1. Introduction

With the continuous increase in speed of high-speed train, the material widely used is high-aluminum alloy because of its lightweight and higher strength and good fatigue properties [

1,

2]. The gearbox of high-speed train is one of the important parts of its drive system, and is of great importance for operation safety of high-speed train. High-strength aluminum alloy A356, a key material of the gearbox, which has excellent properties of rigidity, strength, ductility, fatigue, casting, and shrinkage tendency [

3]. At present, the development of this material has almost been completed, but performance analysis of service process has not been done [

4,

5]. As the operational safety is important for transportation purposes, a method of non-destructive and real-time detection for the material is urgently required.

Traditional method for materials research is microscopic observation, but this method is always accompanied by destructive testing and not in real time. Among the common non-destructive method such as acoustic emission (AE), X-ray and ultrasound, AE is a dynamic non-destructive testing method and not limited by materials [

6]. Lugo

et al. [

7] studied the damage evolution in a 7075 aluminum alloy by using acoustic emissions to quantify the evolution of damage, but their research is based on the destructive experiment. Behrens

et al. [

8] presented an approach for online crack detection during cold forging of steel components using the acoustic emission technique, but the data was obtained by off-line laboratory experiments. Han

et al. [

9] investigated the effects of the change in macro-structures due to heat treatment and weld on fatigue and corresponding acoustic emission behaviors of Q345 steels, but they only considered AE counts possibility in their work. Maillet

et al. [

10] used an energy-based procedure to select AE events generated by damage in composite materials, but it was only appropriate for the composite materials and the AE signal of metal materials is different. Therefore, the technical feasibility and relative analysis method of the AE method used for non-destructive testing should be further studied especially in real-time detection and characterization for materials.

Material performance degradation is an important direction for life prediction and service safety assessment. Since the structural dimension and the whole life degradation data are difficult to be achieved in limited time and cost, the method of performance degradation can be used. In a service process, although the direct degradation data cannot be achieved, the indirect degradation data such as strength, amplitude and event count can be detected and used to characterize the degradation process. Recorded data at different times can be analyzed and used to establish failure threshold and degradation model. By extrapolation, it can also be used to estimate the remaining life of structural material before failure. Roca

et al. [

11,

12] used neural networks and acoustic emission signals to estimate the stability of gas metal arc welding (GMAW) process, and it is a good method to analyze the AE signals, although the characteristics of AE signal of high-speed train gearbox shell is different from that of GMAW. Cholette

et al. [

13] presented a novel data-driven degradation modeling and monitoring methodology based on hidden Markov models; but the method needs a large data set. Hong

et al. [

14] put forward a novel performance degradation assessment method based on ensemble empirical mode composition and Gaussian mixture model, however, their data was not in real-time. Savage

et al. [

15] investigated a methodology to provide the cumulative failure distribution for degrading, uncertain, and dynamic systems, but this uncertainty method was not appropriate for engineering applications. Dobrica

et al. [

16] developed a hydrodynamic model to simulate the operation of scratched journal bearings, but the parametric study presented in their paper corresponds to a particular journal bearing configuration. Presently, there is still no life prediction data and the traditional testing method, which is expensive and time-consuming for high-speed train gearbox materials.

The aim of this work is to investigate the tensile damage of gearbox shell material of the high-speed train using an AE detection system. The AE system was implemented to obtain the AE signals during the tensile test process, and relative analysis method was then used to determine the performance degradation characteristic parameters and failure criteria.

2. Materials and Methods

2.1. Materials Tensile Damage

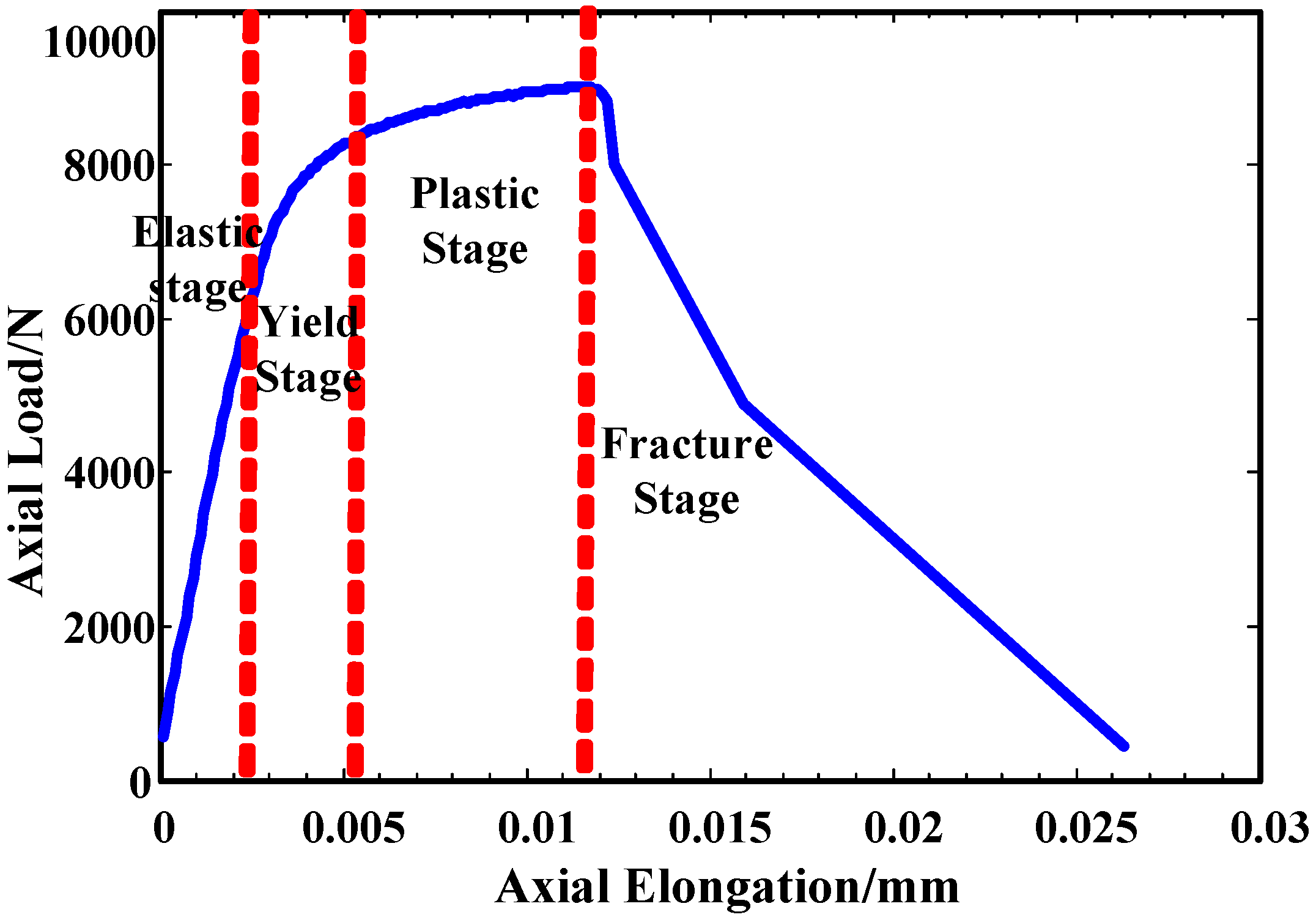

The results of the tensile test process of ductile metallic materials can be divided into four stages as elastic, yield, plasticity and fracture [

17]. These four stages depend on the different characteristics of the tensile test process as identified on the axial load-axial elongation curve of the materials studied which is shown in

Figure 1. Based on the axial load-axial elongation curve, according to different characteristics of the four stages of tensile process, the four stages can be clearly divided.

Figure 1.

The axial load-axial elongation curve and four stages of tensile process.

Elastic stage: the material deformation is elastic, and the force and elongation is proportional. If withdraw the force, the elongation disappears, and no residual elongation.

Yield stage: In this stage, a lot of dislocation and metal bond cleavage occurs inside the metal material, the plastic deformation begins, which accompanied by a large number of acoustic emission phenomena [

18].

Plastic deformation stage: the material is deformed under the action of external forces, and when the external force is removed, the original material cannot be recovered.

Fracture stages: stress increased while strain decreased, and the material eventually fractured.

For the material service, when the material is in the elastic stage, it is considered safe. When the material enters the yield stage, final fracture will be attained quickly. In this paper, the transition point from elastic stage to yield stage is the failure point of the tensile process.

2.2. Acoustic Emission Technology

Material deformation and crack propagation under stress are an important mechanism of structural failure. Acoustic Emission (AE) is a phenomenon of rapid release of energy and generation of transient elastic wave from a localized source of the material. This elastic wave is also known as the stress wave emission [

18]. The elastic wave emitted from the sound emission source can reach the surface of the material, and can cause the displacement which can be detected by acoustic emission sensors. The mechanical vibration of the material which is caught by the detectors is converted to an electrical signal, is then amplified, processed and recorded.

AE instrument with high sensitivity can detect micro crack propagation with the change of micrometer. AE diagnostic methods are used to diagnose the crack generation and propagation due to plastic deformation, fatigue and wear. Acoustic emission parameter analysis method is used to analyze and interpret AE signal based on waveform characteristics of the acoustic emission signal. Commonly used parameters of AE are energy, ring-down count, duration, amplitude, effective voltage and so on. For the same acoustic emission source, these parameters are correlated.

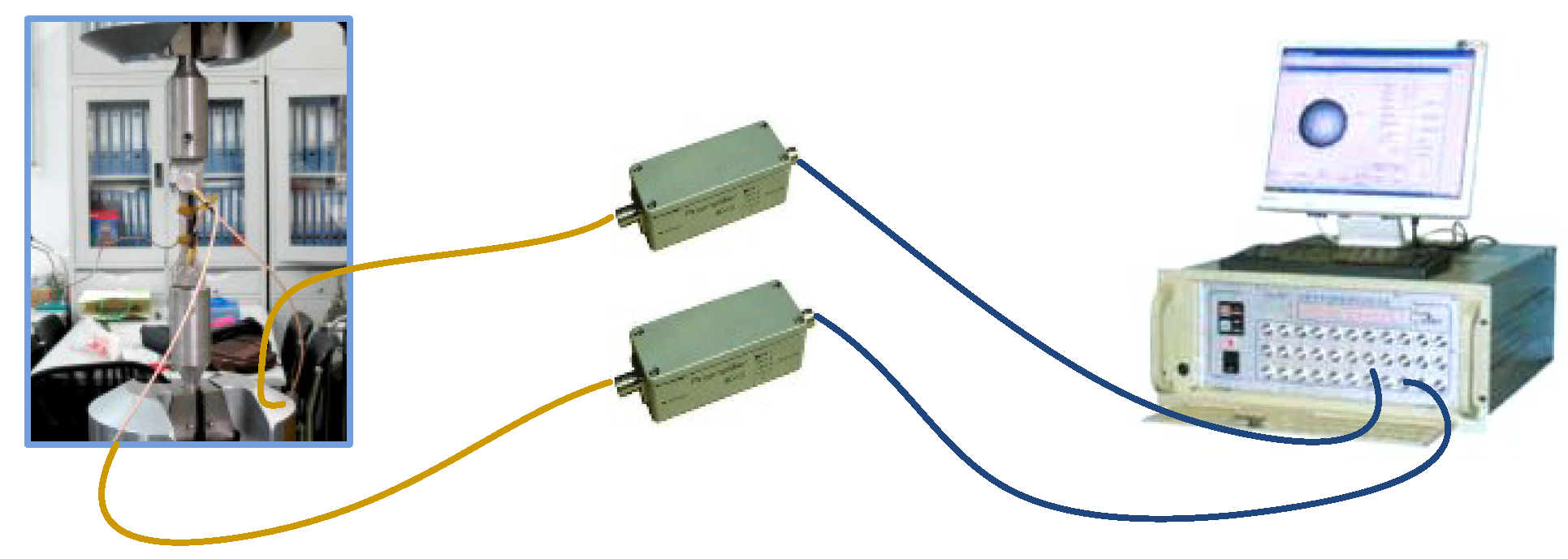

2.3. System of Tensile Test with Acoustic Emission Instrument

The system of tensile test with acoustic emission testing includes tensile testing machine, acoustic emission instrument and workstation. The acoustic emission probes are fixed on the test samples. When tensile testing machine is working, acoustic emission instrument is synchronously triggered. The acoustic emission instrument parameters can be adjusted through the workstation, and the acoustic emission signals are stored.

Figure 2 shows the tensile test system with acoustic emission instrument.

Figure 2.

The system of tensile test with acoustic emission instrument.

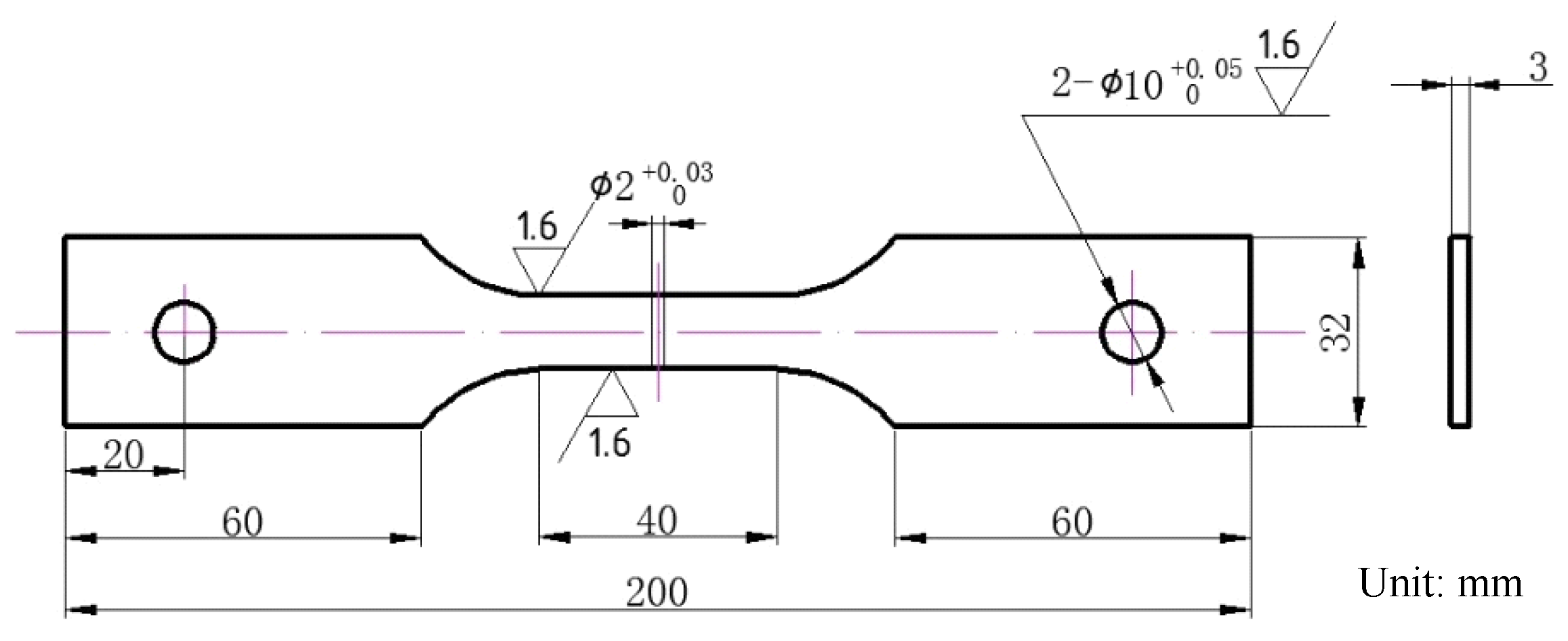

Material tensile is performed on MTS810 material testing machine, MTS632.12C-20. The strain rate was 10

−4/s and test environment was 27 °C and 40% RH. Three test samples were cut from the gearbox shell, and the parameters of sample size are shown in

Figure 3.

Figure 3.

The sample size of aluminum alloy.

Acoustic emission instrument used in the test was SAMOS acoustic emission system of PAC Company. The sensors type was R15A; resonant frequency was 150 kHz; pre-gain amplifier was 40 dB; threshold was 45 dB; peak identification time (PDT) was 300 µs; impact identification time (HDT) was 600 µs; hit lockout time (HLT) was 1000 µs; sampling frequency was 1 MHz; and the crash file length was 2 kB.

3. Results and Discussion

3.1. Characteristic of AE Signal for the Tensile Test Process

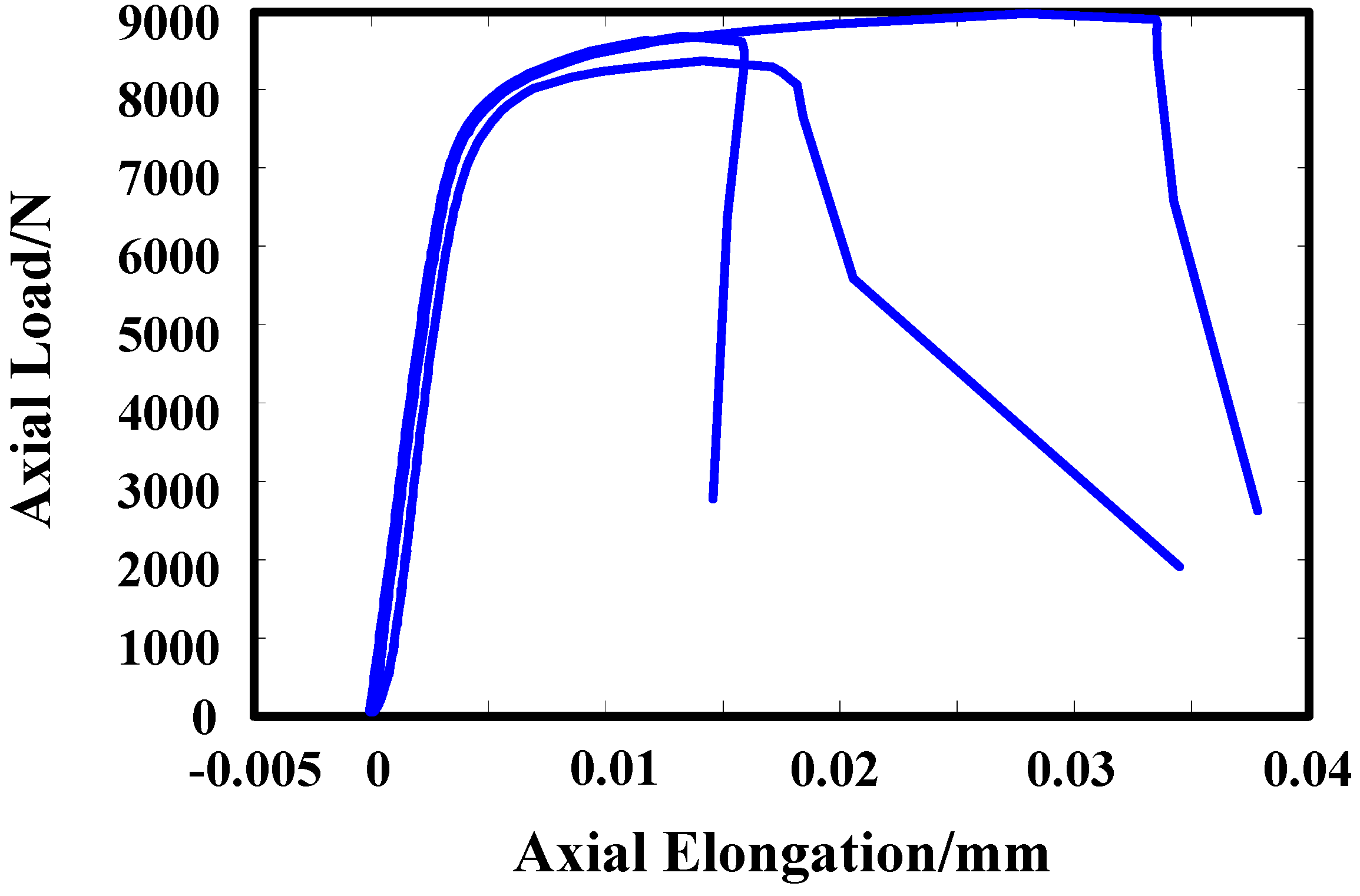

Form

Figure 4, the axial load-axial elongation curves of multiple samples are drawn in a graph. It can be seen that although there are some differences in the axial load-axial elongation curves, the transition point from elasticity to yield is more concentrated. It indicated that this process is of high reproducibility and consistent rules, so it is available to use statistical analysis method to develop the research.

Figure 4.

The axial load-axial elongation curve of multiple samples.

In the same tensile process, the AE signal and axial elongation were shown in

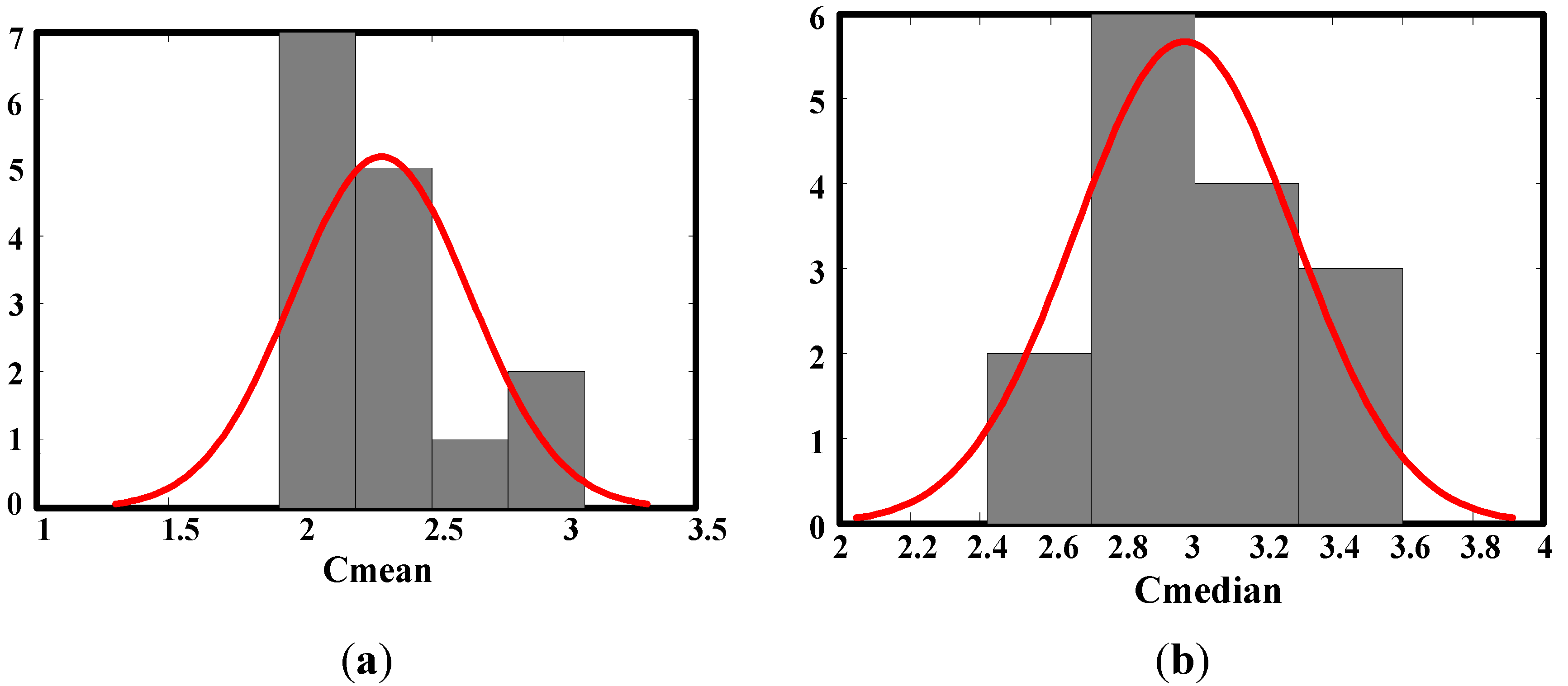

Figure 5. It can be seen that the AE signals increased significantly at the point from the elastic stage to the yield stage, so the AE signals can characterize the process from the elastic stage to the yield stage of the material tensile damage. But the AE signal boundary between elastic stage and yield stage is not clear, and the AE signals of different samples have the same tendency but different values. The point from the elastic stage to the yield stage cannot be determined by using actual measured AE signals. But the characteristic of the AE signals of different samples at the point are having statistical regularity, and it is considered appropriate to use statistical analysis method to find the characteristic parameters of the material performance degradation.

Figure 5.

Acoustic emission (AE) signal and axial elongation curve. (a) Ring-down count and axial elongation curve; (b) Energy and axial elongation curve.

4. Conclusions

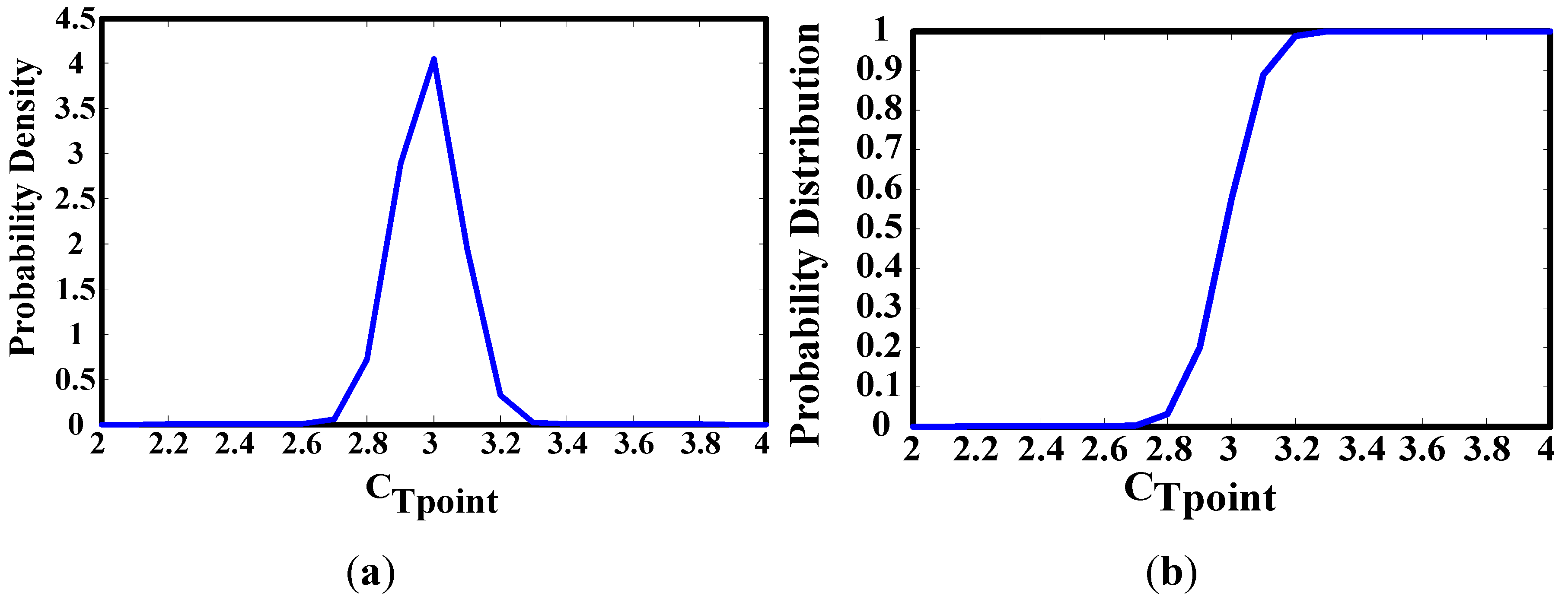

In this paper, the acoustic emission instrument was used for the performance degradation research of tensile damage of a high-strength aluminum alloy. Through data analysis and transformation of AE signals, the characteristics parameter of the material performance degradation Cmedian has been determined, the failure criteria of the material performance degradation has been developed and obeyed normal distribution N (μmedian,

).

This result will provide basic research for further life prediction research.

The material researched in this paper is used for the gearbox shell of high-speed train. This research will provide non-destructive and real-time performance degradation analysis as a new method and approach, and also provide a new application background of the acoustic emission instrument. The result of this work expected to be widely used in other material performance degradation.