Constitutive Relationship Modeling and Characterization of Flow Behavior under Hot Working for Fe–Cr–Ni–W–Cu–Co Super-Austenitic Stainless Steel

Abstract

:1. Introduction

2. Experimental Material and Methods

3. Results and Discussion

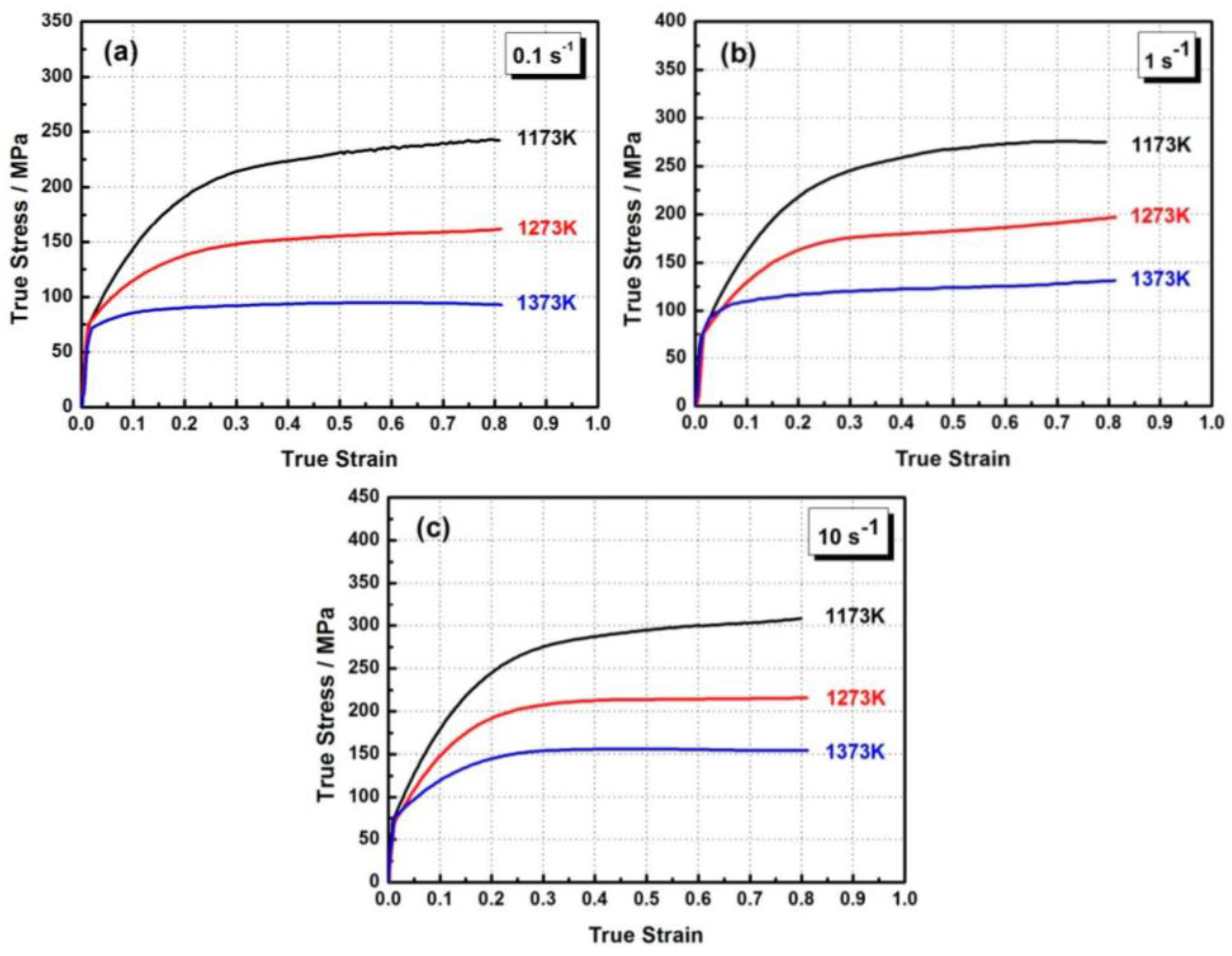

3.1. Flow Behavior

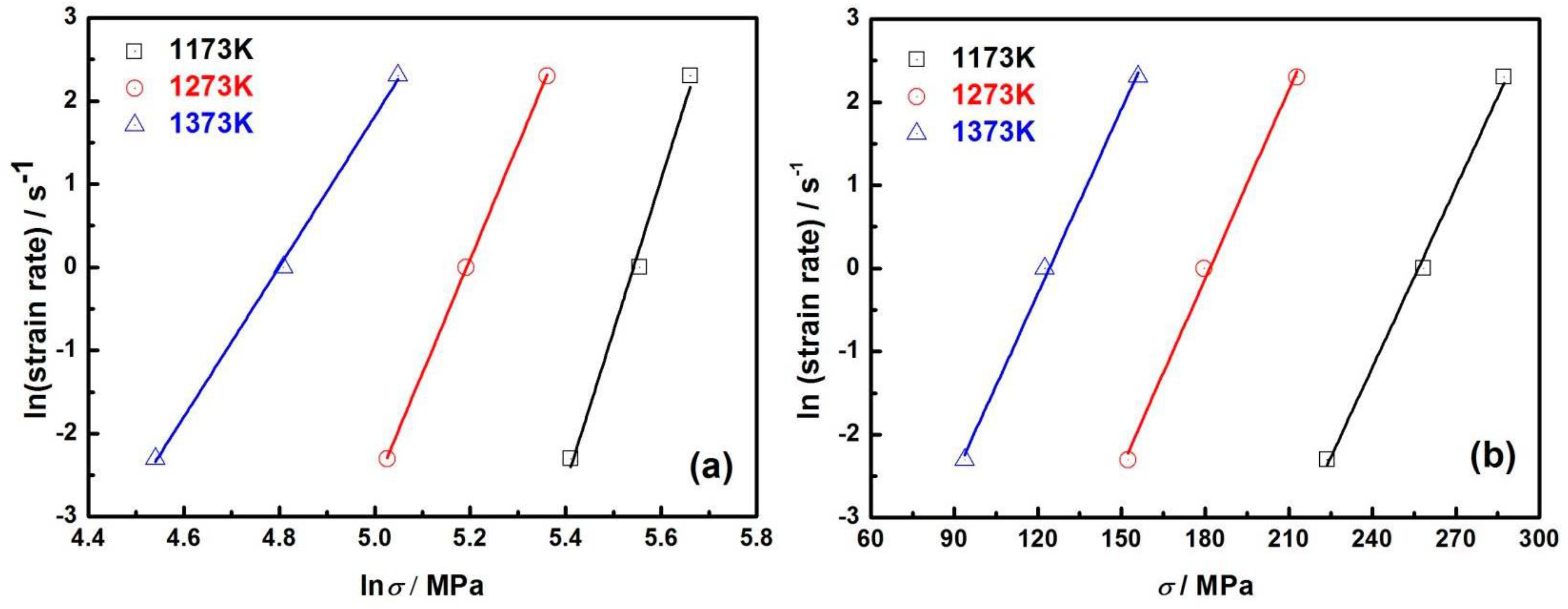

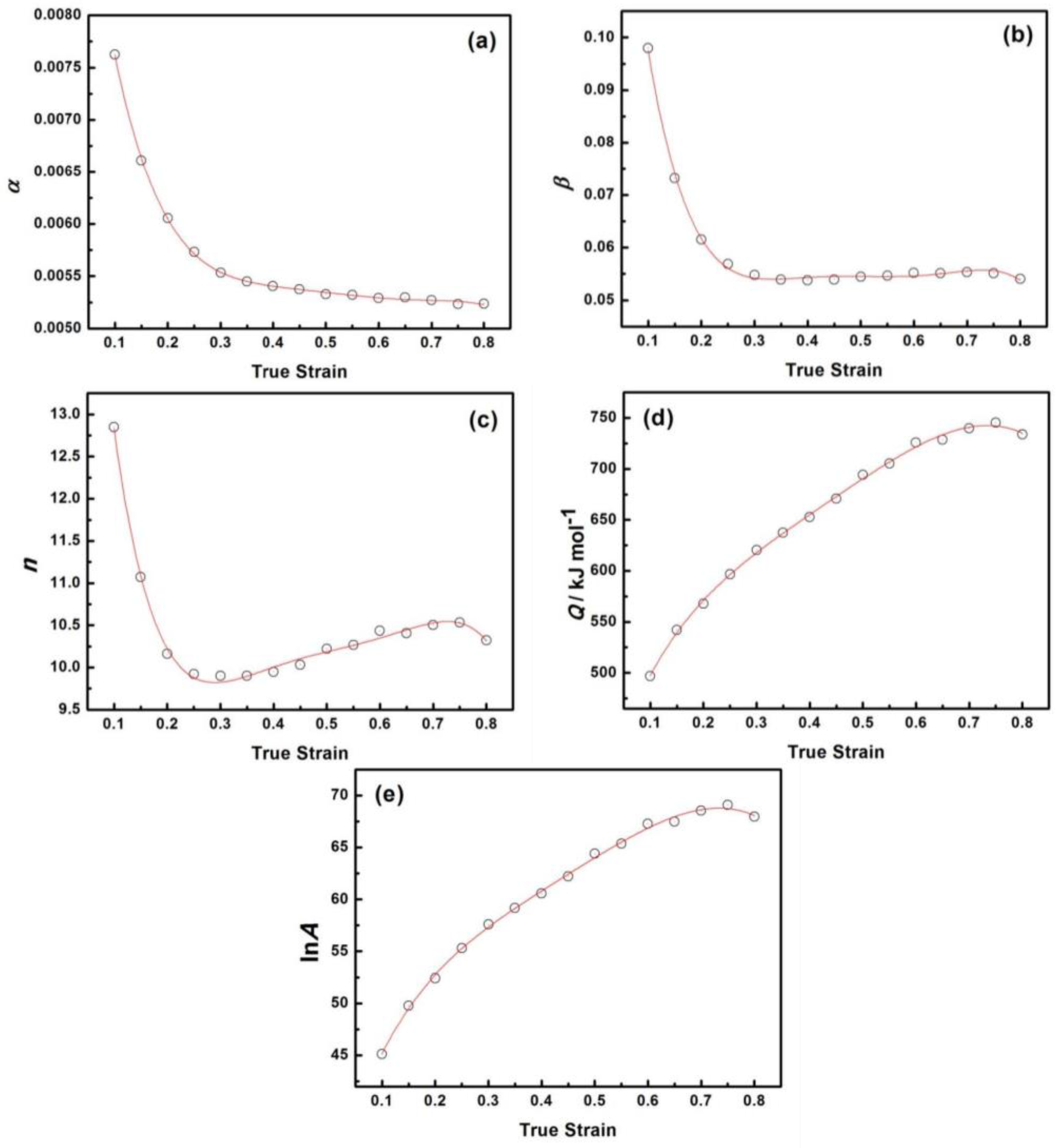

3.2. Constitutive Flow Curves Equations

| α (MPa−1) | β (MPa−1) | n1 | n | Q (kJ·mol−1) | |

|---|---|---|---|---|---|

| 0.005 | 0.074 | 13.692 | 10.066 | 652.73 | 2.124 × 1026 |

3.3. Verification of the Developed Constitutive Model with Strain Compensation

| α | Value | β | Value | n | Value | Q | Value | lnA | Value |

|---|---|---|---|---|---|---|---|---|---|

| B0 | 0.011 | C0 | 0.201 | D0 | 20.820 | E0 | 366.971 | F0 | 31.416 |

| B1 | −0.056 | C1 | −1.573 | D1 | −122.340 | E1 | 1727.233 | F1 | 183.033 |

| B2 | 0.205 | C2 | 6.529 | D2 | 520.308 | E2 | −5021.468 | F2 | −538.010 |

| B3 | −0.379 | C3 | −13.180 | D3 | −1063.531 | E3 | 8758.577 | F3 | 917.189 |

| B4 | 0.346 | C4 | 12.967 | D4 | 1062.198 | E4 | −6905.828 | F4 | −710.467 |

| B5 | −0.124 | C5 | −4.975 | D5 | −415.579 | E5 | 1661.322 | F5 | 170.838 |

| Strain Rate (s−1) | Temperature (K) | AARE (%) | R |

|---|---|---|---|

| 0.1 | 1173 | 0.865 | 0.999 |

| 1273 | 0.699 | 0.998 | |

| 1373 | 3.236 | 0.999 | |

| 1 | 1173 | 2.638 | 0.999 |

| 1273 | 1.911 | 0.992 | |

| 1373 | 1.077 | 0.994 | |

| 10 | 1173 | 6.758 | 0.962 |

| 1273 | 1.669 | 0.912 | |

| 1373 | 3.475 | 0.994 |

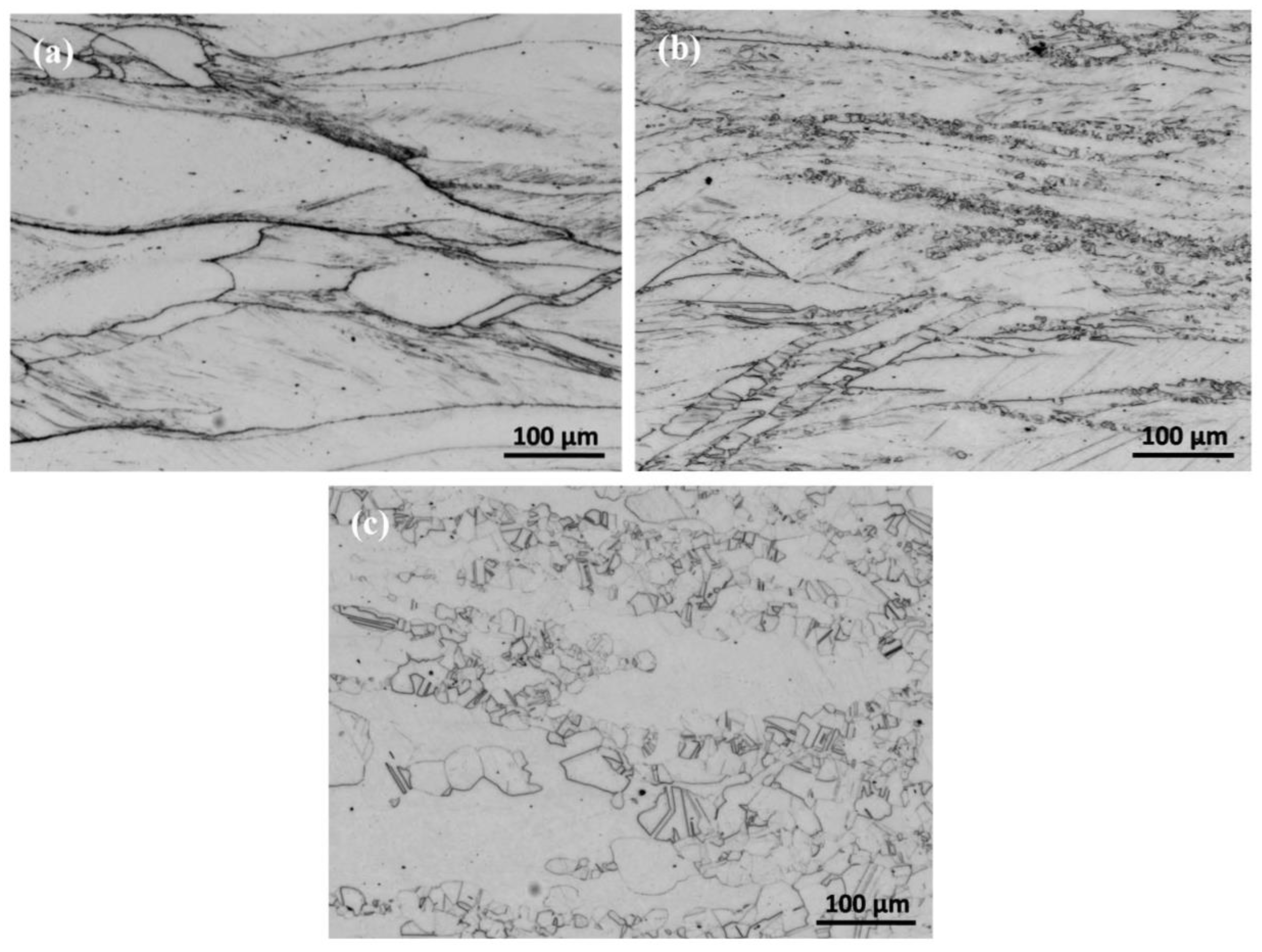

3.4. Relationship between the Dynamic Restoration Condition and the Zener-Hollomon Parameter

4. Conclusions

- All flow stress curves gradually returned to a balanced stress state without notable peak stress characteristics and flow softening. Most of the flow curves presented a slight increase in stress with the increasing of the strain, which was a result of the unfinished dynamic balance of the work hardening and restoration processes.

- The constitutive model of the studied steel was developed on an Arrhenius-type equation to predict the flow behavior under specific deformation conditions. The material constants and deformation activation energy (including α, β, n, Q, and A) were incorporated with strain compensation with fifth order polynomial fitting, and the results indicated good correlation and generalization.

- The comparison between the experimental and predicted values exhibited a high precision and good reliability with regard to the constitutive equations according to the mean error. The absolute average relative error (AARE) values for all of the deformation conditions were below 6.8% and all the correlation coefficient (R) values were found to be above 0.9.

- From the exponent-type Zener-Hollomon parameter map and corresponding observation of the microstructure, the critical values for the occurrence of the dynamic restoration processes at large strains were determined. A lower value could give rise to higher levels of recrystallization and increment of grain size.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, T.H.; Kim, S.J.; Jung, Y.C. Crystallographic details of precipitates in Fe–22Cr–21Ni–6Mo–(N) superaustenitic stainless steels aged at 900 °C. Metall. Mater. Trans. A 2000, 31, 1713–1723. [Google Scholar] [CrossRef]

- Fonda, R.W.; Lauridsen, E.M.; Ludwig, W.; Tafforeau, P.; Spanos, G. Two-dimensional and three-dimensional analyses of sigma precipitates and porosity in a superaustenitic stainless steel. Metall. Mater. Trans. A 2007, 38, 2721–2726. [Google Scholar] [CrossRef]

- Wang, S.H.; Wu, C.C.; Chen, C.Y.; Yang, J.R.; Chiu, P.K.; Fang, J. Cyclic deformation and phase transformation of 6Mo superaustenitic stainless steel. Met. Mater. Int. 2007, 13, 275–283. [Google Scholar] [CrossRef]

- Koutsoukis, T.; Redjaimia, A.; Fourlaris, G. Phase transformations and mechanical properties in heat treated superaustenitic stainless steels. Mater. Sci. Eng. A 2013, 561, 477–485. [Google Scholar] [CrossRef]

- Muller, C.; Chumbley, L.S. Fracture toughness of heat-treated superaustenitic stainless steel. J. Mater. Eng. Perform. 2010, 19, 714–720. [Google Scholar] [CrossRef]

- Phillips, N.S.L.; Chumbley, L.S.; Gleeson, B. Phase transformations in cast superaustenitic stainless steels. J. Mater. Eng. Perform. 2009, 18, 1285–1293. [Google Scholar] [CrossRef]

- Bradaskja, B.; Pirnar, B.; Fazarinc, M.; Fajfar, P. Deformation behavior and microstructural evolution during hot compression of AISI 904L. Steel Res. Int. 2011, 82, 346–351. [Google Scholar] [CrossRef]

- Zambon, A.; Ferro, P.; Bonollo, F. Microstructural, compositional and residual stress evaluation of CO2 laser welded superaustenitic AISI 904L stainless steel. Mater. Sci. Eng. A 2006, 424, 117–127. [Google Scholar] [CrossRef]

- Mataya, M.C.; Nilsson, E.R.; Brown, E.L.; Krauss, G. Hot working and recrystallization of as-cast 317L. Metall. Mater. Trans. A 2003, 34, 3021–3041. [Google Scholar] [CrossRef]

- Mataya, M.C.; Nilsson, E.R.; Brown, E.L.; Krauss, G. Hot working and recrystallization of as-cast 316L. Metall. Mater. Trans. A 2003, 34, 1683–1703. [Google Scholar] [CrossRef]

- Schramn, R.E.; Reed, R.P. Stacking fault energies of seven commercial austenitic steels. Metall. Trans. A 1975, 6, 1345–1351. [Google Scholar] [CrossRef]

- Han, Y.; Liu, G.W.; Zou, D.N.; Liu, R.; Qiao, G.J. Deformation behavior and microstructural evolution of as-cast 904L austenitic stainless steel during hot compression. Mater. Sci. Eng. A 2013, 565, 342–350. [Google Scholar] [CrossRef]

- Ebrahimi, G.R.; Keshmiri, H.; Momeni, A.; Mazinani, M. Dynamic recrystallization behavior of a superaustenitic stainless steel containing 16% Cr and 25% Ni. Mater. Sci. Eng. A 2011, 528, 7488–7493. [Google Scholar] [CrossRef]

- Pu, E.; Zheng, W.; Ziang, J.; Song, Z.; Li, J. Hot deformation characteristic and processing map of superaustenitic stainless steel S32654. Mater. Sci. Eng. A 2014, 598, 174–182. [Google Scholar] [CrossRef]

- Momeni, A.; Dehghani, K.; Keshmiri, H.; Ebrahimi, G.R. Hot deformation behavior and microstructural evolution of a superaustenitic stainless steel. Mater. Sci. Eng. A 2010, 527, 1605–1611. [Google Scholar] [CrossRef]

- Mirzaei, A.; Hanzaki, A.Z.; Haghdadi, N.; Marandi, A. Constitutive description of high temperature flow behavior of Sanicro-28 super-austenitic stainless steel. Mater. Sci. Eng. A 2014, 589, 76–82. [Google Scholar] [CrossRef]

- Han, Y.; Qiao, G.; Sun, Y.; Zou, D. Modeling the constitutive relationship of Cr20Ni25Mo4Cu superaustenitic stainless steel during elevated temperature. Mater. Sci. Eng. A 2012, 539, 61–67. [Google Scholar] [CrossRef]

- Zou, D.N.; Liu, R.; Han, Y.; Zhang, W.; Wu, K.; Liu, X.H. On dynamic recrystallization under hot working of superaustenitic stainless steel. Mater. Sci. Technol. 2014, 30, 411–417. [Google Scholar] [CrossRef]

- Liang, R.; Khan, A.K. A critical review of experimental results and constitutive models for BCC and FCC metals over a wide range of strain rates and temperatures. Int. J. Plast. 1999, 15, 963–980. [Google Scholar] [CrossRef]

- Bernard, P.; Bag, S.; Huang, K.; Logé, R.E. A two-site mean field model of discontinuous dynamic recrystallization. Mater. Sci. Eng. A 2011, 528, 7357–7367. [Google Scholar] [CrossRef]

- Momeni, A.; Ebrahimi, G.R.; Jahazi, M.; Bocher, P. Microstructure evolution at the onset of discontinuous dynamic recrystallization: A physics-based model of subgrain critical size. J. Alloys Compd. 2014, 587, 199–210. [Google Scholar] [CrossRef]

- Beltran, O.; Huang, K.; Logé, R.E. A mean field model of dynamic and post-dynamic recrystallization kinetics, grain size and flow stress. Comput. Mater. Sci. 2015, 102, 293–303. [Google Scholar] [CrossRef]

- Jonas, J.J.; Sellars, C.M.; McTegart, W.J. Strength and structure under hot-working conditions. Int. Metall. Rev. 1969, 14, 1–24. [Google Scholar] [CrossRef]

- Shamsolhodaei, A.; Hanzaki, A.Z.; Ghambari, M.; Moememi, S. The high temperature flow behavior modeling of NiTi shape memory alloy employing phenomenological and physical based constitutive models: A comparative study. Intermetallics 2014, 53, 140–149. [Google Scholar] [CrossRef]

- Zhou, M.; Lin, Y.C.; Deng, J.; Jiang, Y.Q. Hot tensile deformation behaviors and constitutive model of an Al–Zn–Mg–Cu alloy. Mater. Des. 2014, 59, 141–150. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Haghdadi, N.; Hanzaki, A.Z.; Abedi, H.R. The flow behavior modeling of cast A356 aluminum alloy at elevated temperatures considering the effect of strain. Mater. Sci. Eng. A 2012, 535, 252–257. [Google Scholar] [CrossRef]

- Quan, G.Z.; Shi, Y.; Wang, Y.X.; Kang, B.S.; Ku, T.W.; Song, W.J. Constitutive modeling for the dynamic recrystallization evolution of AZ80 magnesium alloy based on stress-strain data. Mater. Sci. Eng. A 2011, 528, 8051–8059. [Google Scholar] [CrossRef]

- Doherty, R.D.; Hugues, D.A.; Humphreys, F.J.; Jonas, J.J.; Jenson, D.J.; Kassner, M.E.; King, W.E.; McNelley, T.R.; McQueen, H.J.; Rollett, A.D. Current issues in recrystallization: A review. Mater. Sci. Eng. A 1997, 238, 219–274. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K.; Venugopal, S.; Sivaprasad, P.V. Analysis and mathematical modeling of elevated temperature flow behavior of austenitic stainless steels. Mater. Sci. Eng. A 2011, 528, 1937–1943. [Google Scholar] [CrossRef]

- Khamei, A.A.; Dehghani, K. Modeling the hot-deformation behavior of Ni60 wt. %–Ti40 wt. % intermetallic alloy. J. Alloys Compd. 2010, 490, 377–381. [Google Scholar] [CrossRef]

- Liu, J.T.; Chang, H.B.; Wu, R.H.; Hsu, T.Y.; Ruan, X.Y. Investigation on hot deformation behavior of AISI T1 high-speed steel. Mater. Charact. 2000, 45, 175–186. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhang, J. Modeling of flow stress of 42CrMo steel under hot compression. Mater. Sci. Eng. A 2009, 499, 88–92. [Google Scholar] [CrossRef]

- Xiao, Y.H.; Guo, C.; Guo, X.Y. Constitutive modeling of hot deformation behavior of H62 brass. Mater. Sci. Eng. A 2011, 528, 6510–6518. [Google Scholar] [CrossRef]

- Han, Y.; Wu, H.; Zhang, W.; Zou, D.; Liu, G.; Qiao, G. Constitutive equation and dynamic recrystallization behavior of as-cast 254SMO super-austenitic stainless steel. Mater. Des. 2015, 69, 230–240. [Google Scholar] [CrossRef]

- Mandal, S.; Rakesh, V.; Sivaprasad, P.V.; Venugopal, S.; Kasiviswanathan, K.V. Constitutive equations to predict high temperature flow stress in a Ti-modified austenitic stainless steel. Mater. Sci. Eng. A 2009, 500, 114–121. [Google Scholar] [CrossRef]

- Srinivasulu, S.; Jain, A. A comparative analysis of training methods for artificial neural network rainfall-runoff models. Appl. Soft Comput. 2006, 6, 295–306. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.-C.; Pan, Y.-T.; Chen, I.-G.; Lin, D.-Y. Constitutive Relationship Modeling and Characterization of Flow Behavior under Hot Working for Fe–Cr–Ni–W–Cu–Co Super-Austenitic Stainless Steel. Metals 2015, 5, 1717-1731. https://doi.org/10.3390/met5031717

Yang L-C, Pan Y-T, Chen I-G, Lin D-Y. Constitutive Relationship Modeling and Characterization of Flow Behavior under Hot Working for Fe–Cr–Ni–W–Cu–Co Super-Austenitic Stainless Steel. Metals. 2015; 5(3):1717-1731. https://doi.org/10.3390/met5031717

Chicago/Turabian StyleYang, Li-Chih, Yeong-Tsuen Pan, In-Gann Chen, and Dong-Yih Lin. 2015. "Constitutive Relationship Modeling and Characterization of Flow Behavior under Hot Working for Fe–Cr–Ni–W–Cu–Co Super-Austenitic Stainless Steel" Metals 5, no. 3: 1717-1731. https://doi.org/10.3390/met5031717