Experimental Investigation of the Equal Channel Forward Extrusion Process

Abstract

:1. Introduction

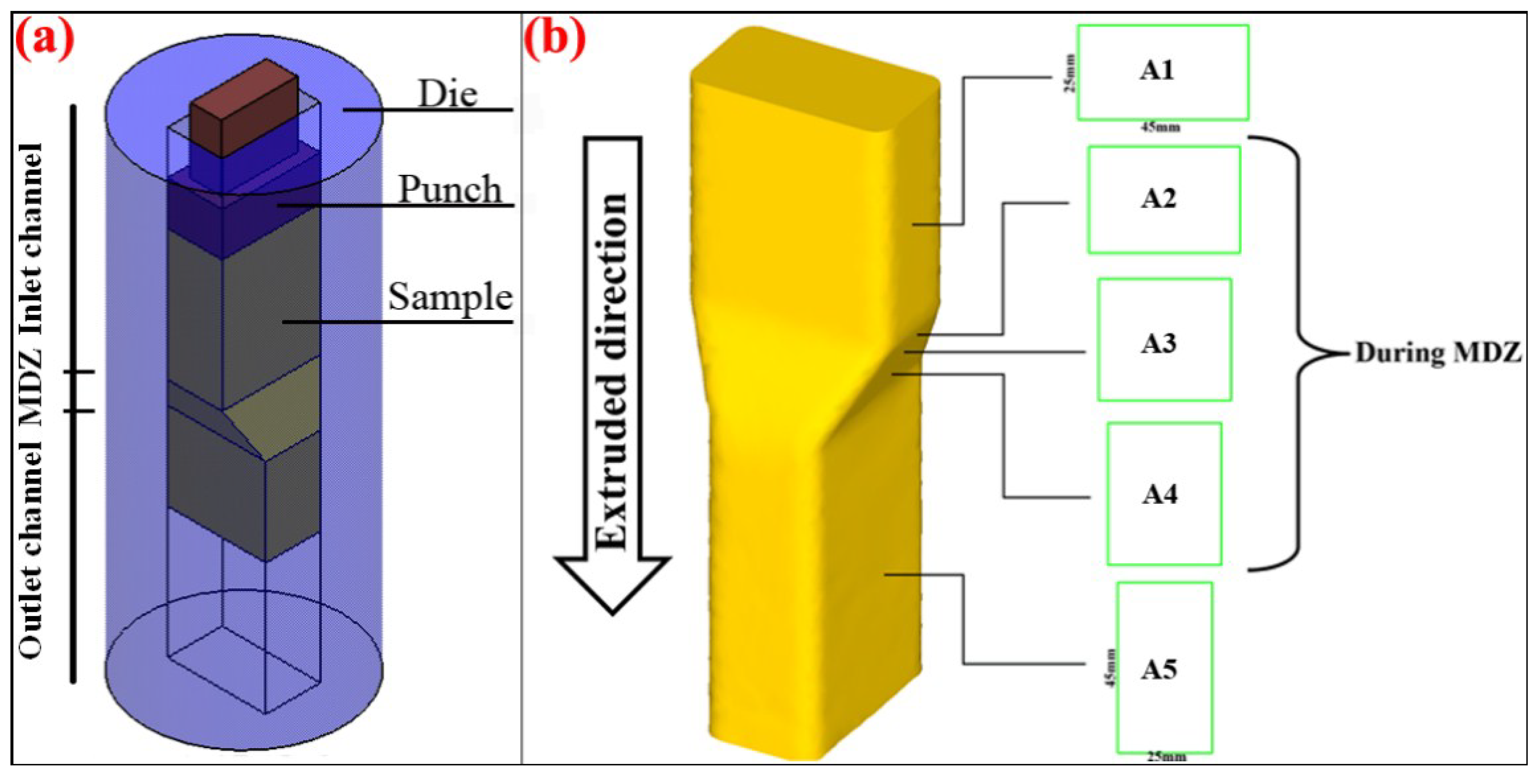

2. Principle of the ECFE Process

3. Experimental Procedure

3.1. Materials

3.2. ECFE Die

3.3. Microstructural Testing

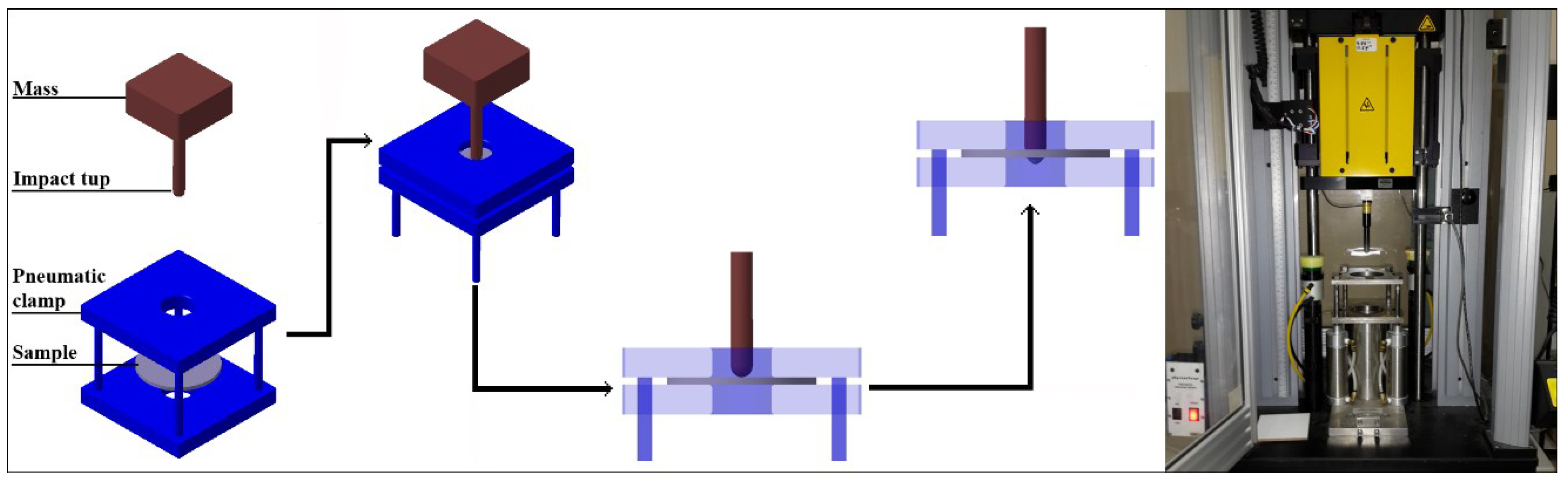

3.4. Mechanical Testing

4. Results and Discussion

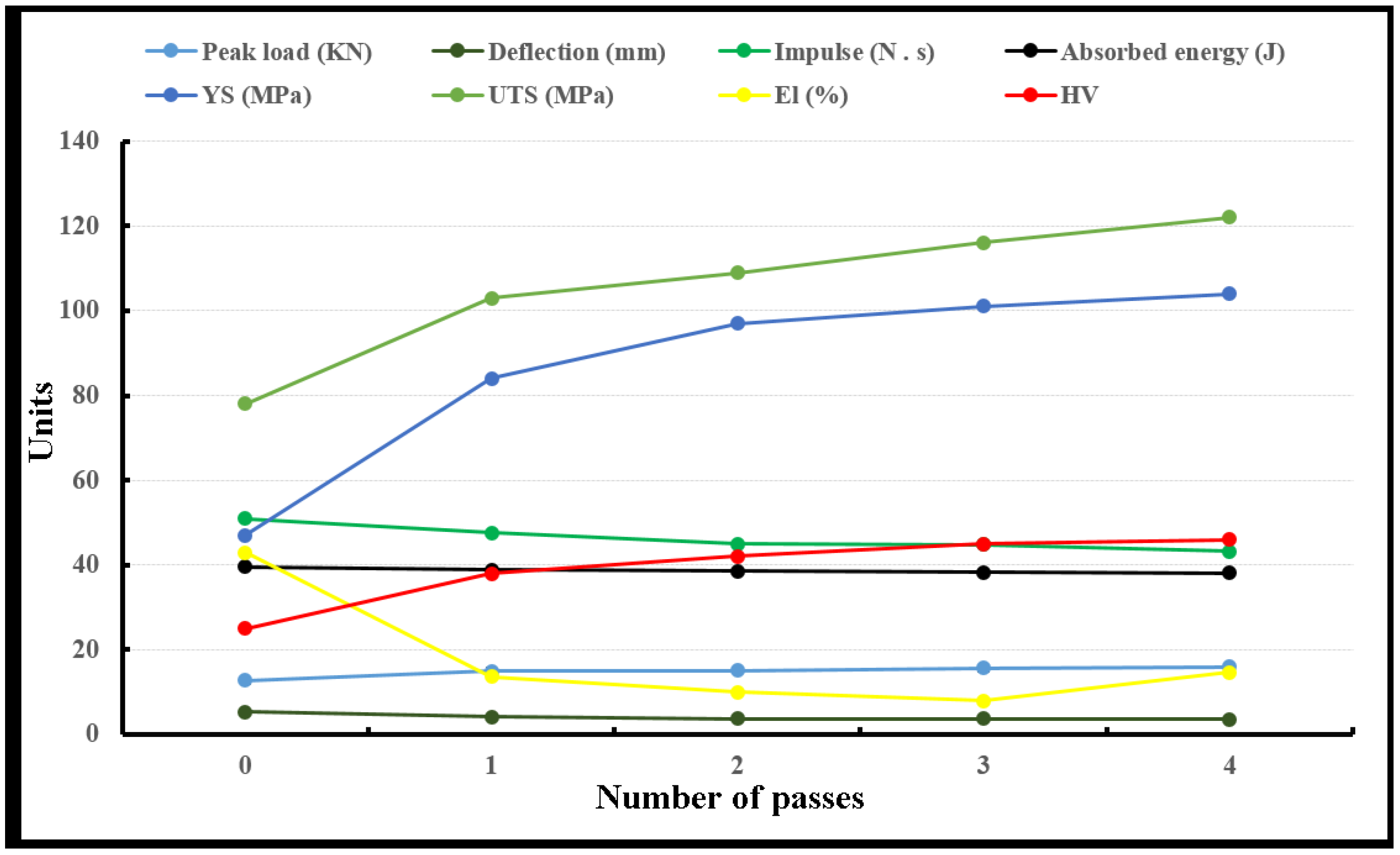

4.1. Mechanical Properties

| Pass Number | YS (MPa)[SD] | UTS (MPa)[SD] | El (%)[SD] | HV [SD] | Cell/sub-grain size (nm) |

|---|---|---|---|---|---|

| 0 | 47 [1.63] | 78 [0.78] | 43 [0.28] | 25 [1.05] | ~2000 |

| 1 | 84 [1.34] | 103 [0.78] | 13.7 [0.14] | 38 [1.82] | ~460 |

| 2 | 97 [1.70] | 109 [1.13] | 10 [0.14] | 42 [1.37] | - |

| 3 | 101 [1.27] | 116 [0.56] | 8 [0.21] | 45 [1.56] | - |

| 4 | 104 [1.98] | 122 [0.92] | 14.7 [0.35] | 46 [1.63] | ~350 |

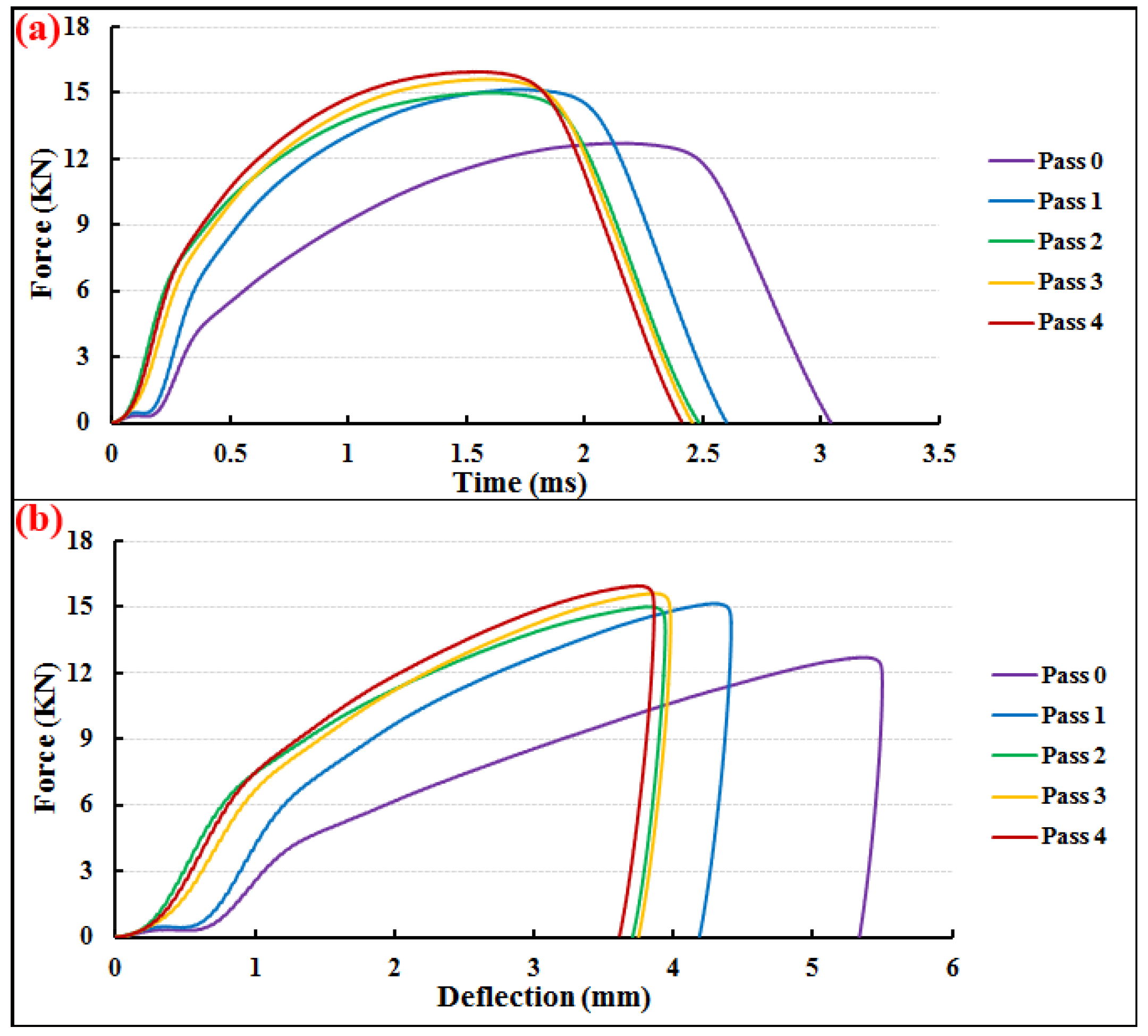

| Pass Number | Peak load (KN)[SD] | Deflection (mm)[SD] | Impulse (N∙s)[SD] | Absorbed energy (J)[SD] |

|---|---|---|---|---|

| 0 | 12.72 [0.03] | 5.33 [0.06] | 50.99 [0.03] | 39.63 [0.02] |

| 1 | 15.03 [0.04] | 4.19 [0.06] | 47.64 [0.06] | 38.92 [0.01] |

| 2 | 15.17 [0.06] | 3.71 [0.01] | 45.03 [0.02] | 38.56 [0.02] |

| 3 | 15.64 [0.06] | 3.75 [0.01] | 44.88 [0.06] | 38.31 [0.03] |

| 4 | 15.98 [0.01] | 3.61 [0.03] | 43.30 [0.06] | 38.16 [0.03] |

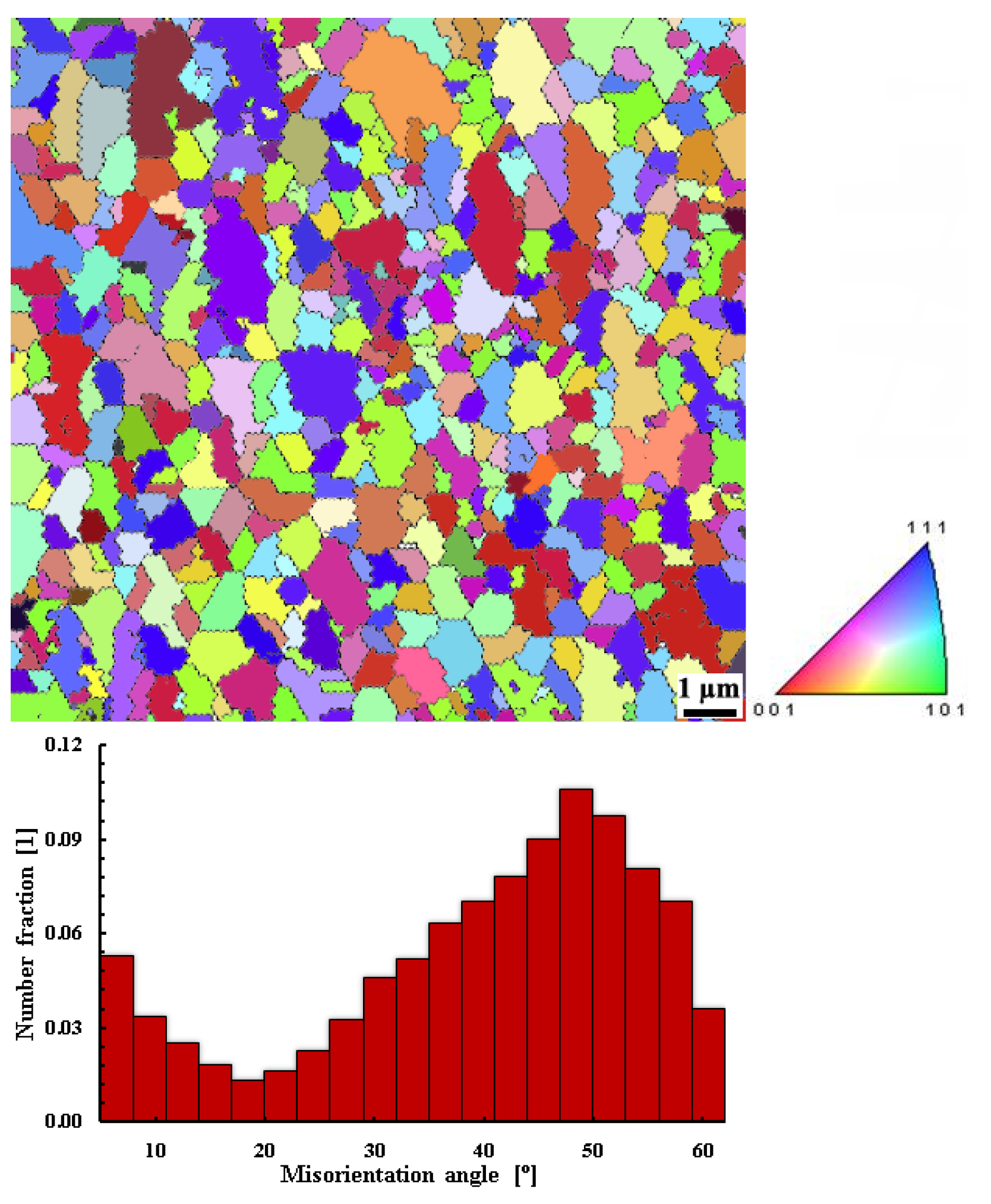

4.2. Microstructural Characteristics

5. Conclusions

- The magnitudes of yield strength, ultimate tensile strength, and Vickers micro-hardness have increased from 47 MPa, 78 MPa, and 25 HV for the annealed condition to 104 MPa, 122 MPa, and 46 HV for the fourth pass of the ECFE process, which indicate improvements of about 121%, 56%, and 84%, respectively. In addition, there is about a 66% reduction at the elongation to failure in this way. Additionally, significant enhancements in the strengthening of CP aluminum billets was achieved after the first pass of the ECFE process, which is in agreement with the hardness measurements.

- During the drop weight impact test, the magnitudes of peak load, deflection, impulse, and absorbed energy have increased from 12.72 KN, 5.33 mm, 50.99 N∙s, and 39.63 J, to 15.98 KN, 3.61 mm, 43.3 N∙s, and 38.16 J after four passes of the ECFE process, which means that material with the enhanced strength and brittle behavior has been attained.

- This superior improvement in the mechanical properties of the ECFE CP aluminum billet is accompanied with grain size reduction. The use of the classic Williamson–Hall method on the XRD patterns indicates that about 77% and 82% reductions have been obtained in the cell/sub-grain size of the first and fourth passes of the aluminum billets, in comparison with the annealed condition. Additionally, the EBSD scan of the final pass indicates an average grain size of about 480 nm.

Author Contributions

Conflicts of Interest

References

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Kim, W.J.; An, C.W.; Kim, Y.S.; Hong, S.I. Mechanical properties and microstructures of an AZ61 Mg Alloy produced by equal channel angular pressing. Scr. Mater. 2002, 47, 39–44. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Stolyarova, V.V.; Valiev, R.Z.; Mukherjee, A.K. Enhanced superplasticity in a Ti-6Al-4V alloy processed by severe plastic deformation. Scr. Mater. 2000, 43, 819–824. [Google Scholar] [CrossRef]

- Rafizadeh, E.; Mani, A.; Kazeminezhad, M. The effects of intermediate and post-annealing phenomena on the mechanical properties and microstructure of constrained groove pressed copper sheet. Mater. Sci. Eng. A 2009, 515, 162–168. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Varyukhin, V.; Synkov, S.; Orlov, D. Useful properties of twist extrusion. Mater. Sci. Eng. A 2009, 503, 14–17. [Google Scholar] [CrossRef]

- Kwan, C.C.F.; Wang, Z. Cyclic deformation of ultra-fine grained commercial purity aluminum processed by accumulative roll-bonding. Materials 2013, 6, 3469–3481. [Google Scholar] [CrossRef]

- Lee, J.C.; Seok, H.K.; Suh, J.Y. Microstructural evolutions of the Al strip prepared by cold rolling and continuous equal channel angular pressing. Acta Mater. 2002, 50, 4005–4019. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Shin, D.H.; Park, J.J.; Kim, Y.S.; Park, K.T. Constrained groove pressing and its application to grain refinement of aluminum. Mater. Sci. Eng. A 2002, 328, 98–103. [Google Scholar] [CrossRef]

- Tóth, L.S.; Arzaghi, M.; Fundenberger, J.J.; Beausir, B.; Bouaziz, O.; Arruffat-Massion, R. Severe plastic deformation of metals by high-pressure tube twisting. Scr. Mater. 2009, 60, 175–177. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Akbarzadeh, A. Accumulative spin-bonding (ASB) as a novel SPD process for fabrication of nanostructured tubes. Mater. Sci. Eng. A 2010, 528, 180–188. [Google Scholar] [CrossRef]

- Faraji, G.; Mashhadi, M.M.; Kim, H.S. Tubular channel angular pressing (TCAP) as a novel severe plastic deformation method for cylindrical tubes. Mater. Lett. 2011, 65, 3009–3012. [Google Scholar] [CrossRef]

- Xue, Q.; Beyerlein, I.J.; Alexander, D.J.; Gray, G.T. Mechanisms for initial grain refinement in OFHC copper during equal channel angular pressing. Acta Mater. 2007, 55, 655–668. [Google Scholar] [CrossRef]

- Zhao, G.; Xu, S.; Luan, Y.; Guan, Y.; Lun, N.; Ren, X. Grain refinement mechanism analysis and experimental investigation of equal channel angular pressing for producing pure aluminum ultra-fine grained materials. Mater. Sci. Eng. A 2006, 437, 281–292. [Google Scholar] [CrossRef]

- Su, C.W.; Lu, L.; Lai, M.O. A model for the grain refinement mechanism in equal channel angular pressing of Mg alloy from microstructural studies. Mater. Sci. Eng. A 2006, 434, 227–236. [Google Scholar] [CrossRef]

- Shin, D.H.; Kim, I.; Kim, J.; Park, K.T. Grain refinement mechanism during equal-channel angular pressing of a low-carbon steel. Acta Mater. 2001, 49, 1285–1292. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Djavanroodi, F. Experimental and numerical analyses of pure copper during ECFE process as a novel severe plastic deformation method. Prog. Nat. Sci. Mater. Inter. 2014, 24, 68–74. [Google Scholar] [CrossRef]

- Wang, J.W.; Duan, Q.Q.; Huang, C.X.; Wu, S.D.; Zhang, Z.F. Tensile and compressive deformation behaviors of commercially pure Al processed by equal-channel angular pressing with different dies. Mater. Sci. Eng. A 2008, 496, 409–416. [Google Scholar] [CrossRef]

- Reihanian, M.; Ebrahimi, R.; Moshksar, M.M.; Terada, D.; Tsuji, N. Microstructure quantification and correlation with flow stress of ultrafine grained commercially pure Al fabricated by equal channel angular pressing (ECAP). Mater. Charact. 2008, 59, 1312–1323. [Google Scholar] [CrossRef]

- Mukherjee, P.; Sarkar, A.; Barat, P.; Bandyopadhyay, S.K.; Sen, P.; Chattopadhyay, S.K.; Chatterjee, P.; Chatterjee, S.K.; Mitra, M.K. Deformation characteristics of rolled zirconium alloys: A study by X-ray diffraction line profile analysis. Acta Mater. 2004, 52, 5687–5696. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, F.; Lavernia, E.J. On the analysis of grain size in bulk nanocrystalline materials via X-ray diffraction. Metall. Mater. Trans. A 2003, 34, 1349–1355. [Google Scholar] [CrossRef]

- Hosseini, E.; Kazeminezhad, M. Nanostructure and mechanical properties of 0–7 strained aluminum by CGP: XRD, TEM and tensile test. Mater. Sci. Eng. A 2009, 526, 219–224. [Google Scholar] [CrossRef]

- Múgica, J.I.; Aretxabaleta, L.; Ulacia, I.; Aurrekoetxea, J. Impact characterization of thermoformable fibre metal laminates of 2024-T3 aluminum and AZ31B-H24 magnesium based on self-reinforced polypropylene. Compos. Part A 2014, 61, 67–75. [Google Scholar] [CrossRef]

- Liu, B.; Villavicencio, R.; Soares, C.G. On the failure criterion of aluminum and steel plates subjected to low-velocity impact by a spherical indenter. Int. J. Mech. Sci. 2014, 80, 1–15. [Google Scholar] [CrossRef]

- Shokuhfar, A.; Nejadseyfi, O. A comparison of the effects of severe plastic deformation and heat treatment on the tensile properties and impact toughness of aluminum alloy 6061. Mater. Sci. Eng. A 2014, 594, 140–148. [Google Scholar] [CrossRef]

- Krasilnikov, N.; Lojkowski, W.; Pakiela, Z.; Valiev, R. Tensile strength and ductility of ultra-fine-grained nickel processed by severe plastic deformation. Mater. Sci. Eng. A 2005, 397, 330–337. [Google Scholar] [CrossRef]

- Bystrzycki, J.; Fraczkiewicz, A.; Lyszkowski, R.; Mondon, M.; Pakiela, Z. Microstructure and tensile behavior of Fe–16Al-based alloy after severe plastic deformation. Intermetallics 2010, 18, 1338–1343. [Google Scholar] [CrossRef]

- Puertas, I.; Luis Pérez, C.J.; Salcedo, D.; León, J.; Fuertes, J.P.; Luri, R. Design and mechanical property analysis of AA1050 turbine blades manufactured by equal channel angular extrusion and isothermal forging. Mater. Des. 2013, 52, 774–784. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Salehi, M.T.; Seyyedein, S.H.; Abutalebi, M.R.; Park, J.K. Microstructure and mechanical properties of Al-7075 alloy processed by equal channel angular pressing combined with aging treatment. Mater. Des. 2014, 57, 250–257. [Google Scholar] [CrossRef]

- Harai, Y.; Edalati, K.; Horita, Z.; Langdon, T.G. Using ring samples to evaluate the processing characteristics in high-pressure torsion. Acta Mater. 2009, 57, 1147–1153. [Google Scholar] [CrossRef]

- Tolaminejad, B.; Dehghani, K. Microstructural characterization and mechanical properties of nanostructured AA1070 aluminum after equal channel angular extrusion. Mater. Des. 2012, 34, 285–292. [Google Scholar] [CrossRef]

- Luo, P.; McDonald, D.T.; Xu, W.; Palanisamy, S.; Dargusch, M.S.; Xia, K. A modified Hall–Petch relationship in ultrafine-grained titanium recycled from chips by equal channel angular pressing. Scr. Mater. 2012, 66, 785–788. [Google Scholar] [CrossRef]

- Azimi, A.; Tutunchilar, S.; Faraji, G.; Besharati Givi, M.K. Mechanical properties and microstructural evolution during multi-pass ECAR of Al1100–O alloy. Mater. Des. 2012, 42, 388–394. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebrahimi, M.; Djavanroodi, F.; Tiji, S.A.N.; Gholipour, H.; Gode, C. Experimental Investigation of the Equal Channel Forward Extrusion Process. Metals 2015, 5, 471-483. https://doi.org/10.3390/met5010471

Ebrahimi M, Djavanroodi F, Tiji SAN, Gholipour H, Gode C. Experimental Investigation of the Equal Channel Forward Extrusion Process. Metals. 2015; 5(1):471-483. https://doi.org/10.3390/met5010471

Chicago/Turabian StyleEbrahimi, Mahmoud, Faramarz Djavanroodi, Sobhan Alah Nazari Tiji, Hamed Gholipour, and Ceren Gode. 2015. "Experimental Investigation of the Equal Channel Forward Extrusion Process" Metals 5, no. 1: 471-483. https://doi.org/10.3390/met5010471

APA StyleEbrahimi, M., Djavanroodi, F., Tiji, S. A. N., Gholipour, H., & Gode, C. (2015). Experimental Investigation of the Equal Channel Forward Extrusion Process. Metals, 5(1), 471-483. https://doi.org/10.3390/met5010471