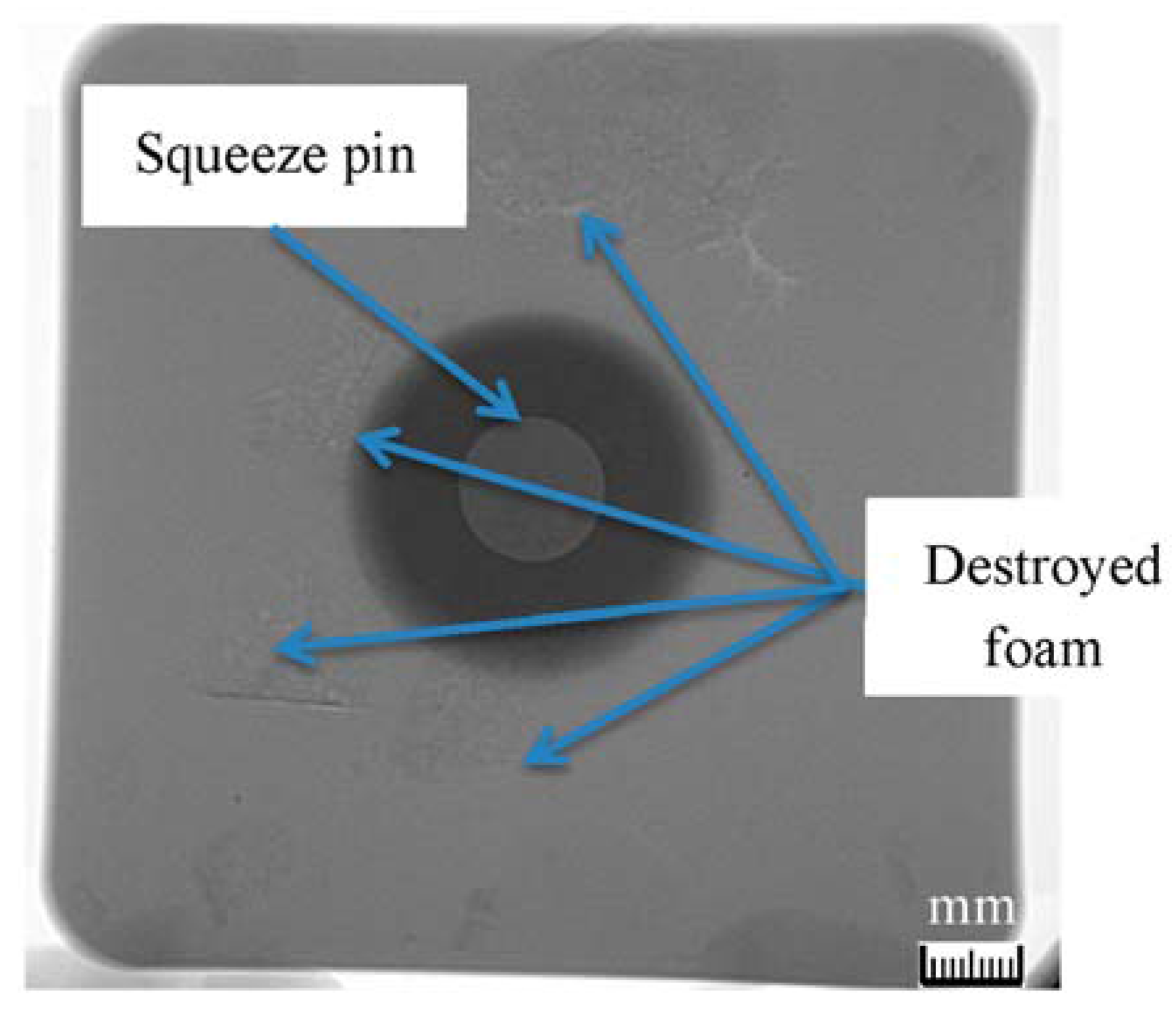

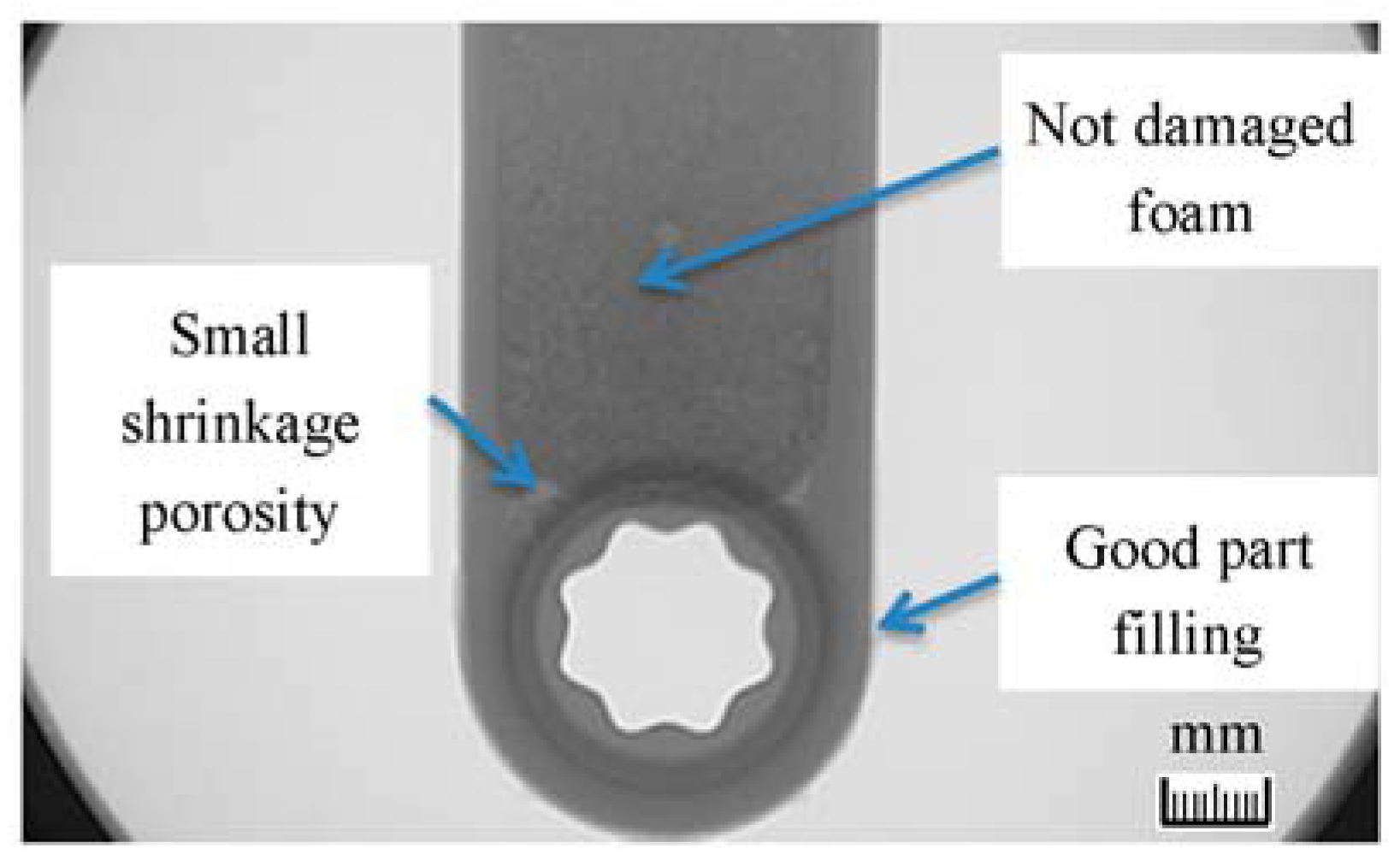

3.3. Determination of Squeeze Pin Suitability for Composite Cast Parts

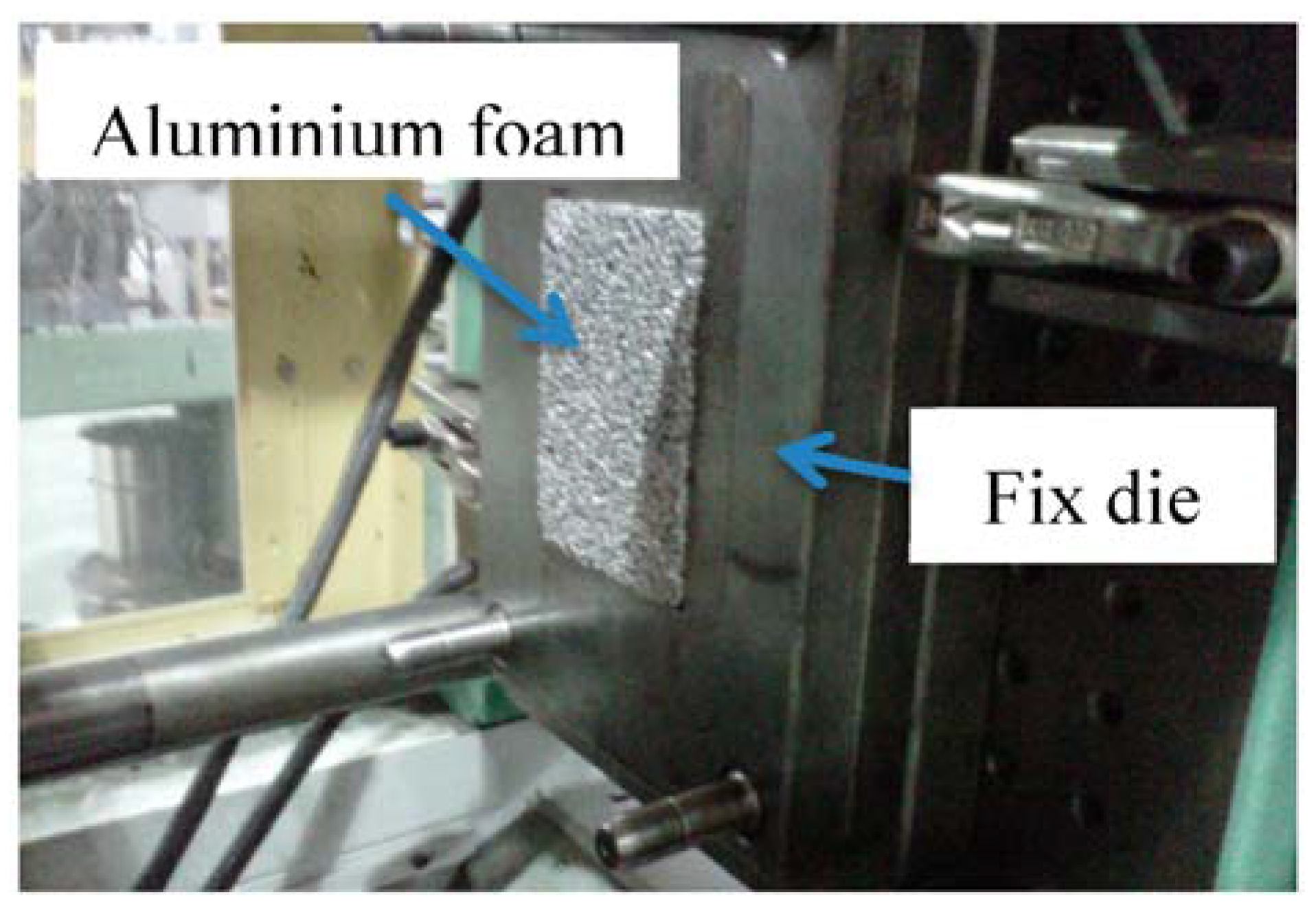

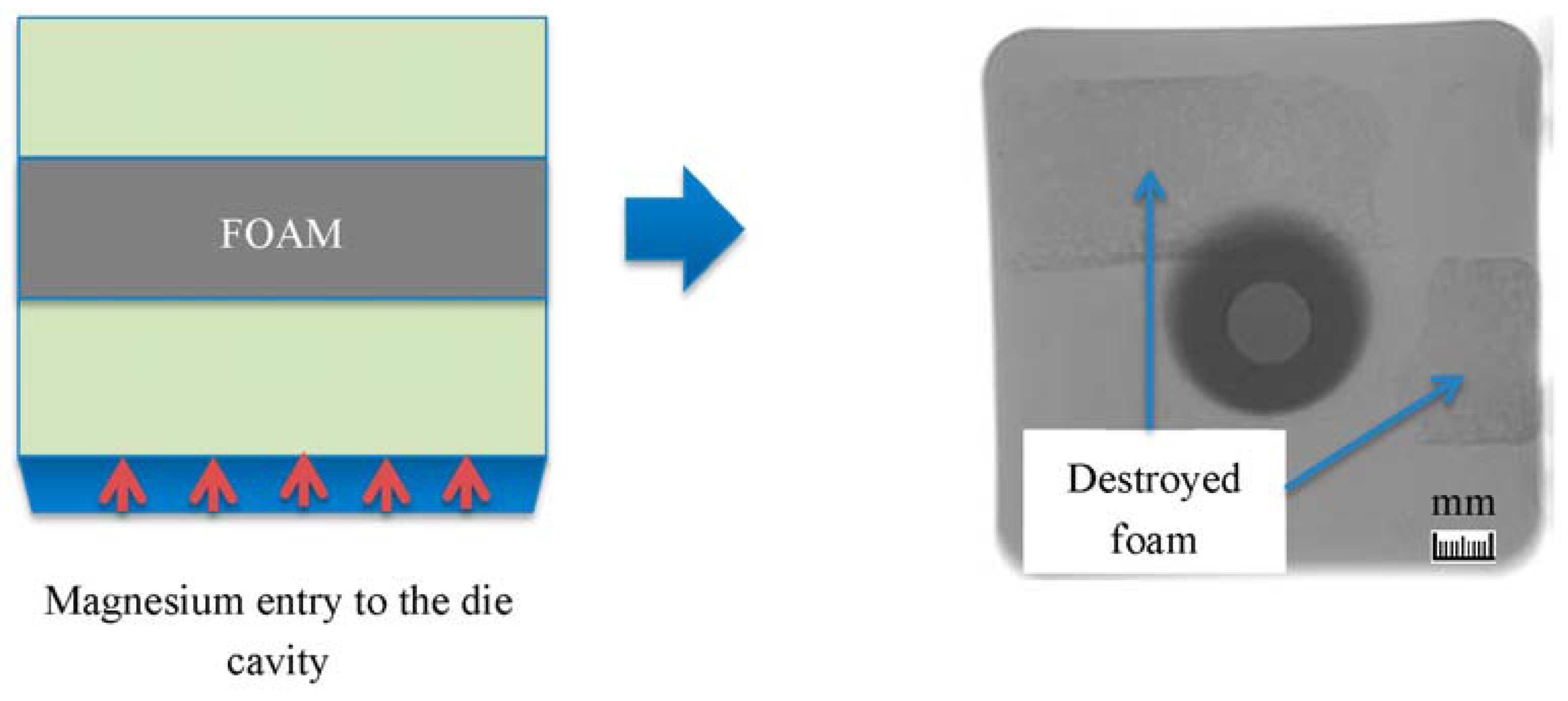

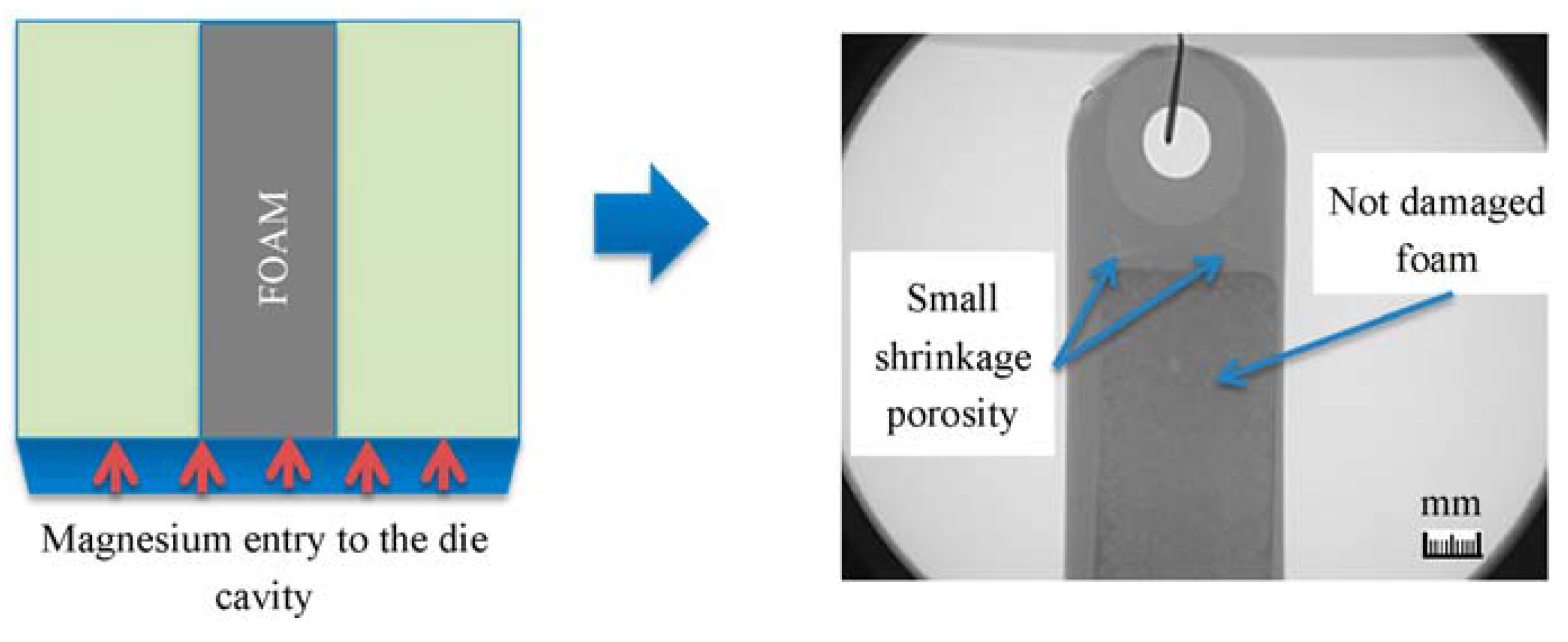

3.4. Determination of Core Placement

3.5. Determination of Injection Speed

3.6. Determination of Mechanical Properties

| Sample | YS (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|

| AM60B | 141 ± 4.3 | 219 ± 3.6 | 3 ± 0.5 |

| Composite | 79 ± 1.75 | 122 ± 2.16 | 3 ± 0.5 |

| Extrapolation of composite properties (47% of area reduction) | 149 ± 3.3 | 230 ± 4.1 | 3 ± 0.5 |

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Schultz, R. Aluminium Association Auto and Light Truck Group 2009 Update on North American Light Vehicle Aluminium Content Compared to the other Countries and Regions of the World. Phase II; Ducker Worlwide LLC: Troy, MI, USA, 2008; pp. 8–19. [Google Scholar]

- Bonollo, F.; Urban, J.; Bonatto, B.; Botter, M. Gravity and low pressure die casting of aluminium alloys: A technical and economical benchmark. Metall. Ital. 2005, 97, 23–32. [Google Scholar]

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloys 2013, 1, 2–22. [Google Scholar] [CrossRef]

- Gertsberg, G.; Nagar, N.; Lautzker, M.; Bronfin, B. Effect of HPDC parameters on the performance of creep resistant alloys MRI153M and MRI230D. SAE Tech. Pap. 2005, 1, 1–7. [Google Scholar]

- Otarawanna, S.; Laukli, H.I.; Gourlay, C.M.; Dahle, A.K. Feeding mechanisms in high-pressure die castings. Metall. Mater. Trans. A 2010, 41, 1836–1846. [Google Scholar] [CrossRef]

- Bonollo, F.; Gramegna, N.; Timelli, G. High-pressure die-casting: Contradictions and challenges. JOM 2015, 67, 901–908. [Google Scholar] [CrossRef]

- Yim, C.D.; Shin, K.S. Semi-solid processing of magnesium alloys. Mater. Trans. 2003, 44, 558–561. [Google Scholar] [CrossRef]

- Sabau, A.S.; Dinwiddie, R.B. Characterization of spray lubricants for the high pressure die casting processes. J. Mater. Process. Technol. 2008, 195, 267–274. [Google Scholar] [CrossRef]

- Kimura, R.; Yoshida, M.; Sasaki, G.; Pan, J.; Fukunaga, H. Characterization of heat insulating and lubricating ability of powder lubricants for clean and high quality die casting. J. Mater. Process. Technol. 2002, 130–131, 289–293. [Google Scholar] [CrossRef]

- Puschmann, F.; Specht, E. Transient measurement of heat transfer in metal quenching with atomized sprays. Exp. Therm. Fluid Sci. 2004, 28, 607–615. [Google Scholar] [CrossRef]

- Rogers, K.J.; Savage, G. In-cavity pressure sensors-errors, robustness and some process insights. Die Cast Eng. 2000, 44, 76–80. [Google Scholar]

- Kong, L.X.; She, F.H.; Gao, W.M.; Nahavandi, S.; Hodgson, P.D. Integrated optimization system for high pressure die casting processes. J. Mater. Process. Technol. 2008, 201, 629–634. [Google Scholar] [CrossRef]

- Keber, K.; Bormann, D.; Möhwald, K.; Hollander, U.; Bach, W. Compound casting of aluminium and magnesium alloys by High Pressure Die Casting. In Proceedings of the Magnesium 8th International Conference on Magnesium Alloys and Their Applications, Weimar, Germany, 26–29 October 2009; pp. 390–397.

- Kunst, M.; Fischersworring-bunk, A.; Liebscher, C.; Glatzel, U.; Esperance, G.L.; Plamondon, P.; Baril, E.; Labelle, P. Microstructural characterization of Die Cast Mg-Al-Sr (AJ) Alloy. In Proceedings of the Magnesium: Proceedings of the 7th International Conference on Magnesium Alloys and Their Applications, Dresden, Germany, 6–9 November 2006; pp. 498–505.

- Vicario, I. Study of high pressure die cast AZ91D magnesium alloy with surface treated aluminium 6063 cores for Al-Mg multi-material. In Proceedings of the 2nd Annual World Congress of Advanced Materials, Suzhou, China, 5–7 June 2013; pp. 7–21.

- Yaokawa, J.; Miura, D.; Anzai1, K.; Yamada, Y.; Yoshii, H. Strength of salt core composed of alkali carbonate and alkali chloride mixtures made by casting technique. Mater. Trans. 2007, 5, 1034–1041. [Google Scholar] [CrossRef]

- Moschini, R. Production of Hollow Components in HPDC through the Use of Ceramic Lost Cores; XXXI Congreso Tecnico di Fonderia: Vincenza, Italy, 2012; pp. 1–33. [Google Scholar]

- Yamada, Y.; Yaokawa, J.; Yoshii, H.; Anzai, K.; Noda, Y.; Fujiwara, A.; Suzuki, T.; Fukui, H. Developments and application of expendable salt core materials for high pressure die casting to apply closed-deck type cylinder block. SAE Int. 2007, 32-0084, 1–5. [Google Scholar]

- Vicario, I.; Egizabal, P.; Galarraga, H.; Plaza, L.M.; Crespo, I. Study of an Al-Si-Cu HPDC alloy with high Zn content for the production of components requiring high ductility and tensile properties. Int. J. Mater. Res. 2013, 4, 392–397. [Google Scholar] [CrossRef]

- Benedick, C. Production and application of aluminium foam, past product potential revisited in the new millennium. Light Met. Age 2002, 60, 24–29. [Google Scholar]

- Bausmesiter, J.; Weise, J. Structural Materials and Processes in Transportation, Metal Foams; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 415–440. [Google Scholar]

- Banhar, J. Metal foams: Production and stability. Adv. Eng. Mater. 2006, 9, 781–794. [Google Scholar] [CrossRef]

- Coleto, J.; Goñi, J.; Maudes, J.; Leizaola, I. Applications and manufacture of open and closed cell metal foams by foundry routes. In Proceedings of International Congress Eurofond, La Rochelle, France, 2–4 June 2004; pp. 1–10.

- Körner, C.; Hirschmann, M.; Wiehler, H. Integral Foam Moulding of Light Metals. Mater. Trans. 2006, 47, 2188–2194. [Google Scholar] [CrossRef]

- Baumeister, J.; Weise, J. Application of aluminium-polymer hybrid foam sandwiches in battery housings for electric vehicles. Procedia Mater. Sci. 2014, 4, 301–330. [Google Scholar] [CrossRef]

- Vesenjak, M.; Borovinšek, M.; Fiedler, T.; Higa, Y.; Ren, Z. Structural characterisation of advanced pore morphology (APM) foam elements. Mater. Lett. 2013, 110, 201–203. [Google Scholar] [CrossRef]

- Miyoshi, T.; Itoh, M.; Akiyama, S.; Kitahara, A. Aluminium foam, “ALPORAS”: The production process, properties and application. In Materials Research Society Symposium Proceedings, Boston, MA, USA, 1–3 December 1998; 1998; pp. 133–137. [Google Scholar]

- Miyoshi, T.; Itoh, M.; Akiyama, S.; Kitahara, A. Alporas aluminum foam: Production process, properties, and applications. Adv. Eng. Mater. 2000, 2, 179–183. [Google Scholar] [CrossRef]

- Gegerly, V.; Clyne, T.W. The formgrip process: Foaming of reinforced metals by gas release in precursors. Adv. Eng. Mater. 2002, 2, 175–178. [Google Scholar]

- Gergely, V.; Curran, D.C.; Clyne, T.W. Advances in the melt route production of closed cell aluminium foams using gas-generating agents. In Proceedings of Global Symposium of Materials Processing and Manufacturing Processing & Properties of Lightweight Cellular Metals and Structures, Seattle, WA, USA, 17–21 February 2002; pp. 3–8.

- Baumeister, J. Production technology for aluminium foam/steel sandwiches. In Proceedings of the International Conference on Metal Foams and Porous Metal Structures, Bremen, Germany, 14–16 June 1999; pp. 113–118.

- Seeliger, H.W. Cellular Metals: Manufacture, properties, applications. In Proceedings of the MetFoam, Berlin, Germany, 23–25 June 2003; pp. 5–12.

- Kováãik, J.; Simančík, F.; Jerz, J.; Tobolka, P. Reinforced aluminium foams. In Proceedings of the International Conference on Advanced Metallic Materials, Smolenice, Slovakia, 5–7 November 2003; pp. 154–159.

- Braune, R.; Otto, A. Tailored blanks based on foamable aluminium sandwich material. In Proceedings of the International Conference on Metal Foams and Porous Metal Structures, Bremen, Germany, 14–16 June 1999; pp. 119–124.

- Gutiérrez-Vázquez, J.A.; Oñoro, J. Fabricación y comportamiento de espumas de aluminio con diferente densidad a partir de un precursor AlSi12. Rev. Metal. 2010, 46, 274–284. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vicario, I.; Crespo, I.; Plaza, L.M.; Caballero, P.; Idoiaga, I.K. Aluminium Foam and Magnesium Compound Casting Produced by High-Pressure Die Casting. Metals 2016, 6, 24. https://doi.org/10.3390/met6010024

Vicario I, Crespo I, Plaza LM, Caballero P, Idoiaga IK. Aluminium Foam and Magnesium Compound Casting Produced by High-Pressure Die Casting. Metals. 2016; 6(1):24. https://doi.org/10.3390/met6010024

Chicago/Turabian StyleVicario, Iban, Ignacio Crespo, Luis Maria Plaza, Patricia Caballero, and Ion Kepa Idoiaga. 2016. "Aluminium Foam and Magnesium Compound Casting Produced by High-Pressure Die Casting" Metals 6, no. 1: 24. https://doi.org/10.3390/met6010024

APA StyleVicario, I., Crespo, I., Plaza, L. M., Caballero, P., & Idoiaga, I. K. (2016). Aluminium Foam and Magnesium Compound Casting Produced by High-Pressure Die Casting. Metals, 6(1), 24. https://doi.org/10.3390/met6010024