3.1. Microstructural Analysis

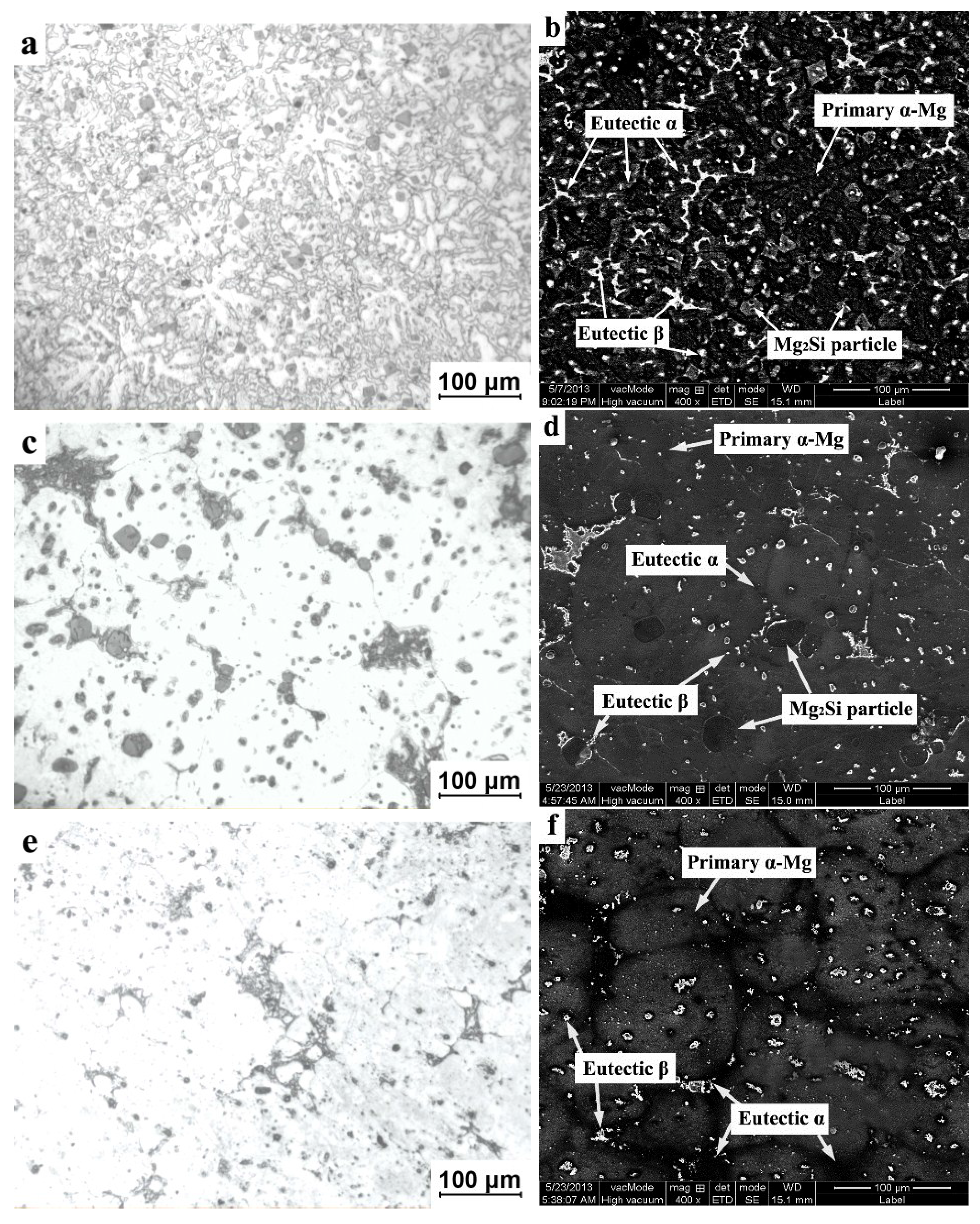

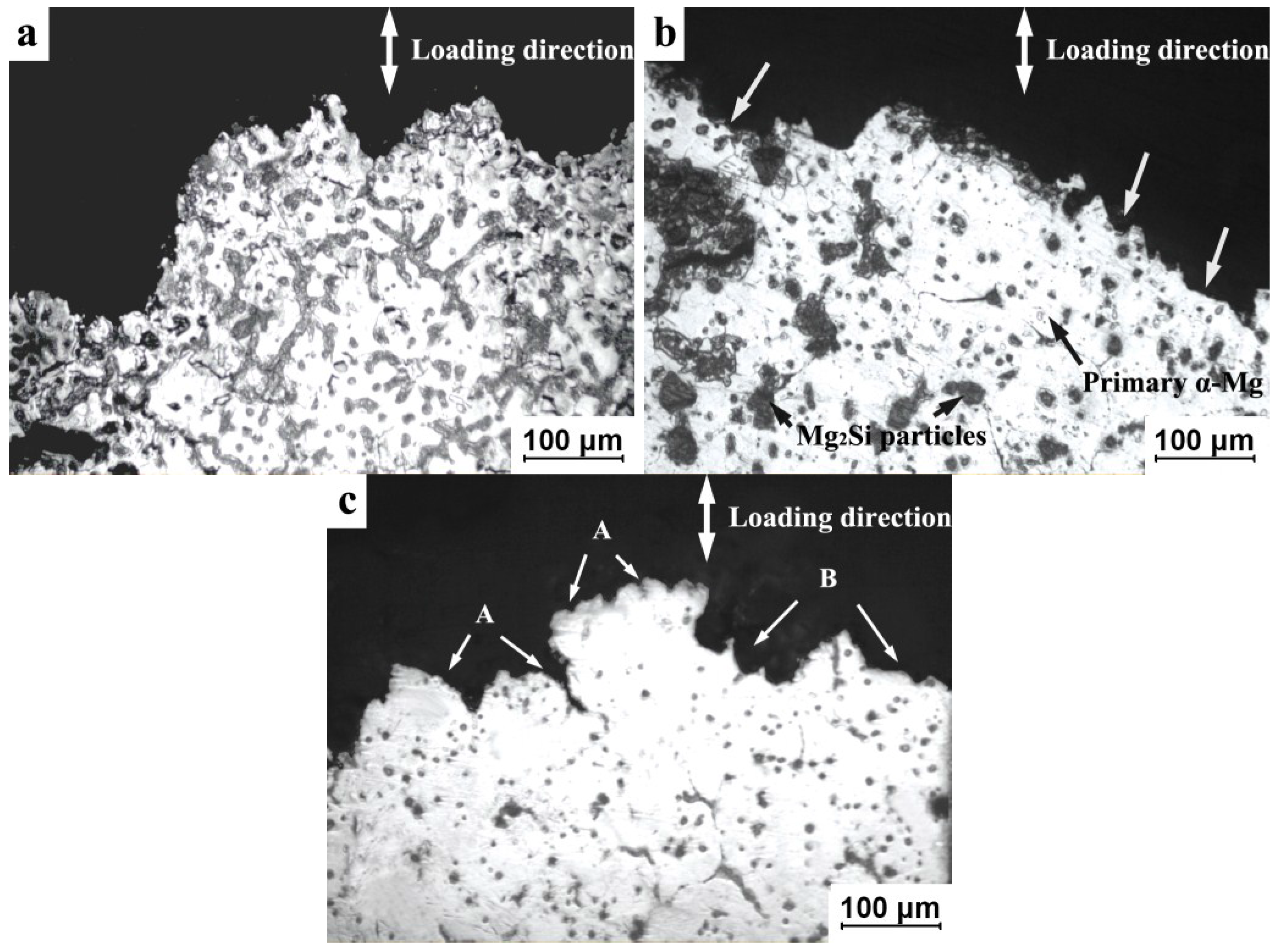

Figure 1 presents the microstructures of the as-cast composite, the thixoforged composite and AM60B revealed by OM and SEM, respectively. The microstructure of the as-cast composite mainly consists of primary α-Mg dendrites, Mg

2Si particles and eutectic phases (

Figure 1a). The size of the primary α-Mg dendrites is around 70~90 μm, which is relatively large compared with the reported value in the literature [

18,

19]. This is primarily due to the somewhat slow solidification rate taking place in the current work. The diameter of the mold in this work is 50 mm, which is only 16 mm in the literature. The primary Mg

2Si particles with a size of 15~30 μm were located at the primary α-Mg dendrite boundaries. The SEM result (

Figure 1b) displays that the β-Mg

17Al

12 eutectic phase (bright contrast) belongs to divorced eutectics and tend to form a network surrounding the α-Mg phase (dark contrast). According to the Mg-Al binary phase diagram [

20], it is known that AM60B alloy is a hypoeutectic alloy, since its Al content and composition is far away from the eutectic point. Under this circumstance, the residual liquid amount should be very low when the eutectic reaction occurs and exists in thin layers between the primary α-Mg dendrites and dendrite arms. Then, the eutectic α phase preferentially directly grows on the primary α-Mg phase without renucleation, and only the eutectic β and eutectic Mg

2Si phases are left in the interdendritic regions. The previously-formed primary Mg

2Si particles are pushed to the interdendritic regions by the growing interface.

As shown in

Figure 1c, the microstructure of the thixoforged composite is composed of primary α-Mg particles, secondarily solidified structures and Mg

2Si particles. The morphology of the primary α-Mg particles and the distribution of both the eutectic β phases and Mg

2Si particles are completely different from those present in the as-cast composite. The primary α-Mg particles coarsen and connect to each other, the size being approximately 90~120 μm, which is significantly larger than the primary α-Mg dendrites in as-cast microstructure. The Mg

2Si particles coarsen, as well, and their size is about 30~40 μm. The sharp edges and corners become blunt. However, the Mg

2Si particles in the thixoforged coupon not only surround the primary α-Mg particles, but also some of them locate inside the primary α-Mg particles. The size and amount of the β phase clearly decrease in the thixoforged specimen, which is located at the boundaries and inside the primary α-Mg particles, as well (shown in

Figure 1d).

Figure 1e presents the microstructure of the thixoforged AM60B alloy. It indicates that the primary α-Mg particles slightly coarsen, and the outline becomes indistinct (comparing

Figure 1f with 1d). The secondarily solidified structures almost disappear and only can be found in some triple point. As shown in

Figure 1f, the β phase size and amount of both the thixoforged composite and AM60B alloy are at a comparable level.

The morphological change of the α-Mg phase occurs during the reheating process. The thixoforged composites are subjected to a partial remelting treatment. During this technical process, the primary α-Mg dendrites transform into spheroidal primary α-Mg particles uniformly suspended in the liquid phase. During the subsequent thixoforging, the liquid solidifies to form secondarily-solidified structures. Coarsening of the primary α-Mg grains in the thixoforged specimen should be attributed to the following two aspects. One is Ostwald ripening and the coalescence of the nearby primary α-Mg grains during reheating, driven by minimizing the interfacial energy [

21]. Grain growth by coalescence by grain boundary migration is dominant for short times after the liquid is formed, and Ostwald ripening is dominant for longer times [

22]. This is a common phenomenon in thixoforged materials [

23,

24,

25]. The Mg

2Si particles and the liquid might be engulfed by the merged primary α-Mg grains, so Mg

2Si particles or the eutectic β phase would distribute inside the primary α-Mg grains in the thixoforged specimens. The other is the solidification behavior of the thixoforged materials.

Table 2 gives the compositions of α-Mg phase under these three methods. It reveals that the Al concentration in these two thixoforged materials is significantly higher than that in the as-cast coupon. This is because the eutectic phase is dissolving towards the primary α-Mg grains during reheating, which results in the Al concentration increase in the primary α-Mg grains and a decrease in the liquid. In this case, the formed secondarily primary α-Mg phase (to differentiate the primary α-Mg grains, the primary α-Mg phase solidified form of the liquid is named the secondarily primary α-Mg phase) and the eutectic α-Mg phase should increase, accompanied by the decrease of the eutectic β phase (the Al element is a necessary constituent for forming the eutectic β phase). The secondarily primary α-Mg phase should preferentially directly grow on the surfaces of the primary α-Mg grains, and then, the eutectic α-Mg phase also preferentially attaches on the surfaces of the secondarily primary α-Mg phase, which leads to the primary α-Mg grains coarsening and connecting with each other.

Although the reheating temperature of 600 °C is lower than the eutectic point of Mg-Mg

2Si (637.6 °C) [

20], the primary Mg

2Si particles and eutectic Mg

2Si phases should partially melt due to the penetration of the liquid and diffusion of Mg and Si atoms between Mg

2Si and liquids, especially at the sharp edges and corners. During the thixoforging, the melted Mg

2Si (including primary and eutectic Mg

2Si phases) grows as halos surrounding the nearly spherical Mg

2Si particles. Therefore, the Mg

2Si particles are somewhat coarse and spherical in the thixoforged specimen compared to those in the as-cast specimen.

With regard to the Mg

2Si particles, two primary factors affect the semisolid microstructural evolution, as described in this section. Firstly, the Mg

2Si particle acting as a ceramic phase with the low thermal conductivity, which uniformly distributes in the matrix, would block the heat transfer from the edge to the center of the semisolid ingot [

26]. This would suggest that the heating rate is delayed, so that the phase transformation rate is reduced. It is known that the microstructure evolution closely depends on the phase transformation. Therefore, coarsening from Ostwald ripening is suppressed. This would also affect the composition of the primary α-Mg grains simultaneously. On the other hand, the pin effect of the Mg

2Si particles in the primary α-Mg boundary prevent the primary α-Mg boundary from rotation or migration [

27]. Thus, the coalescence of the contacted primary α-Mg grains through mergence would be suppressed. As a result, the size and Al solubility of the primary α-Mg grains in thixoforged composite are slightly lesser than in the thixoforged AM60B alloy. Based on these standpoints, it is no difficult to understand the resultant microstructures under those different processing technologies.

Figure 1.

OM micrographs and SEM images of: (a,b) as-cast composite; (c,d) thixoforged composite; and (e,f) thixoforged AM60B.

Table 2.

Compositions of primary α-Mg dendrites or the grains of these materials.

| Materials | Compositions/wt% |

|---|

| Al | Mg |

|---|

| As-cast composite | 4.74 | 95.26 |

| Thixoforged composite | 6.87 | 93.13 |

| Thixoforged AM60B | 7.20 | 92.80 |

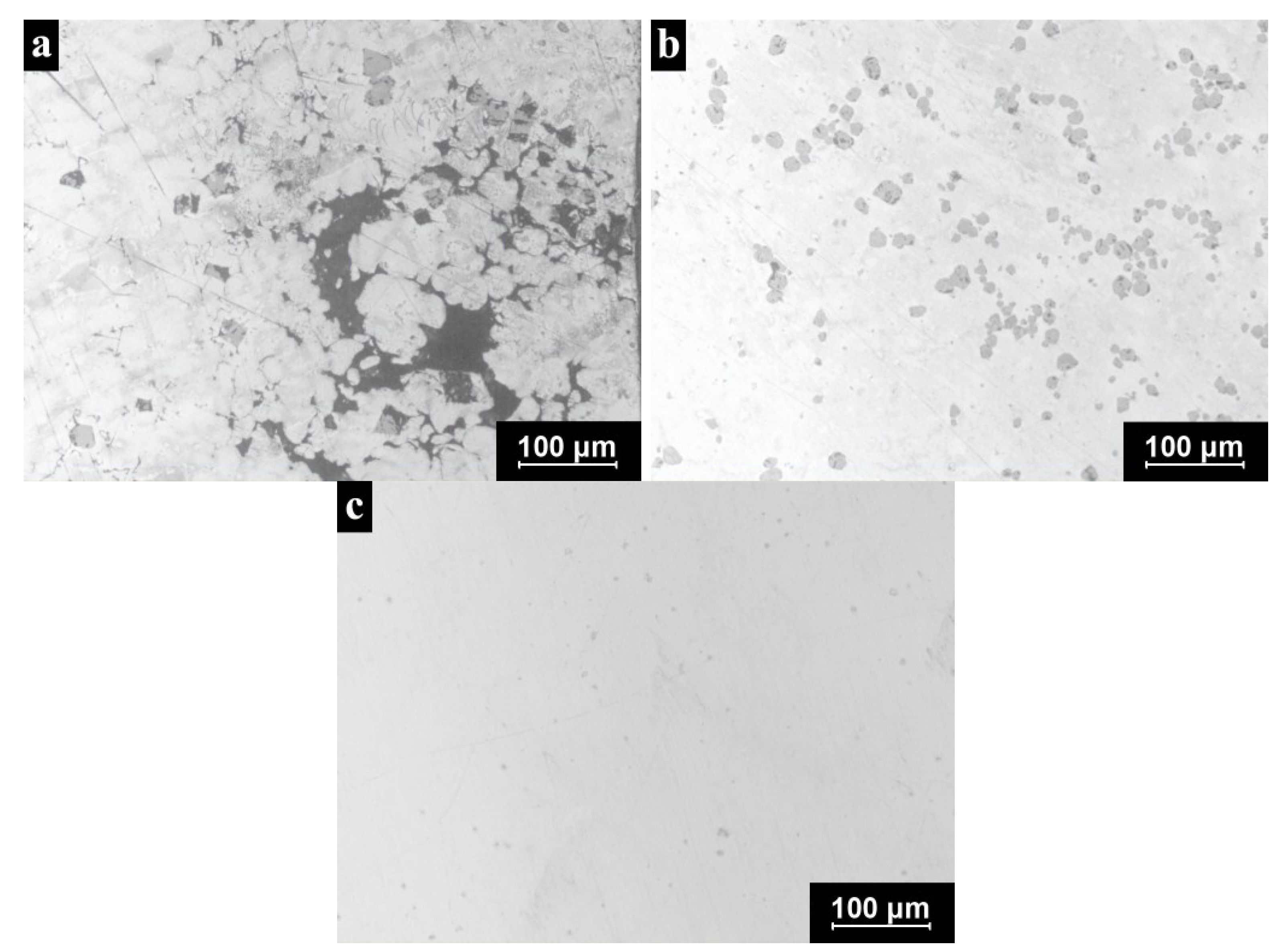

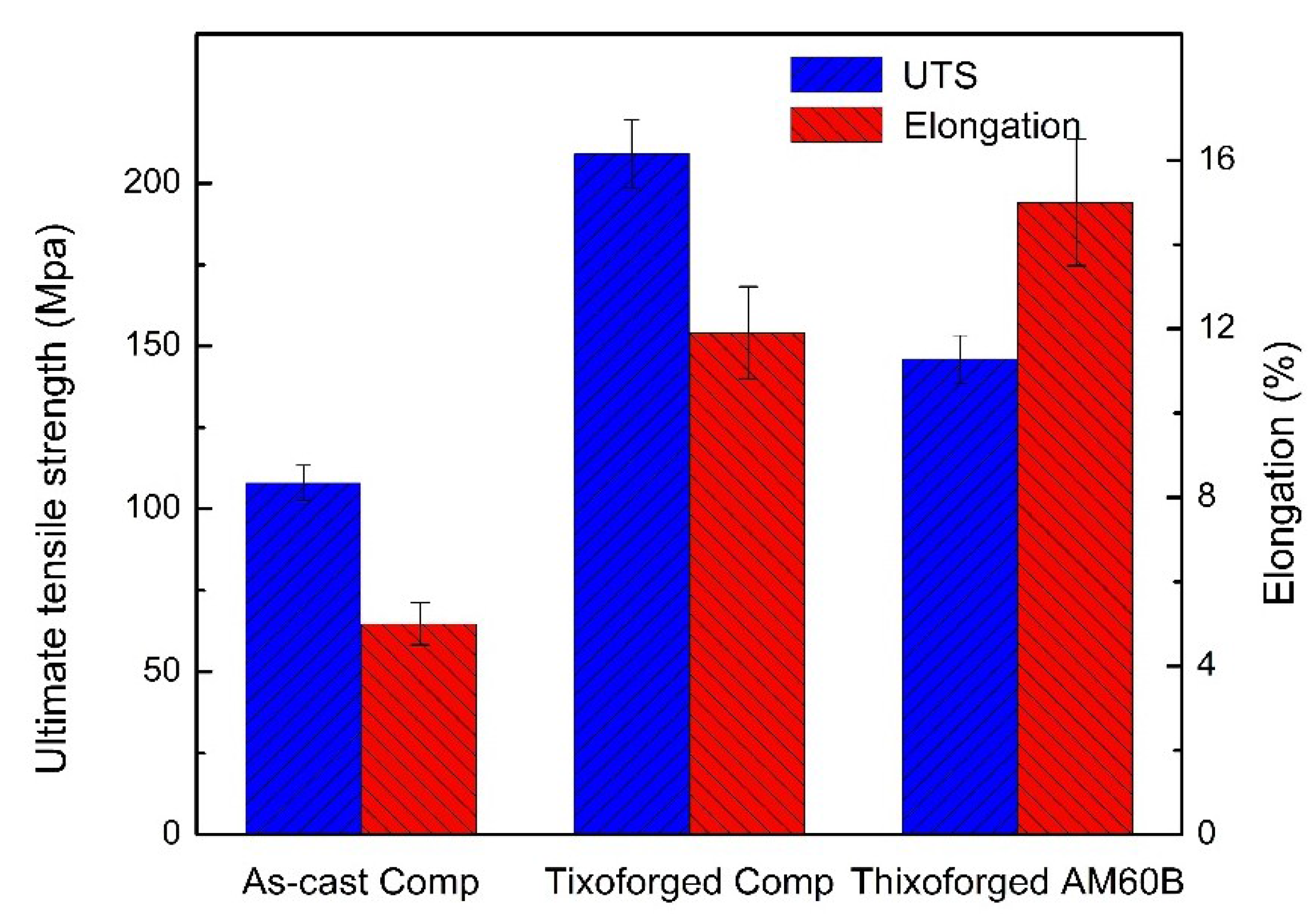

3.3. Tensile Properties

Figure 3 gives the tensile properties of those three materials. It can be evidently seen from

Figure 3 that the UTS of the thixoforged composite is 209 MPa, which is significantly higher than that of the as-cast conditions (108 MPa) and the thixoforged AM60B alloy (146 MPa). However, the elongation of the thixoforged AM60B is 13.3%, which is the maximum value among these three materials. The thixoforged composite has the highest comprehensive tensile properties, UTS of 209 MPa and elongation of 10.2%.

Figure 3.

Tensile properties of the materials at room temperature. UTS, ultimate tensile strength.

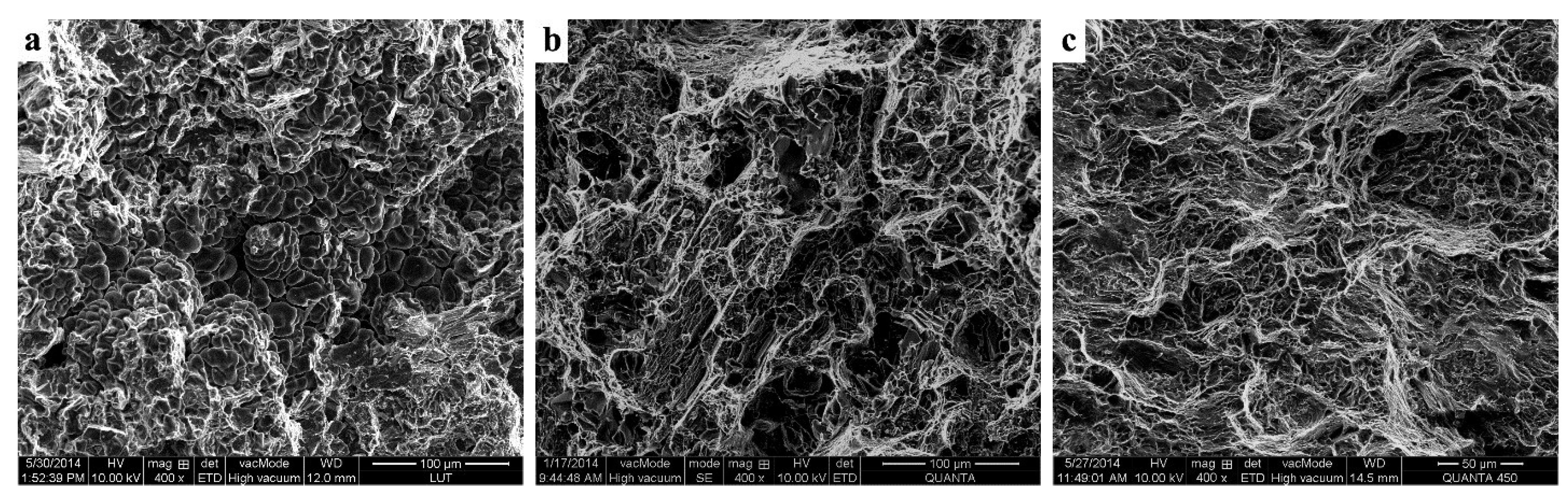

Figure 4 shows the typical fractographs of these three materials. It indicates that the fracture surface of the as-cast composite is characterized by porosity features (

Figure 4a), which are somewhat brittle in nature. As mentioned above, the porosities can be obviously observed from the micrograph of as-cast composite, which should generate in the last solidified zones,

i.e., the eutectic structures between the primary α-Mg dendrites. The porosities serve as the initiation point of cracks in the as-cast specimens. Then, the cracks grow and propagate along the eutectic structures during tensile testing, which is depicted in

Figure 5a. The failure is mainly attributed to the intergranular fracture and is partially caused by the segregation of the brittle eutectic β phase at dendrite boundaries. As described in the previous section, the thixoforged composite is virtually free of gas and shrinkage porosities. Correspondingly, the porosity characteristics on the fracture surface of the thixoforged composite disappear and are substituted by small dimples (

Figure 4b). Plenty of fractured Mg

2Si particles could be observed on the fracture surface. The crack propagation path turns from along the eutectic structures into across the primary α-Mg grains (

Figure 5b, marked by arrows). The failure transfers to the transgranular fracture mode. The resultant fractographs and side-view of the fractured surfaces of both the as-cast and thixoforged composite are in good agreement with the data of tensile properties shown in

Figure 3. It is well established that the tensile properties of the material are determined by their microstructures. Therefore, it is concluded that the elimination of porosity, the decrease of the eutectic β phase and enhancement of solution strengthening are responsible for the superior tensile properties of the thixoforged composite.

Figure 4c illustrates the fracture surface of the thixoforged AM60B alloy, which is characterized by small dimples and flat facets. The dimples result from localized microvoid coalescence, due to the dislocation motion or grain boundary sliding. The microvoids grow and connect, eventually leading to the creation of cracks. The flat facets are caused by cracks moving through the primary α-Mg grains. Cracks propagate between the primary α-Mg grains (marked by A) and occasionally across the primary α-Mg grains (marked by B) in some local zones (

Figure 5c), which is consistent with the fracture surface. The fracture of the thixoforged AM60B belongs to a mixture of transgranular and intergranular modes. The inferior UTS of the thixoforged AM60B should be ascribed to there being no reinforcing phase to strengthen the α-Mg phase. A large amount of eutectic β phase is a harmful effect for UTS. However, the amount of the β phase reduced to a given value may also decrease the UTS, owing to the strengthening role of the β phase being reduced. This is also the same reason that results in the superior elongation of this alloy. However, the adopted technologic parameters (reheating time and temperature, mold preheating temperature,

etc.) in this work are optimum for the thixoforged composite. There may not be optimized parameters for the thixoforged AM60B alloy. It can be reasonably concluded that the tensile properties of the thixoforged AM60B alloy will be further improved through adjusting the technologic parameters. This will be discussed in further work.

Figure 4.

SEM fractographs of: (a) as-cast composite; (b) thixoforged composite and (c) thixoforged AM60B.

Figure 5.

OM images reveal the side-view of the fracture surface: (a) as-cast composite; (b) thixoforged composite; and (c) thixoforged AM60B.

3.4. Strengthening Mechanisms of the Mg2Si Grains

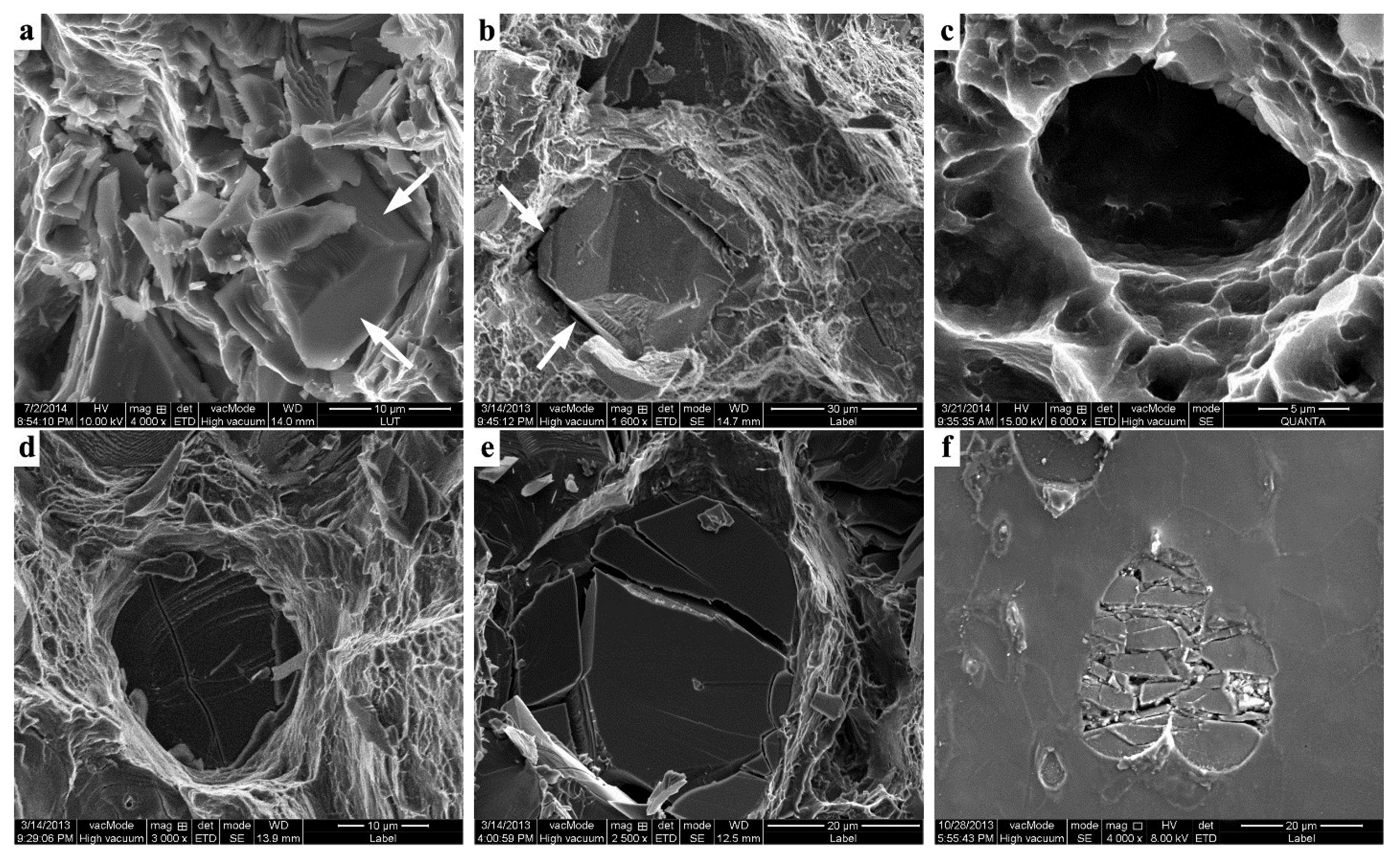

For the purpose of verifying the strengthening mechanism of Mg

2Si particles for the α-Mg matrix, some typical fracture surfaces are carefully observed with high magnification (

Figure 6). Pay attention to the composite in the as-cast condition: the Mg

2Si particles can only be found in some local zone on the fracture surface. The Mg

2Si particles are surrounded by the deformed α-Mg matrix and keep their original morphology (

Figure 6a). During tensile testing, the pin effect of the Mg

2Si particles in the grain boundaries keeps them from sliding. The interfaces of the Mg

2Si

p/matrix belong to an incoherent interface, due to the differences of the crystal structures and the lattice constants [

29]. Therefore, local stress concentration should be preferentially generated at the sharp edges and corners of the Mg

2Si particles. Therefore, the interfaces of the Mg

2Si

p/matrix are easily debonded under this local stress (marked by arrows in

Figure 6a). Subsequently, the debonding areas extend and connect with the cracks, which initiate from the eutectic structure or porosity, eventually leading to the final fracture. Owing to the non-compact microstructure of the as-cast composite, the reinforcement of Mg

2Si particles of the matrix has not fully taken part in the contribution to the improved the tensile properties.

Figure 6.

Typical SEM images showing Mg2Si particles in: (a) as-cast composite; (b–e) the thixoforged composite fracture surface; (f) the thixoforged composite tensile bar.

There are two kinds of failure behaviors related to the Mg

2Si particles, which can be found on the thixoforged composite fracture surface. One is the interfacial debonding of Mg

2Si

p/matrix (

Figure 6b). As mentioned above, the sharp edges and corners become blunt. Therefore, the local stresses are uniformly distributed along the Mg

2Si

p/matrix interfaces and increase as the tensile stress increases. Microvoids should generate in the surrounding matrix under this local stress. Then, the localized microvoids’ coalescence results in the debonding of the interface (

Figure 6c). The other is the fragmentation of Mg

2Si particles. There are two ways for the Mg

2Si particle to fracture: either fractured parallel to the fracture surface of the whole specimen (

Figure 6d) or broken into several parts (

Figure 6e). The composite mainly contains two phases with very different mechanical behaviors: the α-Mg phase and Mg

2Si particles. While the soft magnesium alloy deforms plastically during tensile testing, the Mg

2Si particles are rigid and deform only elastically. The reinforcing Mg

2Si particles prevent the straining of the surrounding matrix. Thus, the composite is plastically non-homogeneous, because the plastic deformation gradient is imposed on the Mg

2Si

p/matrix interfaces. Therefore, a high stress concentration generates at the interface and gives rise to the increase of tensile strain. The existing investigation supposed that the stress concentration was two- to four-times higher than that of the α-Mg matrix [

30]. When the stress concentration exceeds some value, this should even result in the fragmentation of Mg

2Si particles (

Figure 6d,e).

Figure 6f reveals that the Mg

2Si particles split into several parts and that there are no visible cracks in the surrounding matrix. The interfacial debonding and particle fragmentation are the indications of the absorption of energy and the relaxation of local stress concentration. This is just due to the formation of local stress concentration at the Mg

2Si/matrix interface and the subsequent relaxation; the growth rate and nucleation of the crack in the surrounding matrix are delayed. Thus, the strengthening of the Mg

2Si particles of the matrix should primarily be the result of the load transfer mechanism. The particle splitting and interfacial debonding are the main damage patterns of the composite.

The contribution of Mg

2Si particles to improving the mechanical properties should also be attributed to other mechanisms. One is the Orowan looping mechanism, which is described as the interaction between dislocations and fine particles: the resistance of the reinforcing particles to the passage of dislocations from a balance between the force acting on the dislocation and the force coming from the line tension acting on both sides of the reinforcing particle [

31]. However, this mechanism is only effective in action when the reinforcing particles are located within the grains. In the composite employed in this work, the Mg

2Si particles are mainly located at the boundaries of primary α-Mg grains and occasionally located inside of them. Therefore, the strengthening effect due to the Orowan mechanism will be minor. The other is the dislocation strengthening mechanism, which results from the coefficient of thermal expansion (CTE) mismatch between Mg

2Si particles and the matrix: dislocations are created, due to the relaxation of thermal expansion mismatch between reinforcing particles and matrix, and may cause an increase in the dislocation density [

32]. This effect can impede the dislocation movement, also playing a very important role in strengthening the matrix.

Although the contribution of each strengthening mechanism to improving the mechanical properties has not been calculated separately, it should also be believed that an additive or synergetic effect probably occurs by combining several mechanisms. Among them, the load transfer mechanism should primarily take part in strengthening the matrix, and the Orowan looping mechanism and dislocation strengthening mechanism should be minor.