Robots Working with Humans or Humans Working with Robots? Searching for Social Dimensions in New Human-Robot Interaction in Industry

Abstract

:1. Introduction

2. Robots Everywhere

3. Robots and New Forms of HRI

- (a)

- augmented reality, haptics and human enhancement

- (b)

- task complexity

- (c)

- intuitive interfaces

3.1. Augmented Reality, Haptics, Human Enhancement

- (1)

- Users have better functioning in visually sparse or simple environments.

- (2)

- Studies that manipulated visual features to mitigate workload report a positive impact from the interventions.

- (3)

- As task demands are increased, auditory and tactile feedback facilitates operator’s work [13] (p. 846).

3.2. Task Complexity

3.3. Intuitive Interfaces

4. Social Aspects of HRI: New Concepts?

5. Concluding Remarks: Humans Working with Robots

- (a)

- Considering that HRI is not a merely technical approach, do they also offer possibilities with regard to improve working conditions in industry?

- (b)

- How far are the approaches to designing intuitive robot interfaces related to new concepts of HRI?

- (c)

- Are image schemes and their metaphorical extensions useful for user interface design?

- (d)

- Is the human-robot interaction characterized by a relationship of trust? In other words, How far do humans trust in robots in work environments?

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AGV | auto-guided vehicle |

| AS | autonomous systems |

| CICS.NOVA | Interdisciplinary Centre of Social Sciences |

| CIMS | complex integrated manufacturing system |

| CNC | computerized numerical control |

| CWE | complex work environments |

| CWS | complex working system |

| FCT-UNL | Faculdade de Ciências e Tecnologia [Faculty of Sciences and Technology]—Universidade Nova de Lisboa |

| HMI | Human-machine interaction |

| HRI | human-robot interaction |

| ICT | information and communication technology |

| IFR | International Federation of Robotics |

| ILO | International Labor Office |

| IMF | International Monetary Fund |

| IoT | Internet of Things |

| IR | industrial robot |

| ISO | International Standard Organization |

| ITAS | Institute for Technology Assessment and Systems Analysis |

| KIT | Karlsruhe Institute of Technology |

| OECD | Organizational for Economic Cooperation and Development |

| OTA | Office for Technology Assessment |

| SR | service robot |

| WRI | worker-robot interaction |

References

- Van Est, R.; Kools, L. (Eds.) Working on the Robot Society; Rathenau Instituut: The Hague, The Netherlands, 2015.

- Kelly, G. The robots are coming. Will they bring wealth or a divided society? Available online: https://www.theguardian.com/technology/2014/jan/04/robots-future-society-drones (accessed on 12 July 2016).

- New York Times. Cheaper Robots, Fewer Workers. Available online: http://www.nytimes.com/2015/04/25/technology/robotica-cheaper-robots-fewer-workers.html (accessed on 29 July 2016).

- New York Times: Bits Robotica series. Available online: http://www.nytimes.com/video/robotica (accessed on 12 July 2016).

- Ejiri, M. Towards meaningful robotics for the future: Are we headed in the right direction? Robot. Auton. Syst. 1996, 18, 1–5. [Google Scholar] [CrossRef]

- Jasanoff, S. (Ed.) States of Knowledge: The Co-Production of Science and Social Order; Routledge: Abingdon, VA, USA, 2006.

- De Santis, A.; Siciliano, B.; De Luca, A.; Bicchi, A. An atlas of physical human-robot interaction. Mech. Mach. Theory 2008, 43, 253–270. [Google Scholar] [CrossRef]

- Hartwig, M.; Windel, A. Safety and health at work through persuasive assistance systems. In Digital Human Modeling and Applications in Health, Safety, Ergonomics, and Risk Management. Human Body Modeling and Ergonomics; Springer: Berlin/Heidelberg, Germany, 2013; pp. 40–49. [Google Scholar]

- Heyer, C. Human-robot interaction and future industrial robotics applications. In Proceedings of the International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 4749–4754.

- Moniz, A.B.; Krings, B.-J. Technology assessment approach to human-robot interactions in work environments. In Proceedings of the 7th International Conference on Human System Interactions (HSI 2014), Caparica, Portugal, 16–18 June 2014; pp. 282–289.

- Sheridan, T.B. Human-Robot Interaction: Status and Challenges. Hum. Factors 2016, 58, 525–532. [Google Scholar] [CrossRef] [PubMed]

- Thrun, S. Toward a Framework for Human-Robot Interaction. Human–Comput. Interact. 2004, 19, 9–24. [Google Scholar] [CrossRef]

- Prewett, M.S.; Johnson, R.C.; Saboe, K.N.; Elliott, L.R.; Coovert, M.D. Managing workload in human-robot interaction: A review of empirical studies. Comput. Hum. Behav. 2010, 26, 840–856. [Google Scholar]

- Heise, R. Demonstration Instead of Programming: Focussing Attention in Robot Task Acquisition; Research Report no. 89/360/22; University of Calgary: Calgary, AB, Canada, 1989. [Google Scholar]

- Exploratory Workshop on the Social Impacts of Robotics—Summary and Issues. A Background Paper. Available online: http://ota.fas.org/reports/8209.pdf (accessed on 29 July 2016).

- Bijker, W.E.; Hughes, T.P.; Pinch, T. The Social Construction of Technological Systems; MIT Press: Cambridge, MA, USA, 1987. [Google Scholar]

- Braverman, H. Labor and Monopoly Capital: The Degradation of Work in the Twentieth Century; Monthly Review: New York, NY, USA, 1974. [Google Scholar]

- Ennals, R.; Gustavsen, B. Work Organisation and Europe as a Development Coalition; John Benjamins: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Fischer, M.; Lehrl, W. Industrieroboter—Entwicklung und Anwendung im Kontext von Politik, Arbeit, Technik und Bildung; Donat: Bremen, Germany, 1991. (In German) [Google Scholar]

- Ellul, J. La Technique ou l'Enjeu du Siècle; Collection Sciences Politiques: Armand Colin, Paris, France, 1954. (In French) [Google Scholar]

- Blauner, R. Alienation and Freedom; University of Chicago: Chicago, IL, USA, 1964. [Google Scholar]

- Kern, H.; Schumann, M. Das Ende der Arbeitsteilung? Rationalisierung in der industriellen Produktion: Bestandsaufnahme, Trendbestimmung (The End of the Division of Labour? Rationalization in Industrial Production: StockTaking and Trend Determination); Verlag C.H. Beck: Munich, Germany, 1984. (In German) [Google Scholar]

- Corbett, J.M.; Rasmussen, L.B.; Rauner, F. Crossing the Border. The Social and Engineering Design of Computer Integrated Manufacturing Systems; Springer: London, UK, 1991. [Google Scholar]

- Frey, C.B.; Osborne, M.A. The Future of Employment: How Susceptible Are Jobs to Computerisation; Oxford Martin School: Oxford, UK, 2013. [Google Scholar]

- Greenan, N.; Kocoglu, Y.; Walkowiak, E.; Csizmadia, P.; Makó, C. The Role of Technology in Value Chain Restructuring; Katholieke Universiteit: Leuven, Belgium, 2009. [Google Scholar]

- Huws, U. (Ed.) The Transformation of Work in a Global Knowledge Economy: Towards a Conceptual Framework; WORKS: Leuven, Belgium, 2006.

- Huws, U.; Dahlmann, S.; Flecker, J.; Holtgrewe, U.; Schönnauer, A.; Ramioul, M.; Geurts, K. Value Chain Restructuring in Europe in a Global Economy; Katholieke Universiteit: Leuven, Belgium, 2009. [Google Scholar]

- Anderson, R.L.; Gartner, W.B. When robots and people work together. Robotics 1985, 1, 69–76. [Google Scholar]

- Bernstein, D.; Crowley, K.; Nourbakhsh, I. Working with a robot: Exploring relationship potential in human-robot systems. Interact. Stud. 2007, 8, 465–482. [Google Scholar]

- Cypher, A.I. Watch What I Do: Programming by Demonstration; MIT Press: Cambridge, MA, USA, 1993. [Google Scholar]

- Laessoe, J.; Rassmussen, L. Human-Centered Methods—Development of Computer-Aided Work Processes; Esprit-Project 1217(1199); Tekniske Hojskole Kongena: Lyngby, Danmark, 1989. [Google Scholar]

- Moniz, A.B. Anthropocentric-based robotic and autonomous systems: Assessment for new organisational options. In Robo- and Informationethics: Some Fundamentals; Decker, M., Gutmann, M., Eds.; LIT: Zurich, Switzerland, 2012; pp. 123–157. [Google Scholar]

- Ritter, H. (Ed.) Human Centered Robot Systems. Cognition, Interaction, Technology; Springer: Berlin/Heidelberg, Germany, 2009.

- Krings, B.-J. Arbeit und Technik. In Handbuch Technikethik; Grunwald, A., Ed.; Metzlerpp: Stuttgart & Weimar, Germany, 2013; pp. 217–222. [Google Scholar]

- Sandberg, T. Work Organization and Autonomous Groups; LiberFörlag: Lund, Sweden, 1982. [Google Scholar]

- Van den Besselaar, P.; Clement, A.; Jarvinen, P. (Eds.) Information System, Work and Organization Design; North-Holland: Amsterdam, The Netherlands, 1991.

- Gorle, P.; Clive, A. Positive Impact of Industrial Robots on Employment; IFR/Metra Martech: London, UK, 2011. [Google Scholar]

- IFR-International Federation of Robotics. World Robotics 2015; IFR: Frankfurt, Germany, 2015. [Google Scholar]

- Moniz, A.B.; Krings, B.-J.; van Hootegem, G.; Huys, R. Technological practices in the European auto industry: Exploring cases from Belgium, Germany and Portugal. Int. J. Automot. Technol. Manag. 2002, 2, 84–100. [Google Scholar]

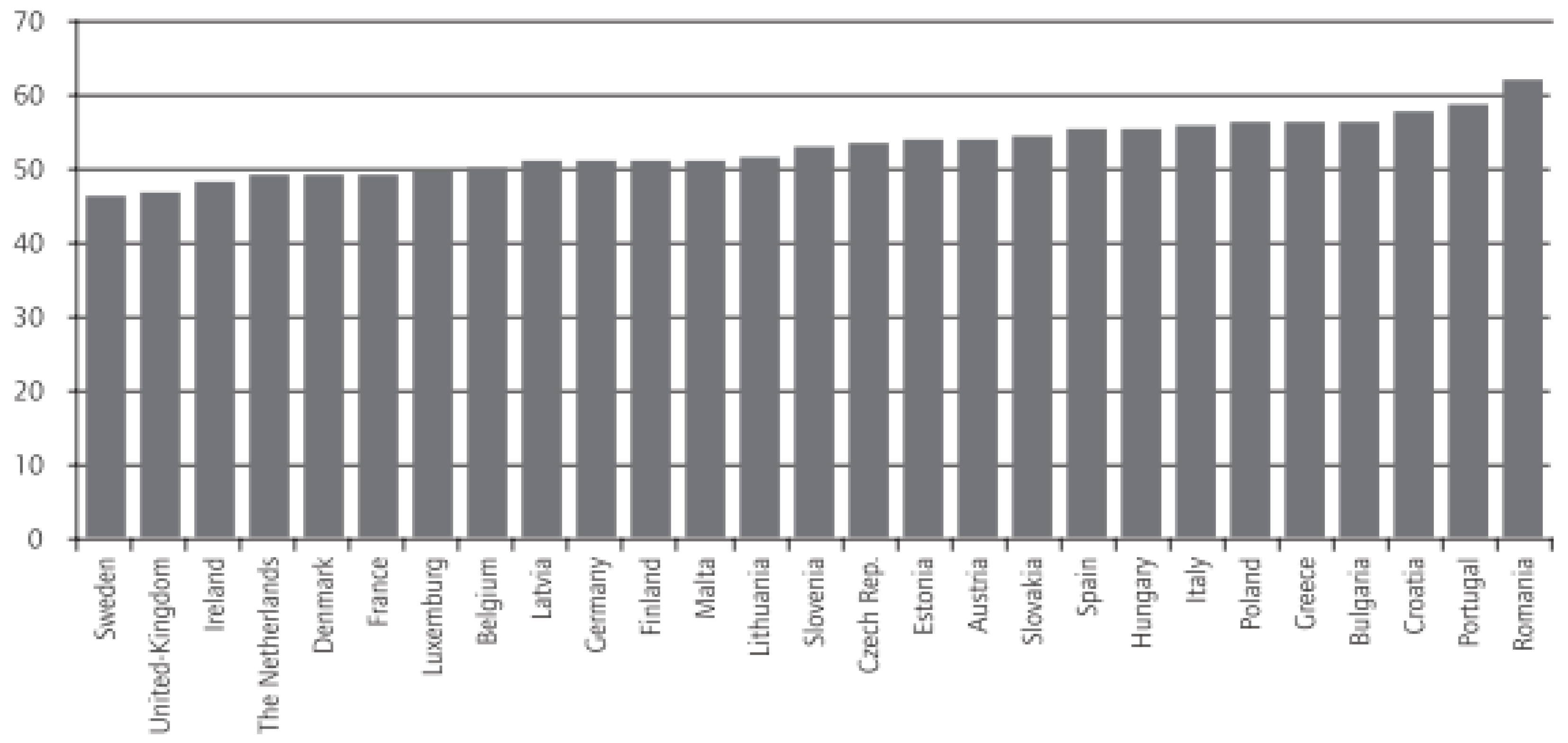

- Chart of the Week: 54% of EU Jobs at Risk of Computerisation. Available online: http://bruegel.org/2014/07/chart-of-the-week-54-of-eu-jobs-at-risk-of-computerisation/ (accessed on 8 July 2016).

- Gorle, P.; Clive, A. Positive Impact of Industrial Robots on Employment: Updated in January 2013 to Take Account of More Recent Data; IFR/Metra Martech: London, UK, 2013. [Google Scholar]

- Corbett, J.M. Human Centred Advanced Manufacturing Systems: From Rhetoric to Reality. Int. J. Ind. Ergon. 1990, 5, 83–90. [Google Scholar]

- Ramioul, M. Organisational change and the demand for skills. In The Transformation of Work in a Global Knowledge Economy: Towards a Conceptual Framework; Huws, U., Ed.; WORKS: Leuven, Belgium, 2006; pp. 97–118. [Google Scholar]

- Miller, B.; Atkinson, R.D. Are Robots Taking Our Jobs, or Making Them? Available online: http://www2.itif.org/2013-are-robots-taking-jobs.pdf (accessed on 29 July 2016).

- Barattini, P.; Wögerer, C.; Robertson, N.; Morand, C.; Pichler, A.; Rovetta, A.; Corradini, A.; Samani, H.; Hopgood, J.; Almajai, I. In the Reference Proposal to the Workshop on Human Interaction with Industrial Collaborative Autonomous Robots. In Proceedings of the 2012 Conference on RO-Man, Paris, France, 9–13 September 2012.

- EUROP. Robotic Visions to 2020 and beyond—The Strategic Research Agenda for Robotics in Europe. Available online: http://www.eurosfaire.prd.fr/7pc/doc/1286200019_g44_geoffpegman.pdf (accessed on 29 July 2016).

- Moniz, A.B. Redesigning Work Organizations and Technologies: Experiences from European Projects. Available online: https://ideas.repec.org/p/pra/mprapa/6170.html (accessed on 29 July 2016).

- OCED. The Future of Productivity; OECD Publishing: Paris, France, 2015. [Google Scholar]

- Jäger, A.; Cornelius, M.; Oliver, S.; Zanker, C. Analysis of the Impact of Robotic Systems on Employment in the European Union; Publications Office of the European Union: Luxembourg, Luxembourg, 2015. [Google Scholar]

- Brödner, P.; Latniak, E. Sources of Innovation and Competitiveness: National Programmes Supporting the Development of Work Organisation. Available online: http://www.iat.eu/aktuell/veroeff/ps/broedner02c.pdf (accessed on 29 July 2016).

- Vasic, M.; Billard, A. Safety issues in human–robot interaction. In Proceedings of IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 197–204.

- Lenz, C. Context-Aware Human-Robot Collaboration as a Basis for Future Cognitive Factories. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2011. [Google Scholar]

- Prassler, E.; Lawitzky, G.; Stopp, A.; Grunwald, G.; Hägele, M.; Dillmann, R.; Iossifidis, I. (Eds.) Advances in Human-Robot Interaction; Springer: Berlin/Heidelberg, Germany, 2005.

- Wagner, J.J.; van der Loos, H.F.; Leifer, L.J. Construction of social relationships between user and robot. Robot. Auton. Syst. 2000, 31, 185–191. [Google Scholar]

- Dario, P.; Guglielmelli, E.; Genovese, V.; Toro, M. Robot assistants: Applications and evolution. Robot. Auton. Syst. 1996, 18, 225–234. [Google Scholar]

- Albu-Schäffer, A.; Haddadin, S.; Ott, C.; Stemmer, A.; Wimböck, T.; Hirzinger, G. The DLR lightweight robot: Design and control concepts for robots in human environments. Ind. Robot Int. J. 2007, 34, 376–385. [Google Scholar]

- Kaiser, M. A Framework for the Generation of Robot Controllers from Examples. In Proceedings of the 10th ISPE/IFAC International Conference on CAD/CAM, Robotics and Factories of the Future, Ottawa, ON, Canada, 21–24 August 1994; IFAC: Ottawa, ON, Canada.

- Kochan, A. Robots and operators work hand in hand. Ind. Robot Int. J. 2006, 33, 422–424. [Google Scholar]

- Krüger, J.; Lien, T.K.; Verl, A. Cooperation of human and machines in assembly lines. CIRP Ann. Manuf. Technol. 2009, 58, 628–646. [Google Scholar]

- Kobayashi, Y.; Onishi, M.; Hosoe, S.; Luo, Z. Multi-tasking arbitration and behaviour design for human-interactive robots. Int. J. Syst. Sci. 2013, 44, 795–811. [Google Scholar]

- Medeiros, D.; Sadowski, R. Simulation of robotic manufacturing cells: A modular approach. Simulation 1983, 40, 3–12. [Google Scholar]

- Nee, A.Y.C.; Ong, S.K.; Chryssolouris, G.; Mourtzis, D. Augmented reality applications in design and manufacturing. CIRP Ann. Manuf. Technol. 2012, 61, 657–679. [Google Scholar]

- Drury, J.L.; Scholtz, J.; Yanco, H.A. Applying CSCW and HCI Techniques to Human-Robot Interaction. Available online: http://robotics.cs.uml.edu/fileadmin/content/publications/2004/drury-scholtz-yanco-chi04-wkshp.pdf (accessed on 29 July 2016).

- Mayer, M.; Odenthal, B.; Faber, M.; Winkelholz, C.; Schlick, C. Cognitive Engineering of Automated Assembly Processes. Hum. Factors Ergon. Manuf. Serv. Ind. 2014, 24, 348–368. [Google Scholar]

- Mohs, C.; Naumann, A.; Meyer, H.A.; Pohlmeyer, A. IUUI—Intuitive Use of User Interfaces. In Usability Professionals 06; Chapter der Usability Professionals’ Association: Stuttgart, Germany, 2006. [Google Scholar]

- Tsarouchi, P.; Makris, S.; Chryssolouris, G. Human-robot interaction review and challenges on task planninand programming. Int. J. Comput. Integr. Manuf. 2016, 29, 916–931. [Google Scholar]

- Das, A.; Jayaram, J. Socio-technical perspective on manufacturing system synergies. Int. J. Prod. Res. 2007, 45, 169–205. [Google Scholar]

- Kiesler, S.; Hinds, P. Introduction to this special issue on Human-Robot Interaction. Hum. Comput. Interact. 2004, 19, 1–8. [Google Scholar]

- Moniz, A.B. Intuitive interaction between humans and robots in work functions at industrial environments: The role of social robotics. In Social Robots from a Human Perspective; Springer: Cham, Switzerland, 2015; pp. 67–76. [Google Scholar]

- Unmanned Systems Integrated Roadmap FY2011–2036. Available online: http://www.acq.osd.mil/sts/docs/Unmanned%20Systems%20Integrated%20Roadmap%20FY2011-2036.pdf (accessed on 29 July 2016).

- Colombo, D.; Dallefrate, D.; Tosatti, L.M. PC Based Control Systems for Compliance Control and Intuitive Programming of Industrial Robots. Available online: http://www.smerobot.org/08_scientific_papers/#2006 (accessed on 12 July 2016).

- Lenz, C.; Nair, S.; Rickert, M.; Knoll, A.; Rosel, W.; Gast, J.; Bannat, A.; Wallhoff, F. Joint-action for humans and industrial robots for assembly tasks. In Proceedings of the 17th IEEE International Symposium on Robot and Human Interactive Communication (RO-MAN 2008), Munich, Germany, 1–3 August 2008.

- Morioka, M.; Sakakibara, S. A new cell production assembly system with human–robot cooperation. CIRP Ann. Manuf. Technol. 2010, 59, 9–12. [Google Scholar]

- Barthélemy, J.P.; Bisdorff, R.; Coppin, G. Human centred processes and decision support systems. Eur. J. Oper. Res. 2002, 136, 233–252. [Google Scholar]

- Akan, B.; Ameri, A.; Cürüklü, B.; Asplund, L. Intuitive Industrial Robot Programming through Incremental Multimodal Language and Augmented Reality. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011.

- Haddadin, S.; Suppa, M.; Fuchs, S.; Bodenmüller, T.; Albu-Schäffer, A.; Hirzinger, G. Towards the Robotic Co-Worker. In Robotics Research; Pradalier, C., Siegwart, R., Hirzinger, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 261–282. [Google Scholar]

- Hinds, P.J.; Roberts, T.L.; Jones, H. Whose job is it anyway? A study of Human-Robot Interaction in a collaborative task. Hum. Comput. Interact. 2004, 19, 151–181. [Google Scholar]

- Eason, K.D. Representing socio-technical systems options in the development of new forms of work organization. Eur. J. Work Organ. Psychol. 1996, 5, 399–420. [Google Scholar]

- Groom, V.; Takayama, L.; Ochi, P.; Nass, C. I Am My Robot: The Impact of Robot-building and Robot Form on Operators. In Proceedings of the 4th ACM/IEEE International Conference on Human Robot Interaction (HRI ’09), San Diego, CA, USA, 11–13 March 2009.

- Weiss, A.; Wurhofer, D.; Lankes, M.; Tscheligi, M. Autonomous vs. tele-operated: How people perceive human-robot collaboration with HRP-2. In Proceedings of the 4th ACM/IEEE International Conference on Human Robot Interaction, San Diego, CA, USA, 11–13 March 2009; pp. 257–258.

- Kock, S.; Vittor, T.; Matthias, B.; Jerregard, H.; Källman, M.; Lundberg, I.; Hedelind, M. A Robot Concept for Scalable, Flexible Assembly Automation: A technology study on a harmless dual-armed robot from ABB. In Proceedings of the IEEE ISAM 2011 International Symposium on Assembly and Manufacturing, Tampere, Finland, 25–27 May 2011.

- Ribeiro, L.; Barata, J.; Barreira, P. Is Ambient Intelligence a truly Human-Centric Paradigm in Industry? Current Research and Application Scenario. Available online: https://run.unl.pt/handle/10362/4098 (accessed on 29 July 2016).

- Schraft, R.D.; Meyer, C. The need for an Intuitive Teaching Method for Small and Medium Enterprises. VDI Ber. 2006, 1956. [Google Scholar] [CrossRef]

- Moniz, A.B. The Collaborative Work Concept and the Information Systems Support: Perspectives for and from Manufacturing Industry. Technikfolgenabschätzung—Theorie und Praxis 2007, 16, 49–57. [Google Scholar]

- Jara, C.A.; Candelas, F.A.; Gil, P.; Fernández, M.; Torres, F. An augmented reality interface for training robotics through the web. Available online: https://rua.ua.es/dspace/bitstream/10045/10163/1/Paper_ISR09_Proc.pdf (accessed on 29 July 2016).

- Interactions between New Technologies and the Job Market, Flexicurity and Training/Vocational Training. Available online: http://www.itas.kit.edu/pub/v/2007/krmu07a.pdf (accessed on 29 July 2016).

- Paulos, M.R.; Moniz, A.B. Fragmentation? The future of work in Europe in a global economy: The WORKS final International Conference debate. Enterp. Work Innov. Stud. 2008, 4, 167–169. [Google Scholar]

- Krings, B.-J. Global restructuring and its effects on occupations: Towards a new division of labor? In Proceedings of the International Confence DFG Graduate School Topology of Technology, Darmstadt, Germany, 30–31 October 2008.

- Tranfield, D.; Smith, S.; Ley, C.; Bessant, J.; Levy, P. Changing organizational design and practices for computer integrated technologies. Int. J. Technol. Manag. 1991, 6, 211–221. [Google Scholar]

- Wallhoff, F.; Blume, J.; Bannat, A.; Rösel, W.; Lenz, C.; Knoll, A. A skill-based approach towards hybrid assembly, Adv. Eng. Inform. 2010, 24, 329–339. [Google Scholar]

- Münch, S.; Kreuziger, J.; Kaiser, M.; Dillmann, R. Robot programming by demonstration—Using machine learning and user interaction methods for the development of easy and comfortable robot programming systems. In Proceedings of the International Symposium on Industrial Robots (ISIR ’94), Hannover, Germany, 25–27 April 1994; pp. 685–693.

- Rogalla, O.; Ehrenmann, M.; Zöllner, R.; Becher, R.; Dillmann, R. Using gesture and speech control for commanding a robot assistant. In Proceedings of the IEEE International Workshop on Robot and Human Interactive Communication, Berlin, Germany, 27 December 2002; IEEE: Piscataway, NJ, USA, 2002; pp. 454–459. [Google Scholar]

- Marin, R.; Sanz, P.; Sanchez, J. A very high level interface to teleoperate a robot via Web including augmented reality. In Proceedings of the 2002 IEEE International Conference on Robotics and Automation, Washington, DC, USA, 11–15 May 2002; pp. 2725–2730.

- The Role of Autonomy in DOD Systems. Available online: http://www3.nd.edu/~dhoward1/autonomy.pdf (accessed on 29 July 2016).

- Huws, U. Working online, living offline: Labour in the Internet Age. Work Organ. Labour Glob. 2013, 7. [Google Scholar] [CrossRef]

- Ribeiro, L.; Barata, J. New Shop Floor Control Approaches for Virtual Enterprises. Enterp. Work Innov. Stud. 2006, 2, 25–32. [Google Scholar]

- 1Hitachi is one of the major robot producers, and this lab is also a think tank. In Japan, such units are scientifically very sound.

- 2For example the projects Social Implications of Robotics in Manufacturing Industry (IR@MI) at KIT (2012–2015), Intuitive Interaction between Humans and Industrial Robot Systems—A Contribution to a Conceptual Approach (I3RS) at KIT (2012–2015), or the EU project Dynamics of Virtual Work supported by the COST program (2013–2016). Within these projects, the authors conducted several interviews with robotics researchers, managers from the manufacturing industry, technology safety experts, workers’ committee members, system developers, and company engineering staff members.

| Annual Rate of Increase in Industrial Production (%) | Robots Per 10,000 Employees in Manufacturing (IFR) | ||||||

|---|---|---|---|---|---|---|---|

| Year | 2000 | 2008 | 2011 | 2000 | 2008 | 2011 | 2008 to 2011 |

| Brazil | 5.7 | 4.9 | 0.3 | <1 | 5 | 7 | 40% |

| China | 11.0 | 13.4 | 13.9 | <1 | 10 | 21 | 210% |

| Germany | 6.6 | 5.2 | 8 | 146 | 236 | 261 | 11% |

| Japan | 5.8 | 1.3 | −3.5 | 337 | 344 | 339 | −1% |

| Korean Rep. | 8.5 | 5.1 | 3.8 | 107 | 221 | 347 | 57% |

| USA | 5.6 | −1.7 | 4.1 | 52 | 96 | 135 | 41% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moniz, A.B.; Krings, B.-J. Robots Working with Humans or Humans Working with Robots? Searching for Social Dimensions in New Human-Robot Interaction in Industry. Societies 2016, 6, 23. https://doi.org/10.3390/soc6030023

Moniz AB, Krings B-J. Robots Working with Humans or Humans Working with Robots? Searching for Social Dimensions in New Human-Robot Interaction in Industry. Societies. 2016; 6(3):23. https://doi.org/10.3390/soc6030023

Chicago/Turabian StyleMoniz, António B., and Bettina-Johanna Krings. 2016. "Robots Working with Humans or Humans Working with Robots? Searching for Social Dimensions in New Human-Robot Interaction in Industry" Societies 6, no. 3: 23. https://doi.org/10.3390/soc6030023

APA StyleMoniz, A. B., & Krings, B.-J. (2016). Robots Working with Humans or Humans Working with Robots? Searching for Social Dimensions in New Human-Robot Interaction in Industry. Societies, 6(3), 23. https://doi.org/10.3390/soc6030023