Performance Evaluation and Lubrication Mechanism of Water-Based Nanolubricants Containing Nano-TiO2 in Hot Steel Rolling

Abstract

:1. Introduction

2. Materials and Experimental Procedure

2.1. Materials

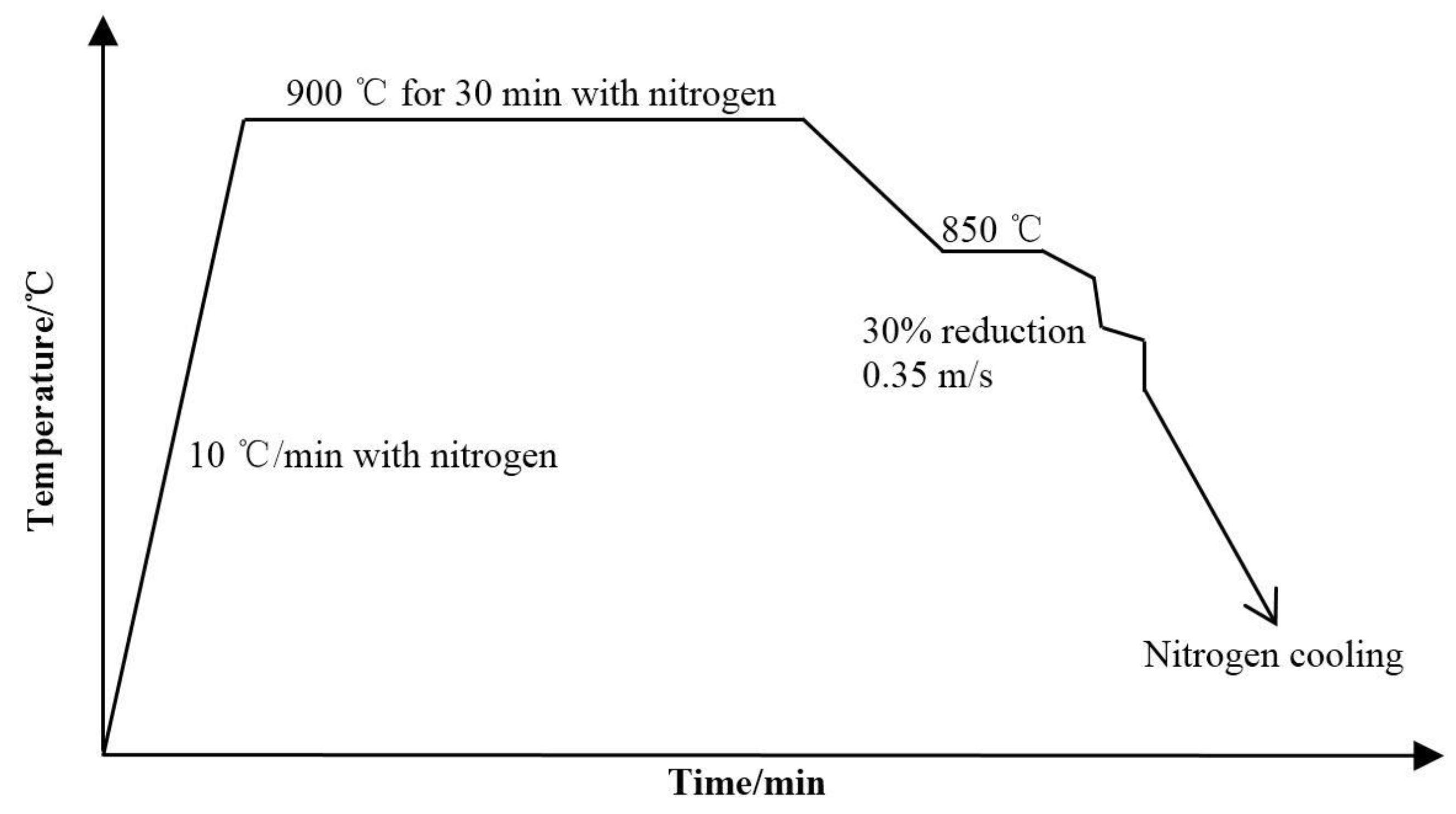

2.2. Hot Rolling Tests

2.3. Characterisation Methodology

3. Results

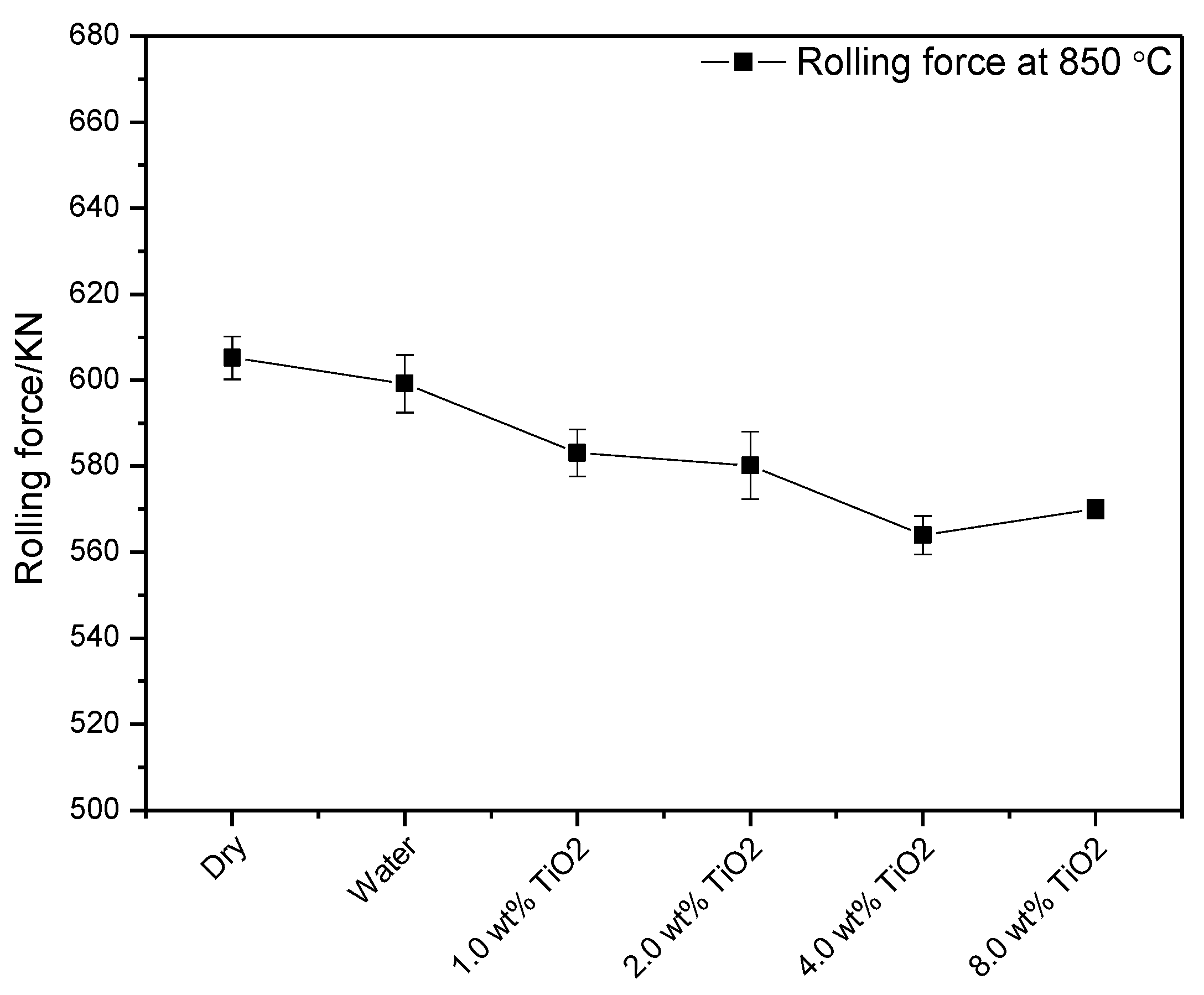

3.1. Lubrication Effect on Rolling Force

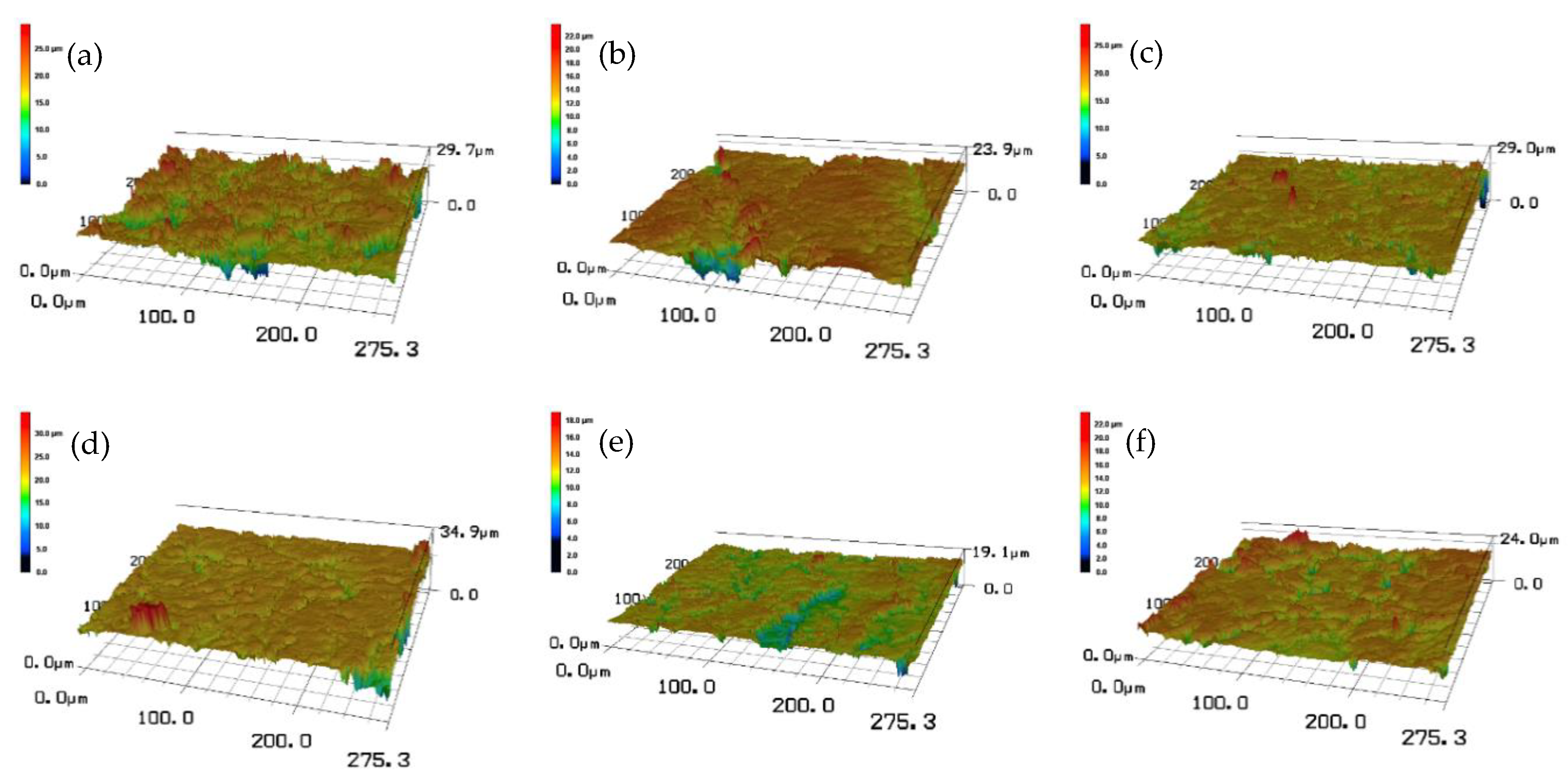

3.2. Lubrication Effect on Surface Roughness

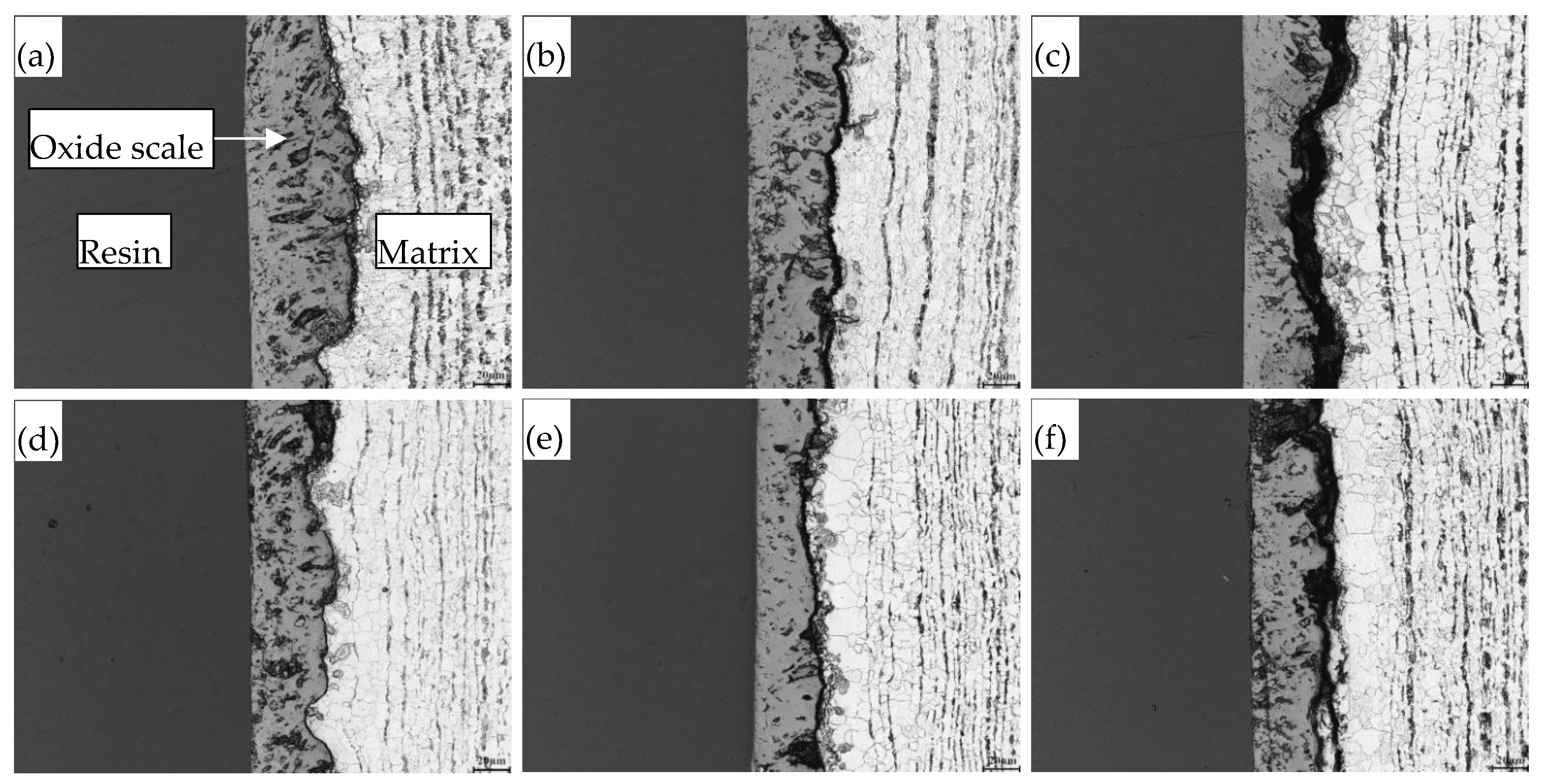

3.3. Lubrication Effect on Oxide Scale

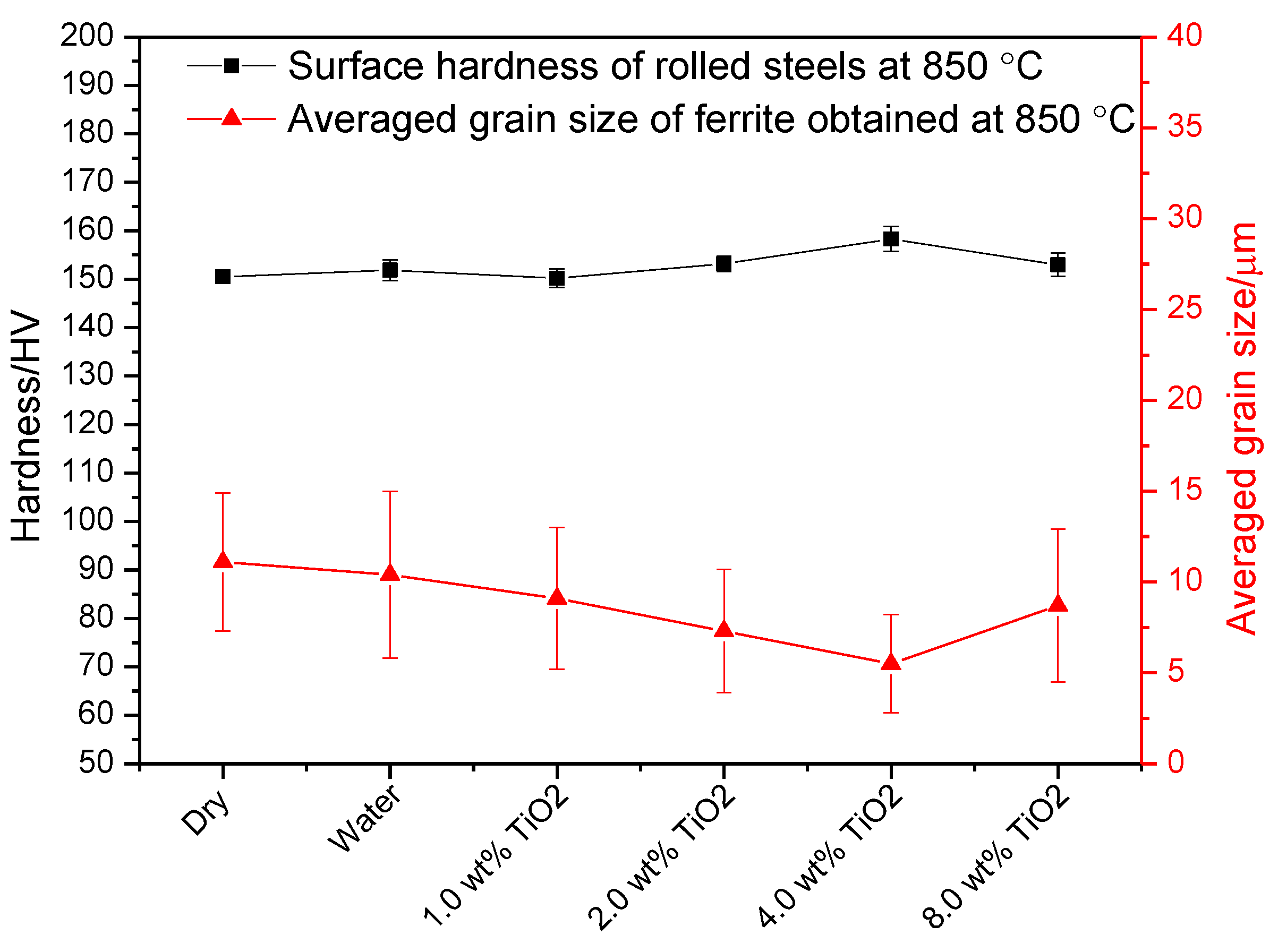

3.4. Lubrication Effect on Surface Microstructure and Hardness

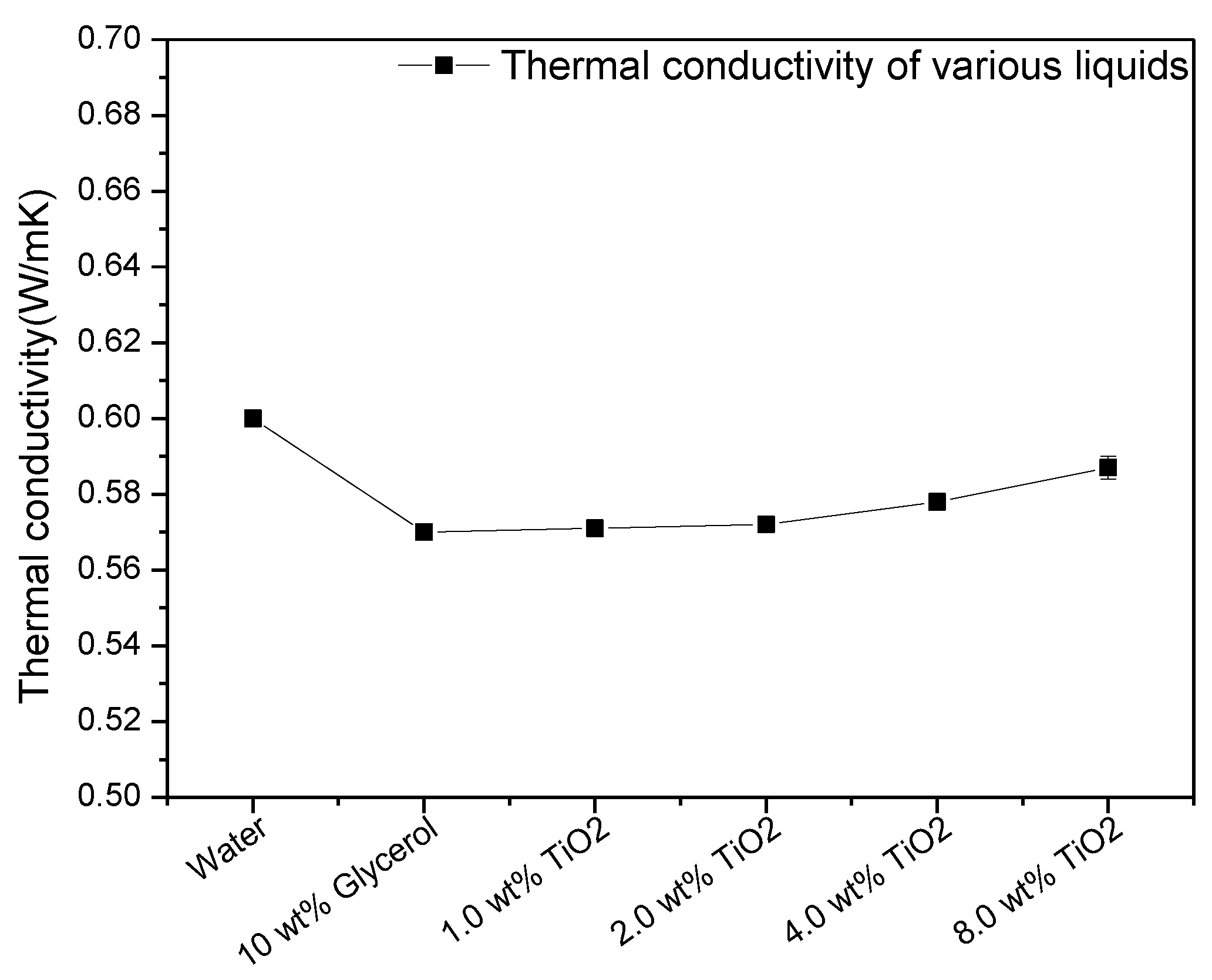

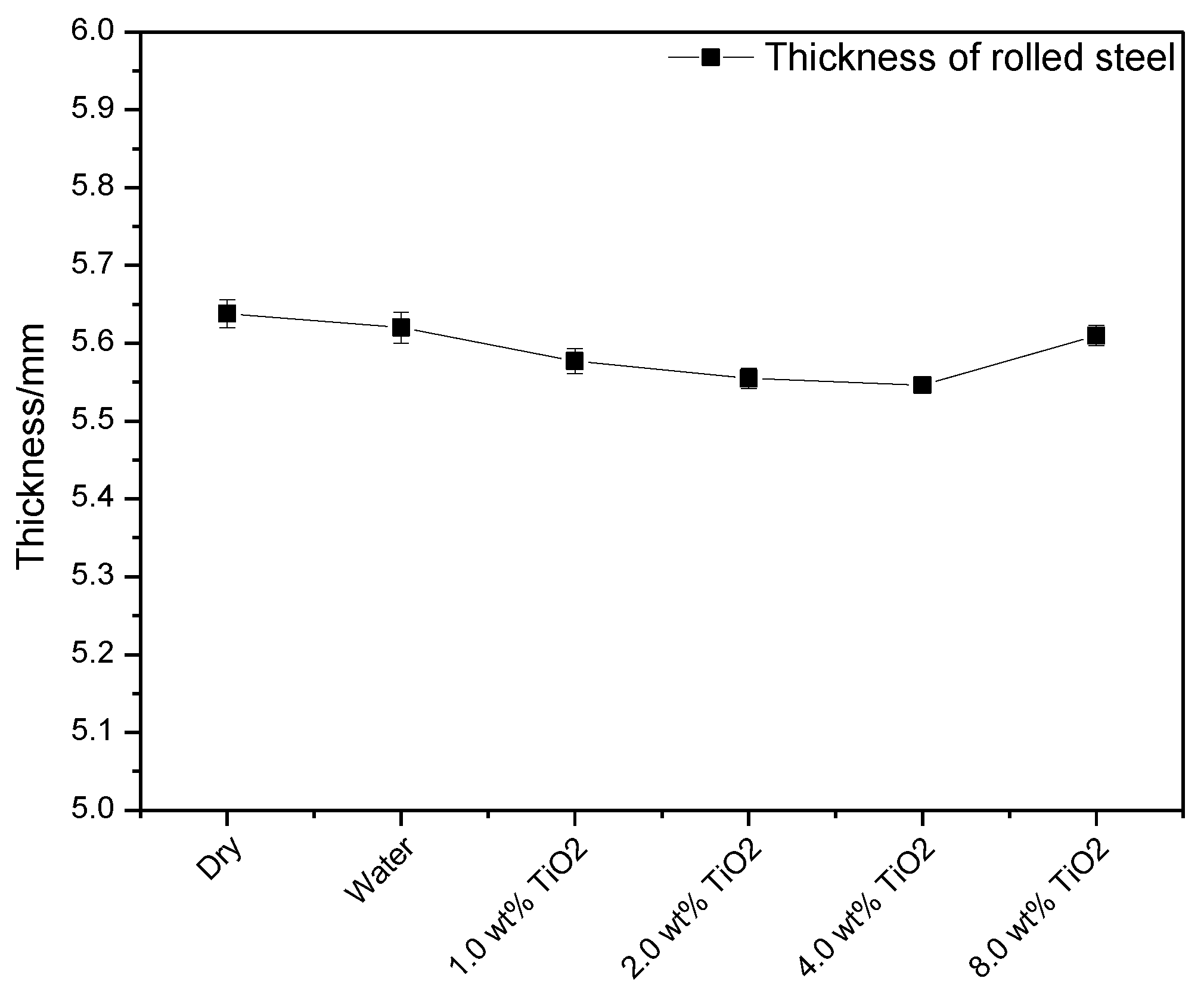

4. Discussion

4.1. FIB-TEM Analysis

4.2. Grain Refinement Mechanism

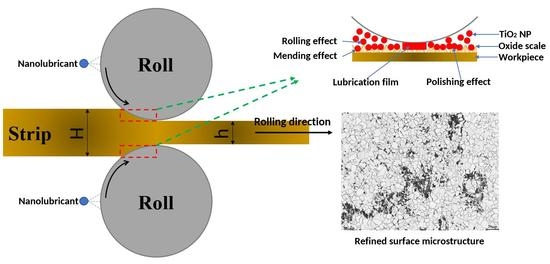

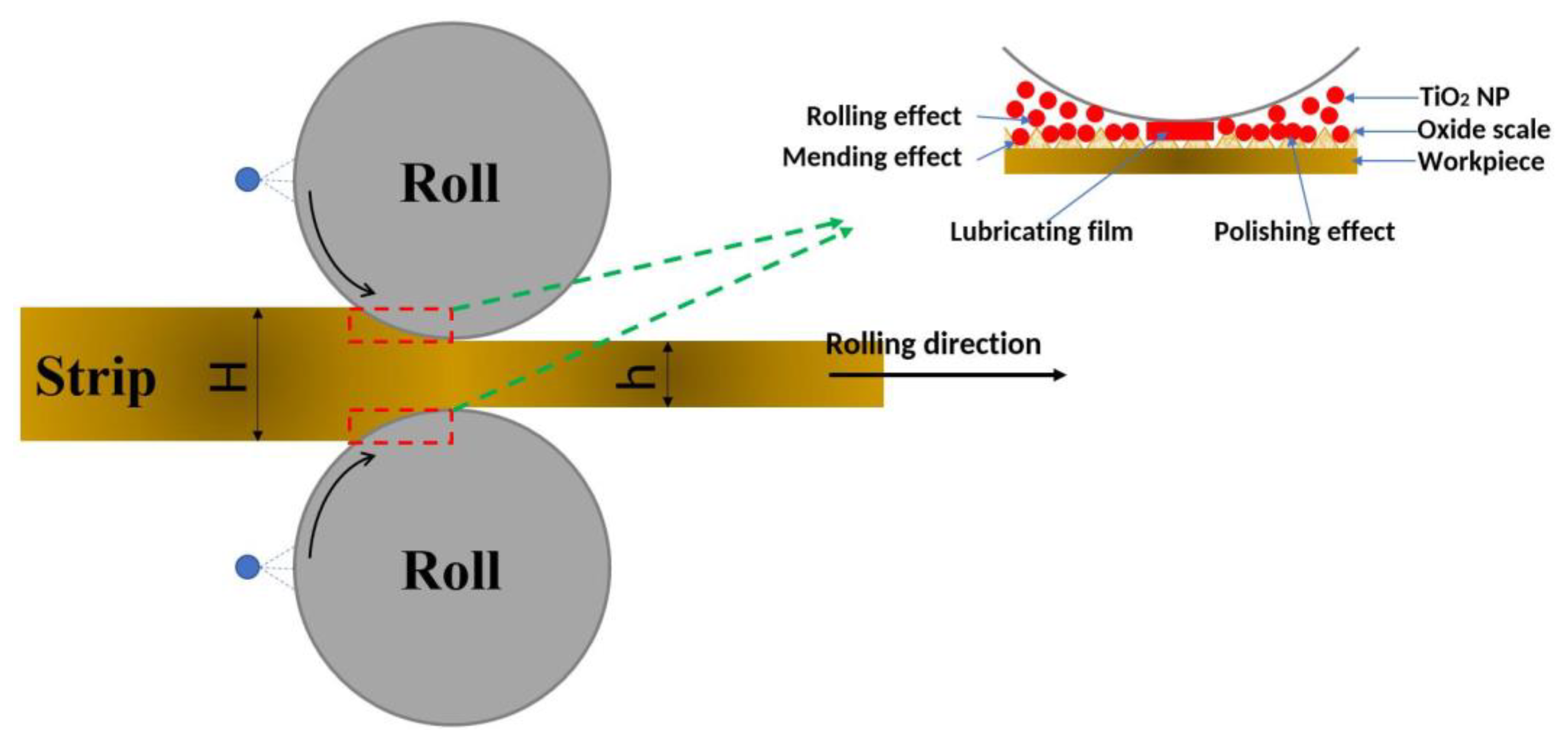

4.3. Illustration of Mechanisms

5. Conclusions

- (1)

- The rolling force obtained under dry condition is the highest among all the tests, which can be reduced maximally by 6.8% to 564 KN when nanolubricant containing 4.0 wt% nano-TiO2 is applied.

- (2)

- The surface roughness of the rolled steels under dry conditions can be improved by 19.5% when using the nanolubricant with 4.0 wt% nano-TiO2. The lubricant also produces the flattest steel surface after hot rolling.

- (3)

- The nanolubricant containing 4.0 wt% TiO2 produces the thinnest oxide scale, which is 43.8% thinner than that obtained under dry conditions.

- (4)

- The use of nanolubricant containing 4.0 wt% TiO2 leads to grain refinement to the largest extent, showing 50% finer ferrite grain size than that of dry conditions.

- (5)

- The lubrication mechanism of water-based nanolubricants containing nano-TiO2 in hot steel rolling is ascribed to the synergistic effect of lubricating film, rolling, polishing and mending.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, H. A Study of Novel Nano-Additive Water-Based Lubrication in Hot Rolling of Steels. Ph.D. Thesis, University of Wollongong, Wollongong, Australia, 2017. [Google Scholar]

- Azushima, A.; Xue, W.D.; Yoshida, Y. Lubrication mechanism in hot rolling by newly developed simulation testing machine. CIRP Ann.-Manuf. Technol. 2007, 56, 297–300. [Google Scholar] [CrossRef]

- Azushima, A.; Xue, W.D.; Yoshida, Y. Influence of Lubricant Factors on Coefficient of Friction and Clarification of Lubrication Mechanism in Hot Rolling. ISIJ Int. 2009, 49, 868–873. [Google Scholar] [CrossRef] [Green Version]

- Matsubara, Y.; Hiruta, T.; Kimura, Y. Effect of oil film thickness on lubrication property in hot rolling. ISIJ Int. 2015, 55, 632–636. [Google Scholar] [CrossRef]

- Williams, K. Tribology in Metal Working±New Developments, I. In Proceedings of the Mechanical Engineering Conference, London, UK, 4–6 July 1980. [Google Scholar]

- Shirizly, A.; Lenard, J.G. The effect of lubrication on mill loads during hot rolling of low carbon steel strips. J. Mater. Process. Technol. 2000, 97, 61–68. [Google Scholar] [CrossRef]

- Meng, Y.; Sun, J.; Wu, P.; Dong, C.; Yan, X. The Role of Nano-TiO2 Lubricating Fluid on the Hot Rolled Surface and Metallographic Structure of SS41 Steel. Nanomaterials 2018, 8, 111. [Google Scholar] [CrossRef] [PubMed]

- Bao, Y.; Sun, J.; Kong, L. Effects of nano-SiO2 as water-based lubricant additive on surface qualities of strips after hot rolling. Tribol. Int. 2017, 114, 257–263. [Google Scholar] [CrossRef]

- Spuzic, S.; Strafford, K.N.; Subramanian, C.; Savage, G. Wear of hot rolling mill rolls: An overview. Wear 1994, 176, 261–271. [Google Scholar] [CrossRef]

- Beese, J.G. Lubrication of hot-strip-mill rolls. Wear 1973, 23, 203–208. [Google Scholar] [CrossRef]

- Barrett, C. Influence of lubrication on through thickness texture of ferritically hot rolled interstitial free steel. Ironmak. Steelmak. 1999, 26, 393–397. [Google Scholar] [CrossRef]

- Lenard, J.G.; Barbulovic-Nad, L. The coefficient of friction during hot rolling of low carbon steel strips. J. Tribol. 2002, 124, 840–845. [Google Scholar] [CrossRef]

- Matsuoka, S.; Morita, M.; Furukimi, O.; Obara, T. Effect of lubrication condition on recrystallization texture of ultra-low C sheet steel hot-rolled in ferrite region. ISIJ Int. 1998, 38, 633–639. [Google Scholar] [CrossRef]

- Yu, Y.; Lenard, J.G. Estimating the resistance to deformation of the layer of scale during hot rolling of carbon steel strips. J. Mater. Process. Technol. 2002, 121, 60–68. [Google Scholar] [CrossRef]

- Haus, F.; German, J.; Junter, -G. Primary biodegradability of mineral base oils in relation to their chemical and physical characteristics. Chemosphere 2001, 45, 983–990. [Google Scholar] [CrossRef]

- He, A.; Huang, S.; Yun, J.H.; Jiang, Z.; Stokes, J.; Jiao, S.; Wang, L.; Huang, H. The pH-dependent structural and tribological behaviour of aqueous graphene oxide suspensions. Tribol. Int. 2017, 116, 460–469. [Google Scholar] [CrossRef]

- He, A.; Huang, S.; Yun, J.H.; Jiang, Z.; Stokes, J.R.; Jiao, S.; Wang, L.; Huang, H. Tribological Characteristics of Aqueous Graphene Oxide, Graphitic Carbon Nitride, and Their Mixed Suspensions. Tribol. Lett. 2018, 66, 42. [Google Scholar] [CrossRef]

- He, A.; Huang, S.; Yun, J.H.; Wu, H.; Jiang, Z.; Stokes, J.; Jiao, S.; Wang, L.; Huang, H. Tribological Performance and Lubrication Mechanism of Alumina Nanoparticle Water-Based Suspensions in Ball-on-Three-Plate Testing. Tribol. Lett. 2017, 65, 40. [Google Scholar] [CrossRef]

- Zhu, Z.; Sun, J.; Niu, T.; Liu, N. Experimental research on tribological performance of water-based rolling liquid containing nano-TiO2. Proc. Inst. Mech. Eng. Part N J. Nanoeng. Nanosyst. 2014, 229, 104–109. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Cheng, X.; Xia, W.; He, A.; Yun, J.H.; Huang, S.; Wang, L.; Huang, H.; Jiao, S.; et al. Friction and wear characteristics of TiO2 nano-additive water-based lubricant on ferritic stainless steel. Tribol. Int. 2018, 117, 24–38. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Xia, W.; Cheng, X.; He, A.; Yun, J.H.; Wang, L.; Huang, H.; Jiao, S.; Huang, L.; et al. A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribol. Int. 2017, 109, 398–408. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Xia, W.; Cheng, X.; He, A.; Yun, J.H.; Wang, L.; Huang, H.; Jiao, S.; Huang, L.; et al. Analysis of TiO2 nano-additive water-based lubricants in hot rolling of microalloyed steel. J. Manuf. Process. 2017, 27, 26–36. [Google Scholar] [CrossRef]

- Yu, X.; Jiang, Z.; Zhao, J.; Wei, D.; Zhou, J.; Zhou, C.; Huang, Q. The role of oxide-scale microtexture on tribological behaviour in the nanoparticle lubrication of hot rolling. Tribol. Int. 2016, 93, 190–201. [Google Scholar] [CrossRef]

- Luo, L.; Jiang, Z.; Wei, D. Influences of micro-friction on surface finish in micro deep drawing of SUS304 cups. Wear 2017, 374, 36–45. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Breidt, C.; Friedrich, K. Tribological properties of epoxy nanocomposites - I. Enhancement of the wear resistance by nano-TiO2 particles. Wear 2005, 258, 141–148. [Google Scholar] [CrossRef]

- Kasraei, S.; Azarsina, M. Addition of silver nanoparticles reduces the wettability of methacrylate and silorane-based composites. Braz. Oral Res. 2012, 26, 505–510. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lim, S.; Horiuchi, H.; Nikolov, A.D.; Wasan, D. Nanofluids Alter the Surface Wettability of Solids. Langmuir 2015, 31, 5827–5835. [Google Scholar] [CrossRef] [PubMed]

- Vafaei, S.; Borca-Tasciuc, T.; Podowski, M.Z.; Purkayastha, A.; Ramanath, G.; Ajayan, P.M. Effect of nanoparticles on sessile droplet contact angle. Nanotechnology 2006, 17, 2523. [Google Scholar] [CrossRef] [PubMed]

- Ingole, S.; Charanpahari, A.; Kakade, A.; Umare, S.S.; Bhatt, D.V.; Menghani, J. Tribological behavior of nano TiO2 as an additive in base oil. Wear 2013, 301, 776–785. [Google Scholar] [CrossRef]

- Tamura, I.; Sekine, H.; Tanaka, T. Thermomechanical Processing of High-Strength Low-Alloy Steels; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Ramires, M.L.; Nieto de Castro, C.A.; Nagasaka, Y.; Nagashima, A.; Assael, M.J.; Wakeham, W.A. Standard Reference Data for the Thermal-Conductivity of Water. J. Phys. Chem. Ref. Data 1995, 24, 1377–1381. [Google Scholar] [CrossRef]

- Tadjarodi, A.; Zabihi, F. Thermal conductivity studies of novel nanofluids based on metallic silver decorated mesoporous silica nanoparticles. Mater. Res. Bull. 2013, 48, 4150–4156. [Google Scholar] [CrossRef]

- Ponzoni, C.; Gualtieri, M.L.; Lugli, E.; Leonelli, C.; Romagnoli, M. Stabilization and thermal conductivity of aqueous magnetite nanofluid from continuous flows hydrothermal microwave synthesis. Mater. Lett. 2016, 173, 195–198. [Google Scholar]

- Kedzierski, M.A.; Brignoli, R.; Quine, K.T.; Brown, J.S. Viscosity, density, and thermal conductivity of aluminum oxide and zinc oxide nanolubricants. Int. J. Refrig. 2017, 74, 3–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Özerinç, S.; Kakaç, S.; Yazıcıoğlu, A.G. Enhanced thermal conductivity of nanofluids: A state-of-the-art review. Microfluid. Nanofluid. 2010, 8, 145–170. [Google Scholar] [CrossRef]

- Zhu, H.T.; Zhang, C.; Tang, Y.; Wang, J.; Ren, B.; Yin, Y. Preparation and thermal conductivity of suspensions of graphite nanoparticles. Carbon 2007, 45, 226–228. [Google Scholar] [CrossRef]

- Ginzburg, V.B. Steel-Rolling Technology: Theory and Practice; Marcel Dekker, Inc.: New York, NY, USA, 1989; p. 791. [Google Scholar]

| C | Si | Mn | Mo | Ni | Cr | P | S | Nb + V + Ti |

|---|---|---|---|---|---|---|---|---|

| 0.16 | 0.25 | 1.5 | 0.007 | 0.006 | 0.02 | 0.015 | 0.004 | <0.02 |

| Lubrication Type | Description |

|---|---|

| 1 | Dry condition |

| 2 | Water |

| 3 | 1.0 wt% TiO2 + 0.01 wt% PEI + 10.0 vol% glycerol + balance water |

| 4 | 2.0 wt% TiO2 + 0.02 wt% PEI + 10.0 vol% glycerol + balance water |

| 5 | 4.0 wt% TiO2 + 0.04 wt% PEI + 10.0 vol% glycerol + balance water |

| 6 | 8.0 wt% TiO2 + 0.08 wt% PEI + 10.0 vol% glycerol + balance water |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Zhao, J.; Luo, L.; Huang, S.; Wang, L.; Zhang, S.; Jiao, S.; Huang, H.; Jiang, Z. Performance Evaluation and Lubrication Mechanism of Water-Based Nanolubricants Containing Nano-TiO2 in Hot Steel Rolling. Lubricants 2018, 6, 57. https://doi.org/10.3390/lubricants6030057

Wu H, Zhao J, Luo L, Huang S, Wang L, Zhang S, Jiao S, Huang H, Jiang Z. Performance Evaluation and Lubrication Mechanism of Water-Based Nanolubricants Containing Nano-TiO2 in Hot Steel Rolling. Lubricants. 2018; 6(3):57. https://doi.org/10.3390/lubricants6030057

Chicago/Turabian StyleWu, Hui, Jingwei Zhao, Liang Luo, Shuiquan Huang, Lianzhou Wang, Suoquan Zhang, Sihai Jiao, Han Huang, and Zhengyi Jiang. 2018. "Performance Evaluation and Lubrication Mechanism of Water-Based Nanolubricants Containing Nano-TiO2 in Hot Steel Rolling" Lubricants 6, no. 3: 57. https://doi.org/10.3390/lubricants6030057