Microstructure and Mechanical Properties of Arc Zone and Laser Zone of TC4 Titanium Alloy Laser–TIG Hybrid Welded Joint

Abstract

:1. Introduction

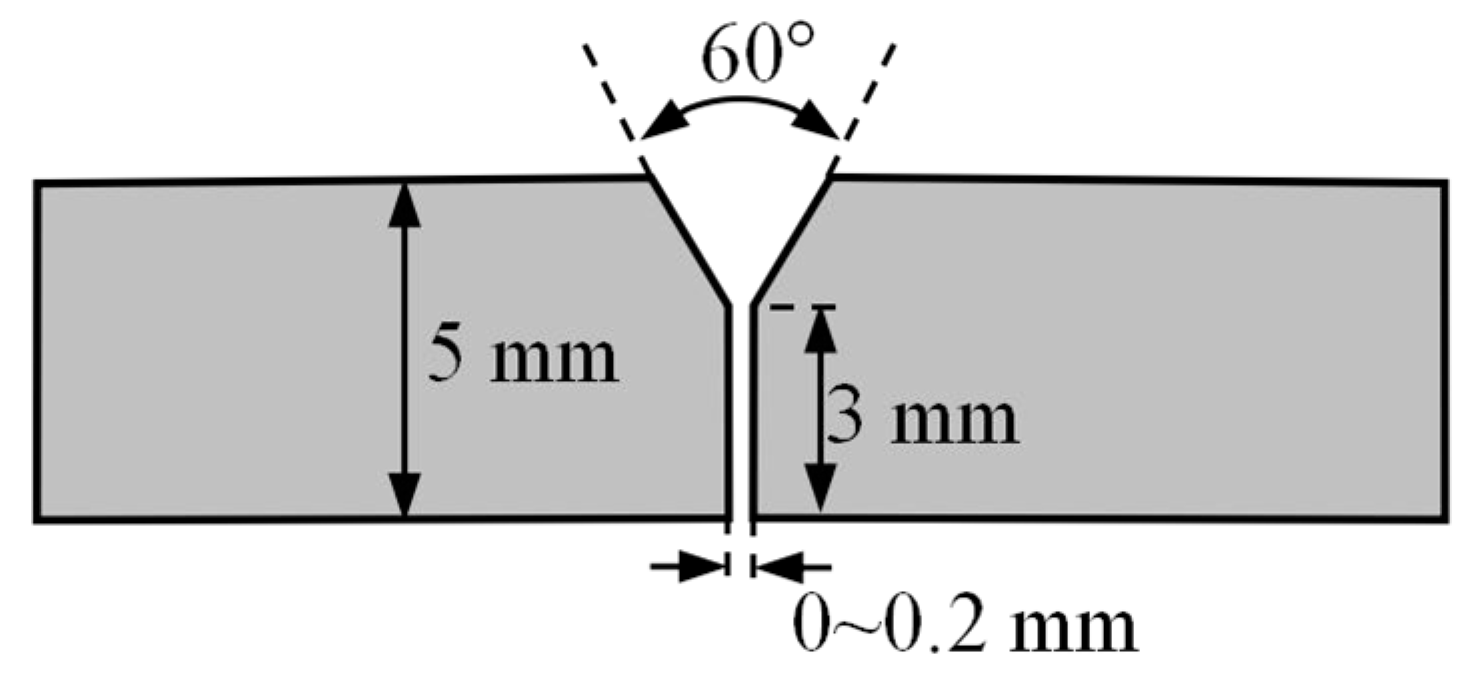

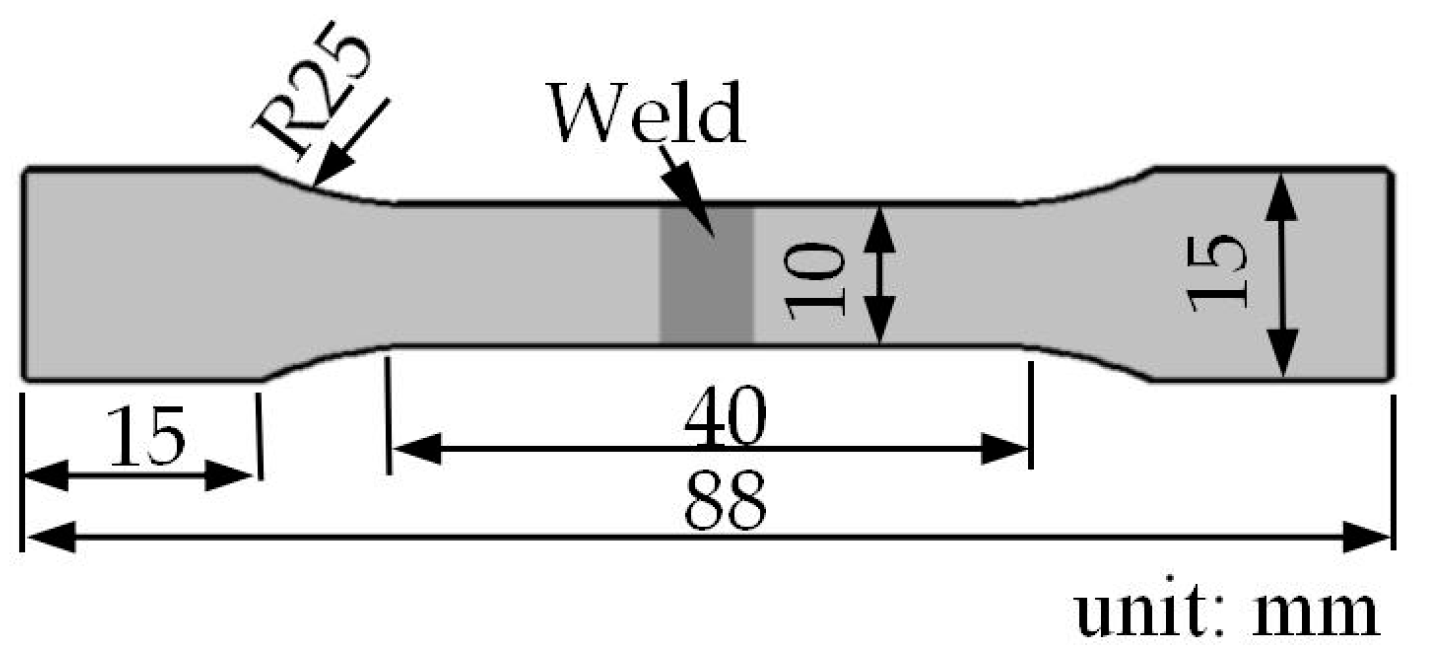

2. Experimental Processes

3. Results and Analysis

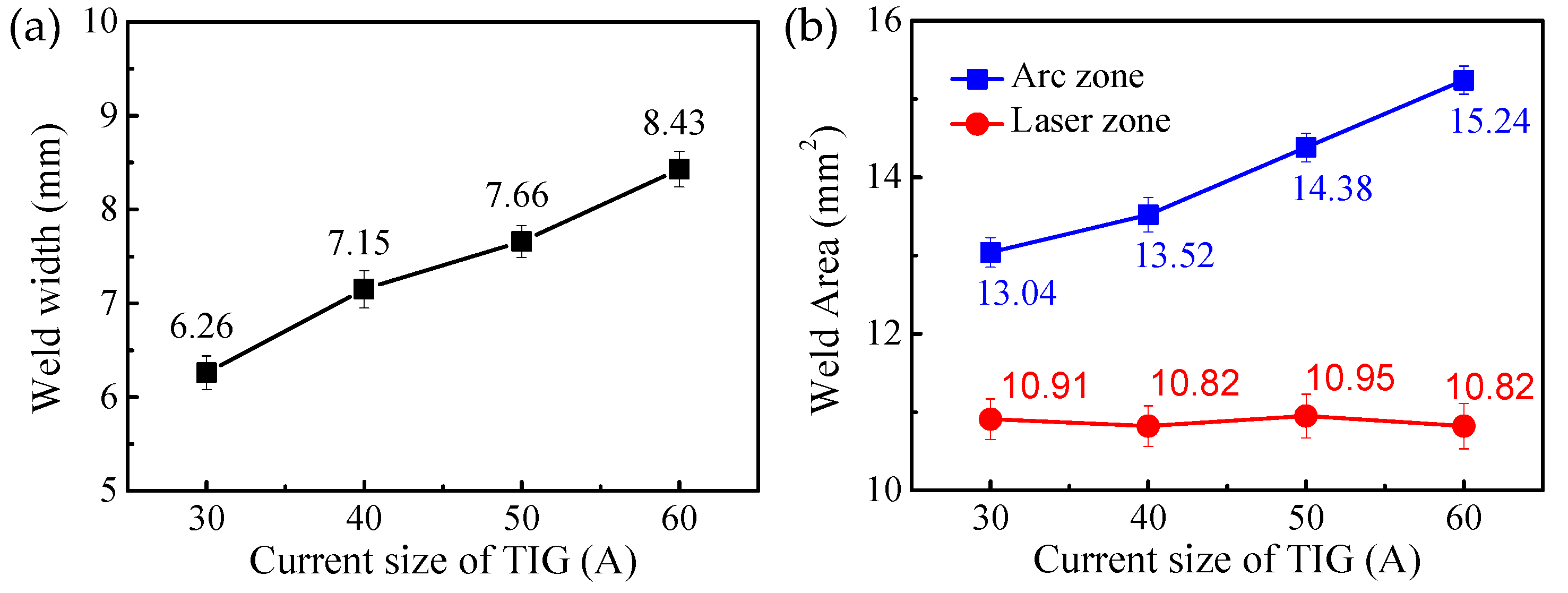

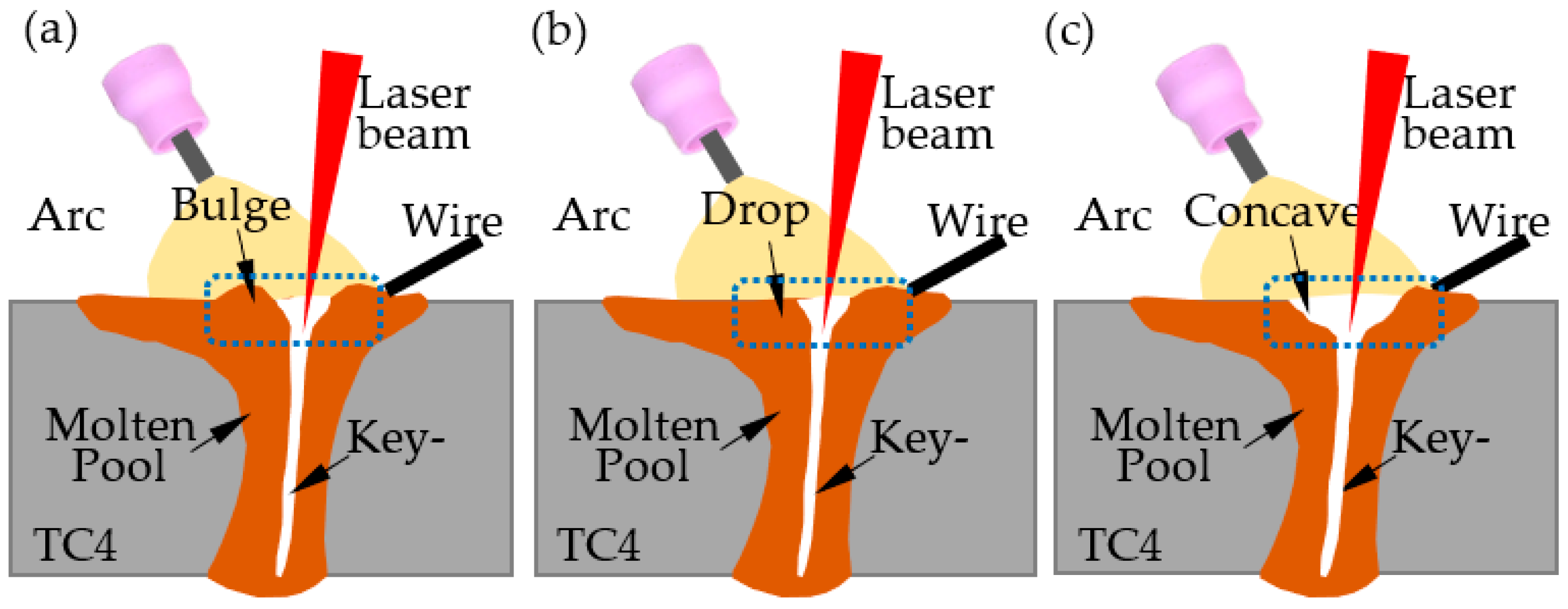

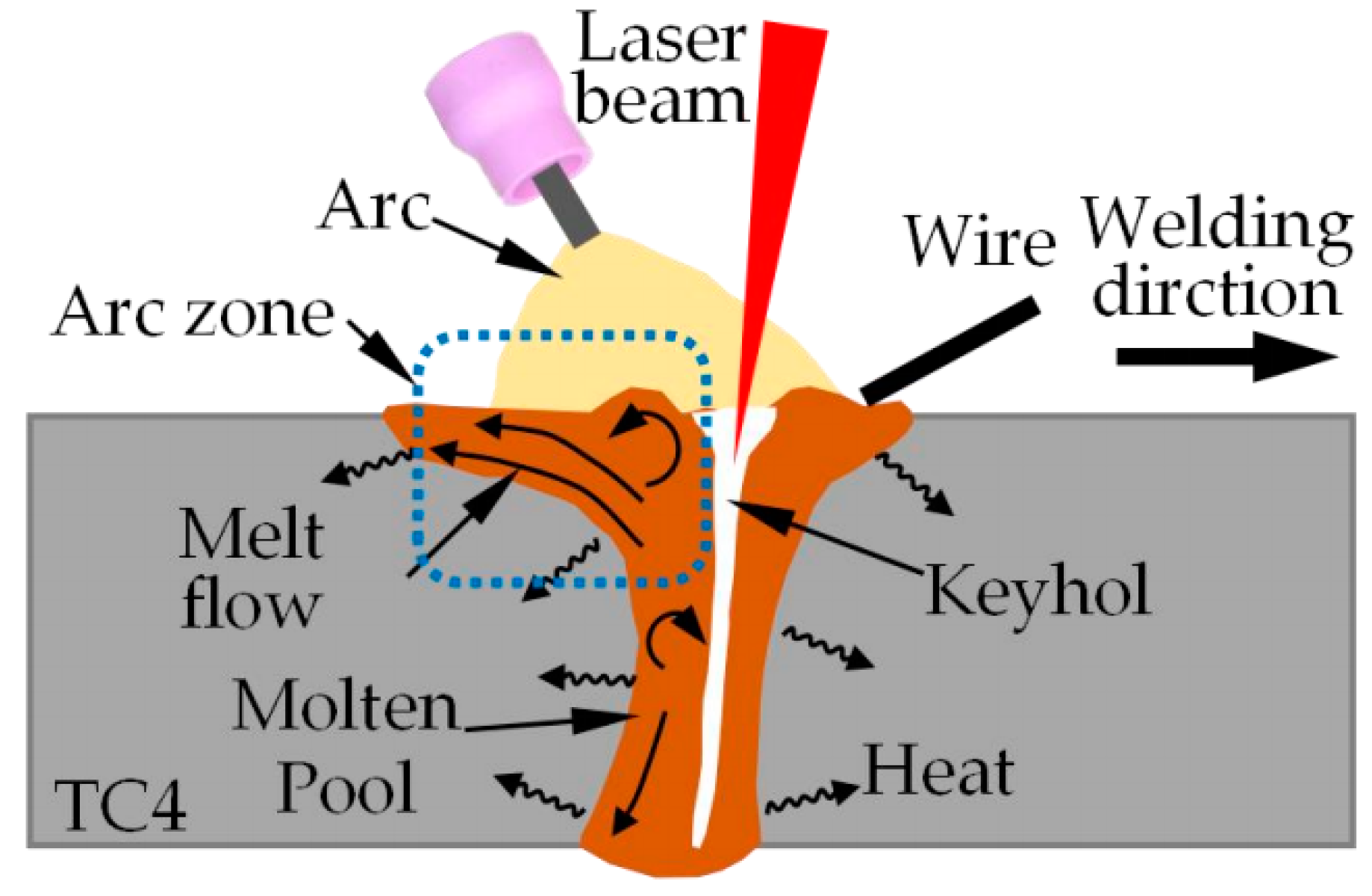

3.1. Effect of Current Size on Welding Formation

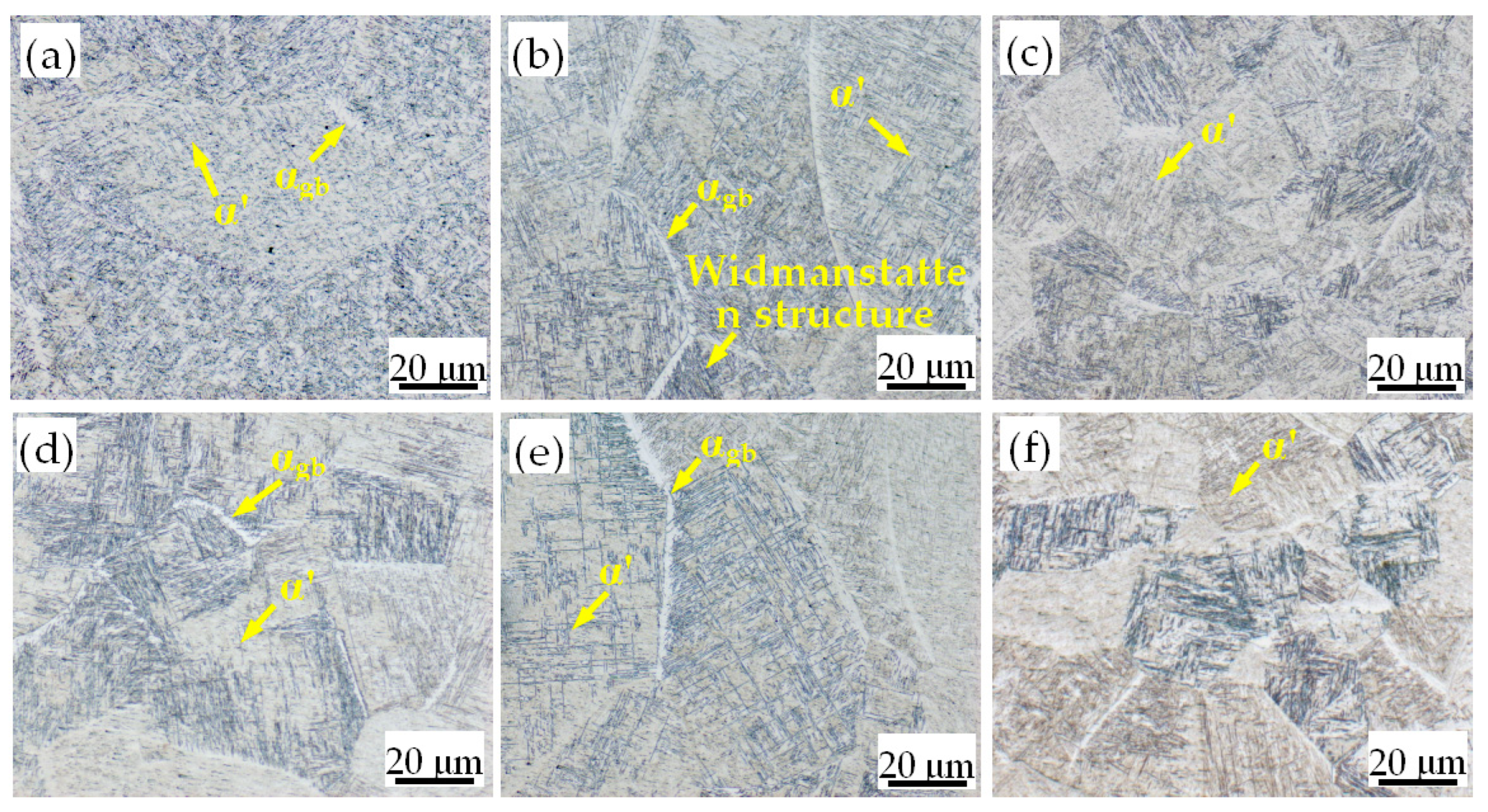

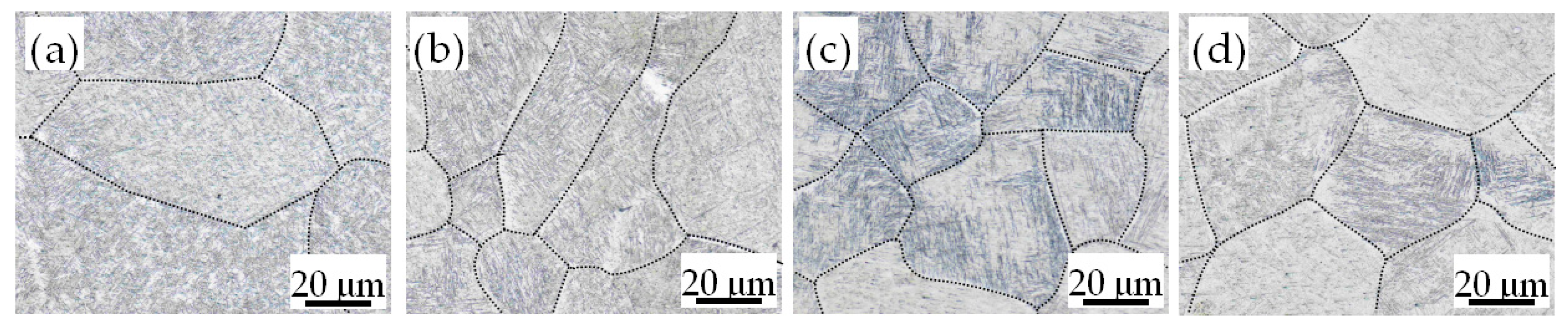

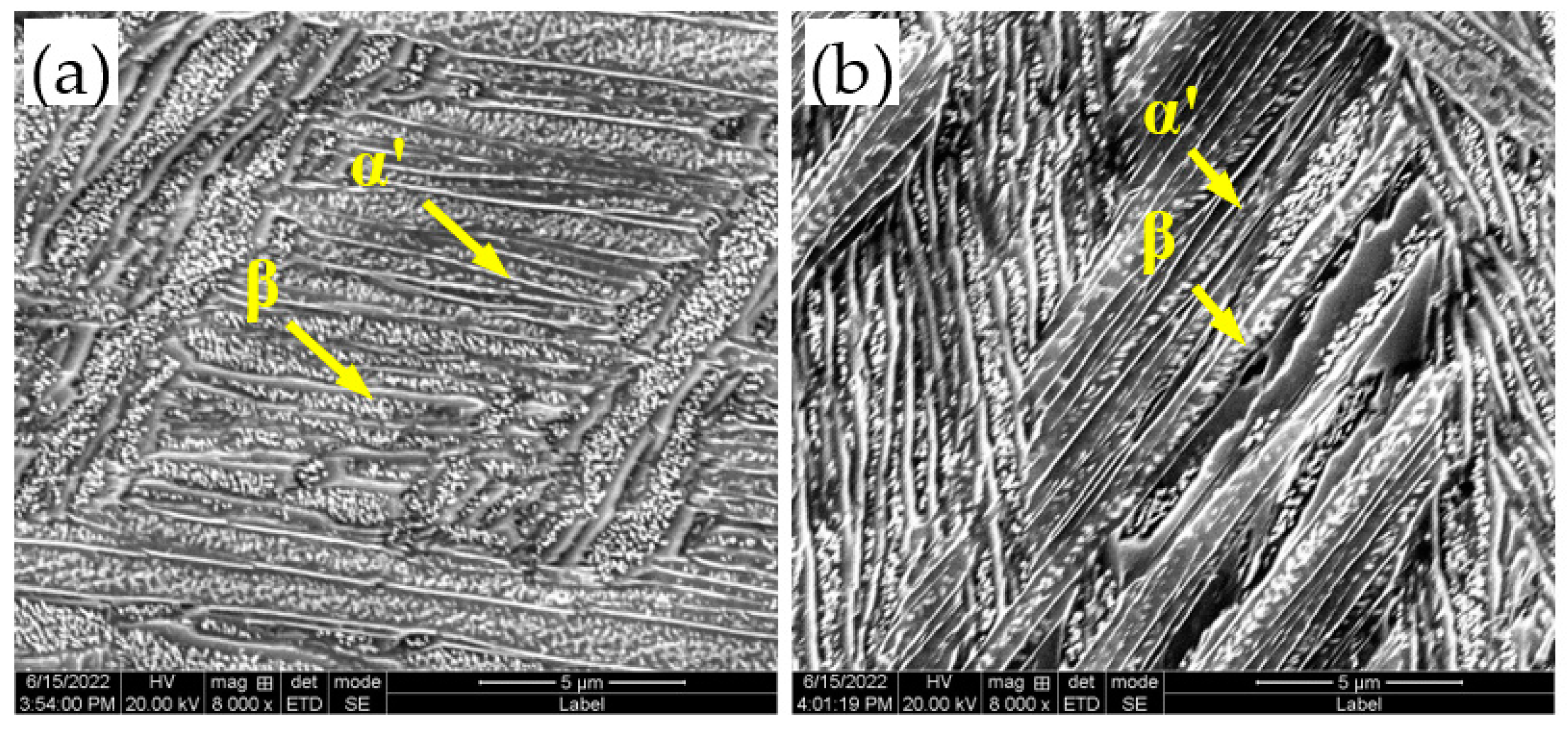

3.2. Effect of Current Size on Microstructure

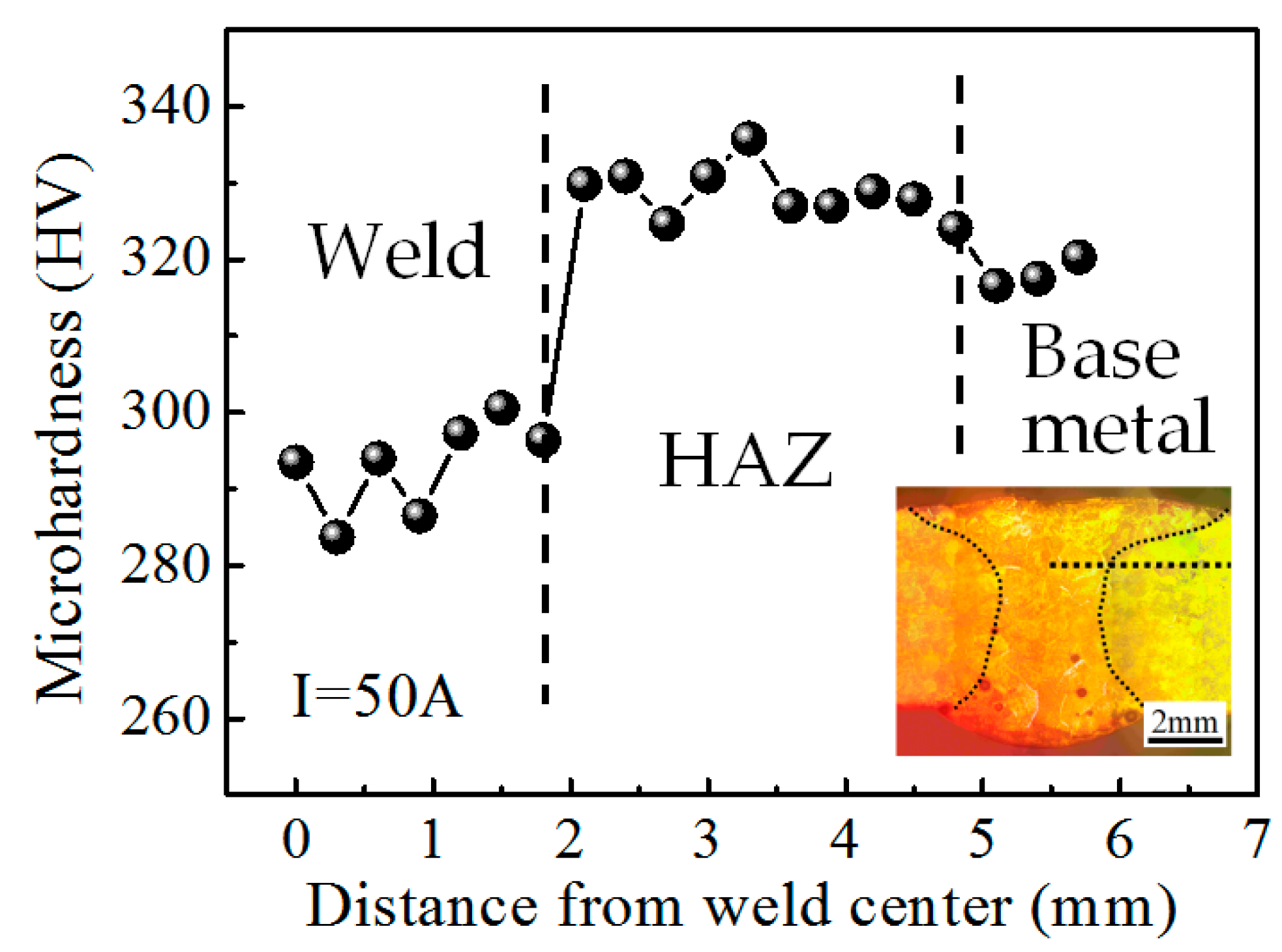

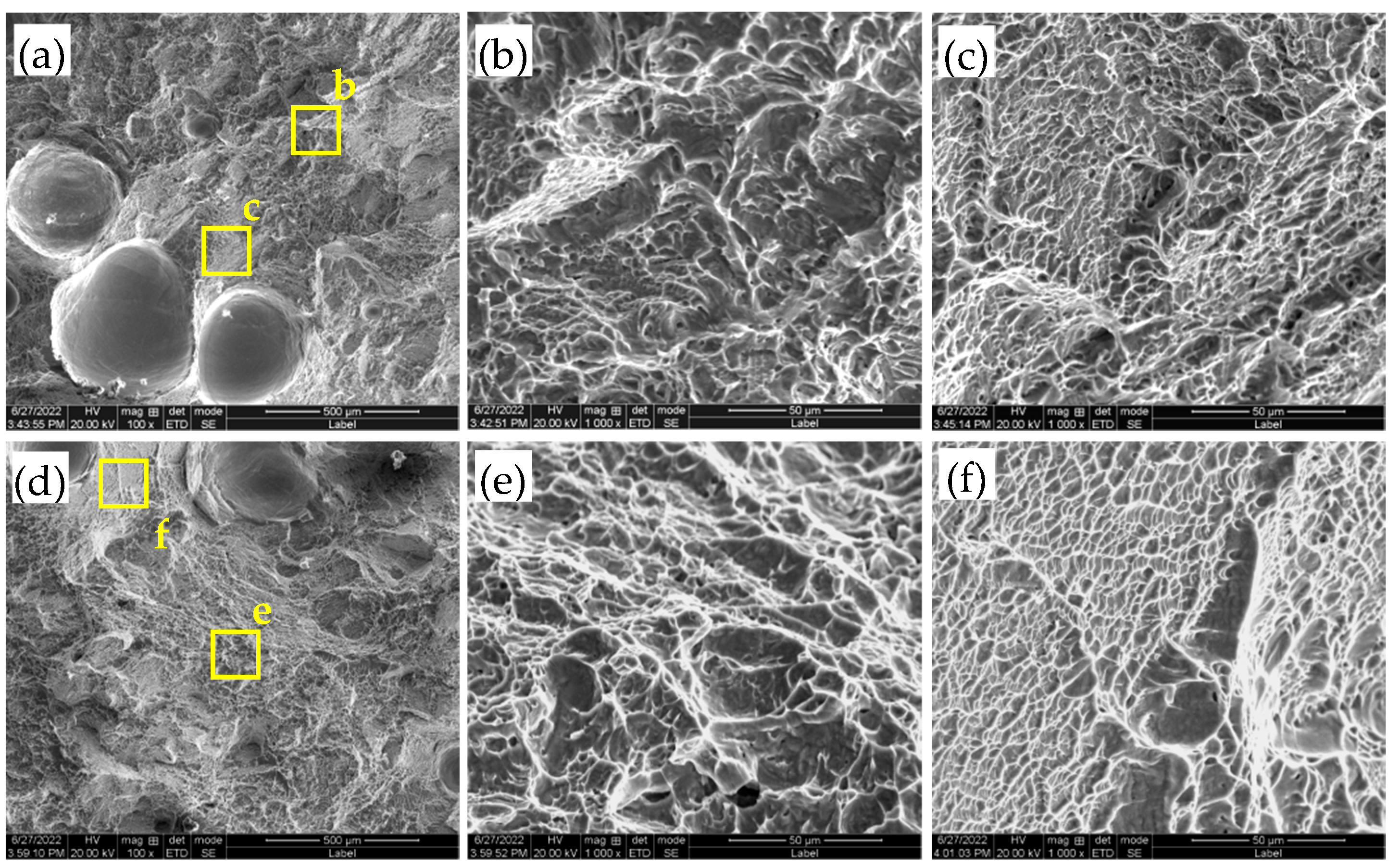

3.3. Mechanical Properties of Welded Joints

4. Discussion

5. Conclusions

- (1)

- As the current increases, the cross-section of the weld gradually changes from a "nail" shape to a "cup" shape. The molten pool in the arc zone will generate a flow with a period of 2 ms, which will have the effect of grain refinement and eliminate pores in the arc zone, so the flow will become more intense as the current increases.

- (2)

- The grain size of the arc zone is smaller than that of the laser zone. The two zones are mainly composed of an acicular α′ martensite interwoven mesh-basket structure, αgb phase, and Widmanstätten structure. The spacing of the α′ martensite beams in the laser zone is narrower, with an average spacing of 0.41 μm.

- (3)

- The β phase increases gradually with an increase in the current, which will lead to a downward trend in the average hardness of both zones. The average hardness value of the laser zone containing more α′ martensite and less β phase is slightly higher than that of the arc zone. The hardness uniformity of the laser zone is also significantly better than that of the arc zone. The tensile strength of the joint shows a trend of increasing first and then decreasing, and the joint with I = 50 A presented the highest tensile strength of 957.3 MPa, approaching 100% of the base metal, and fractured in the fusion zone.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ding, R.; Guo, Z. Microstructural evolution of a Ti–6Al–4V alloy during β-phase processing: Experimental and simulative investigations. Mater. Sci. Eng. A 2004, 365, 172–179. [Google Scholar] [CrossRef]

- Liu, J.; Alfantazi, A.; Asselin, E. A new method to improve the corrosion resistance of titanium for hydrometallurgical applications. Appl. Surf. Sci. 2015, 332, 480–487. [Google Scholar] [CrossRef]

- Huang, J.; Liu, S.; Yu, S.; Yu, X.; Chen, H.; Fan, D. Arc deposition of wear resistant layer TiN on Ti6Al4V using simultaneous feeding of nitrogen and wire. Surf. Coat. Technol. 2020, 381, 125141. [Google Scholar] [CrossRef]

- Fang, N.; Guo, E.; Huang, R.; Yin, L.; Chen, Y.; Zeng, C.; Cao, H.; Zou, J.; Xu, K. Effect of welding heat input on microstructure and properties of TC4 titanium alloy ultra-narrow gap welded joint by laser welding with filler wire. Mater. Res. Express 2021, 8, 016511. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Gao, M.; Zeng, X. Stabilization mechanism and weld morphological features of fiber laser-arc hybrid welding of pure copper. J. Manuf. Process. 2017, 27, 207–213. [Google Scholar] [CrossRef]

- Bagger, C.; Olsen, F.O. Review of laser hybrid welding. J. Laser Appl. 2005, 17, 2–14. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Y.; Li, Q.; Wu, A.; Zhu, R.; Wang, G. Effects of welding condition on weld shape and distortion in electron beam welded Ti2AlNb alloy joints. Mater. Des. 2017, 114, 226–233. [Google Scholar] [CrossRef]

- Panwisawas, C.; Perumal, B.; Ward, R.M.; Turner, N.; Turner, R.P.; Brooks, J.W.; Basoalto, H.C. Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: Experimental and modelling. Acta Mater. 2017, 126, 251–263. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Zhou, Y.; Liu, L. Application of pulsed laser-TIG hybrid heat source in root welding of thick plate titanium alloys. Appl. Sci. 2017, 7, 527. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Gao, M.; Wang, D.; Yin, J.; Zeng, X. Relationship between pool characteristic and weld porosity in laser arc hybrid welding of AA6082 aluminum alloy. J. Mater. Process. Technol. 2017, 240, 217–222. [Google Scholar] [CrossRef]

- Chen, M.; Xin, L.; Zhou, Q.; He, L.; Wu, F. Effect of laser pulse on alternative current arc discharge during laser-arc hybrid welding of magnesium alloy. Opt. Laser Eng. 2018, 100, 208–215. [Google Scholar] [CrossRef]

- Frostevarg, J.; Kaplan, A.F.H. Undercuts in laser arc hybrid welding. Phys. Procedia 2014, 56, 663–672. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Feng, J.; Li, L.; Chang, S.; Ma, G. Microstructure and mechanical properties of a thick-section high-strength steel welded joint by novel double-sided hybrid fibre laser-arc welding. Mater. Sci. Eng. A 2013, 582, 284–293. [Google Scholar] [CrossRef]

- Li, G.; Zhang, C.; Gao, M.; Zeng, X. Role of arc mode in laser-metal active gas arc hybrid welding of mild steel. Mater. Des. 2014, 61, 239–250. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Leo, P.; Benyounis, K.Y.; Olabi, A.G. Study on arc and laser powers in the hybrid welding of AA5754 Al-alloy. Mater. Des. 2014, 61, 191–198. [Google Scholar] [CrossRef]

- Faraji, A.H.; Goodarzi, M.; Seyedein, S.H.; Maletta, C. Effects of welding parameters on weld pool characteristics and shape in hybrid laser-TIG welding of AA6082 aluminum alloy: Numerical and experimental studies. Weld. World 2016, 60, 137–151. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, H.; Hu, J.; Yan, S. Microstructure of laser-MAG hybrid welds of sintered P/M steel. J. Mater. Eng. Perform. 2013, 22, 251–257. [Google Scholar] [CrossRef]

- Liu, F.; Tan, C.; Ma, G.; Han, X.; Chen, B.; Song, X.; Zhao, H.; Wang, G. Improvement of inhomogeneity of microstructure and mechanical properties for 316 stainless steel laser-MIG hybrid welded joint assisted by alternating magnetic field. Sci. Technol. Weld. Joining 2022, 27, 437–445. [Google Scholar] [CrossRef]

- Fang, N.; Guo, E.; Xu, K.; Huang, R.; Ma, Y.; Chen, Y.; Yang, Y.; Xie, J. In-situ observation of grain growth and phase transformation in weld zone of Ti-6Al-4V titanium alloy by laser welding with filler wire. Mater. Res. Express 2021, 8, 056507. [Google Scholar] [CrossRef]

- Fu, Y.; Guo, N.; Zhu, B.; Shi, X.; Feng, J. Microstructure and properties of underwater laser welding of TC4 titanium alloy. J. Mater. Process. Technol. 2020, 275, 116372. [Google Scholar] [CrossRef]

- Long, J.; Zhang, L.; Zhang, L.; Wu, J.; Zhuang, M. Comparison of fatigue performance of TC4 titanium alloy welded by electron beam welding and laser welding with filler wire. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 991–1004. [Google Scholar] [CrossRef]

- Frostevarg, J.; Kaplan, A.F.H. Undercut suppression in laser-arc hybrid welding by melt pool tailoring. J. Laser Appl. 2014, 26, 031501. [Google Scholar] [CrossRef]

- Gao, M.; Zeng, X.; Hu, Q.; Yan, J. Weld microstructure and shape of laser–arc hybrid welding. Sci. Technol. Weld. Join. 2008, 13, 106–113. [Google Scholar] [CrossRef]

- Wei, H.L.; Li, H.; Yang, L.J.; Gao, Y.; Ding, X.P. Arc characteristics and metal transfer process of hybrid laser double GMA welding. Int. J. Adv. Manuf. Technol. 2015, 77, 1019–1028. [Google Scholar] [CrossRef]

- Mahrle, A.; Schmidt, J. The influence of fluid flow phenomena on the laser beam welding process. Int. J. Heat Fluid Flow 2002, 23, 288–297. [Google Scholar] [CrossRef]

- Rai, R.; Kelly, S.M.; Martukanitz, R.P.; DebRoy, T. A convective heat-transfer model for partial and full penetration keyhole mode laser welding of a structural steel. Metall. Mater. Trans. A 2008, 39, 98–112. [Google Scholar] [CrossRef]

- Zhao, L.; Sugino, T.; Arakane, G.; Tsukamoto, S. Influence of welding parameters on distribution of wire feeding elements in CO2 laser GMA hybrid welding. Sci. Technol. Weld. Join. 2009, 14, 457–467. [Google Scholar] [CrossRef]

- Liu, F.; Xu, B.; Song, K.; Tan, C.; Zhao, H.; Wang, G.; Chen, B.; Song, X. Improvement of penetration ability of heat source for 316 stainless steel welds produced by alternating magnetic field assisted laser-MIG hybrid welding. J. Mater. Process. Technol. 2022, 299, 117329. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Liu, L. Research on Laser-TIG Hybrid Welding of 6061-T6 Aluminum Alloys Joint and Post Heat Treatment. Metals 2020, 10, 130. [Google Scholar] [CrossRef] [Green Version]

- Yu, X.; Fan, D.; Huang, J.; Kang, Y. The characteristic of interface microstructure for aluminum-steel butt joint by arc assisted laser welding-brazing. Mater. Res. Express 2019, 6, 096533. [Google Scholar] [CrossRef]

- Hao, K.; Gong, M.; Pi, Y.; Zhang, C.; Gao, M.; Zeng, X. Effect of Ni content on rolling toughness of laser-arc hybrid welded martensitic stainless steel. J. Mater. Process. Technol. 2017, 251, 127–137. [Google Scholar] [CrossRef]

- Wu, K.C. Correlation of properties and microstructure in welded Ti-6Al-6V-2Sn. Weld. J. 1981, 60, 219–226. [Google Scholar]

| Element | Al | V | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|

| TC4 | 5.6~6.5 | 3.5~4.5 | 0.30 | 0.08 | 0.05 | 0.015 | 0.20 | Bal. |

| Number | I (A) | P (kW) | Welding Speed (cm/min) |

|---|---|---|---|

| 1 | 30 | 1.5 | 20 |

| 2 | 40 | ||

| 3 | 50 | ||

| 4 | 60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, H.; Zhou, P.; Li, J.; Huang, J.; Ni, Y.; Hui, Y. Microstructure and Mechanical Properties of Arc Zone and Laser Zone of TC4 Titanium Alloy Laser–TIG Hybrid Welded Joint. Metals 2022, 12, 1854. https://doi.org/10.3390/met12111854

Fan H, Zhou P, Li J, Huang J, Ni Y, Hui Y. Microstructure and Mechanical Properties of Arc Zone and Laser Zone of TC4 Titanium Alloy Laser–TIG Hybrid Welded Joint. Metals. 2022; 12(11):1854. https://doi.org/10.3390/met12111854

Chicago/Turabian StyleFan, Hao, Peng Zhou, Jie Li, Jiankang Huang, Yu Ni, and Yuanyuan Hui. 2022. "Microstructure and Mechanical Properties of Arc Zone and Laser Zone of TC4 Titanium Alloy Laser–TIG Hybrid Welded Joint" Metals 12, no. 11: 1854. https://doi.org/10.3390/met12111854

APA StyleFan, H., Zhou, P., Li, J., Huang, J., Ni, Y., & Hui, Y. (2022). Microstructure and Mechanical Properties of Arc Zone and Laser Zone of TC4 Titanium Alloy Laser–TIG Hybrid Welded Joint. Metals, 12(11), 1854. https://doi.org/10.3390/met12111854