Thermal–Hydrodynamic Behaviour of Coated Pivoted Pad Thrust Bearings: Comparison between Babbitt, PTFE and DLC

Abstract

:1. Introduction

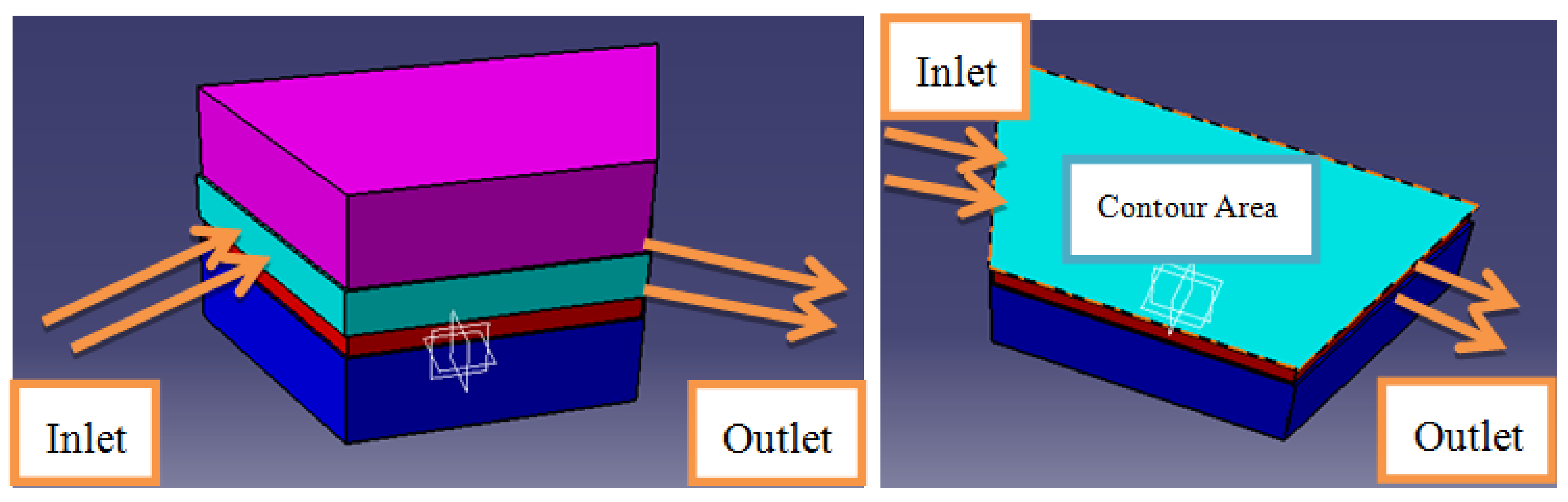

2. Theory

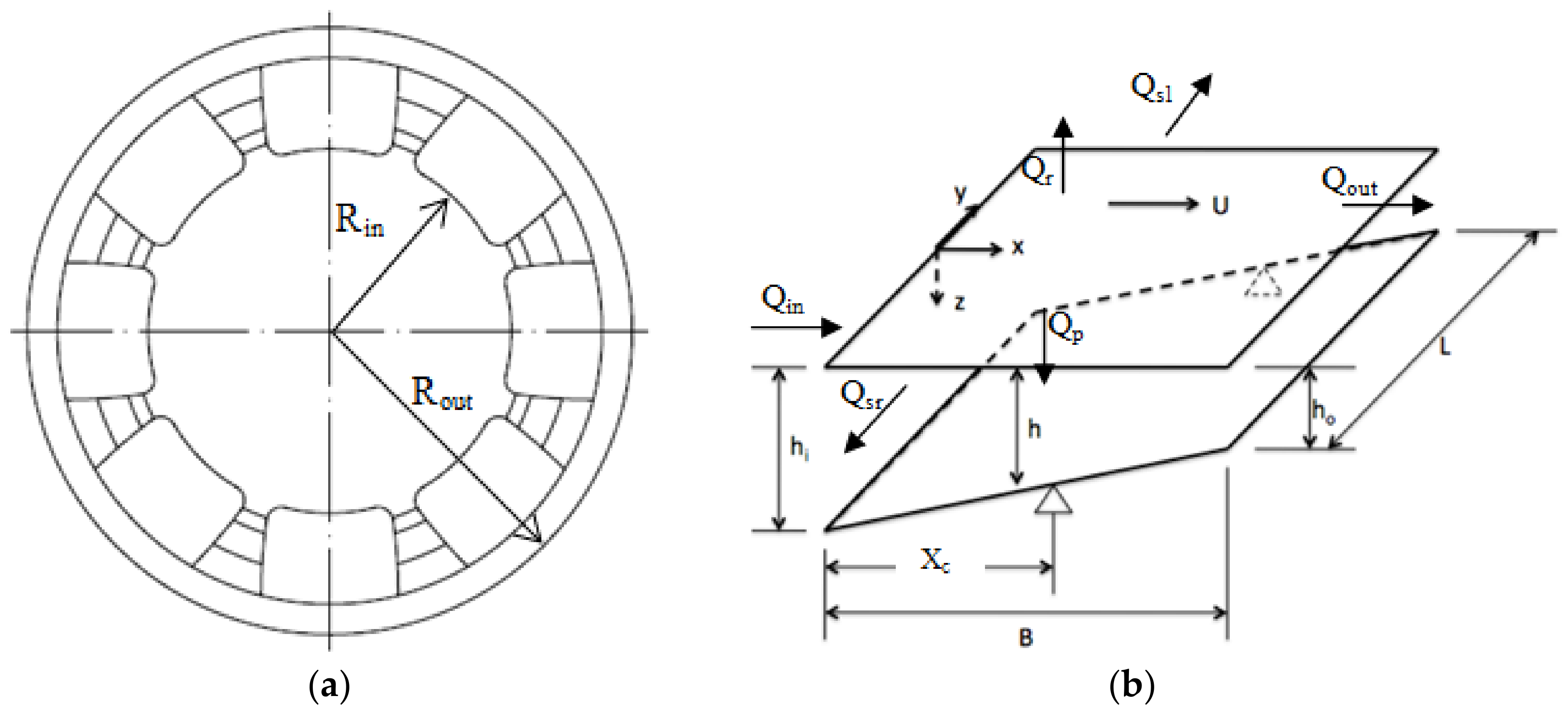

2.1. Hydrodynamic Analysis

Governing Equations and Assumptions

2.2. Thermal Analysis

Energy Equation

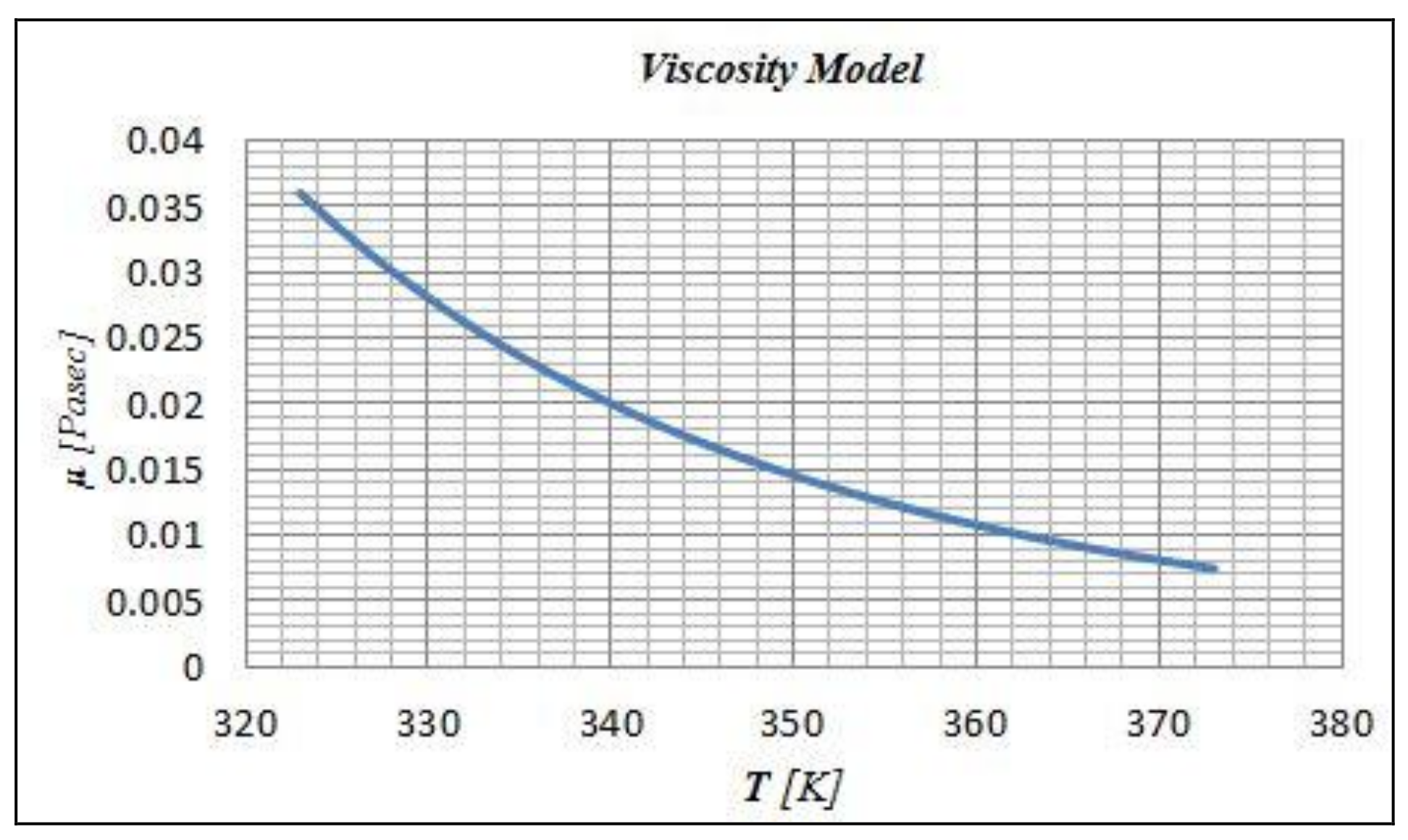

2.3. Viscosity Model

3. Spatial Discretization, Boundary and Initial Conditions

- Fluid–ambient inlet surface:

- Fluid–ambient outlet surface:

- Fluid–ambient Side y = 0 surface:

- Fluid–ambient Side y = L surface:

- Fluid–coating interface:

- Fluid–rotor interface:

- Coating, pad, rotor–ambient interfaces for the inlet, outlet and side surfaces:

- Pad–coating interface:where i = s, r, c, for the cases of the stationary pad, the rotor and the coating layer, j = oil and a = ambient for the case of the lubricant, the ambient temperatures.

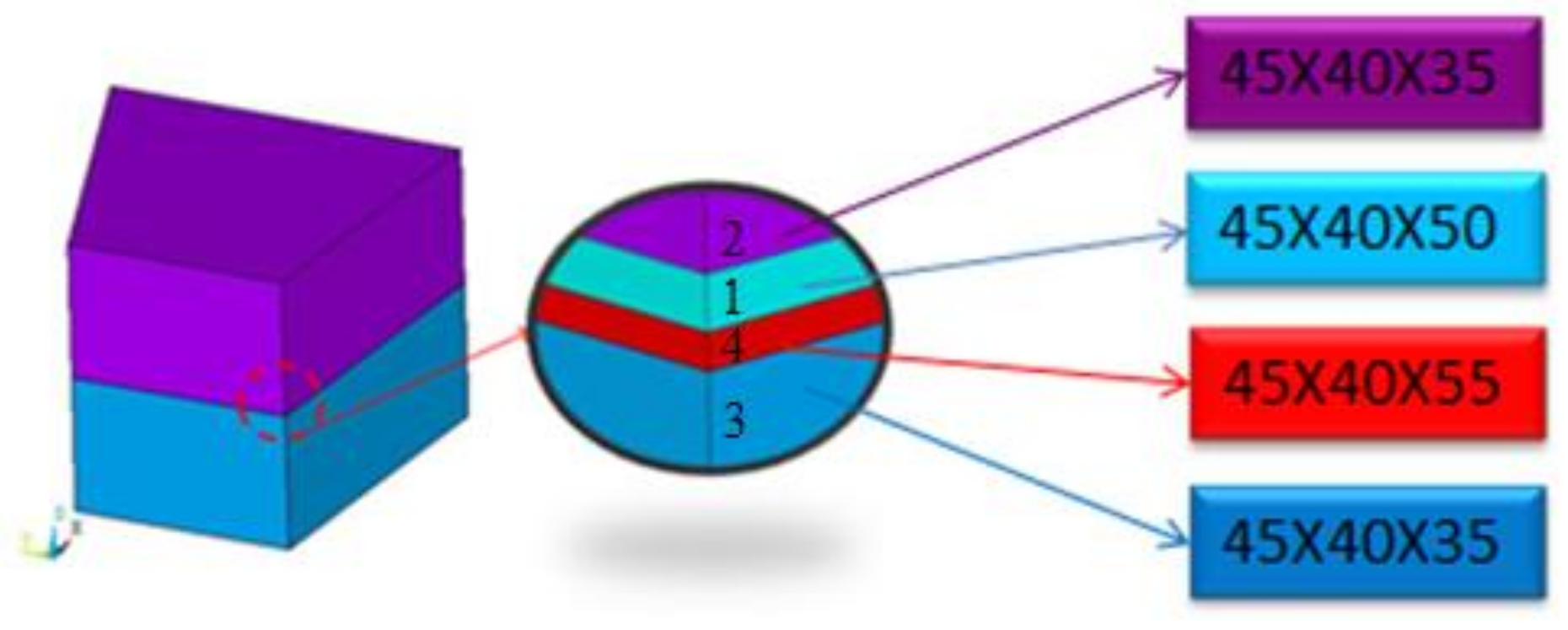

4. Coating Simulation

5. Convergence Criteria

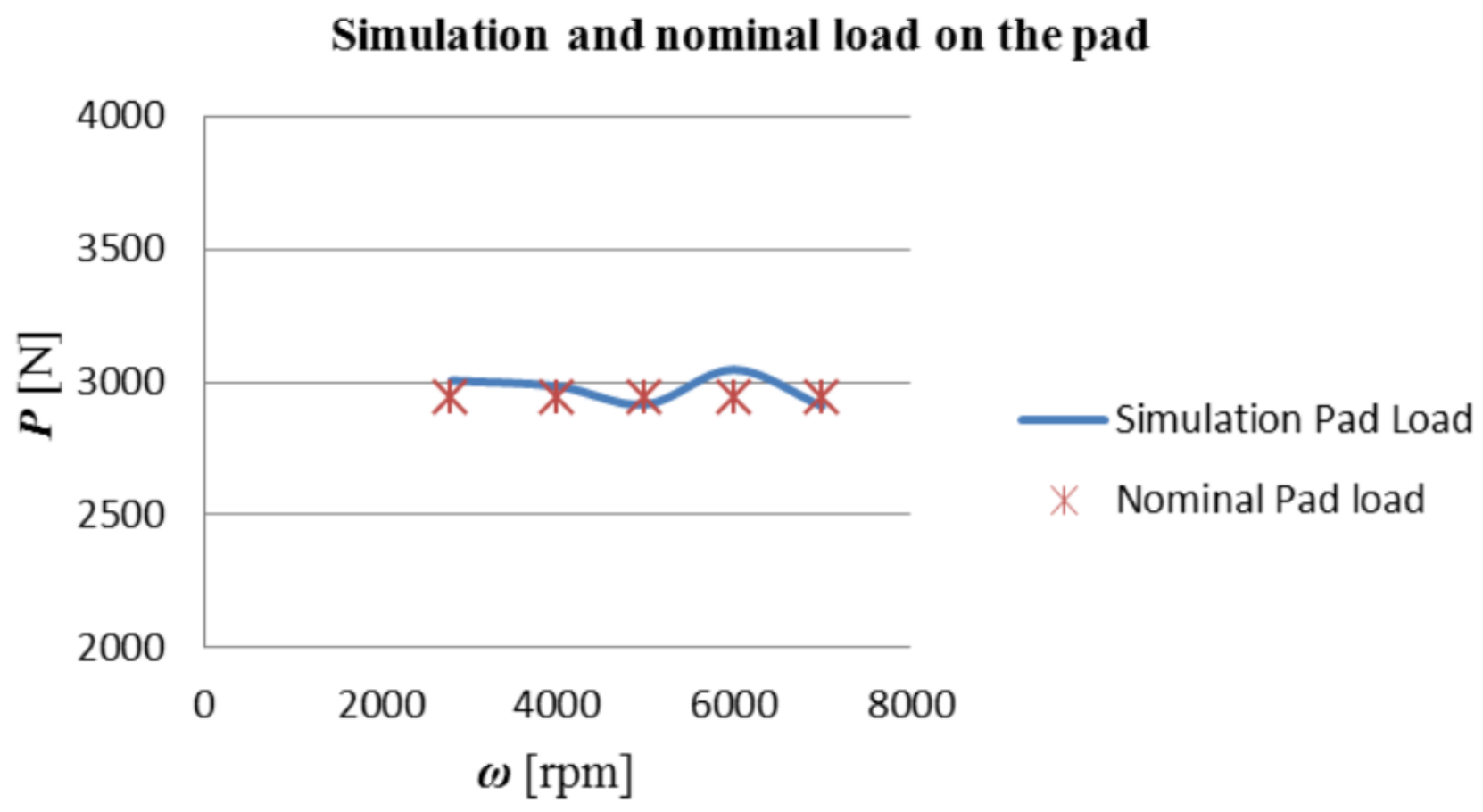

6. Validation

7. Design Parameters

8. Results

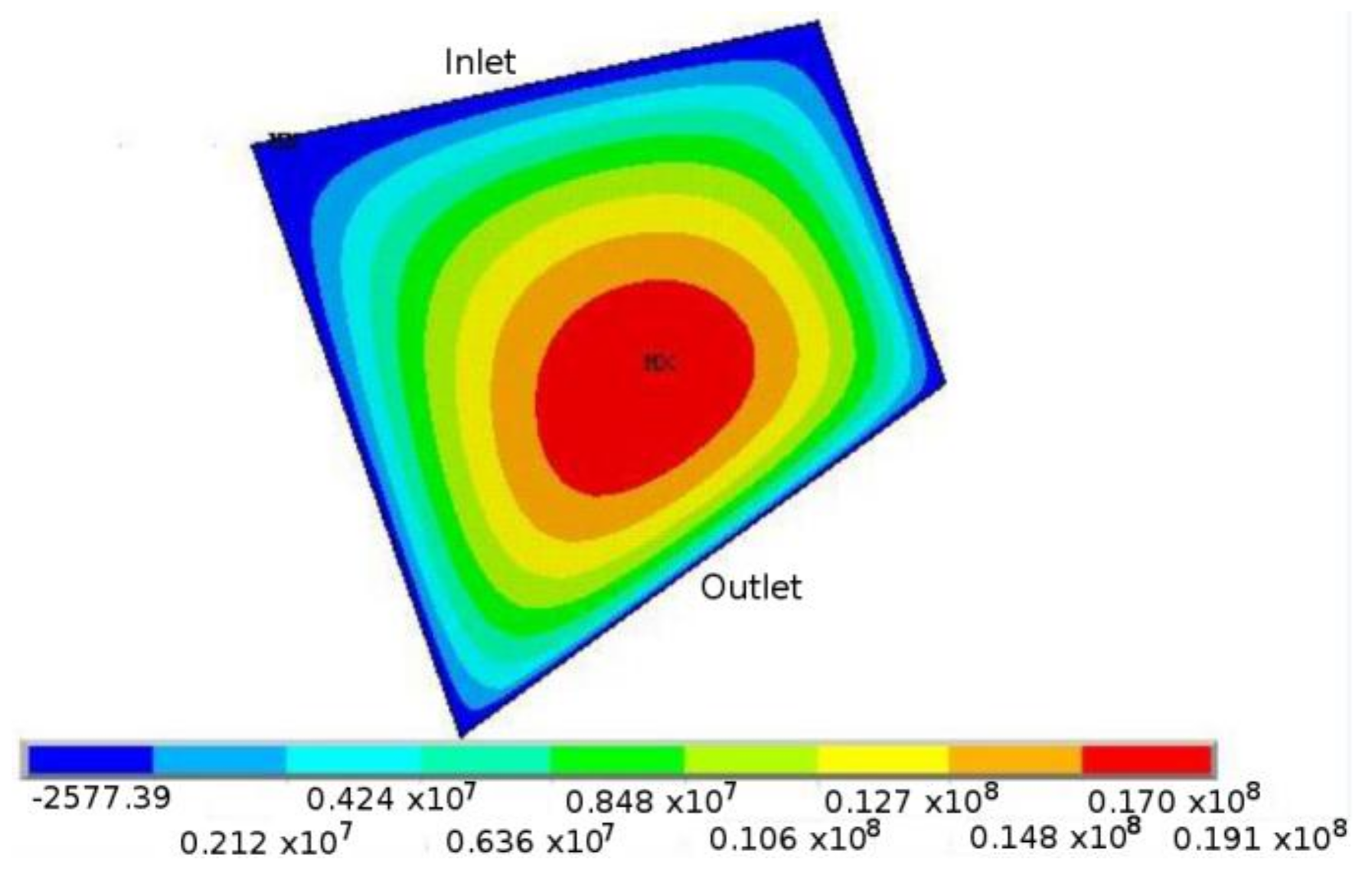

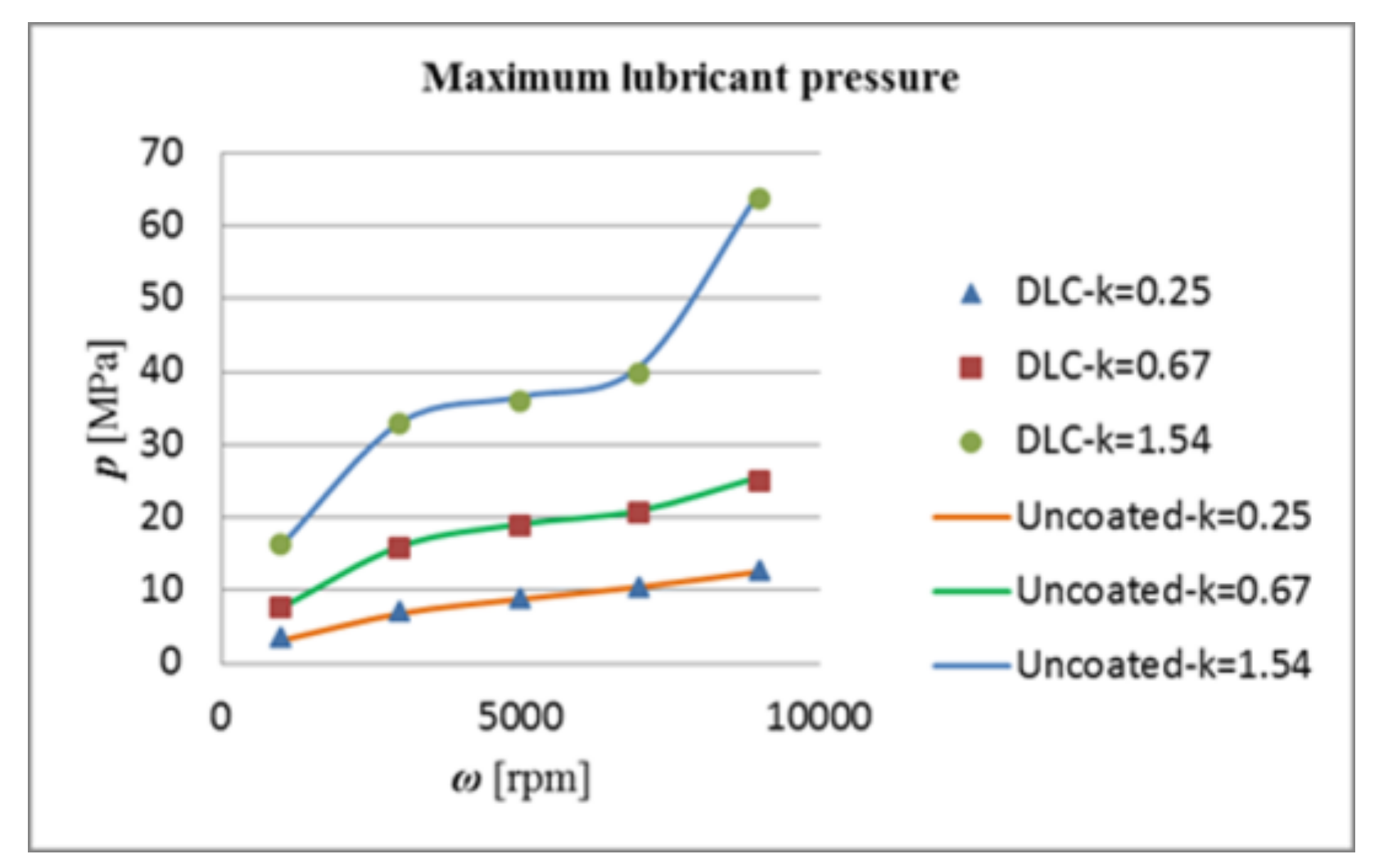

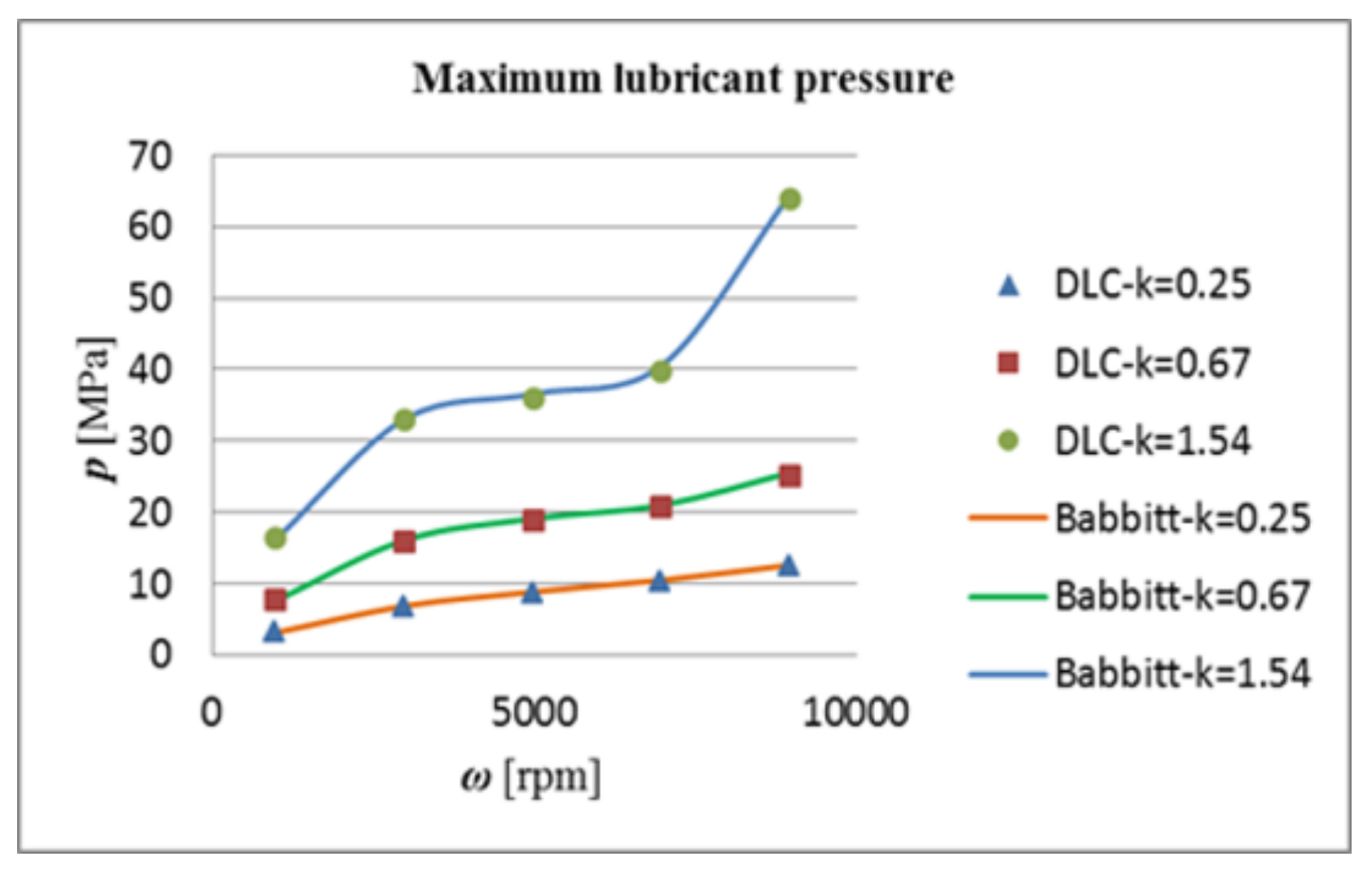

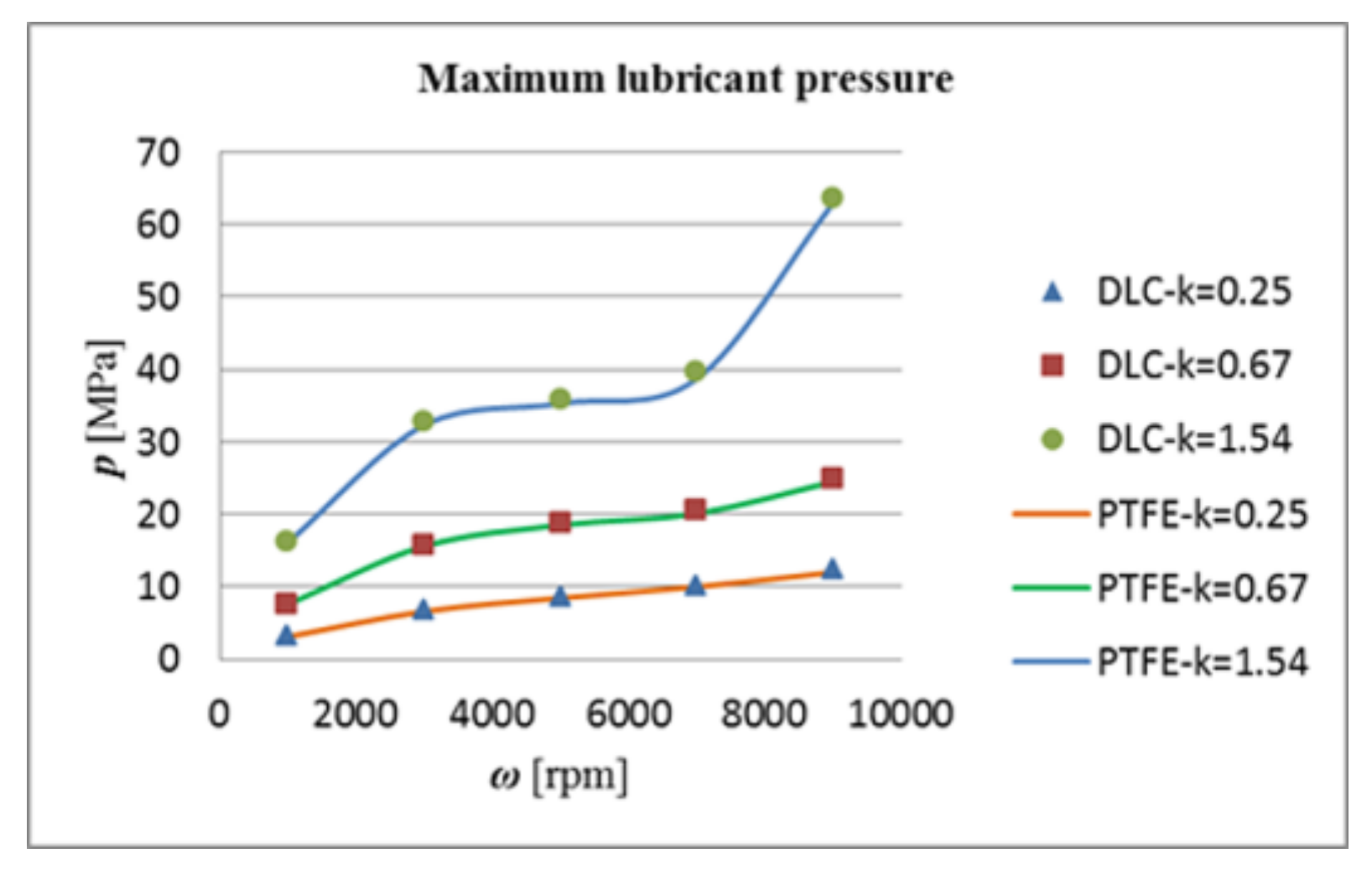

8.1. Hydrodynamic Problem

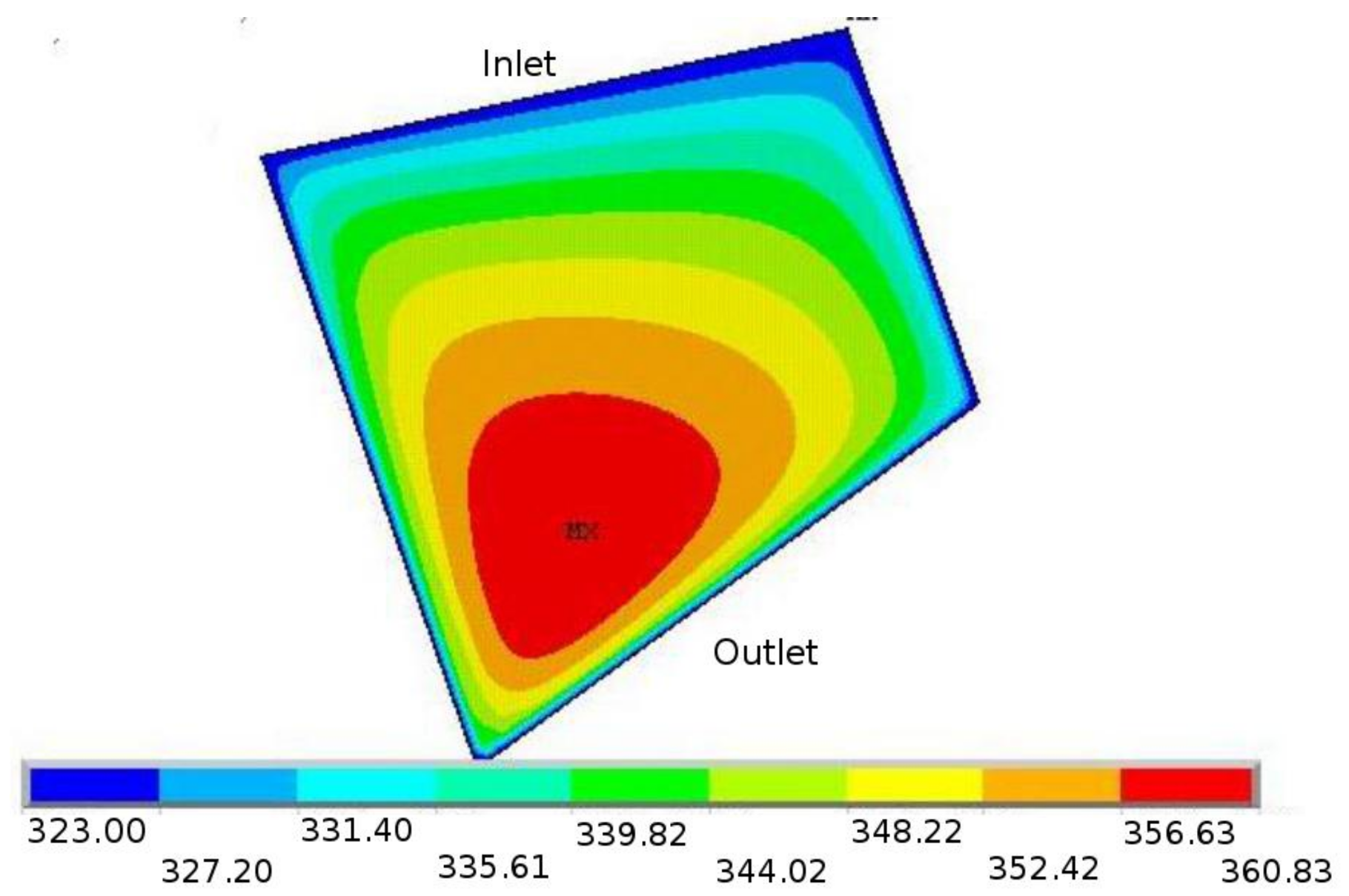

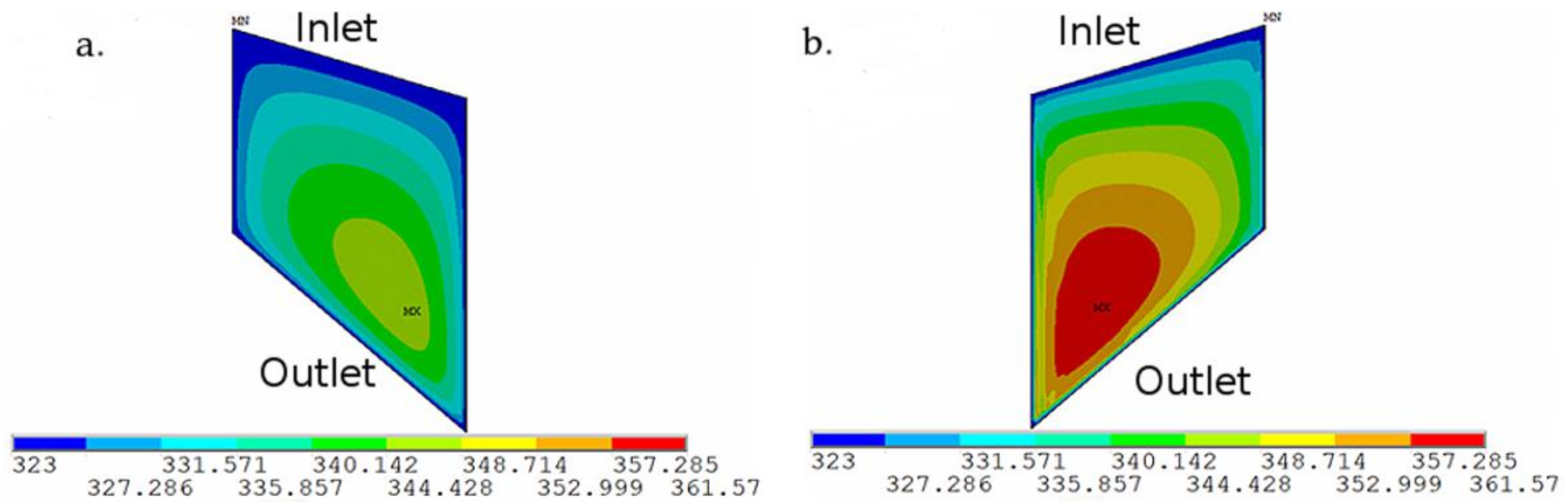

8.2. Thermo-Hydrodynamic Problem

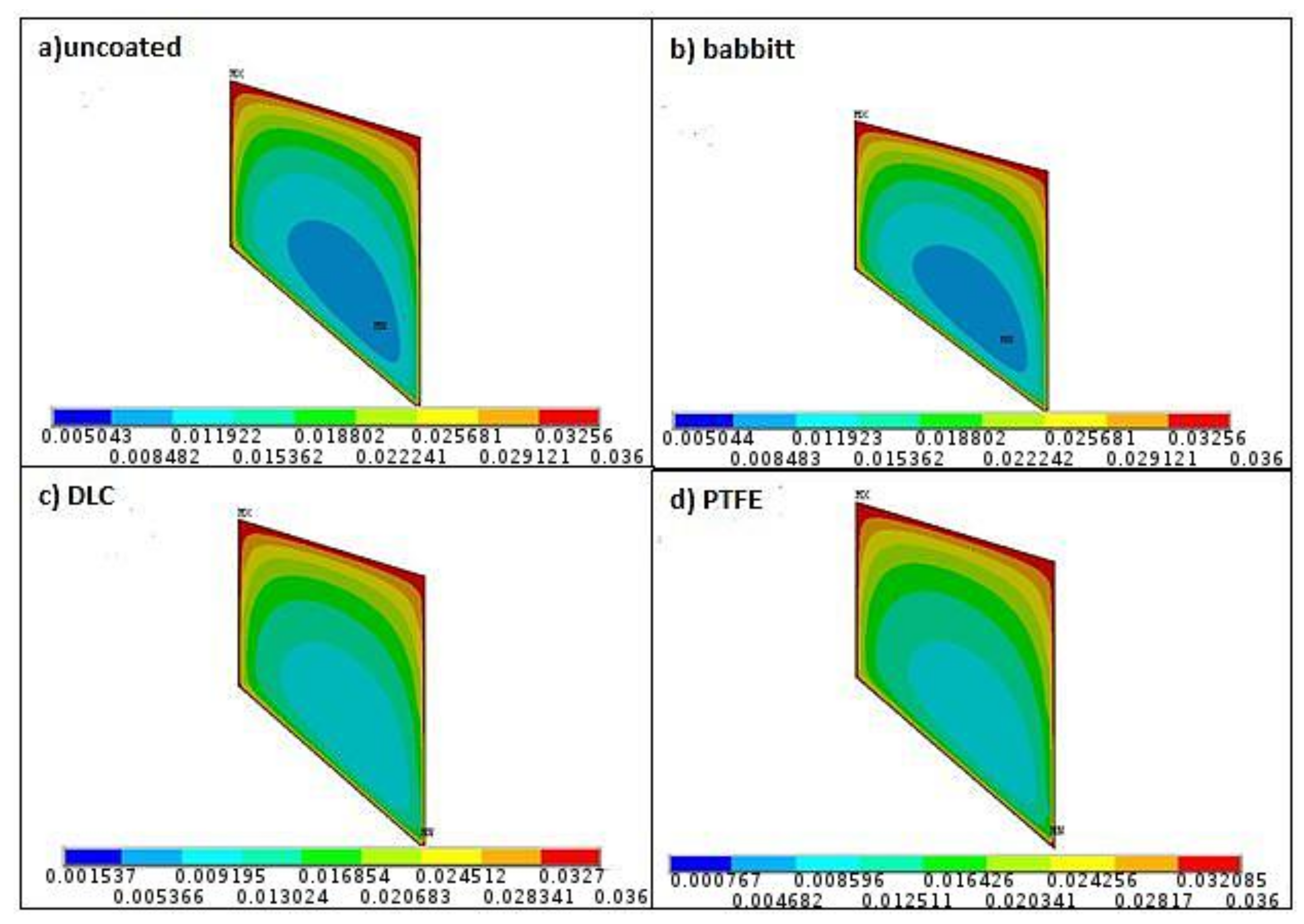

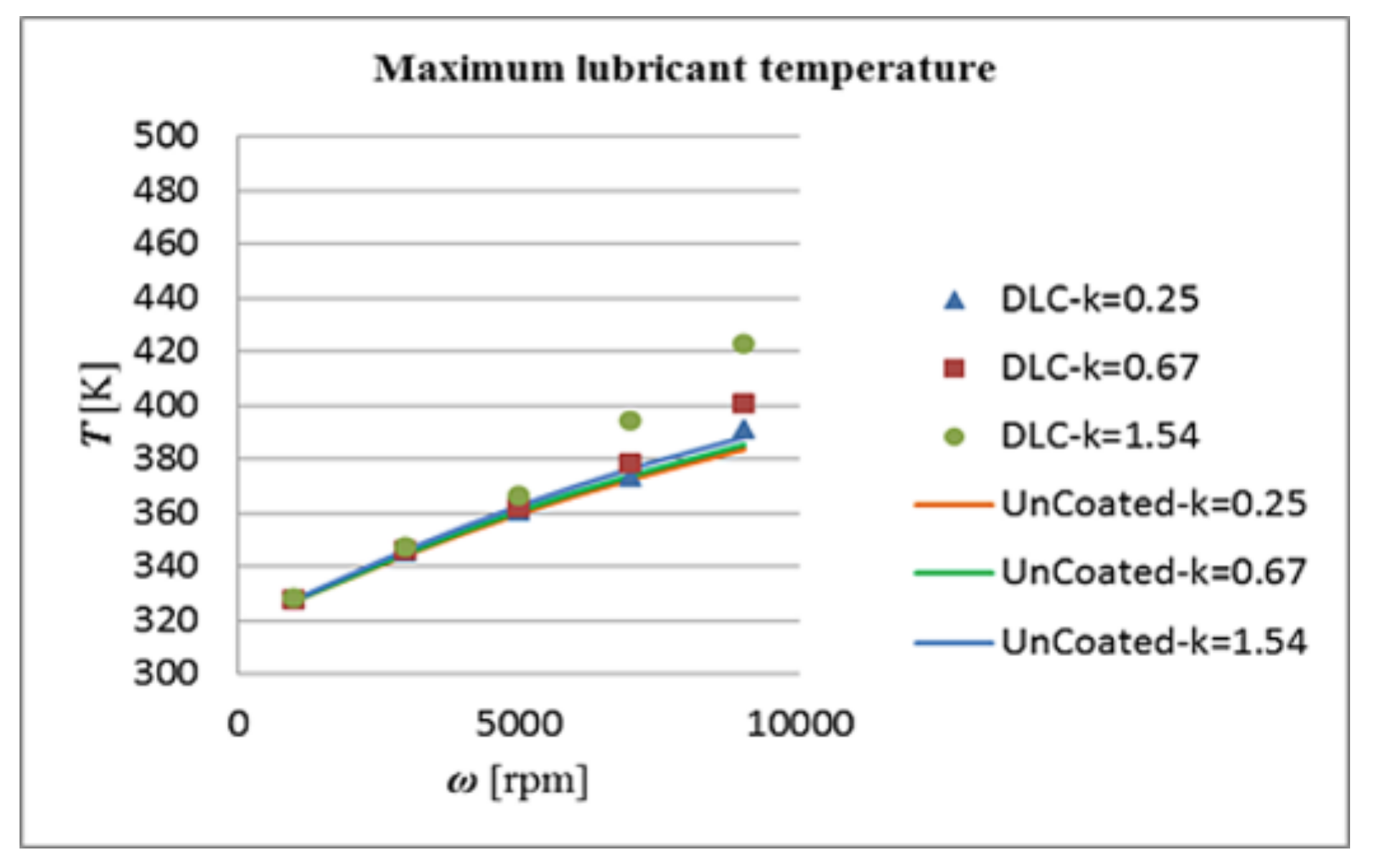

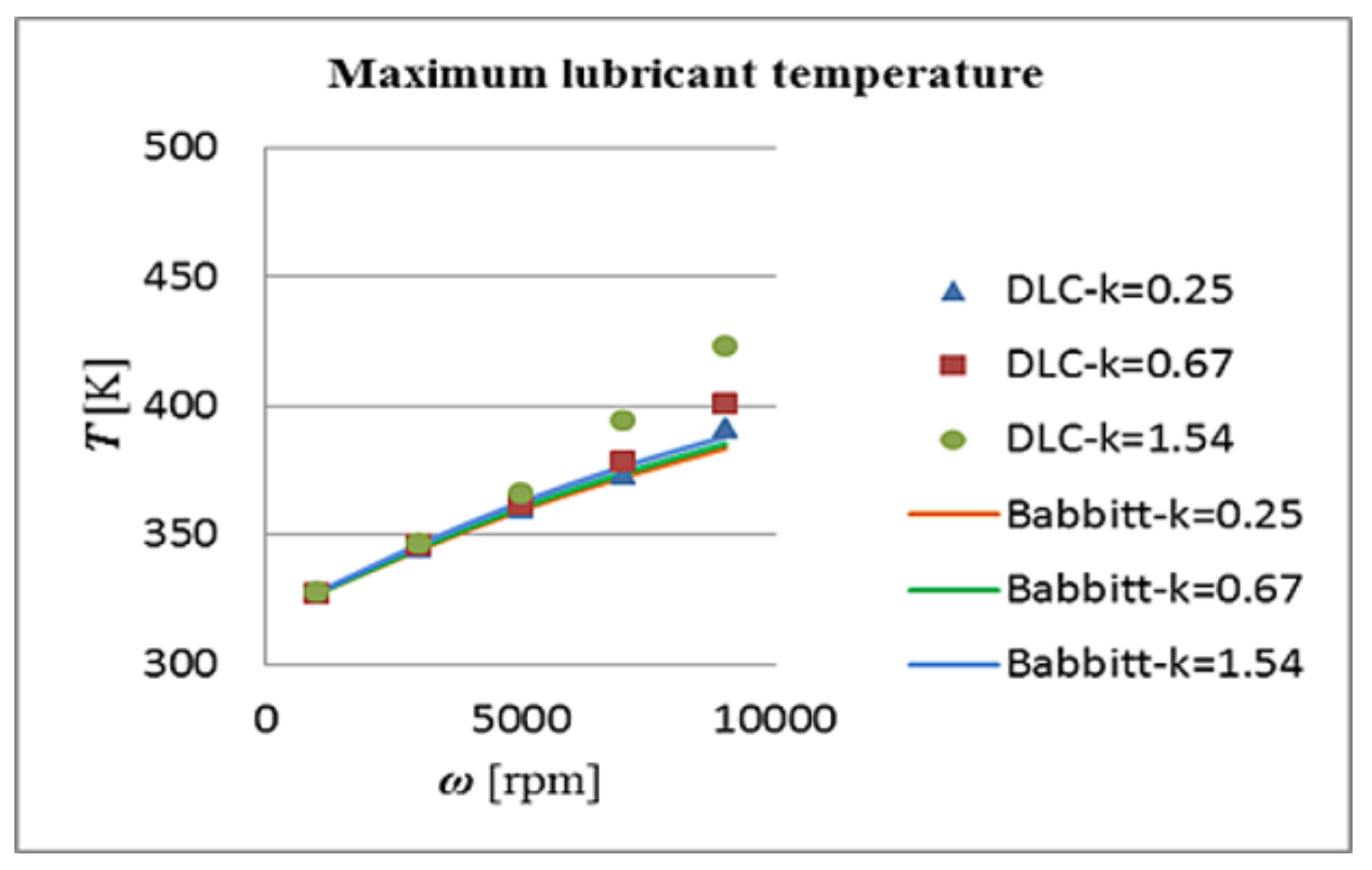

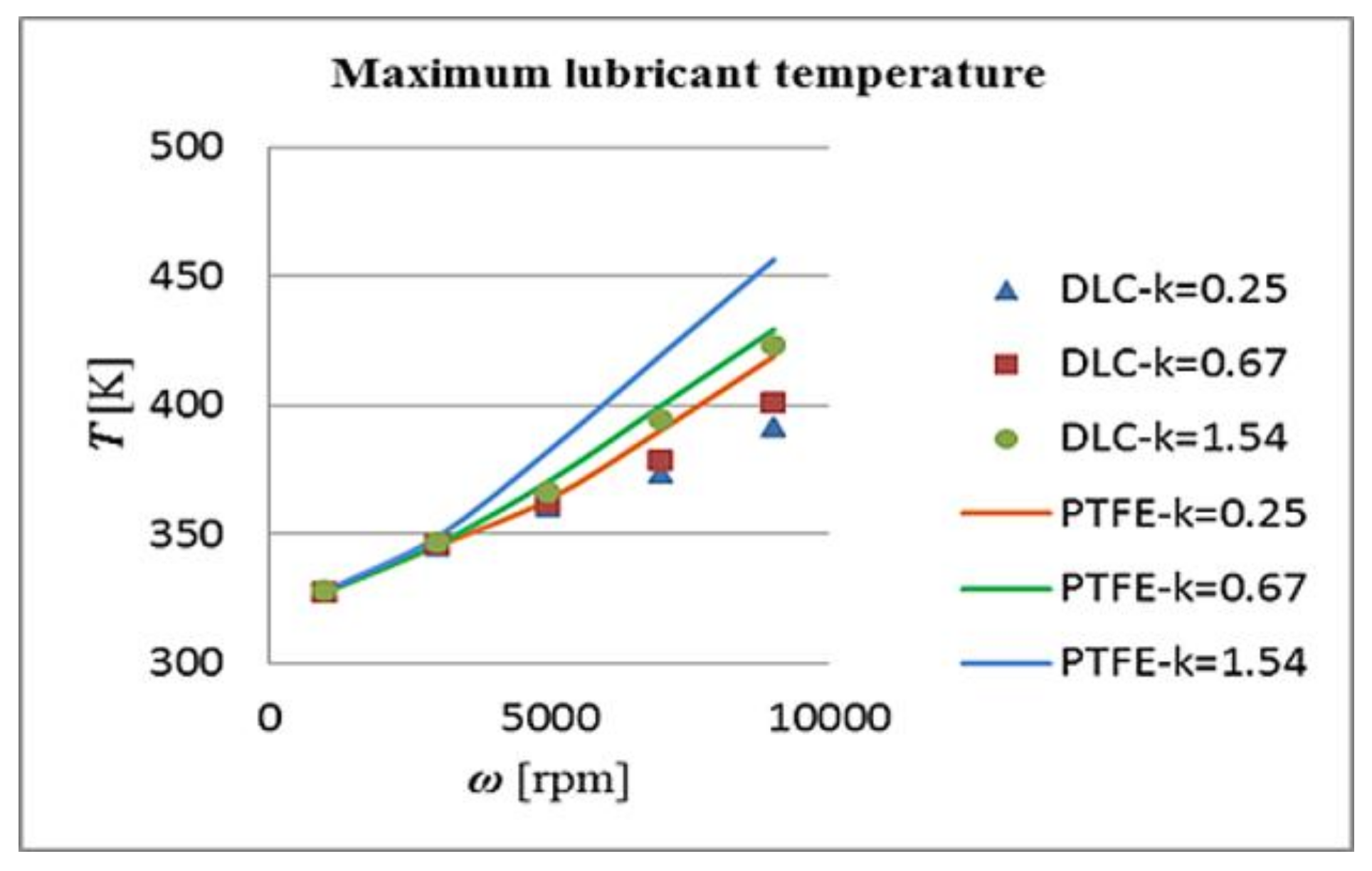

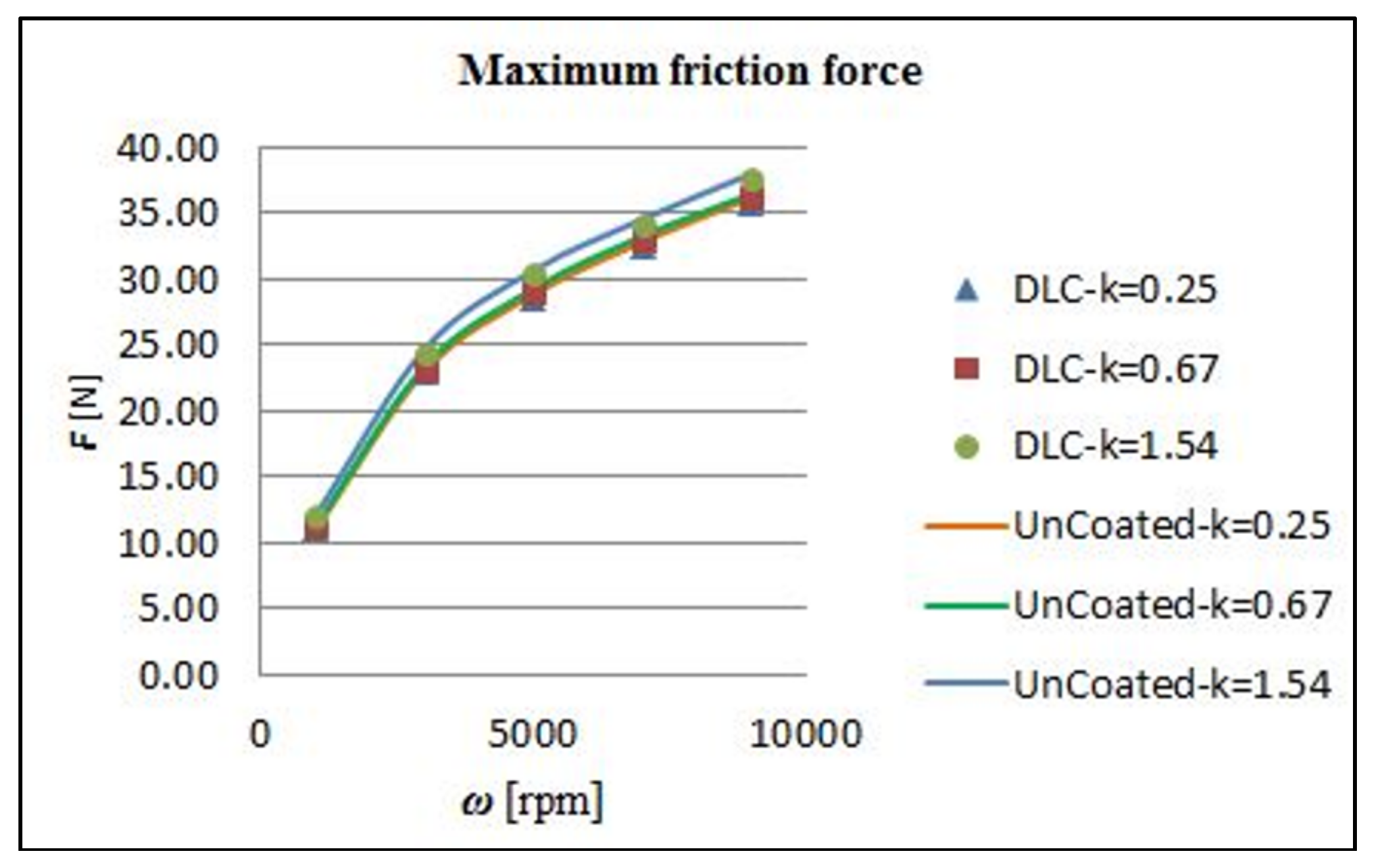

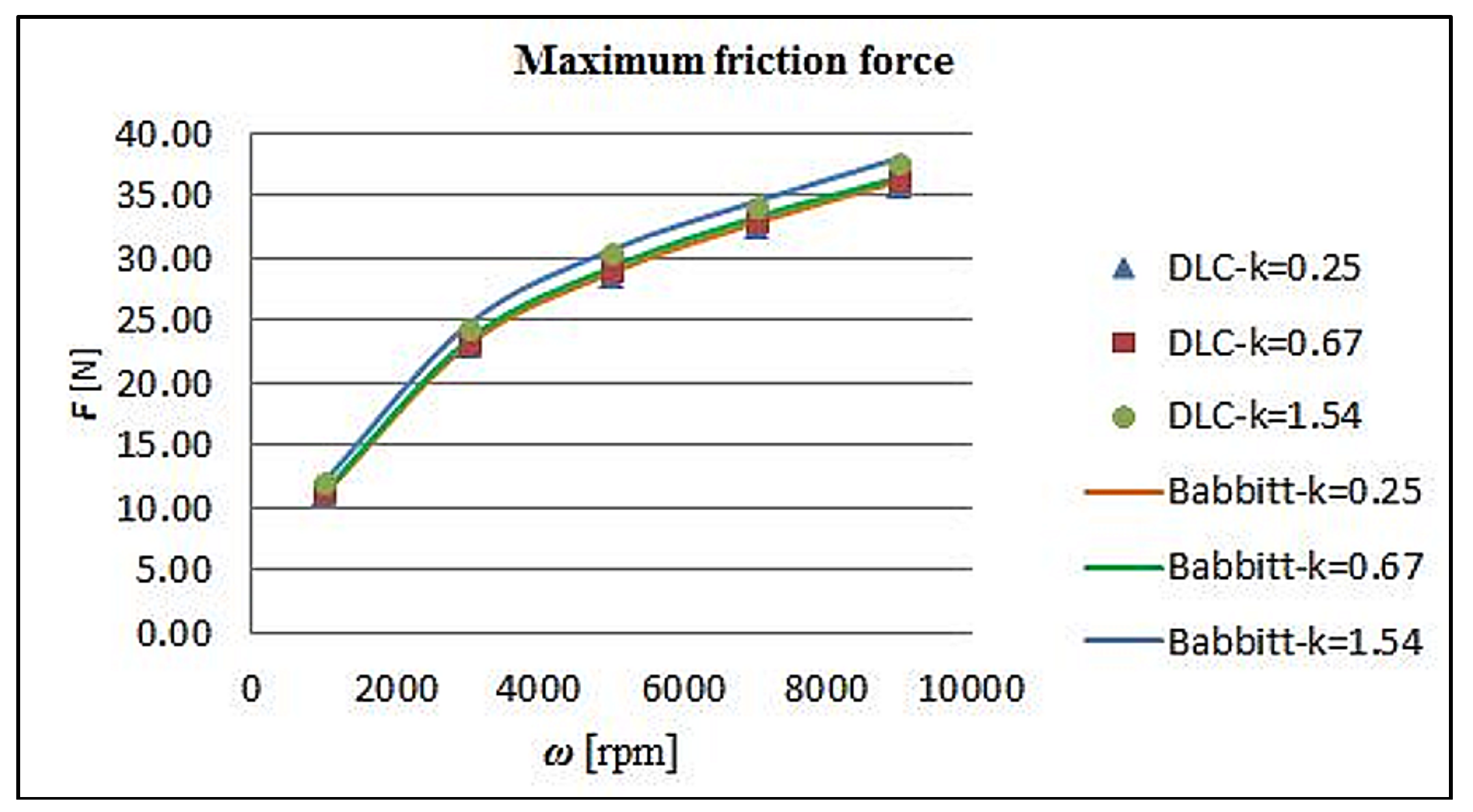

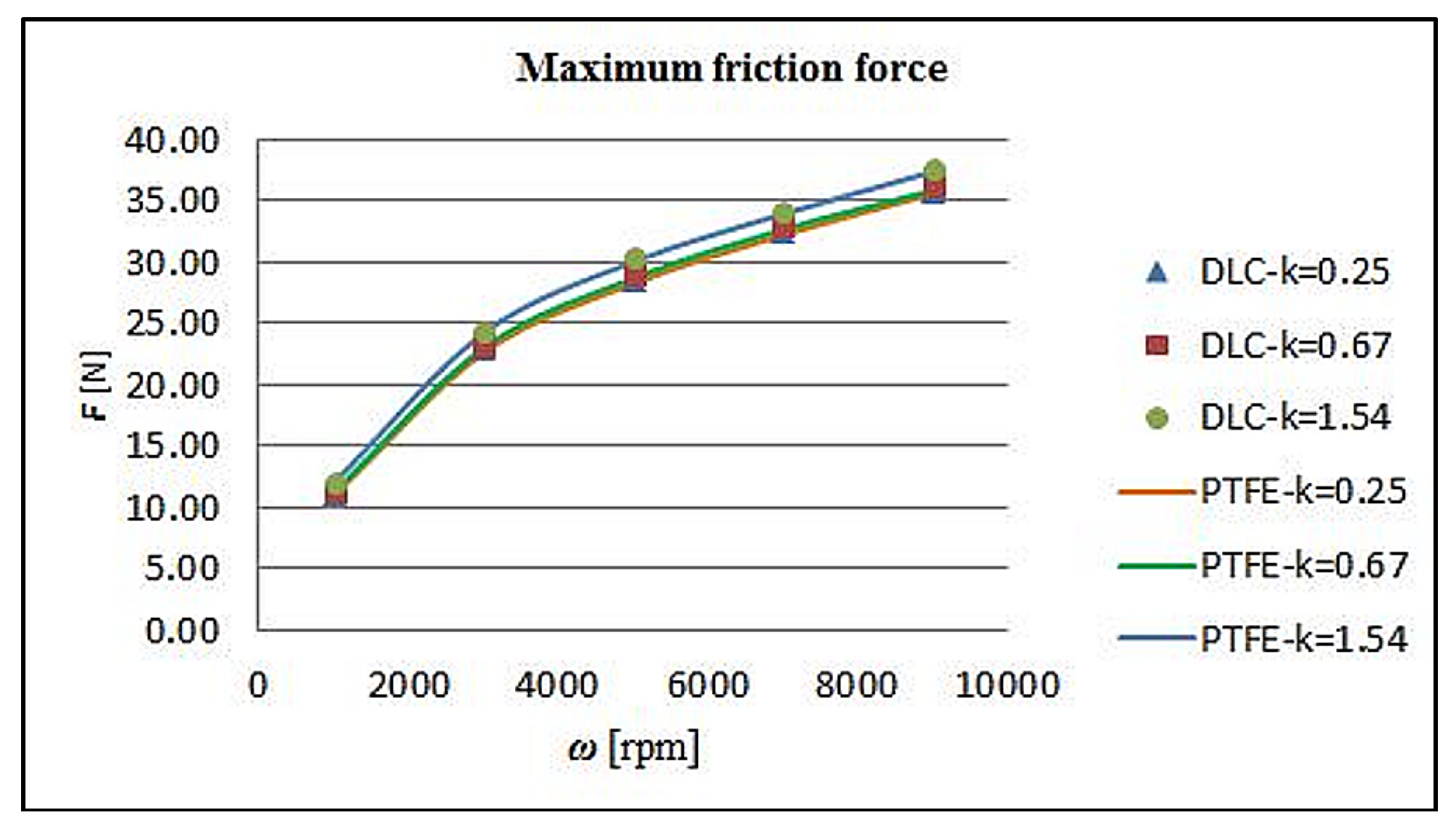

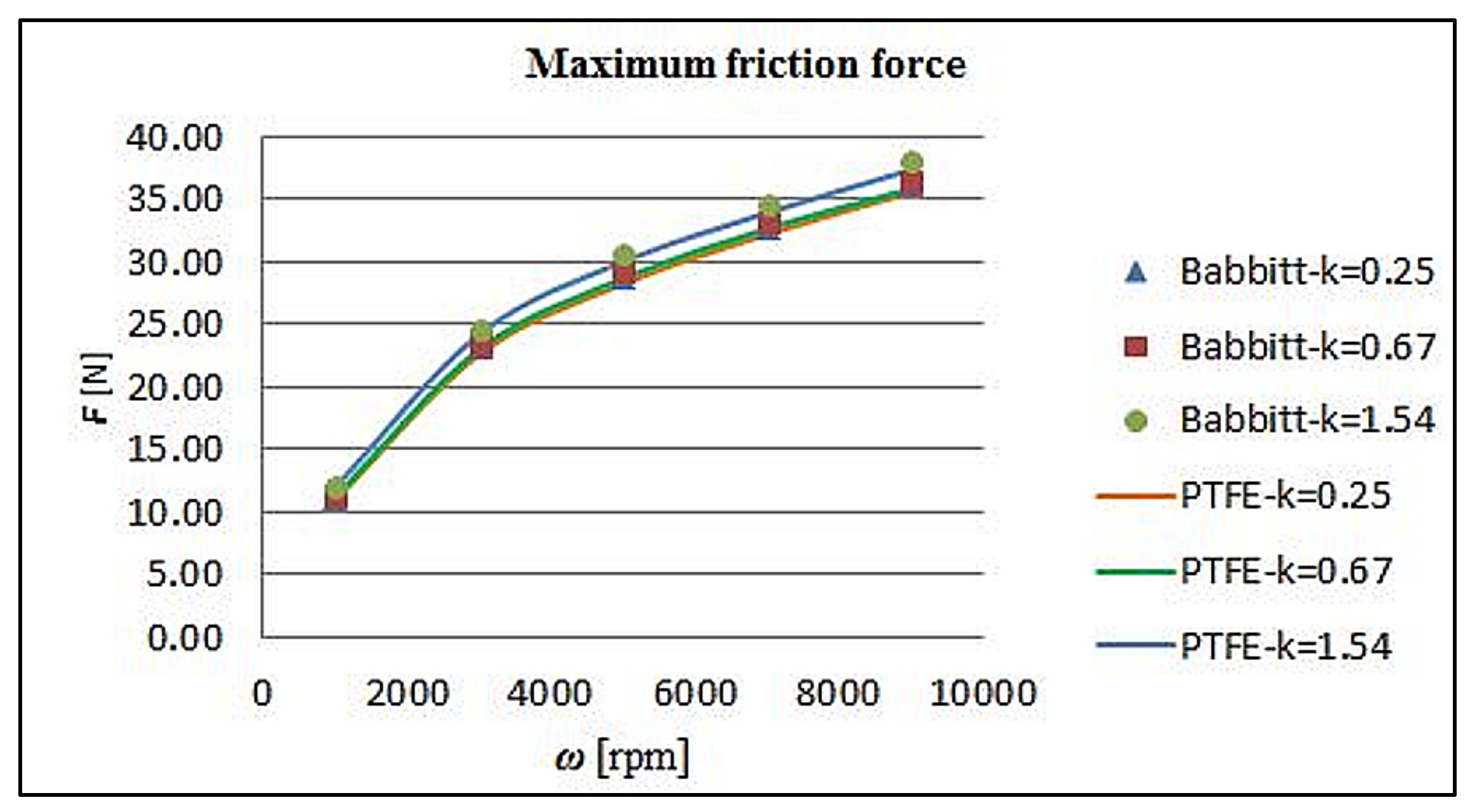

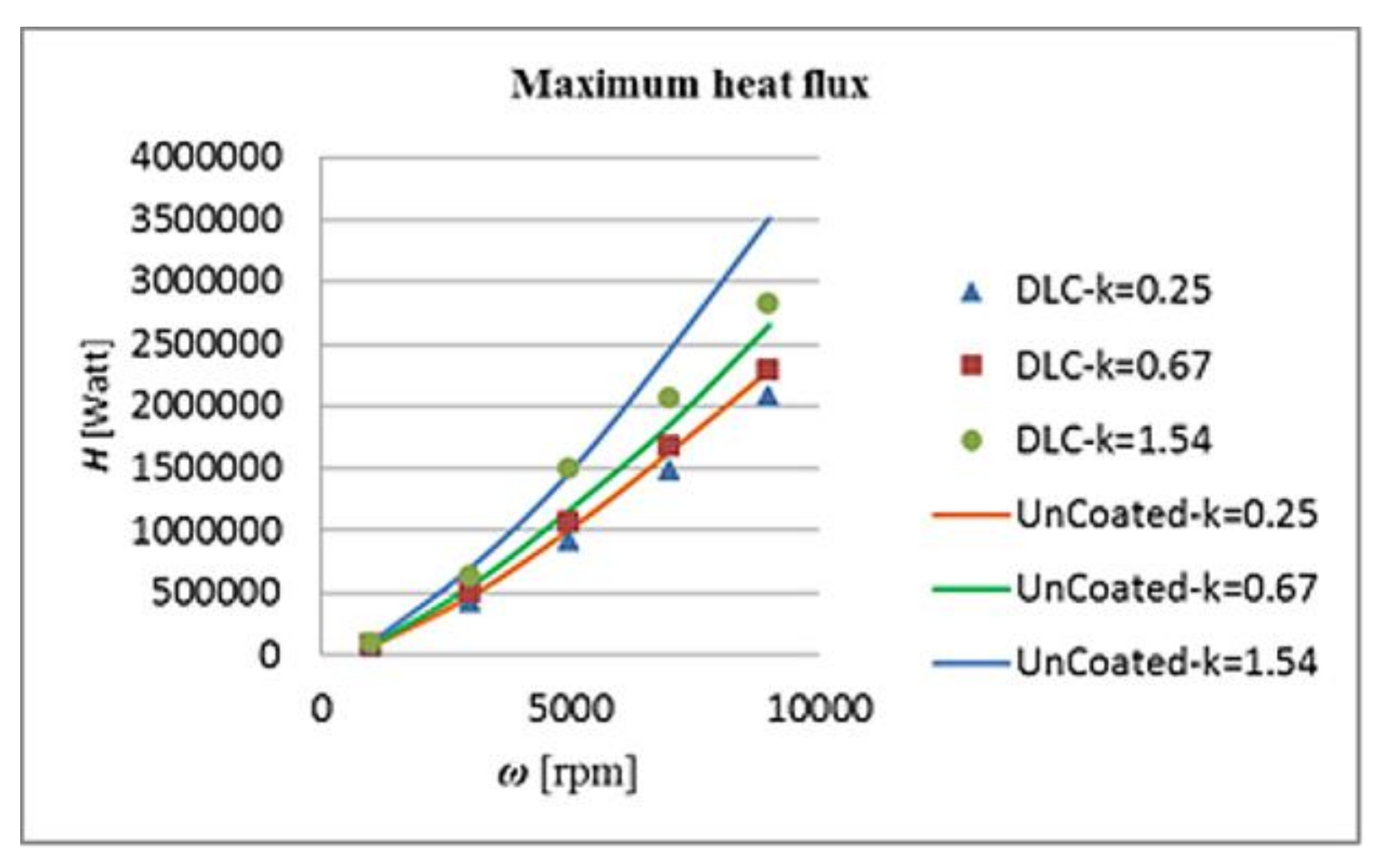

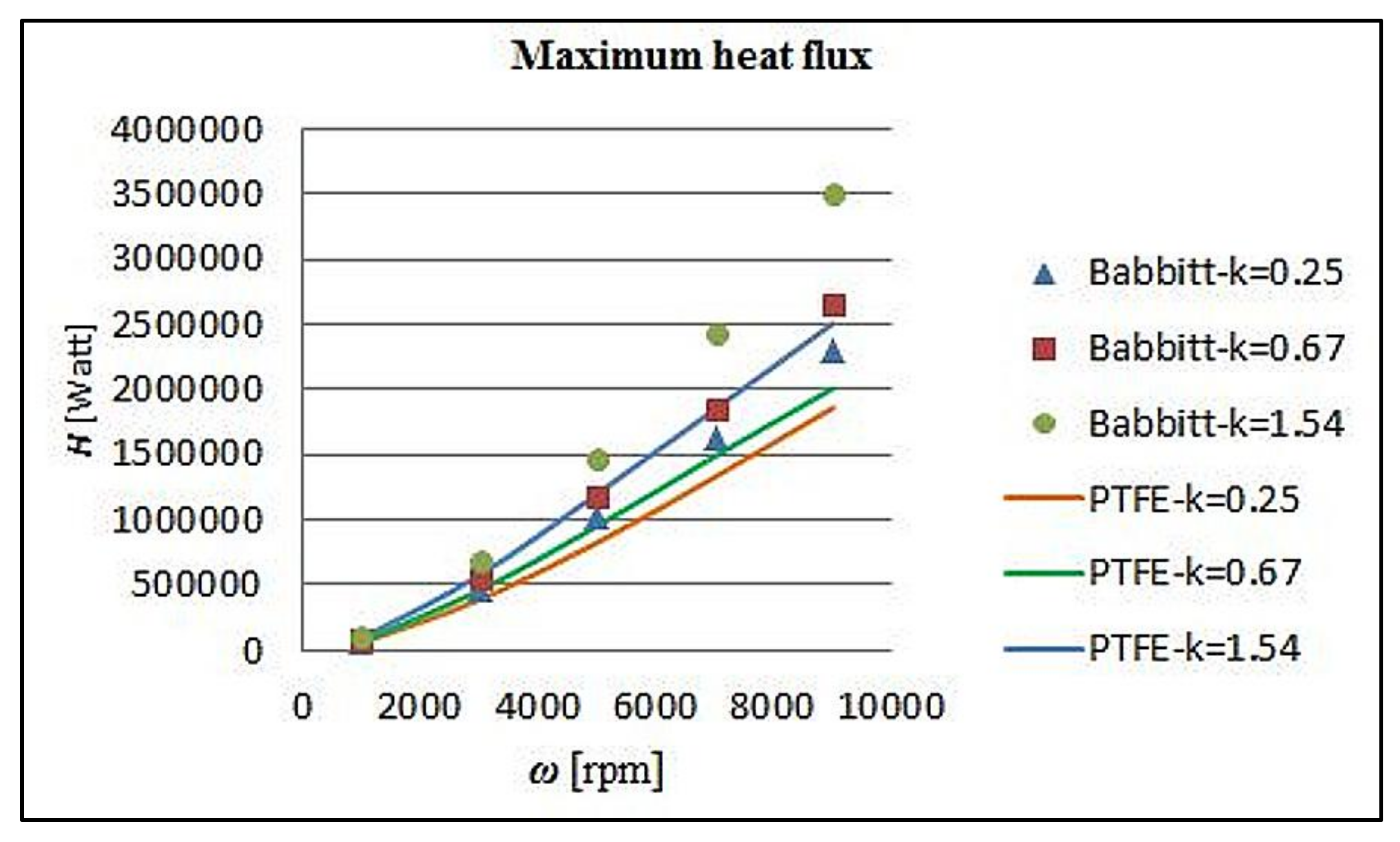

8.3. Thermo-Hydrodynamic Results for the Uncoated and Coated Thrust Bearings

9. Conclusions

- ✓

- The tin-based Babbitt coating has similar properties to steel. As a result, no significant changes were observed for the flow and thermal fields.

- ✓

- The Babbitt coating shows up to 5% higher pressure, 15% lower temperature but 2% higher friction force compered to PTFE. Similarly, when compared to DLC, the corresponding values are 2.5% higher pressure, 7% lower temperature but 1% higher friction force. The low thermal conductivities of DLC and PTFE result in higher temperatures and lower viscosity values for the lubricant. Lower viscosity values result in lower pressure, which corresponds to lower load capacity for the bearing.

- ✓

- The mechanical and thermal properties of PTFE and DLC allow them to be appropriate for a wider range of applications in terms of minimum film thickness and lubricant temperatures. However, DLC shows up to 2.5% higher pressure and 7% lower temperature for the worst case studied, with 1.1% higher friction force for the DLC. PTFE has lower thermal conductivity than DLC. As a result, higher temperatures are observed in the lubricant during operation, which end up in lower viscosity values that affect the flow field and the pressure drops together with the load capacity of the bearing.

Author Contributions

Conflicts of Interest

Nomenclature

| total area of bearing pads [m2] | |

| rotor’s width [m] | |

| first viscosity coefficient—absolute temperature at which μ = μν (323 K) | |

| second viscosity coefficient according to Sutherland’s law = 3800 | |

| third viscosity coefficient according to Sutherland’s law = 30,000 | |

| specific heat [J/Kg K] | |

| film thickness [m] | |

| outlet, inlet film thickness [m] | |

| convective heat transfer coefficient [W/(m2 K)] or [W/(m2 °C)] | |

| minimum film thickness [m]: | |

| convergence ratio: | |

| thermal conductivity [W/(m K)] | |

| thermal conductivity of the rotor [W/(m K)] | |

| thermal conductivity of the stationary pad [W/(m K)] | |

| Np | number of bearing’s pads |

| absolute pressure [Pa] | |

| volumetric heat source (not taken into account) | |

| Re | Reynolds Number |

| absolute temperature [K] | |

| ambient temperature [K] | |

| lubricant temperature [K] | |

| rotor temperature [K] | |

| stationary pad temperature [K] | |

| linear rotor velocity [m/s] | |

| linear rotor velocity-x direction [m/s] | |

| linear rotor velocity-y direction [m/s] | |

| linear rotor velocity-z direction [m/s] | |

| viscosity coefficient [Pas] | |

| nominal viscosity (0.036 Pas) | |

| density [Kg/m3] |

References

- Dowson, D.; Hudson, J. Thermohydrodynamic analysis of the infinite slider bearing: Part I, the plane inclined slider bearing. Proc. Inst. Mech. Eng. 1963, 34, 34–44. [Google Scholar]

- Elrod, H. Efficient numerical method for computation of the thermohydrodynamics of laminar lubricating films. J. Tribol. 1991, 113, 506–511. [Google Scholar] [CrossRef]

- Chowdhury, S.; Ahmadi, G. Thermodynamic analysis of wide thrust bearings operating in laminar inertial flow regimes. Tribol. Int. 1986, 19, 281–288. [Google Scholar] [CrossRef]

- Neale, M.J. The Tribology Handbook; Butterworth-Heinemann: Oxford, UK, 1995. [Google Scholar]

- Shan, X.C.; Zhang, Q.D.; Sun, Y.F.; Maeda, R. Studies on a Micro Turbine Device with both Journal- and Thrust-Air Bearings. Microsyst. Technol. 2007, 13, 1501–1508. [Google Scholar] [CrossRef]

- Boncompain, R.; Fillon, M.; Frene, J. Analysis of thermal effects in hydrodynamic bearings. J. Tribol. 1986, 108, 219–224. [Google Scholar] [CrossRef]

- Ezzat, H.; Rohde, S. A study of the thermohydrodynamic performance of finite slider bearings. J. Tribol. 1973, 95, 298–307. [Google Scholar] [CrossRef]

- Almqvist, T.; Glavatskikh, S.; Larsson, R. THD analysis of tilting pad thrust bearings—Comparison between theory and experiments. J. Tribol. 2000, 122, 412–417. [Google Scholar] [CrossRef]

- Khonsari, M. A review of thermal effects in hydrodynamic bearings part I: Slider and thrust bearings. ASLE Trans. 1987, 30, 19–25. [Google Scholar] [CrossRef]

- Tanaka, M. Recent thermohydrodynamic analyses and designs of thick-film bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2000, 214, 107–122. [Google Scholar] [CrossRef]

- Kalin, M.; Velkavrh, I.; Vižintin, J. The Stribeck curve and lubrication design for Non-fully wetted surfaces. Wear 2009, 267, 1232–1240. [Google Scholar] [CrossRef]

- Kalin, M.; Polajnar, M. The Effect of Wetting and Surface Energy on the Friction and Slip in Oil Lubricated Contacts. Tribol. Lett. 2013, 52, 185–194. [Google Scholar] [CrossRef]

- Kalin, M.; Polajnar, M. The wetting of steel, DLC coatings, ceramics and polymers with oils and water: The importance and correlations of surface energy, surface tension, contact angle and spreading. Appl. Surf. Sci. 2014, 293, 97–108. [Google Scholar] [CrossRef]

- Björling, M.; Isaksson, P.; Marklund, P.; Larsson, R. The influence of DLC coating on EHL friction coefficient. Tribol. Lett. 2012, 47, 285–294. [Google Scholar] [CrossRef]

- Glavatskih, S.B. Evaluating thermal performance of a PTFE-faced tilting pad thrust bearing. J. Tribol. 2003, 125, 319–324. [Google Scholar] [CrossRef]

- Mahieux, C. Experimental characterization of the influence of coating materials on the hydrodynamic behavior of thrust bearings: A comparison of Babbitt, PTFE, and PFA. J. Tribol. 2005, 127, 568–574. [Google Scholar] [CrossRef]

- Zhou, J.; Blair, B.; Argires, J.; Pitsch, D. Experimental Performance Study of a High Speed Oil Lubricated Polymer Thrust Bearing. Lubricants 2015, 3, 3–13. [Google Scholar] [CrossRef]

- Ricci, R.; Chatterton, S.; Pennacchi, P.; Vania, A. (Eds.) Multiphysics Modeling of a Tilting Pad Thrust Bearing: Comparison Between White Metal and Polymeric Layered Pads. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011; American Society of Mechanical Engineers: New York, NY, USA, 2011. [Google Scholar]

- Jahanmir, S.; Hunsberger, A.Z.; Heshmat, H. Load capacity and durability of H-DLC coated hydrodynamic thrust bearings. J. Tribol. 2011, 133, 031301. [Google Scholar] [CrossRef]

- Glavatskih, S.B.; Fillon, M. TEHD analysis of thrust bearings with PTFE—Faced pads. Trans. ASME J. Tribol. 2006, 128, 49–58. [Google Scholar] [CrossRef]

- Ettles, C.; Knox, R.; Ferguson, J.; Horner, D. Test results for PTFE-faced thrust pads, with direct comparison against Babbitt-faced pads and correlation with analysis. J. Tribol. 2003, 125, 814–823. [Google Scholar] [CrossRef]

- Pap, B.; Fillon, M.; Guillemont, M.; Bauduin, L.; Chocron, J.; Gédin, P.; Biadalla, L. Experimental and Numerical Analysis on the Seizure of a Carbon-Filled PTFE Central Groove Journal Bearing during Start-Up Period. Lubricants 2018, 6, 14. [Google Scholar] [CrossRef]

- Aurelian, F.; Patrick, M.; Mohamed, H. Wall slip effects in (elasto) hydrodynamic journal bearings. Tribol. Int. 2011, 44, 868–877. [Google Scholar] [CrossRef]

- Bielec, M.; Leopard, A. (Eds.) Tilting Pad Thrust Bearings: Factors Affecting Performance and Improvements with Directed Lubrication; The Institution of Mechanical Engineers, Tribology Convention: Westminster, UK, 1970. [Google Scholar]

- Periodic Table. Available online: http://www.periodictable.com (accessed on 28 October 2017).

- Engineering Toolbox. Available online: http://www.engineeringtoolbox.com (accessed on 23 December 2017).

- Shamsa, M.; Liu, W.L.; Balandin, A.A.; Casiraghi, C.; Milne, W.I.; Ferrari, A.C. Thermal conductivity of diamond-like carbon films. Appl. Phys. Lett. 2006, 89, 161921. [Google Scholar] [CrossRef]

- Zhou, Z.F.; Li, K.Y.; Bello, I.; Lee, C.S.; Lee, S.T. Study of tribological performance of ECR–CVD diamond-like carbon coatings on steel substrates Part 2. The analysis of wear mechanism. Wear 2005, 258, 1589–1599. [Google Scholar] [CrossRef]

- Blumm, J.; Lindemann, A.; Meyer, M.; Strasser, C. Characterization of PTFE Using Advanced Thermal Analysis Techniques. Int. J. Thermophys. 2010, 31, 1919–1927. [Google Scholar] [CrossRef]

| Velocity (rpm) | Minimum Film Thickness (μm) | Simulation Pad Load (N) | Experimental Pad Load (N) [24] | Simulation Max Pad Temp (°C) | Experimental Pad Temp (°C) [24] |

|---|---|---|---|---|---|

| 2800 | 10.0 | 3005.8 | 2943.5 | 72.07 | 79 |

| 4000 | 10.6 | 2985.0 | 2943.5 | 80.28 | 87 |

| 5000 | 11.0 | 2916.5 | 2943.5 | 85.34 | 94 |

| 6000 | 11.2 | 3047.6 | 2943.5 | 89.92 | 100 |

| 7000 | 11.4 | 2910.4 | 2943.5 | 93.99 | 105 |

| Material | Density (kg/m3) | Specific Heat (J/kg K) | Thermal Conductivity (W/mK) |

|---|---|---|---|

| Bronze Rotor | 8200 | 435 | 110 |

| Steel Pad | 7750 | 452 | 43 |

| Babbitt | 7400 | 297 | 40 |

| DLC | 1860 | 970 | 0.6 |

| PTFE | 2200 | 1200 | 0.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katsaros, K.; Bompos, D.A.; Nikolakopoulos, P.G.; Theodossiades, S. Thermal–Hydrodynamic Behaviour of Coated Pivoted Pad Thrust Bearings: Comparison between Babbitt, PTFE and DLC. Lubricants 2018, 6, 50. https://doi.org/10.3390/lubricants6020050

Katsaros K, Bompos DA, Nikolakopoulos PG, Theodossiades S. Thermal–Hydrodynamic Behaviour of Coated Pivoted Pad Thrust Bearings: Comparison between Babbitt, PTFE and DLC. Lubricants. 2018; 6(2):50. https://doi.org/10.3390/lubricants6020050

Chicago/Turabian StyleKatsaros, Konstantinos, Dimitrios A. Bompos, Pantelis G. Nikolakopoulos, and Stephanos Theodossiades. 2018. "Thermal–Hydrodynamic Behaviour of Coated Pivoted Pad Thrust Bearings: Comparison between Babbitt, PTFE and DLC" Lubricants 6, no. 2: 50. https://doi.org/10.3390/lubricants6020050

APA StyleKatsaros, K., Bompos, D. A., Nikolakopoulos, P. G., & Theodossiades, S. (2018). Thermal–Hydrodynamic Behaviour of Coated Pivoted Pad Thrust Bearings: Comparison between Babbitt, PTFE and DLC. Lubricants, 6(2), 50. https://doi.org/10.3390/lubricants6020050