3.1. Topographic and Microstructural Analysis of TiAl Multi-Layered Thin Films

First, the microstructure of the as-deposited multilayers was studied by TEM.

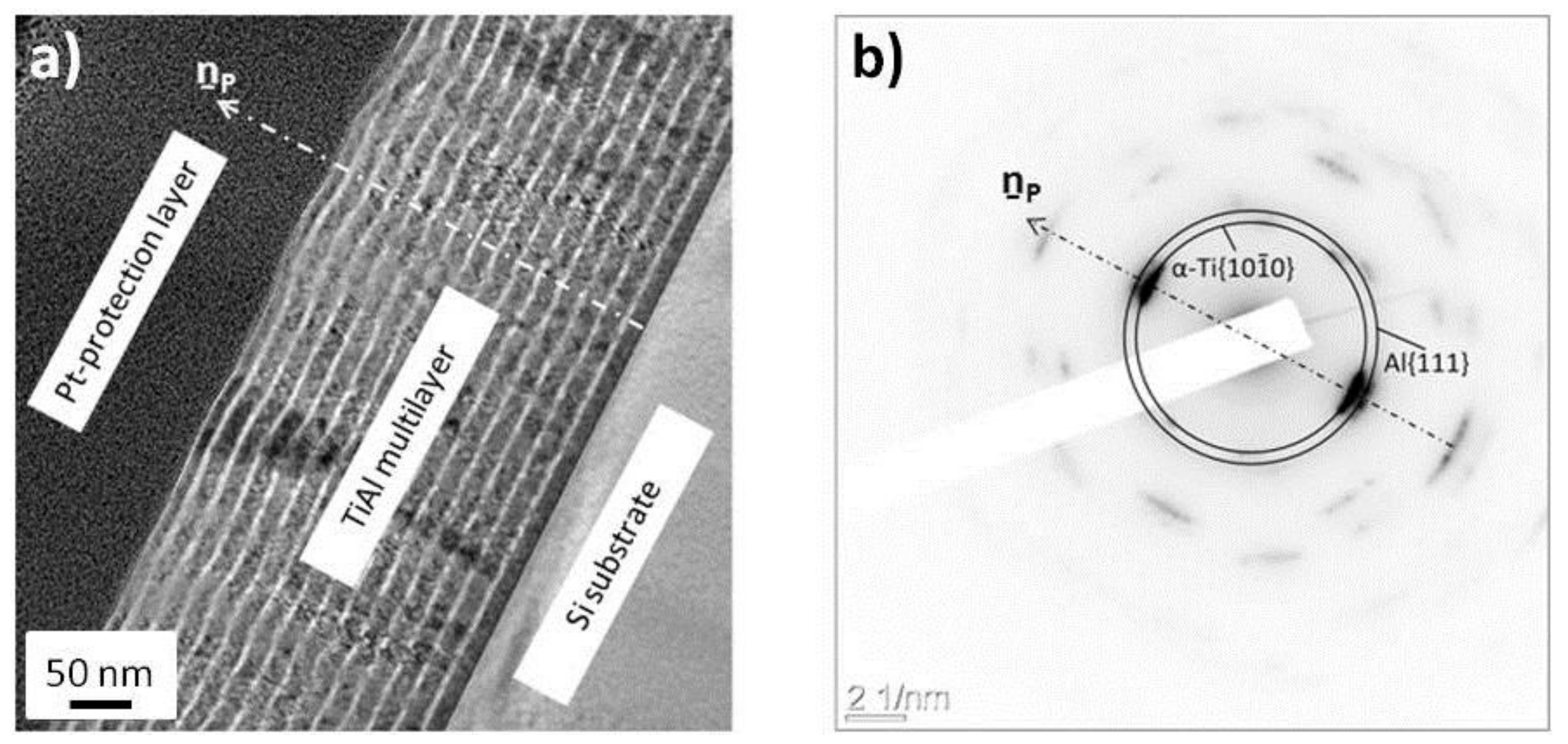

Figure 1a shows a TEM image of the as-deposited TiAl multilayers.

Slight differences in nominal thickness can be explained by uncertainties in the respective sputter rates (Ti: 0.18 nm/s, Al: 0.23 nm/s). TEM foils were prepared by FIB and analyzed by SAD using TEM (

Figure 1b). The diffraction spots were blurred because of overlapping reflections coming from the Al–{111} and Ti–{0001} planes and due to the waviness of the near-surface layers. Despite this, with the Ti–{0001} and Al–{111} planes being parallel to the sample’s surface, a fiber-texture could be identified. Analysis of the topography after magnetron sputtering by WLI revealed a smooth surface, with

Rq roughness of about 1 nm.

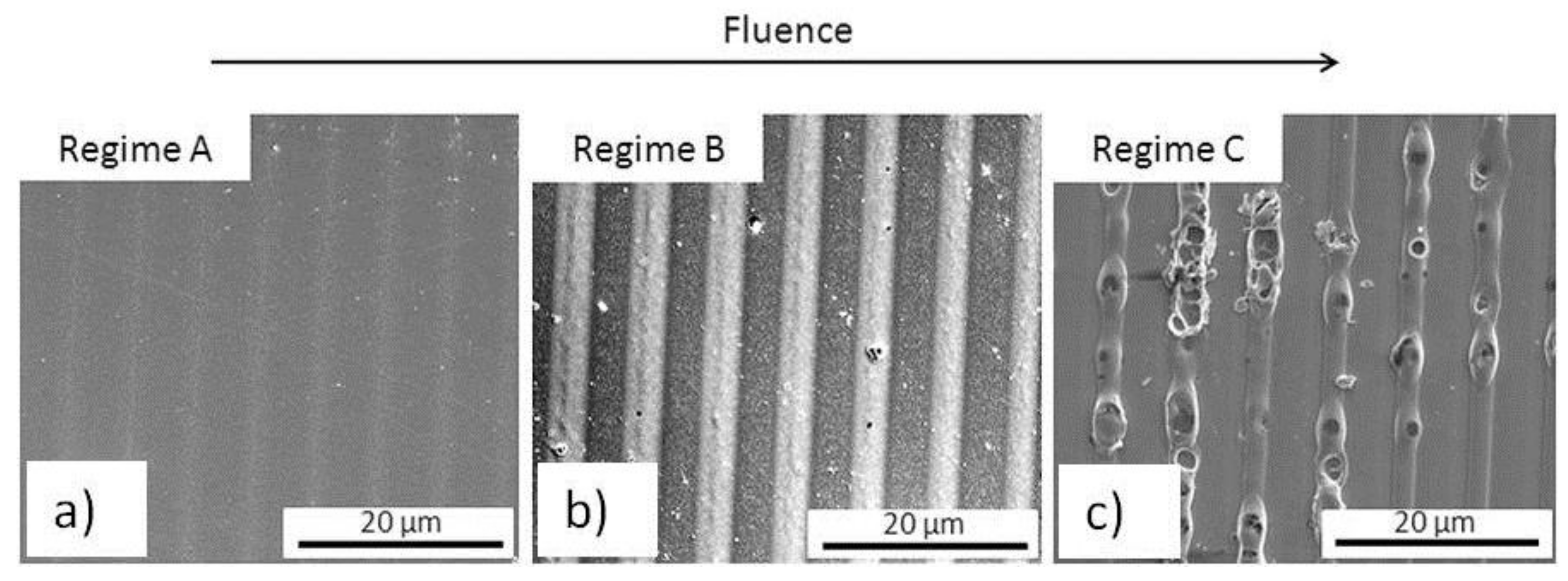

During DLIP, three fluence regimes, independent of the periodicity adjustment, could be identified by performing a fluence series. The resulting surface topography and morphology is displayed in

Figure 2, for a periodicity of 8 µm.

Figure 2 shows SEM images of samples fabricated at distinct laser fluences for a fixed periodicity of 8 µm. In

Figure 2a, the laser patterns are only slightly visible and the topography is very shallow (regime A). The laser fluence in this example was set to 50 mJ/cm

2. In regime B (

Figure 2b), the fluence was increased to 170 mJ/cm

2. The brighter topographic maxima could be clearly seen and the surface patterns appeared homogeneous. Additionally, the melting and mixing of layers started to occur. A further increase in laser fluence (regime C for fluence values of around 476 mJ/cm

2) resulted in bubble-like structures inside the multilayer and ablated areas due to the high energy density (

Figure 2c). The most homogeneous laser patterns were found for fluence values of around 170 mJ/cm

2.

Figure 3 shows a comparison of the resulting XRD-patterns measured for an unpatterned and as-deposited reference sample, as well as specimens irradiated by laser fluences of 170 and 476 mJ/cm

2.

Direct comparison of the XRD-patterns of the reference and specimen B did not reveal considerable differences. At a higher level of laser fluence (regime C at around 476 mJ/cm2), an α–Ti (101) peak was clearly visible. Additionally, a Ti3Al (203) peak appeared, and at 38.4°, a reduction of the overlapping peak could be observed. The unambiguous identification of the phases in this overlapping peak was hindered due to several reflections, such as α–Ti (002), Al (111) and β–Ti (110). The indexing was further complicated by peak shifts due to the formation of a solid solution and residual stresses. In addition, the presence of textures and peak broadening due to small grain size were additional aspects that need to be considered.

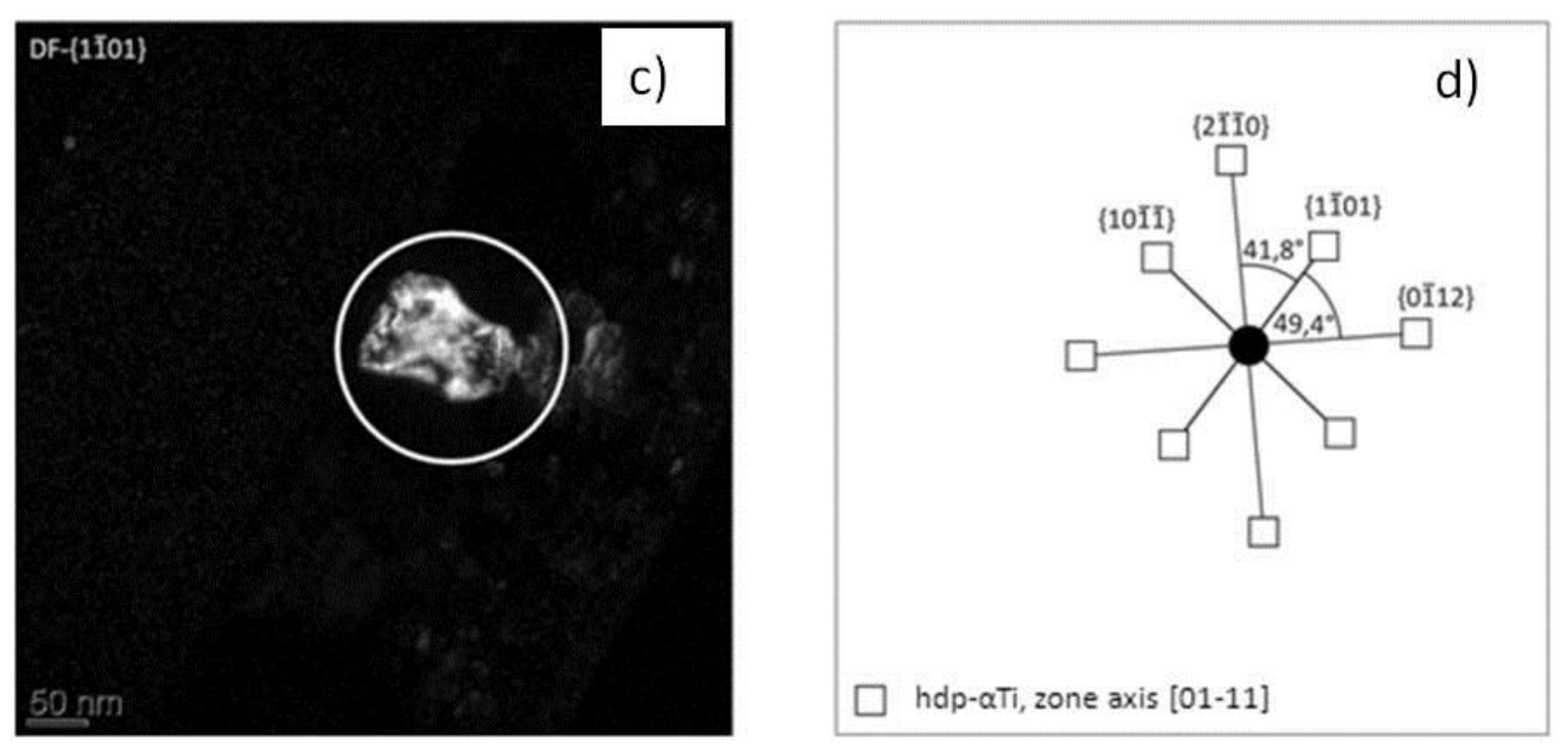

Figure 4 shows the respective TEM dark field image, as well as the related SAD zone-axis pattern for the specimen from regime B.

In

Figure 4a, it can be seen that the lamellar structure of the multilayer in the top area disappeared after DLIP. However, it is worth emphasizing that the reaction did not spread over the entire film thickness. Some layers of the as-deposited state close to the substrate were still visible. The SAD pattern in the reaction zone (

Figure 4b) indicated the presence of hdp α-Ti. A schematic drawing of the diffraction pattern in

Figure 4d considering the respective angles and planes clearly confirms the presence of hdp α–Ti with a (01–11) zone-axis. The findings refer to the diffraction volume of the encircled grain in the top left image of

Figure 4c.

In contrast, TEM analysis of an adjacent grain in the same specimen indicated the existence of bcc β–Ti (see

Figure 5a–c). The determination of diffracting planes and the calculation of the respective angles revealed the existence of bcc β–Ti with a (–111) zone-axis (

Figure 5d).

As a first conclusion, it is worth emphasizing that no complete reaction of the TiAl multilayer specimen over the entire film thickness was observed at a laser fluence of around 170 mJ/cm

2 (regime B). Apart from hdp α–Ti, the metastable β–Ti phase was detected, which could be attributed to high cooling rates on the order of 10

9 K/s [

6]. A deeper discussion about the formation of intermetallic phases in the system TiAl due to DLIP can be found in [

9] for a similar multilayer stack with slightly different laser parameters and SiN as substrate material.

3.2. Thermal Simulation of the DLIP Process

In order to gain a better understanding of the observed microstructural phenomena after DLIP, simulations with COMSOL Multiphysics, based upon the approach in [

10] solving the classical heat diffusion equation with symmetrical boundary conditions, were performed. The heat diffusion equation is given by:

where

p denotes density in (g/cm

3),

Cp the specific heat capacity in (J/kgK),

λ the thermal conductivity in (W/mK), and

Q the laser heat source (further details can be found in [

10])

The following assumptions were made [

9]:

No radiation loss from the surface.

Convection above the surface can be neglected.

No convection occurs due to gravitational or electromagnetic effects during melting.

The laser energy is considered as a sinusoidal function with a Gaussian distribution in time.

The heat conduction includes solid/liquid and liquid/vapor transitions, considering the latent heat required to melt and vaporize metals.

First, it was necessary to determine the maximum depth up to which heat could be absorbed. Using Lambert–Beer’s law and the respective absorption coefficients at 355 nm laser wavelength (

αAl = 153 µm

−1 and

αTi = 71.3 µm

−1 [

11]), the skin depth for Al and Ti was estimated to be 6.6 and 14 nm, respectively. Consequently, most of the laser-induced heat was absorbed in the topmost layers.

The thermal diffusion length for Al and Ti could be calculated using Equation (2):

where

τ is the pulse duration of the laser source (here 10 ns) and κ the thermal diffusivity according to (3):

Table 1 shows the values used for density, specific heat capacity and thermal conductivity for Al, Ti and Si [

11]:

According to Equation (2), the thermal diffusion lengths for Al and Ti were

lD,Al ≈ 2 µm and

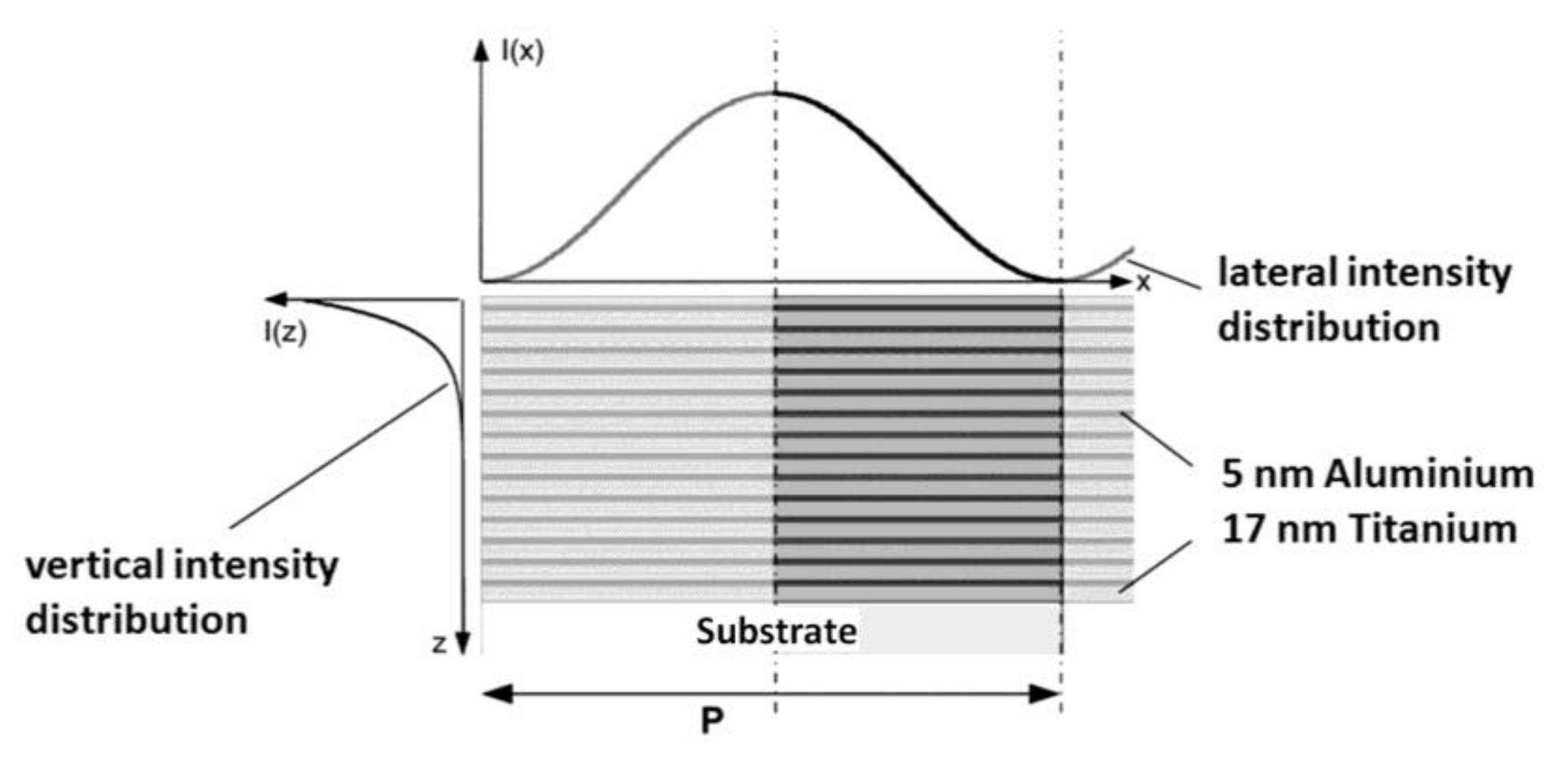

lD,Ti ≈ 0.61 µm, respectively. A schematic representation of the used model is illustrated in

Figure 6.

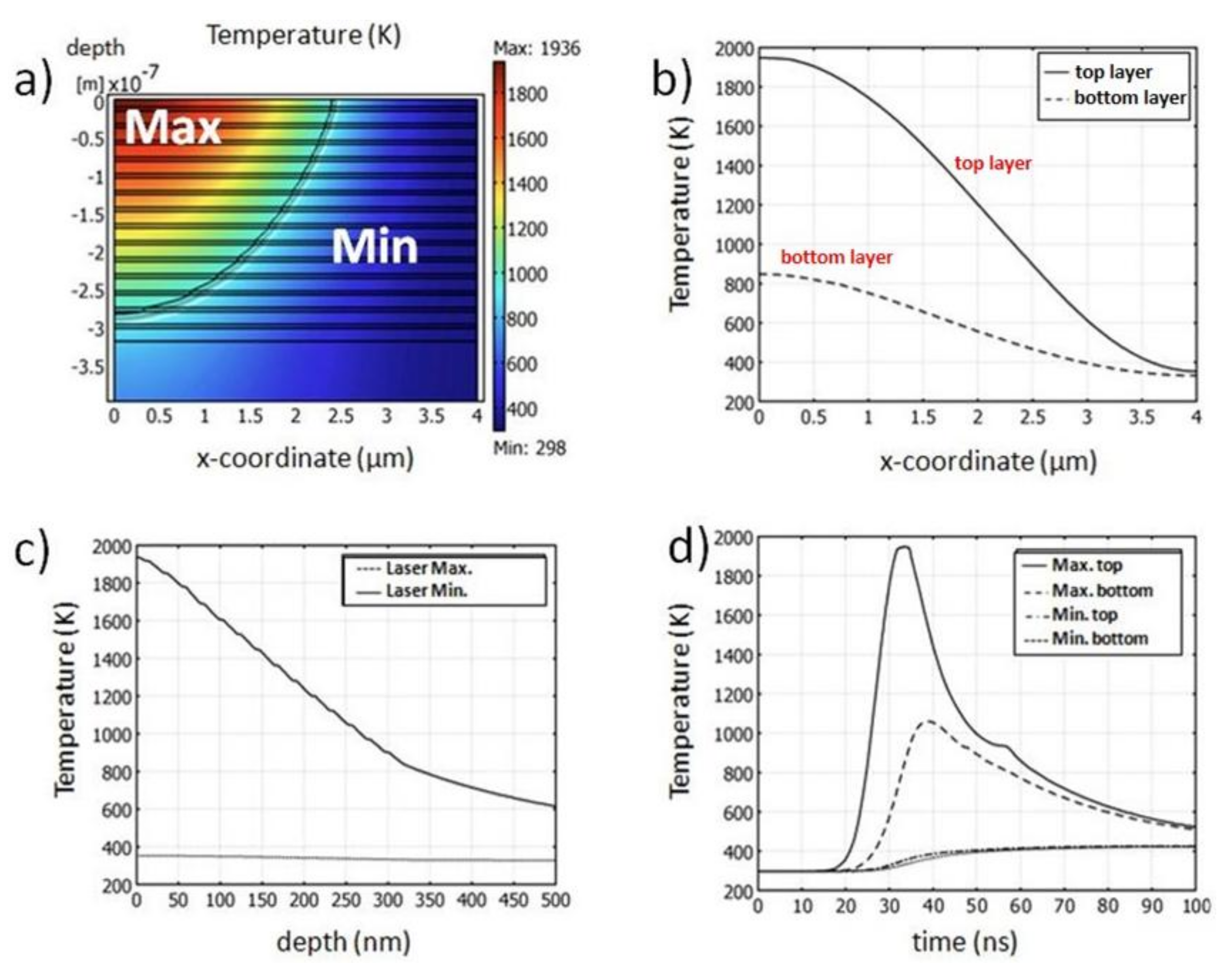

Figure 7 shows the spatial (

Figure 7a–c) and temporal temperature distributions

Figure 7d after

t = 33.5 ns (moment of maximum laser intensity, which corresponds to a maximum temperature of 1936 K (

Figure 7d)) for a fixed pattern periodicity of 8 µm. A comparison of the spatial temperature distribution at the top and bottom layer is given in

Figure 7b. The spatial temperature distribution at the laser intensity minimum and maximum, as a function of the depth, is depicted in

Figure 7c.

As can be seen in

Figure 7d, the maximum temperature for the bottom layer was reached after 38 ns. As far as the minimum laser intensity was concerned, the temperature only gradually increased, finally reaching the maximum temperature at around 60 ns. As can be seen in the temperature curve after laser impact, only Al with a melting point of 934 K was molten, whereas Ti (melting point of 1941 K) remained solid [

11]. Furthermore, it was observed that the temperature in the intensity minimum never exceeded 400 K. Therefore, no significant microstructural influence was expected in these areas for none of the elements. The resolution in the temporal temperature distribution in

Figure 7d was high enough to even reveal the latent heat being released in the temperature distribution of the top layer in the position of maximum laser intensity. There was a pronounced deviation from the continuous cooling taking place between 900 and 1000 K, indicating the solidification point of Al.

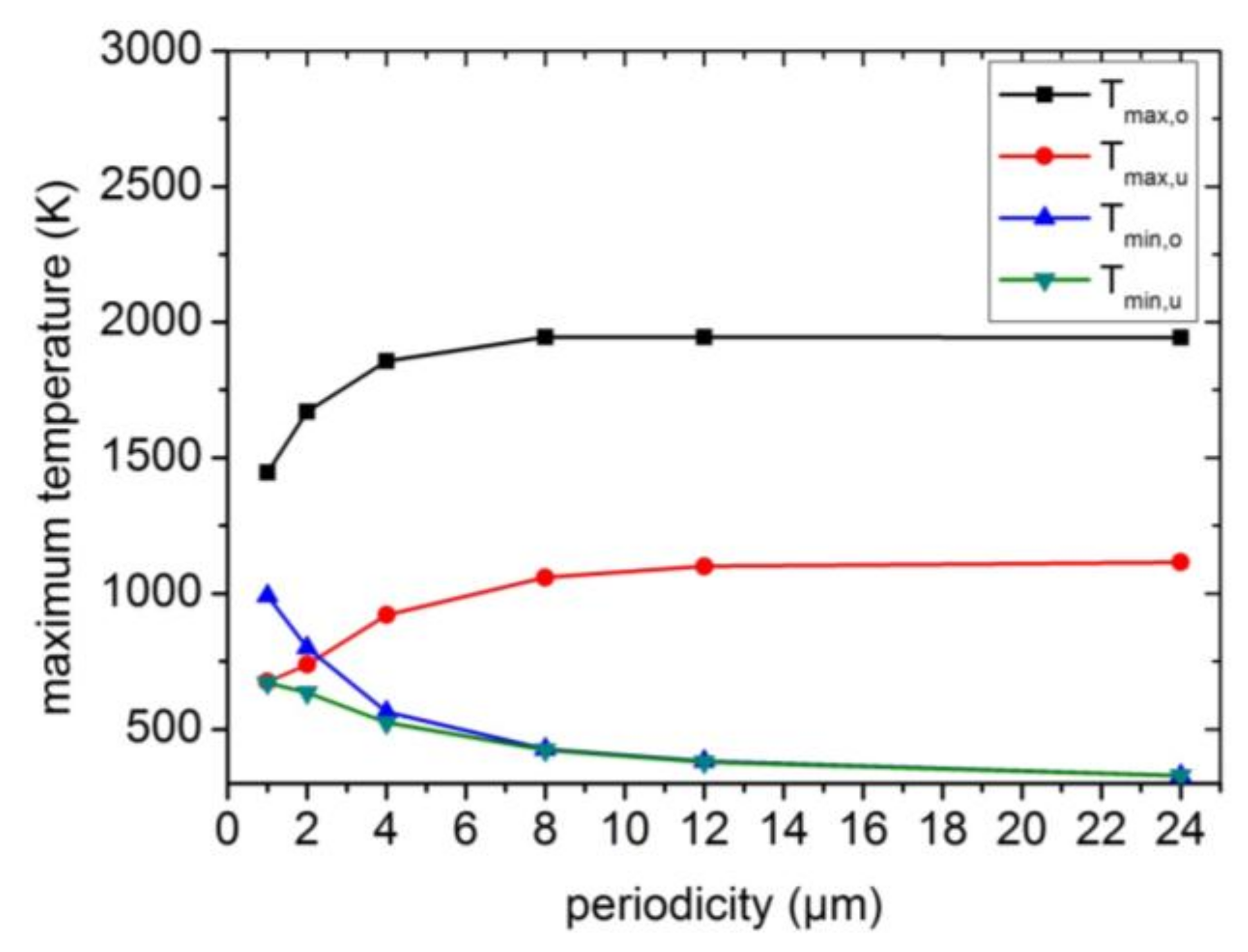

Further characteristic aspects of the thermal simulation were the maximum achievable temperatures, molten fractions, cooling rates and melting durations. The maximum achievable temperatures, as a function of periodicity, are represented in

Figure 8.

Tmax,o and

Tmax,u are the maximum temperatures directly at the surface and the interface TiAl multilayer/substrate for the positions of maximum laser intensity.

Tmin,o/

Tmin,u denote the maximum temperatures for the laser intensity minima positions, respectively.

As can be seen in

Figure 8, the maximum temperatures for

Tmax,o and

Tmax,u were reached at approximately 8 µm and remained almost constant, even for larger periodicities. The maximum temperature for a periodicity of 8 µm was attributed to the fact that for smaller periodicities, the heat is directly carried away due to a larger specific laser patterned area, whereas for larger periodicities, the laser-induced gain in surface by the texturing is smaller and the distances between adjacent intensity minima and maxima larger. Therefore, the material remains molten for a longer time.

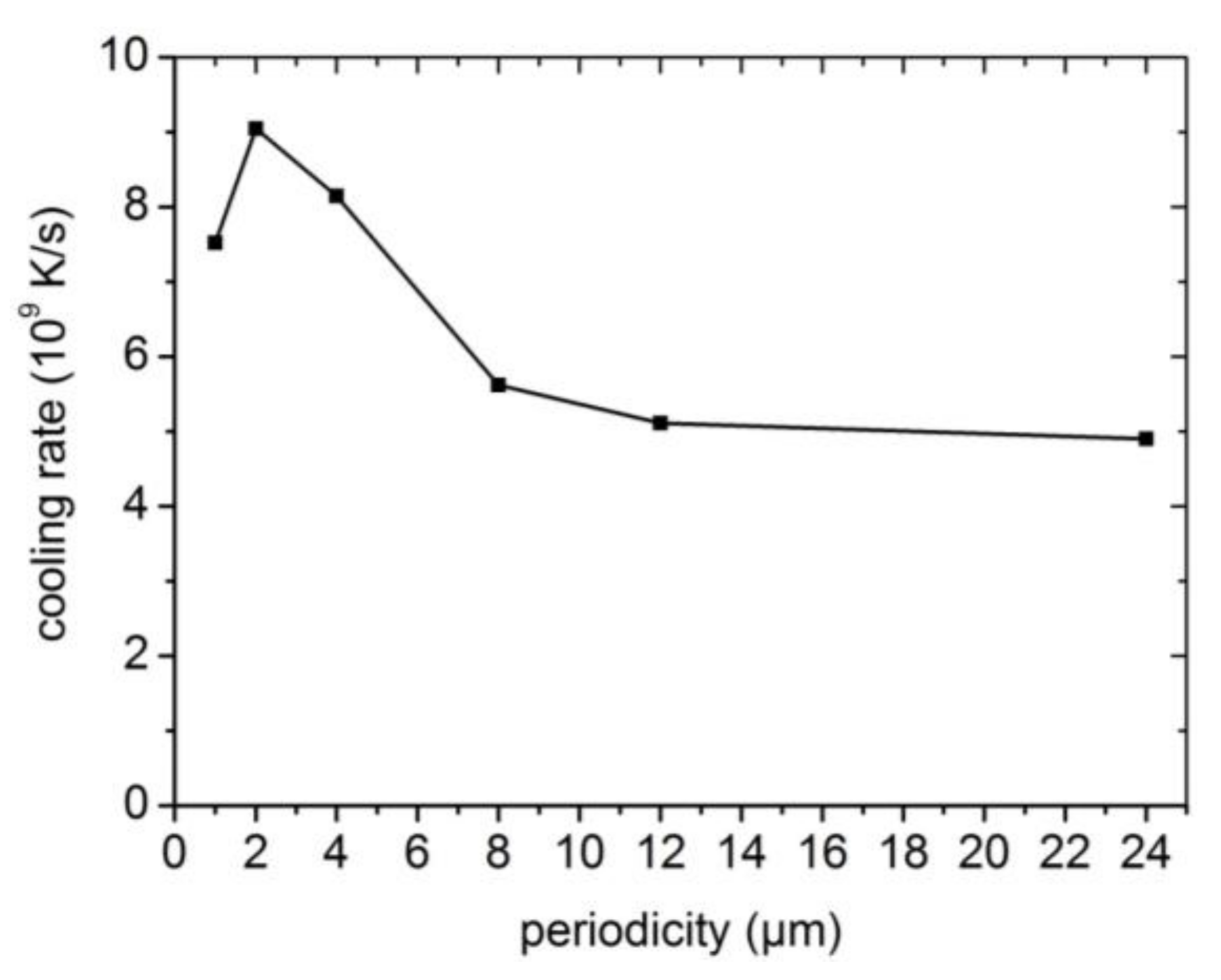

Finally, the respective cooling rate as a function of the periodicity is displayed in

Figure 9.

In this context, the time needed for cooling from 1800 to 1000 K was used to determine the maximum cooling rate. With the exception of one periodicity (1 µm), the cooling rate decreased with increasing periodicities. This can be traced back to higher maximum temperatures and melting durations for larger periodicities. The determined cooling rates, typically on the order of 109 K/s, were much higher than in the case of other solidification processes. Hence, the formation of metastable phases was possible. In most cases, a high cooling rate leads to a more fine-grained microstructure and complicates diffusion-controlled phase transitions. Moreover, the formation of an ultra-fine grained or even nanocrystalline microstructure has immediate implications on the tribo-mechanical properties by Hall–Petch strengthening. Therefore, it is important to take microstructural effects due to surface texturing methods into consideration.

3.3. Tribological Properties

Figure 10 summarizes the results of the tribological experiments dependent on the orientation of the line-like surface topography (parallel or perpendicular to the laser patterns) and the patterns’ periodicity.

As can be seen, there was no significant difference between the specimens, regarding neither the periodicity nor the orientation. This may be attributed to the nearly vanishing topography after DLIP with typical structural depths of about 10–20 nm at a given laser fluence of 170 mJ/cm

2. In this context, Lasagni et al. demonstrated that the structural depth of laser interference patterned surfaces increases with larger periodicities for a given laser fluence [

12]. Only the specimen with the largest periodicity of 12 µm demonstrated a slightly lower COF in the case of perpendicular sliding. In fact, this was the specimen with a slightly larger structural depth of approximately 20 nm.

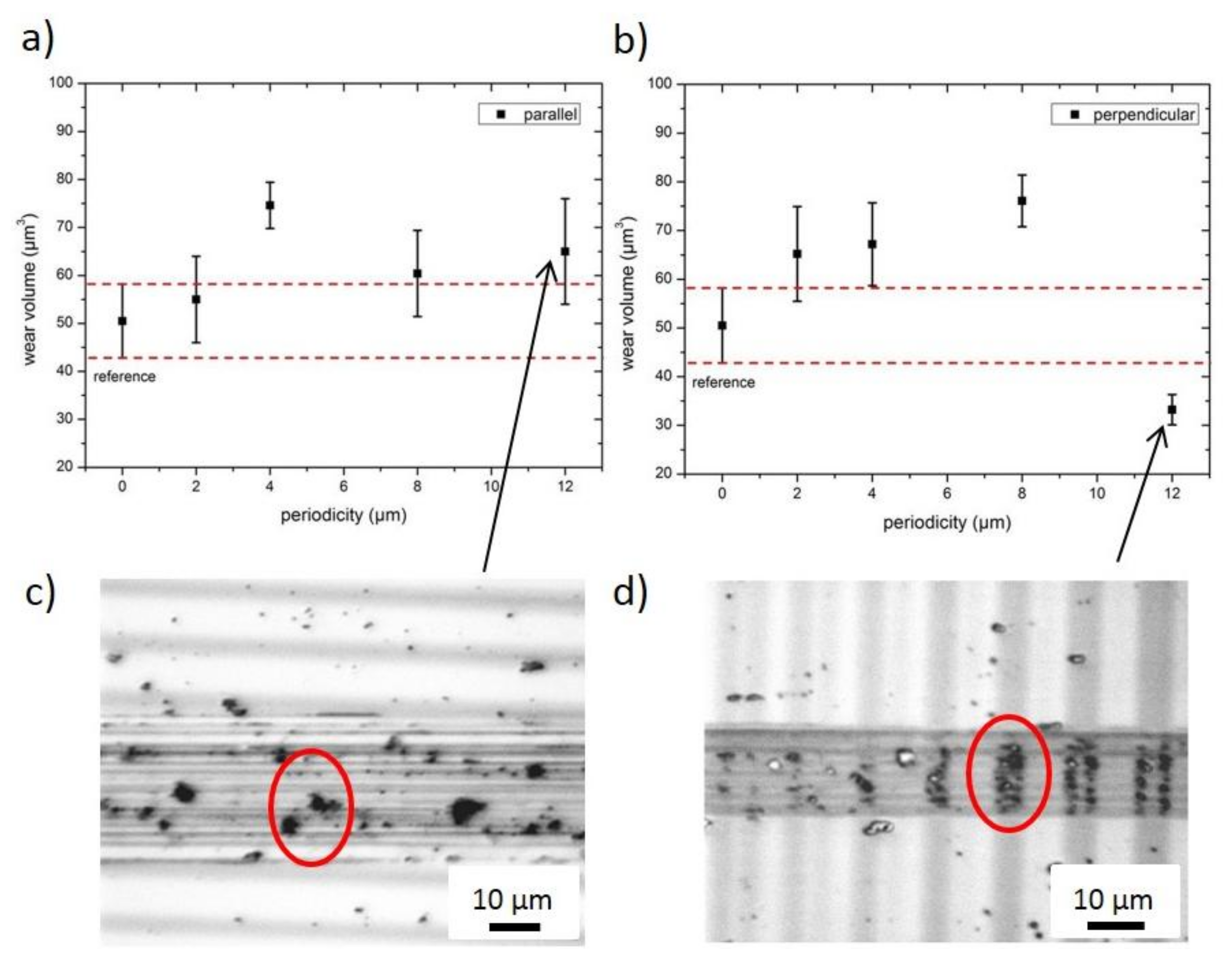

Apart from the COF, the resulting wear volume was determined for each sample by measuring the resulting wear tracks by WLI and considering the ASTM G99 [

13]. The results are shown in

Figure 11 for parallel and perpendicular alignments.

A direct comparison between parallel and perpendicular sliding showed a significant difference (see

Figure 11a,b). Under parallel sliding conditions, wear debris shifted back and forth during the linear reciprocal movement, thus always contributing to abrasion in the wear scar (see

Figure 11c). The textured samples scattered more or less around the error range of the reference sample (the only exception was sample at 4 µm periodicity). On the other hand, perpendicular sliding likely ensured the effective trapping of wear debris in respective recessions if these were deep enough (

Figure 11d). The wear volume of the reference sample was lower than for the textured specimens at 2, 4, and 8 µm because the wear particles were still freely moveable on the surface. It can be noticed that the wear volume slowly increased to 8 µm periodicity as debris was trapped in the topographic valleys but not completely covered, thus still contributing to abrasive behavior. Therefore, topographic recessions can act as debris traps if they are sufficiently deep. Otherwise, the recessions reduce the mobility of the wear particles by blocking them. Therefore, it can be assumed that the abrasive effect of the wear particles is only minimized if the recessions efficiently store the debris, thus resulting in a lower wear volume, as can be seen for the sample with 12 µm periodicity and the largest structural depth. The direct comparison of both wear tracks additionally revealed that the laser texture could not be identified anymore in the parallel case because the abrasive wear particles ploughed through the entire pattern, thus destroying it. In contrast, the line-like pattern was still visible for the perpendicular alignment. These findings are also in good correlation with the recorded COF in

Figure 10. Here, the COF for 12 µm periodicity and perpendicular orientation was slightly lower compared to other periodicities and orientations because of the reduced abrasive component of the COF.