Effects of Different Heat Treatment on Microstructure, Mechanical and Conductive Properties of Continuous Rheo-Extruded Al-0.9Si-0.6Mg (wt%) Alloy

Abstract

:1. Introduction

2. Experimental Section

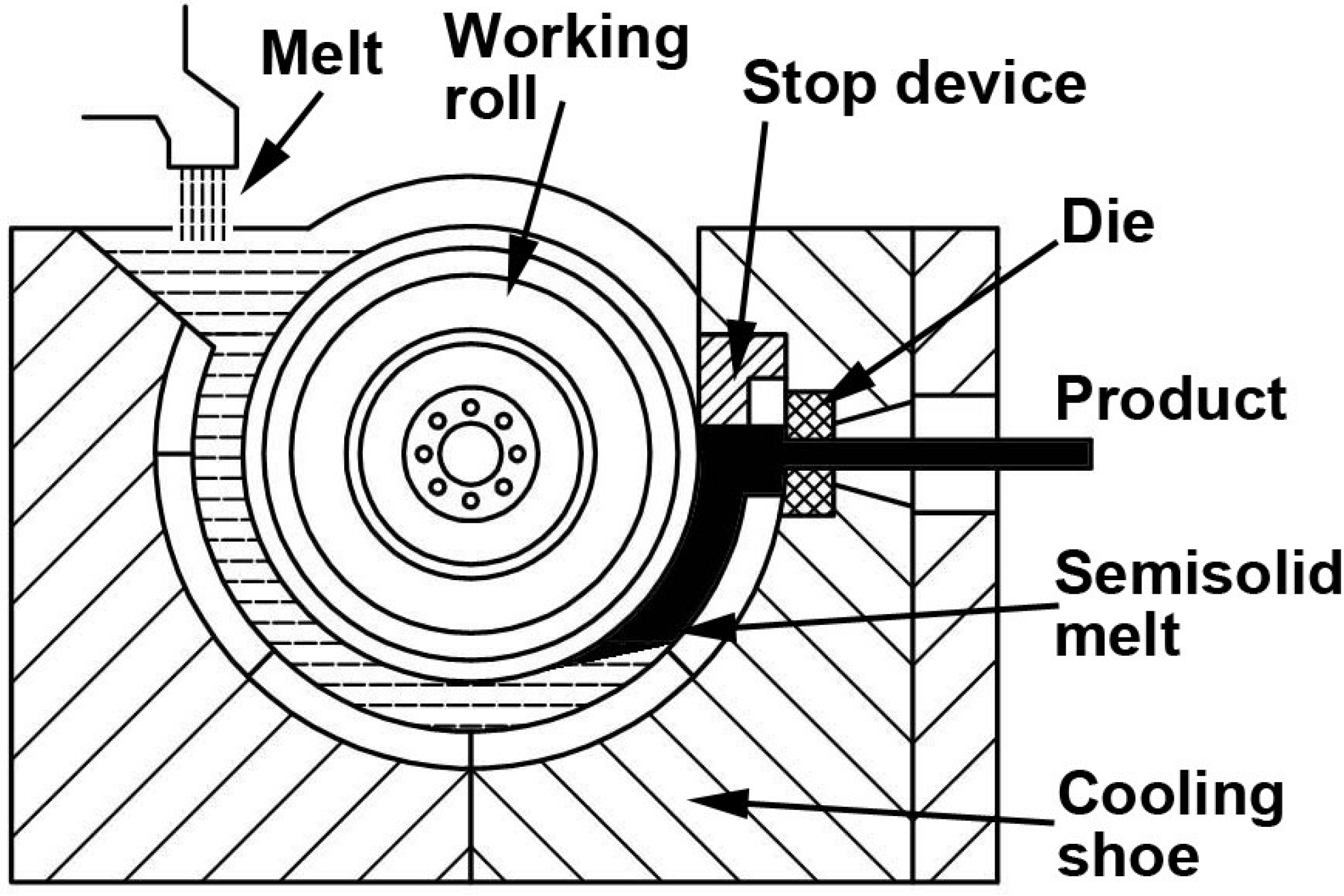

2.1. Continuous Rheo-Extrusion

2.2. Heat Treatment Process

| Heat treatment | Solution temperature (°C) | Aging temperature (°C) | Aging time (h) |

|---|---|---|---|

| T6 | 520 | 150–190 | 2–14 |

| T8 | 520 | 150–170 | 3–7 |

| T9 | 540 | 150–170 | 3–7 |

2.3. Microstructure Analysis

2.4. Mechanical and Conductive Properties

3. Results and Discussion

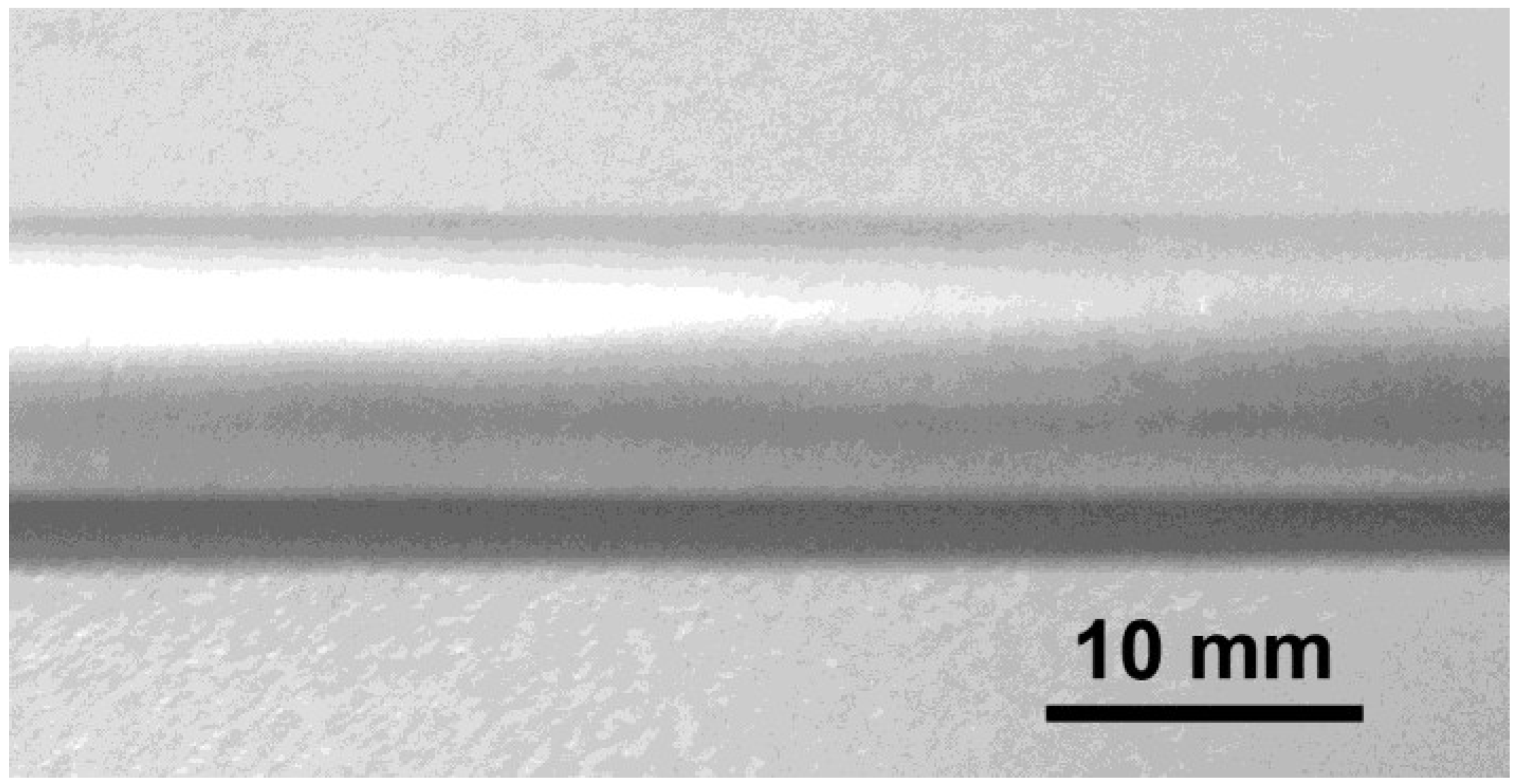

3.1. Optimum of Technical Parameters of Continuous Rheo-Extrusion

3.2. Influence of T6 Aging Treatment on Microstructure and Properties

3.3. Influence of T8 and T9 Aging Treatment on Microstructure and Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yuan, W.; Liang, Z. Effect of zr addition on properties of Al–Mg–Si aluminum alloy used for all aluminum alloy conductor. Mater. Des. 2011, 32, 4195–4200. [Google Scholar]

- Azevedo, C.R.F.; Cescon, T. Failure analysis of aluminum cable steel reinforced (ACSR) conductor of the transmission line crossing the paraná river. Eng. Failure Anal. 2002, 9, 645–664. [Google Scholar]

- Guan, R.-G.; Wen, J.-L.; Wang, S.-C.; Liu, X.-H. Microstructure behavior and metal flow during continuously extending-extrusion forming of semisolid A2017 alloy. Trans. Nonferrous Metals Soc. China 2006, 16, 382–386. [Google Scholar]

- Kerr, A.; Watson, L.M.; Szasz, A.; Muller, H.; Kirchmayr, H. On the electronic stability of the Al-Mg-Si age-hardened alloys. J. Phys. Chem. Solids 1996, 57, 1285–1292. [Google Scholar]

- Flemings, M. Behavior of metal alloys in the semisolid state. MTB 1991, 22, 269–293. [Google Scholar]

- Xu, C.; Schroeder, S.; Berbon, P.B.; Langdon, T.G. Principles of ECAP–Conform as a continuous process for achieving grain refinement: Application to an aluminum alloy. Acta Mater. 2010, 58, 1379–1386. [Google Scholar]

- Mrówka-Nowotnik, G.; Sieniawski, J. Influence of heat treatment on the microstructure and mechanical properties of 6005 and 6082 aluminium alloys. J. Mater. Process. Technol. 2005, 162–163, 367–372. [Google Scholar]

- Guyot, P.; Cottignies, L. Precipitation kinetics, mechanical strength and electrical conductivity of AlZnMgCu alloys. Acta Mater. 1996, 44, 4161–4167. [Google Scholar]

- Jiang, D.; Wang, C. Influence of microstructure on deformation behavior and fracture mode of Al–Mg–Si alloys. Mater. Sci. Eng. A 2003, 352, 29–33. [Google Scholar]

- Tie, D.; Guan, R.G.; Cui, T.; Ling, C.; Wang, X.; Guan, X.H. Optimisation of composition and cast temperature for continuous semisolid extruded Al–Sc–Zr electrical conductor. Mater. Res. Innov. 2014, 18, S4-926–S4-928. [Google Scholar]

- Suzuki, S.; Shibutani, N.; Mimura, K.; Isshiki, M.; Waseda, Y. Improvement in strength and electrical conductivity of Cu–Ni–Si alloys by aging and cold rolling. J. Alloys Compd. 2006, 417, 116–120. [Google Scholar]

- Zhou, W.W.; Cai, B.; Li, W.J.; Liu, Z.X.; Yang, S. Heat-resistant Al–0.2Sc–0.04Zr electrical conductor. Mater. Sci. Eng. A 2012, 552, 353–358. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tie, D.; Guan, R.-g.; Guo, N.; Zhao, Z.; Su, N.; Li, J.; Zhang, Y. Effects of Different Heat Treatment on Microstructure, Mechanical and Conductive Properties of Continuous Rheo-Extruded Al-0.9Si-0.6Mg (wt%) Alloy. Metals 2015, 5, 648-655. https://doi.org/10.3390/met5020648

Tie D, Guan R-g, Guo N, Zhao Z, Su N, Li J, Zhang Y. Effects of Different Heat Treatment on Microstructure, Mechanical and Conductive Properties of Continuous Rheo-Extruded Al-0.9Si-0.6Mg (wt%) Alloy. Metals. 2015; 5(2):648-655. https://doi.org/10.3390/met5020648

Chicago/Turabian StyleTie, Di, Ren-guo Guan, Ning Guo, Zhouyang Zhao, Ning Su, Jing Li, and Yang Zhang. 2015. "Effects of Different Heat Treatment on Microstructure, Mechanical and Conductive Properties of Continuous Rheo-Extruded Al-0.9Si-0.6Mg (wt%) Alloy" Metals 5, no. 2: 648-655. https://doi.org/10.3390/met5020648